When you work with circuit boards, cleaning is one of the easiest ways to keep them reliable and long-lasting. Dust, flux residue, fingerprints, or even moisture can cause corrosion or short circuits if not removed properly.

This guide explains the types of PCB cleaners, how to choose the right one, and the correct way to clean your board safely—plus answers to popular questions like “Can I use rubbing alcohol?” and “Is 70% isopropyl alcohol safe?”

What’s the Best Way to Clean a PCB?

The best PCB cleaner depends on what you’re trying to remove.

- For flux residue and oils, use a high-purity isopropyl alcohol (IPA) or a no-residue electronic cleaner spray.

- For dust or fingerprints, gentle brushing and air blow-off are enough.

- For water damage or corrosion, a mix of IPA and deionized water, followed by thorough drying, works best.

Always follow three basic steps:

- Power off and discharge the board.

- Apply or spray the right cleaner while brushing or rinsing.

- Dry completely before powering up again.

Never rush drying—any leftover moisture can create hidden shorts later.

Types of PCB Cleaners (and When to Use Each)

1. Isopropyl Alcohol (IPA): 70% vs 91% vs 99%

IPA is the most popular PCB board cleaner because it’s cheap, effective, and safe for most electronics. But not all concentrations are the same.

- 99% IPA evaporates quickly, leaves almost no residue, and is ideal for fast, precision cleaning (for example, after soldering).

- 91% IPA still works well but evaporates slightly slower.

- 70% IPA contains more water—it can dissolve some contaminants better, but it also dries slower and may trap moisture under chips or connectors.

If you’re working on high-reliability boards (medical, aerospace, automotive), choose high-purity IPA or a no-residue cleaner. For everyday maintenance or flux removal, 91% IPA is usually fine.

2. Flux Removers and Electronic Cleaner Sprays

Flux removers are purpose-made solvents for removing soldering residue. They dissolve rosin and synthetic flux quickly and evaporate without leaving residue.

When to use:

- After manual or reflow soldering

- During rework or repair

- When boards need high electrical reliability

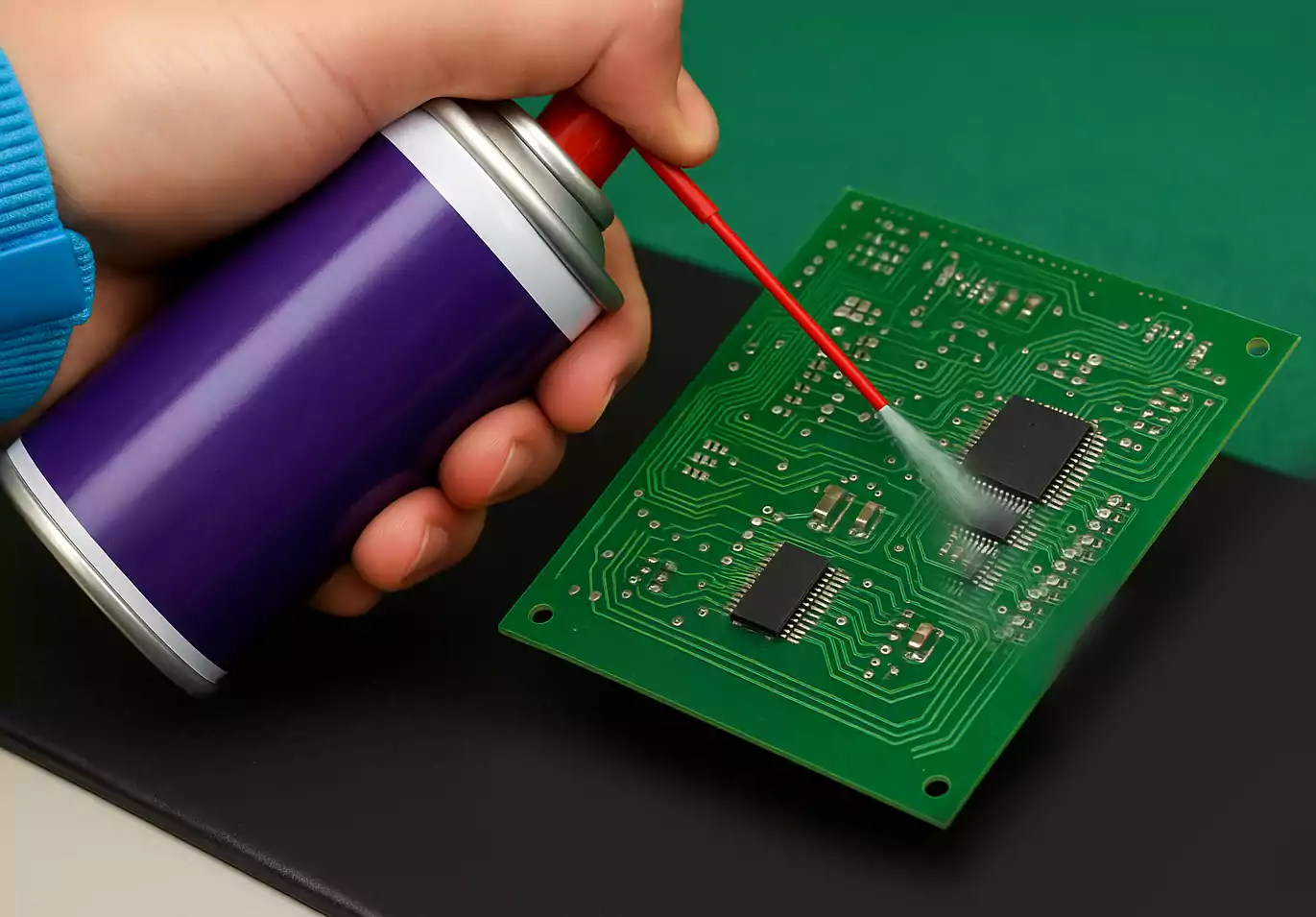

Spray cleaners make the job faster because they deliver strong solvent pressure to wash away residues.

If possible, tilt the board while spraying so that the dirty liquid flows off instead of settling on the surface.

3. Water-Based Cleaners (Deionized Water + Surfactants)

Water-based cleaners are great for mass cleaning or boards designed with water-soluble flux. They often include mild detergents or saponifiers to break down residues.

Advantages:

- Low cost for high-volume cleaning

- Environmentally friendly and less flammable

Drawbacks:

- Must be followed by thorough rinsing with deionized water

- Boards need complete drying afterward—any trapped water can corrode pads or vias

4. Contact Cleaners

Contact cleaners are designed for switches, relays, or connectors. They evaporate fast and leave little or no film.

Use them when:

- Cleaning electrical contacts or sockets

- Removing oxidation or dust from mechanical interfaces

How to Choose the Right PCB Cleaner (Quick Guide)

Choosing depends on two things: what’s dirty and what level of reliability you need.

| Problem / Contaminant | Recommended Cleaner | Notes |

|---|---|---|

| Flux or solder residue | Flux remover or 99% IPA | Use spray + brush, rinse off while wet |

| Dust or fingerprints | Air blower + IPA wipe | Gentle, safe for maintenance |

| Grease or oil | 70–91% IPA | More water helps dissolve oils |

| Moisture or corrosion | IPA + deionized water rinse | Long drying time (≥24 h) |

| Bare PCBs before assembly | Ultrasonic + DI water | No components attached |

If you’re unsure, start with high-purity IPA—it’s compatible with most components and coatings.

Step-by-Step Cleaning Methods (SOP for Common Cases)

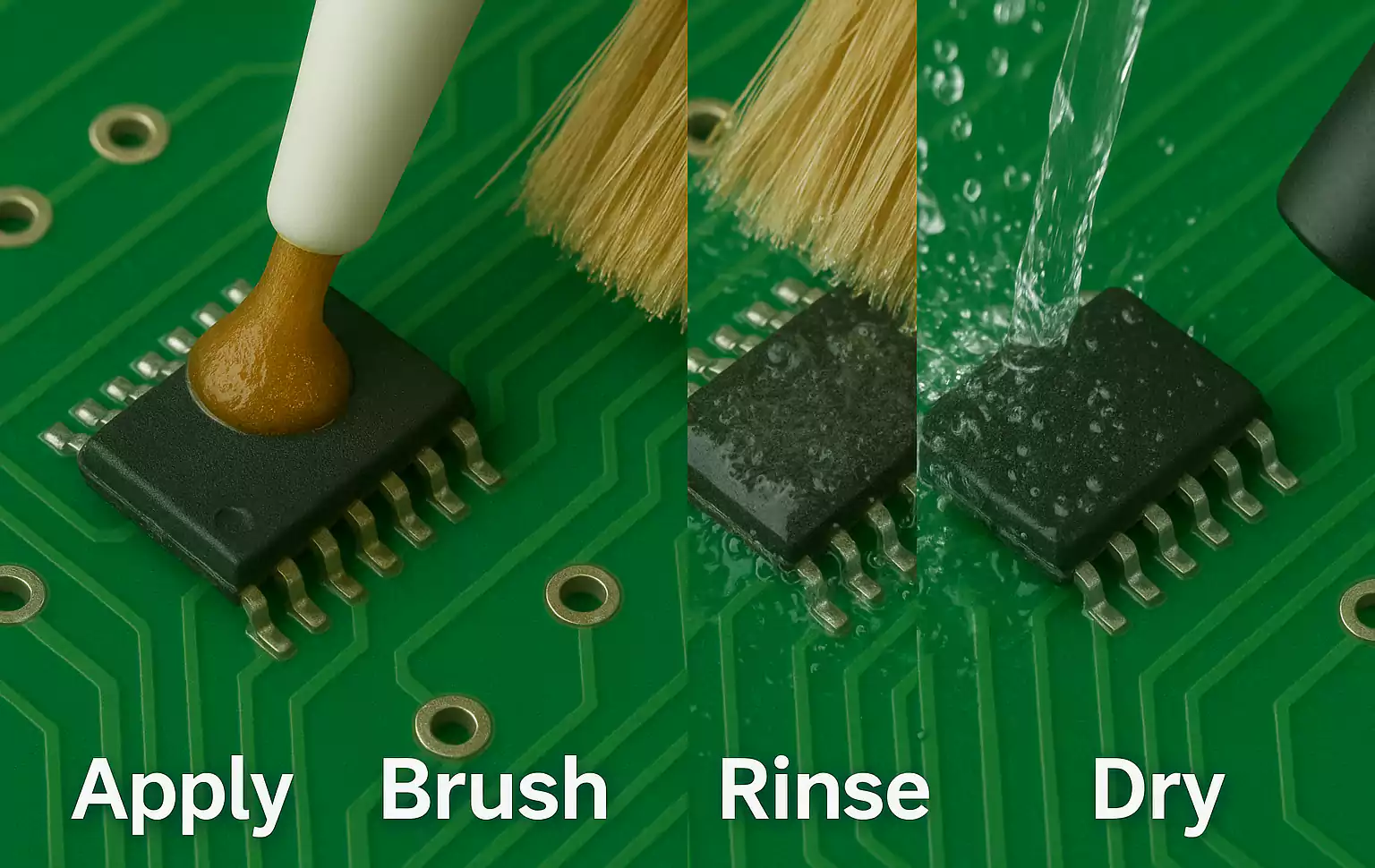

1. Removing Flux After Soldering or Rework

- Disconnect power and ground yourself to avoid ESD.

- Apply flux remover or high-purity IPA directly to the area.

- Use a soft ESD-safe brush to loosen residue.

- While it’s still wet, rinse or spray again to wash away dissolved flux.

- Tilt the board so the solvent drains off.

- Dry thoroughly with compressed air or a warm (not hot) air source.

If you let the solvent evaporate without rinsing, contaminants can re-deposit on the surface. Rinsing carries them away while the solvent is still wet.

2. Routine Cleaning (Dust, Fingerprints, Light Oil)

- Use a compressed air blower or soft antistatic brush to remove loose dust.

- Dampen a lint-free wipe with 91% or 99% IPA.

- Gently wipe the surface in one direction—don’t scrub in circles.

- Allow it to air-dry completely (usually within minutes).

Avoid spraying IPA directly into connectors or between stacked boards—it may pool and trap moisture.

3. Water Damage or Corrosion Recovery

If your circuit board got wet or exposed to humidity:

- Disconnect power immediately and remove the battery if present.

- Rinse the board gently with IPA mixed with deionized water (1:1 ratio).

- Use a soft brush to loosen any corrosion.

- Rinse again with clean IPA to remove water residue.

- Let the board dry at least 24 hours in a warm, ventilated area (or use a low-temperature oven, under 60 °C).

- Once dry, inspect visually and re-test.

This method often saves electronics after mild water exposure—but only if done quickly and thoroughly.

4. Ultrasonic and Machine Cleaning

Ultrasonic cleaners are effective for bare PCBs (before components are installed). They use high-frequency sound waves to shake off contamination.

However, for assembled boards, ultrasonic cleaning can damage delicate components like quartz crystals, MEMS sensors, or inductors. Use it only on unpopulated boards or if the manufacturer explicitly recommends it.

Safety and Material Compatibility

Even safe cleaners can cause damage if used incorrectly. Keep these tips in mind:

- Plastics and coatings: Some solvents can soften acrylic or silicone conformal coatings. Test in a small corner first.

- Rubber parts: IPA may dry out rubber gaskets or keypads. Avoid soaking them.

- Ventilation: All cleaners—especially solvent sprays—should be used in well-ventilated areas.

- ESD safety: Always use antistatic brushes, mats, and wrist straps when working on live PCBs.

- Fire risk: IPA and most electronic cleaners are flammable. Never clean near open flames or soldering irons.

FAQ: Common PCB Cleaning Questions

1. What is the best cleaner for PCB?

There’s no single “best” product for every case. For general cleaning and flux removal, use high-purity IPA (91–99%) or a no-residue electronic cleaner. For industrial or high-reliability boards, use flux removers and always rinse and dry completely.

2. Does WD-40 clean circuit boards?

No. WD-40 can remove grease but leaves residue that may cause shorts or attract dust. Use an electronic contact cleaner spray or IPA instead.

3. Can I use rubbing alcohol to clean PCB?

Yes, but check the concentration. 91–99% IPA is safe and effective. 70% IPA also works but dries slower and can leave moisture behind, so let the board dry longer.

4. Is 70% isopropyl alcohol safe to clean electronics?

It’s generally safe for surface cleaning, but not ideal for critical or fast-turnaround work. The 30% water can cause corrosion or hidden moisture under components. Use higher purity alcohol whenever possible.

5. Should I use an ultrasonic PCB cleaner?

Only for bare boards (no components installed). Ultrasonic waves can damage solder joints, delicate sensors, or oscillators on assembled boards.

Final Thoughts

Cleaning a PCB may look simple, but doing it right can dramatically improve reliability and prevent failure. The key is to match the cleaner to the contamination, apply it the right way, and dry completely before re-powering the circuit.

A few minutes of proper PCB cleaning can save you hours of troubleshooting later—and keep your electronics running like new.