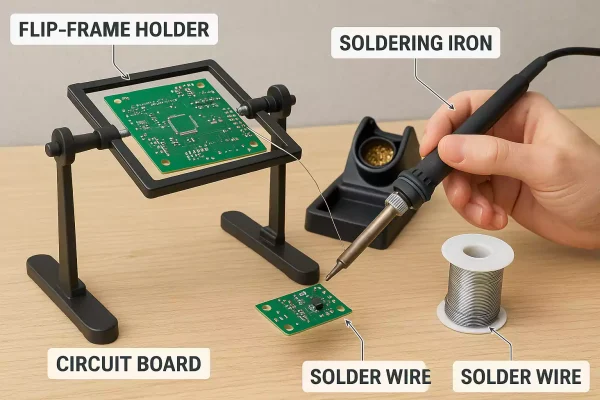

Stabilizing a printed circuit board (PCB) during repair or soldering is challenging due to movement and heat. A PCB Circuit Board Holder effectively addresses these issues.

By freeing your hands and keeping your project secure, a high-quality PCB holder keeps the board steady and prevents damage, improving work accuracy.

This guide explains PCB holders: their purpose, how they function, key types, and essential selection or DIY considerations.

What Is a PCB Circuit Board Holder?

A PCB holder (sometimes called a PCB clamp or circuit board vise) is a simple but essential tool that holds your circuit board in place during soldering, inspection, rework, or cleaning.

It’s designed to keep the board stable, adjustable, and safe. Most holders include a base, clamps or arms to grip the board, and a mechanism that allows you to rotate or tilt the board as you work.

How Does a PCB Holder Work?

A PCB holder works like a third hand. It locks your board firmly between two adjustable grips or edge clamps so you can focus on soldering, not balancing.

Most designs have three main parts:

- Base or mount – sits on your workbench or attaches to the table.

- Clamp mechanism – grips the circuit board edges securely, often with rubber or plastic pads to prevent scratches.

- Rotation or tilt axis – lets you flip the board for double-sided soldering or adjust the angle for better visibility.

When you tighten the knobs, the clamps press gently against the PCB edges. The board stays fixed, but you can easily rotate it 180° or tilt it forward for more comfortable access.

A quality holder keeps the board steady even when you apply pressure with a soldering iron or hot-air gun.

Why You Need a PCB Holder

A PCB holder enhances safety, accuracy, and workflow efficiency when working on circuit boards.

1. Eliminates External Assistance

With a proper holder, you don’t need someone else to hold the board while you work. It gives you full control over positioning and prevents shaky solder joints.

2. Easy Manipulation and Rework

Good holders let you flip and tilt your board without removing it from the clamps. You can solder one side, rotate it, and continue working. This is especially helpful for BGA rework, SMD soldering, or fine-pitch components.

3. Works with Different PCB Sizes

Many holders have adjustable rails or sliding clamps. Whether it’s a small Arduino module or a large control board, you can resize the frame in seconds.

4. Stable, Safe, and Durable

A solid base keeps your board steady. Heat-resistant materials protect against burns, while rubber feet prevent the whole holder from sliding on your desk.

PCB Holder Structure

Even though there are many styles, most PCB holders share the same structure.

- Base: Usually made of metal or heavy plastic for balance. Some models use clamp-on bases that attach directly to your table. Others use magnetic bases for quick setup.

- Clamps: The part that grips the PCB edges. Clamps may be spring-loaded or screw-adjusted, with soft rubber pads to avoid scratching.

- Rotation or tilt joints: Allow the board to turn or tilt while remaining secure. Some holders have self-locking knobs so the board stays at any angle you set.

- Optional add-ons: Holders often include trays for screws, magnifiers, LED lamps, or ESD grounding clips — small extras that make work easier.

How a PCB Holder Helps in Real Work

Let’s look at how using a PCB holder improves your daily electronics tasks.

1. Holding Circuit Boards Steady

A stable board means better solder joints. You can apply just the right amount of heat and solder without chasing a moving target. It also keeps the board off the desk, giving you space for components and wires underneath.

2. Rotating Circuit Boards

When you can rotate the board freely, soldering both sides becomes simple. You don’t need to unscrew or flip the whole setup — just turn the handle or shaft. That saves time and avoids bending delicate parts.

3. Tilting for Comfort

Tilting the board gives you the best viewing angle and wrist position. You’ll get cleaner solder points, fewer bridges, and less strain after long sessions.

If you use a magnifier or microscope, an adjustable tilt becomes even more valuable.

Main Types of PCB Holders

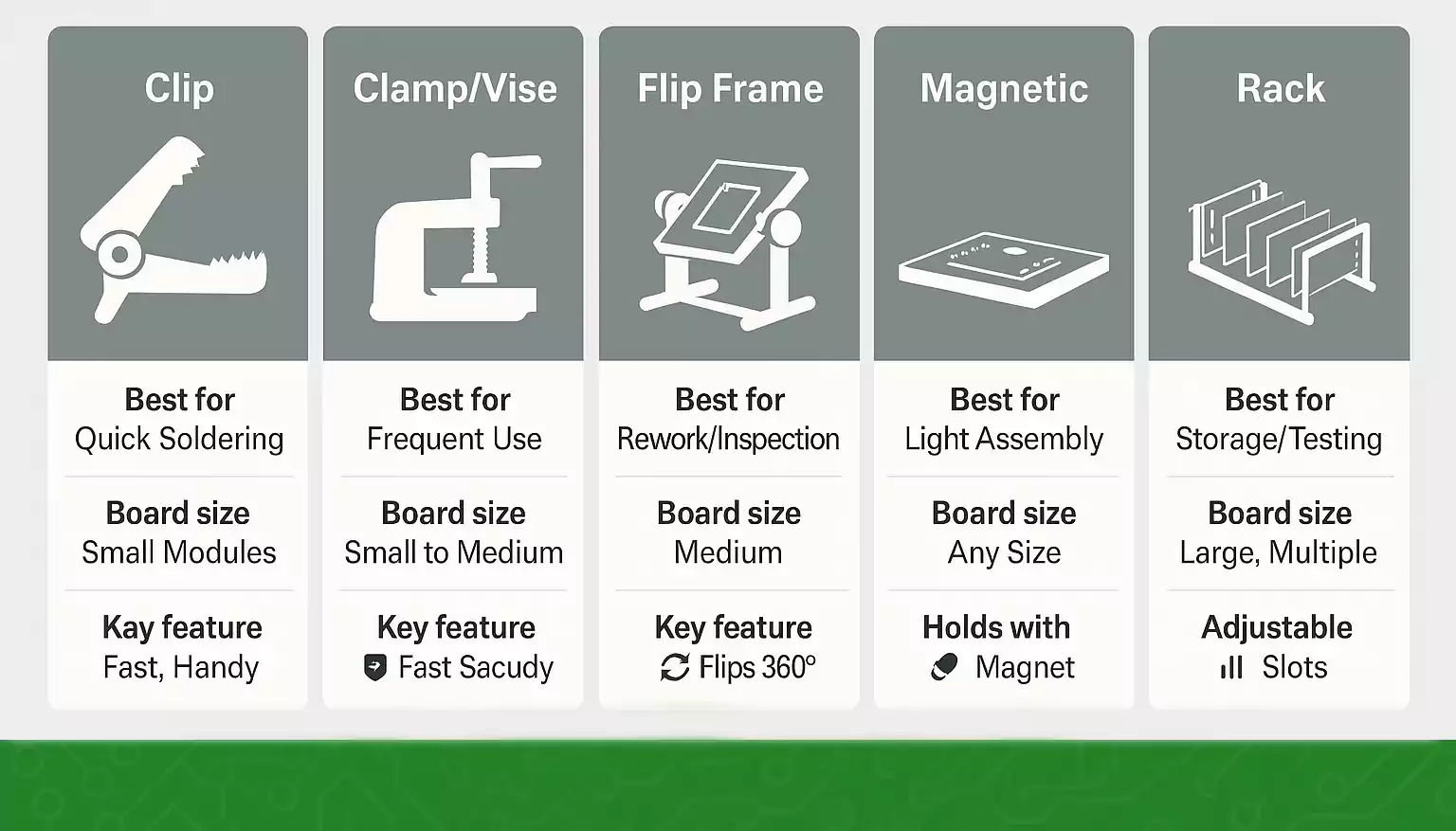

There isn’t a single “best” PCB holder. The right one depends on how you use it.

Here are the most common types you’ll find in labs and workbenches:

1. Clip or “Helping-Hands” Type

These are the small stands with two or more alligator clips and a weighted base. They’re cheap, compact, and perfect for quick solder jobs or learning projects.

However, they’re not very stable for larger boards and can transfer heat to the clips.

2. Clamp or Vise Type (PanaVise-Style)

These look like miniature bench vises. You secure the board between soft jaws and adjust the tilt with a single knob.

They hold the board tightly and stay steady during heavy soldering or desoldering.

3. Edge-Clamp Flip Frame

A larger and more advanced type is used in rework stations. The PCB edges slide into adjustable clamps mounted on rails, allowing full 360-degree rotation.

The frame locks securely at any angle — ideal for double-sided soldering, hot-air rework, or microscope inspection.

4. Magnetic-Base Modular Holders

These consist of several magnetic posts that you can position anywhere on a metal base plate. Each post has a soft clamp to grip a board corner or edge.

5. Rack or Stand Type

These are larger stands that hold multiple boards. Some are designed for drying, cleaning, or transport, rather than soldering.

6. DIY Options

If you enjoy making tools, you can easily build your own PCB holder.

Many DIYers use wood, metal brackets, bolts, and wing nuts to create adjustable frames. Add a rotating joint or two edge clamps, and you have a simple, effective holder.

Basic DIY PCB Holder

You don’t need fancy tools to make a sturdy holder. Here’s a simple design idea:

Materials:

- A wooden or metal base

- Two vertical supports

- A steel rod as the rotation axis

- Two adjustable edge clamps or small aluminum bars

- Bolts, nuts, and soft rubber pads

How to build:

- Fix the supports on the base about 6–8 inches apart.

- Drill holes in the supports and insert the steel rod through both.

- Attach the clamps to the rod so they can rotate and hold the PCB edges.

- Add rubber pads or tape to protect the board.

- Tighten the nuts to lock the angle when needed.

This kind of homemade holder works great for learning or hobby use. It’s cheap, adjustable, and surprisingly durable.

Common Questions About PCB Holders

1. What’s the best PCB holder for soldering?

Choose one that’s heat-resistant, stable, and rotatable.

A clamp-style or flip-frame holder is best for consistent results.

2. What’s the difference between a clip, a clamp, and a rack?

- Clip = small, light, quick to set up.

- Clamp (vise) = stronger, adjustable angle.

- Rack = holds multiple boards, mostly for drying or storage.

3. What about universal or modular holders?

They adapt to any PCB shape and size. Magnetic or sliding modules make them great for prototypes and custom boards.

Conclusion

A PCB circuit board holder is a critical tool for efficient electronics work, ensuring stability and precision. With your hands free, your boards are safe, and your solder joints are clean. From tiny clip stands to advanced flip frames, every option helps you work smarter and faster.

When your setup and process are ready, let FastTurn PCB handle the rest.

We provide fast PCB prototyping, assembly, and full turnkey manufacturing — so you can go from concept to finished product in record time.