Introduction

In the fast-paced world of electronics development, a PCB board prototype is the critical first step between a circuit design on-screen and a fully functional product in hand. Whether you're building consumer gadgets, industrial systems, or IoT devices, prototyping allows you to validate your design, catch costly errors early, and ensure a smooth transition to mass production.

But what exactly is a PCB prototype? Why is it so essential to the development cycle? And how do you choose the right type of prototype or manufacturing partner?

In this guide, we'll walk you through everything you need to know about PCB board prototypes—including their purpose, common types, design considerations, and how to streamline the prototyping process.

Why You Need a PCB Prototype

A PCB board prototype plays a key role in bringing your circuit design to life. It allows you to test functionality, verify design accuracy, and catch issues before committing to full production.

By building a prototype, you can:

- Validate your design – Ensure your layout performs as expected under real conditions.

- Identify errors early – Detect problems like incorrect routing, component placement, or signal integrity issues before they become expensive mistakes.

- Improve manufacturability – Confirm your design meets fabrication and assembly requirements.

- Reduce development time – Prototyping supports faster iterations and shortens your product’s time to market.

In short, prototyping is a low-risk, high-value step that helps ensure a successful final product

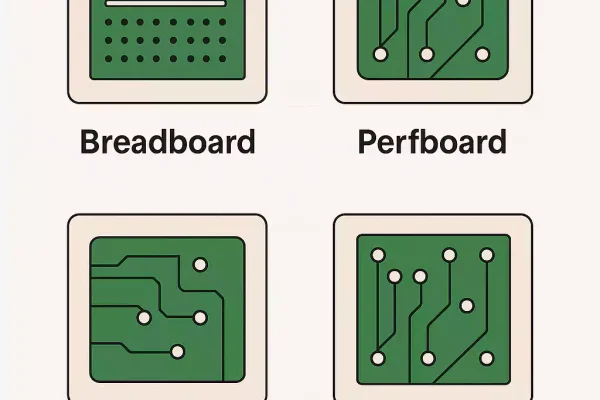

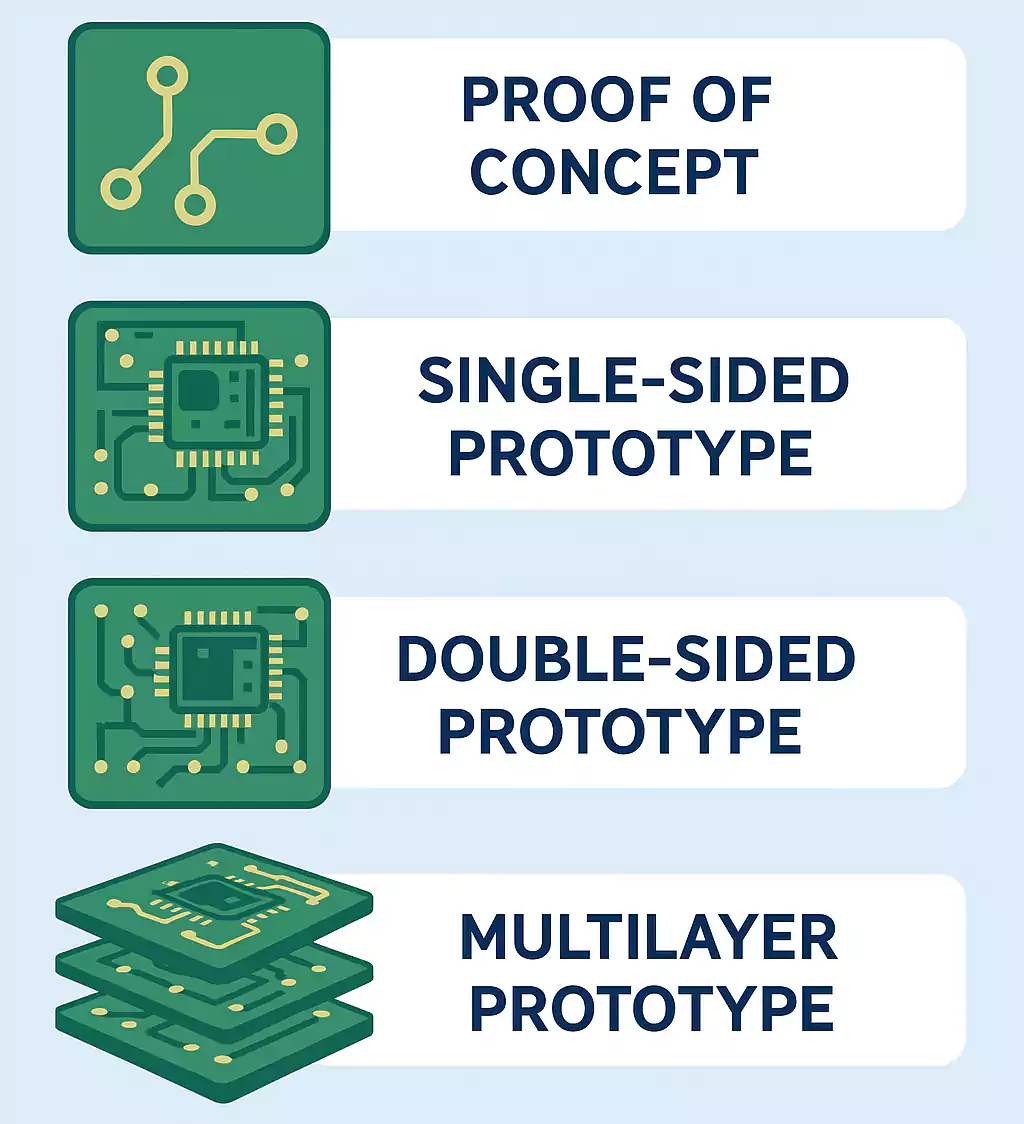

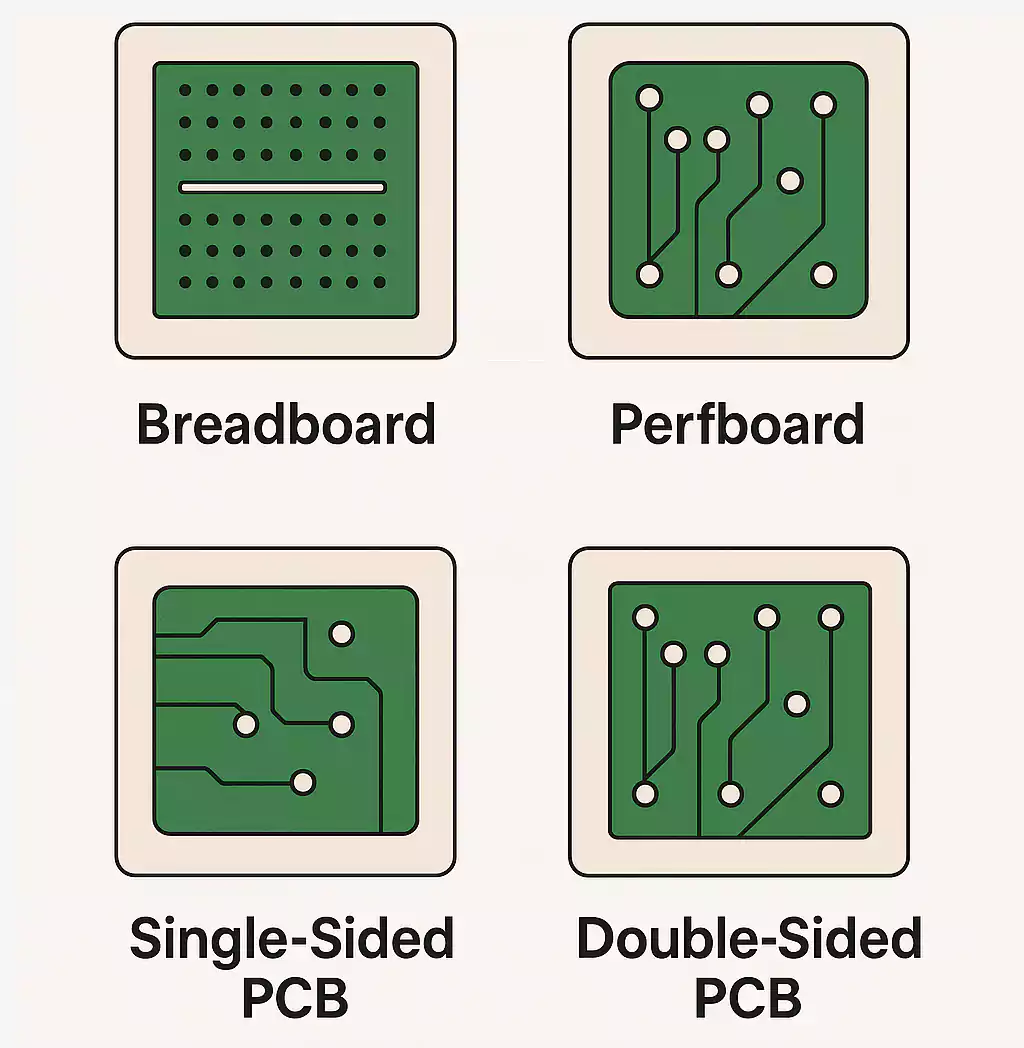

Common PCB Prototype Types

Here are the most common types you’ll encounter:

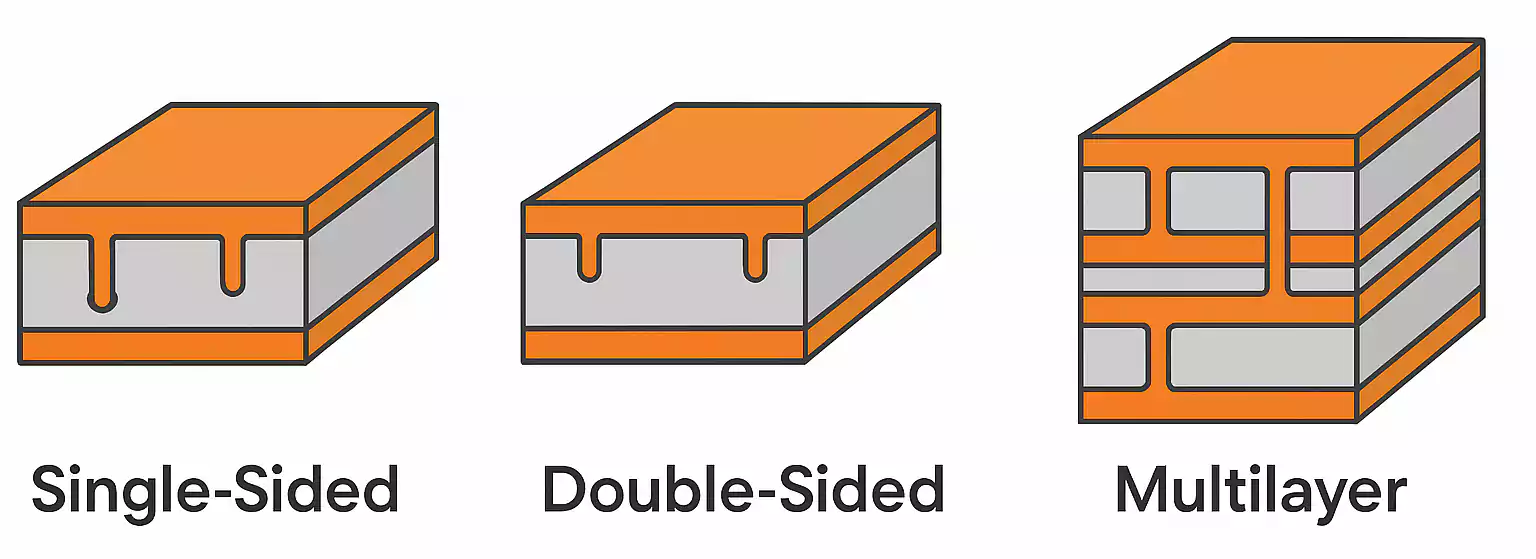

1. Single-Sided PCBs

These have copper traces on only one side of the board. They’re ideal for simple, low-cost circuits and early design validation.

2. Double-Sided PCBs

Copper layers appear on both sides, allowing more complex routing. Common in prototypes for consumer electronics and industrial controls.

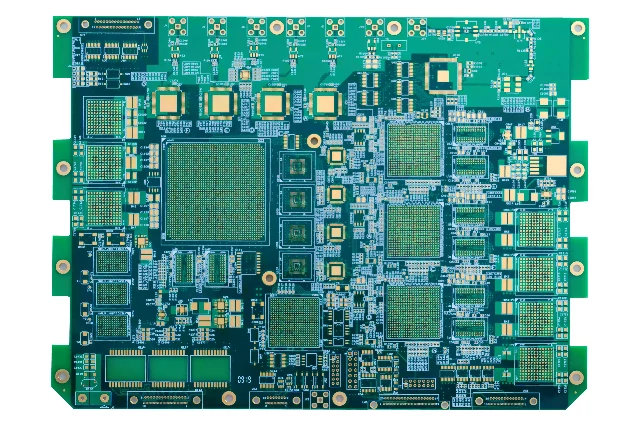

3. Multilayer PCBs

With four or more layers, these are used for high-density designs, such as communication devices, medical equipment, or computing systems. Multilayer prototypes help test signal integrity, EMI shielding, and power distribution.

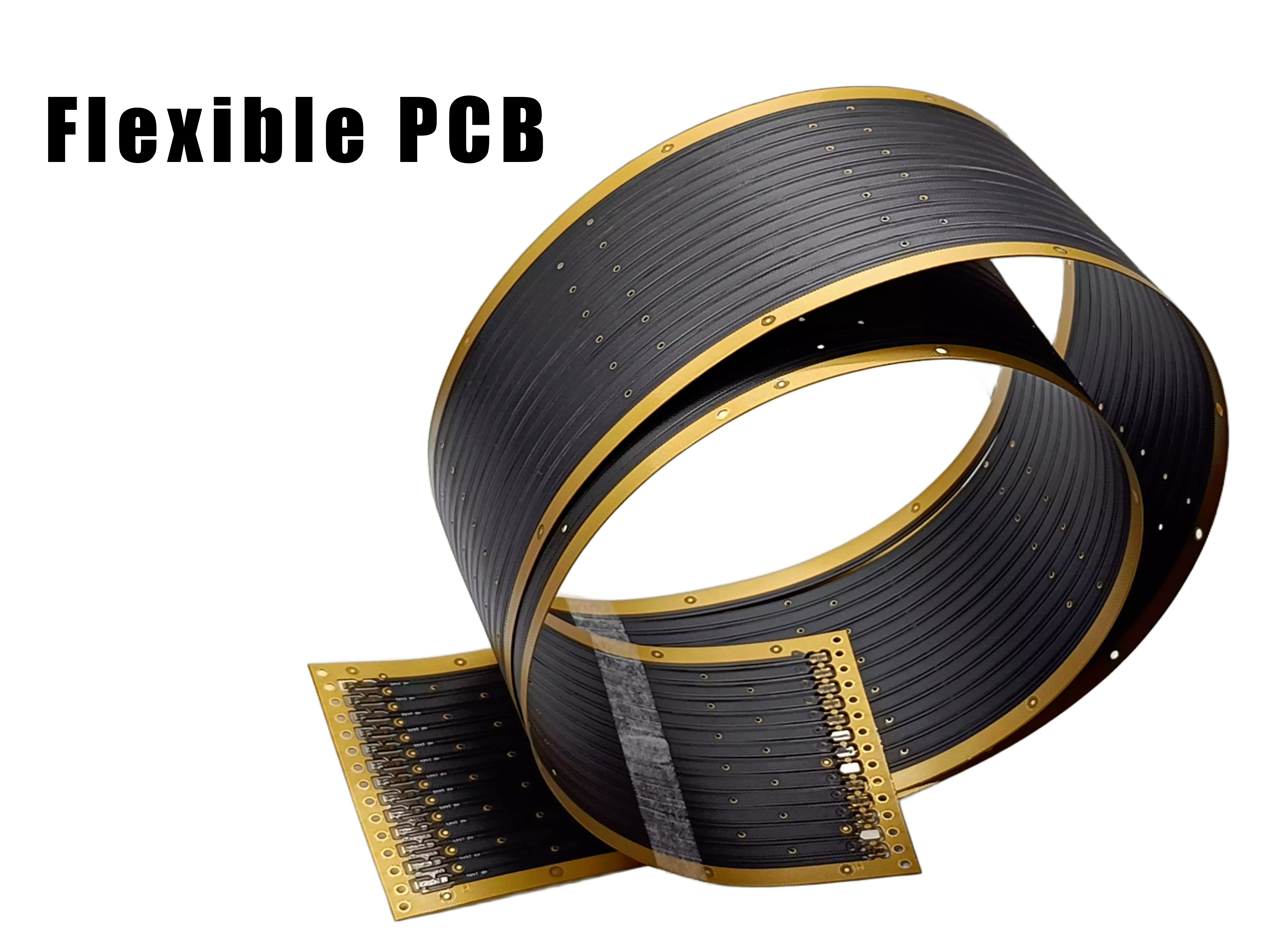

4. Rigid, Flex, and Rigid-Flex PCBs

- Rigid: Standard FR-4 boards used in most prototypes.

- Flex: Built on flexible substrates for tight spaces or dynamic bending.

- Rigid-Flex: Combines both technologies, often used in aerospace or wearable devices.

5. Quick-Turn Prototypes

These prioritize speed over volume, offering rapid fabrication (often in 24–72 hours) for urgent development cycles or proof-of-concept testing.

Each type serves a specific purpose. Selecting the right one ensures your prototype aligns with your product’s goals and performance requirements.

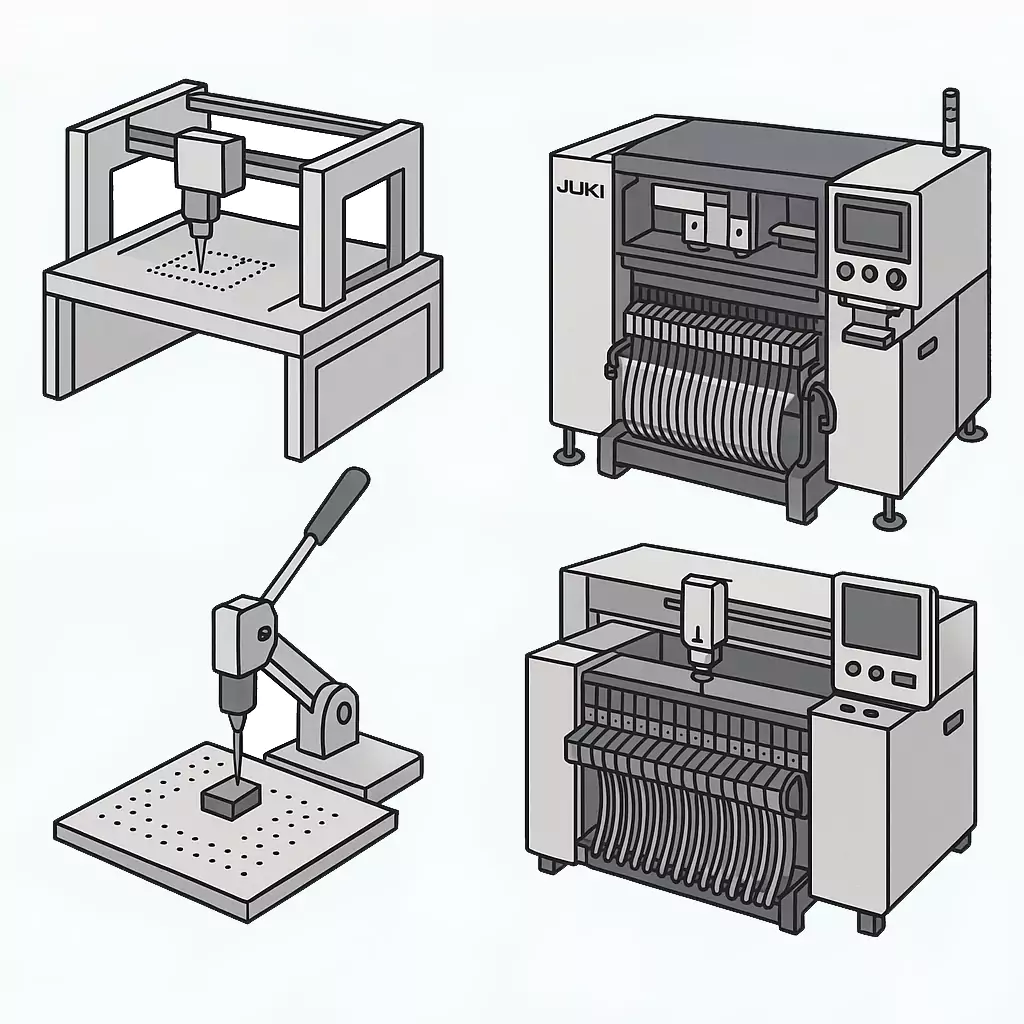

Fast Turn PCB Prototype Process

At Fast Turn PCB, we streamline the entire PCB board prototype process to help you move from concept to test-ready boards—quickly, reliably, and with expert support at every step.

Here’s how our process works:

1. File Submission & DFM Review

You start by uploading your Gerber files, BOM, and design notes. Our engineers perform a fast, free Design for Manufacturability (DFM) check—often within 2 hours—to catch any layout or production issues early.

2. Precision Fabrication

Once approved, we begin fabrication using industry-grade materials, such as FR-4, Rogers, or flexible substrates. We support a wide range of technologies, including:

- 1–50 layers

- 4 mil trace/space

- 0.2 mm minimum drill

- HDI, blind/buried vias, and impedance control

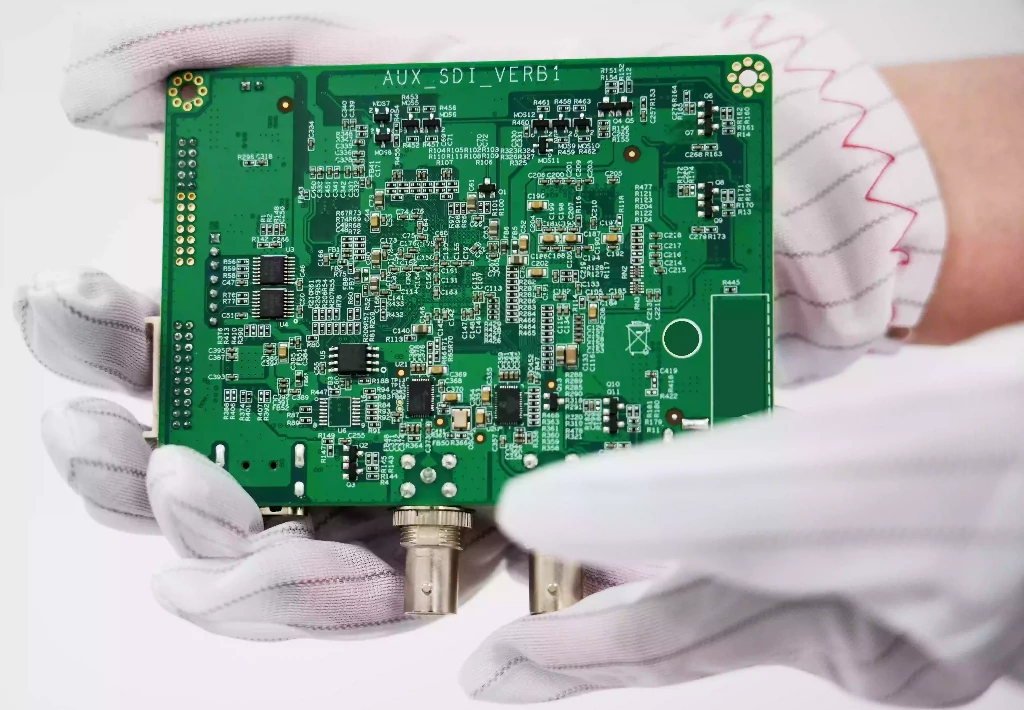

3. Quality Inspection

Every prototype undergoes rigorous inspection:

- AOI (Automated Optical Inspection) for fine-pitch accuracy

- X-ray for BGA and via alignment

- Electrical Testing (ICT) to verify connectivity and function

4. Quick Turn Delivery

With production cycles as short as 3 business days, we offer one of the fastest prototype lead times in the industry. Expedited services and global shipping options ensure you receive your boards on time—no matter where you are.

5. Ongoing Support

Our team is available 7 days a week to assist with questions, design adjustments, or technical concerns throughout the prototyping process.

Common Mistakes in PCB Prototyping

Even minor mistakes in your PCB board prototype can cause delays, rework, and performance issues. Knowing the common pitfalls helps you avoid costly setbacks and keep your development on track.

1. Ignoring DFM Guidelines

Designs that don’t follow Design for Manufacturability (DFM) rules—such as trace widths that are too narrow or vias too close to pads—can cause fabrication failures. Always validate your layout with a DFM review before sending it to production.

2. Incomplete or Misaligned Files

Missing Gerber layers, incorrect drill files, or outdated BOMs can stall the prototyping process. Double-check that all documentation is complete and consistent before uploading your files.

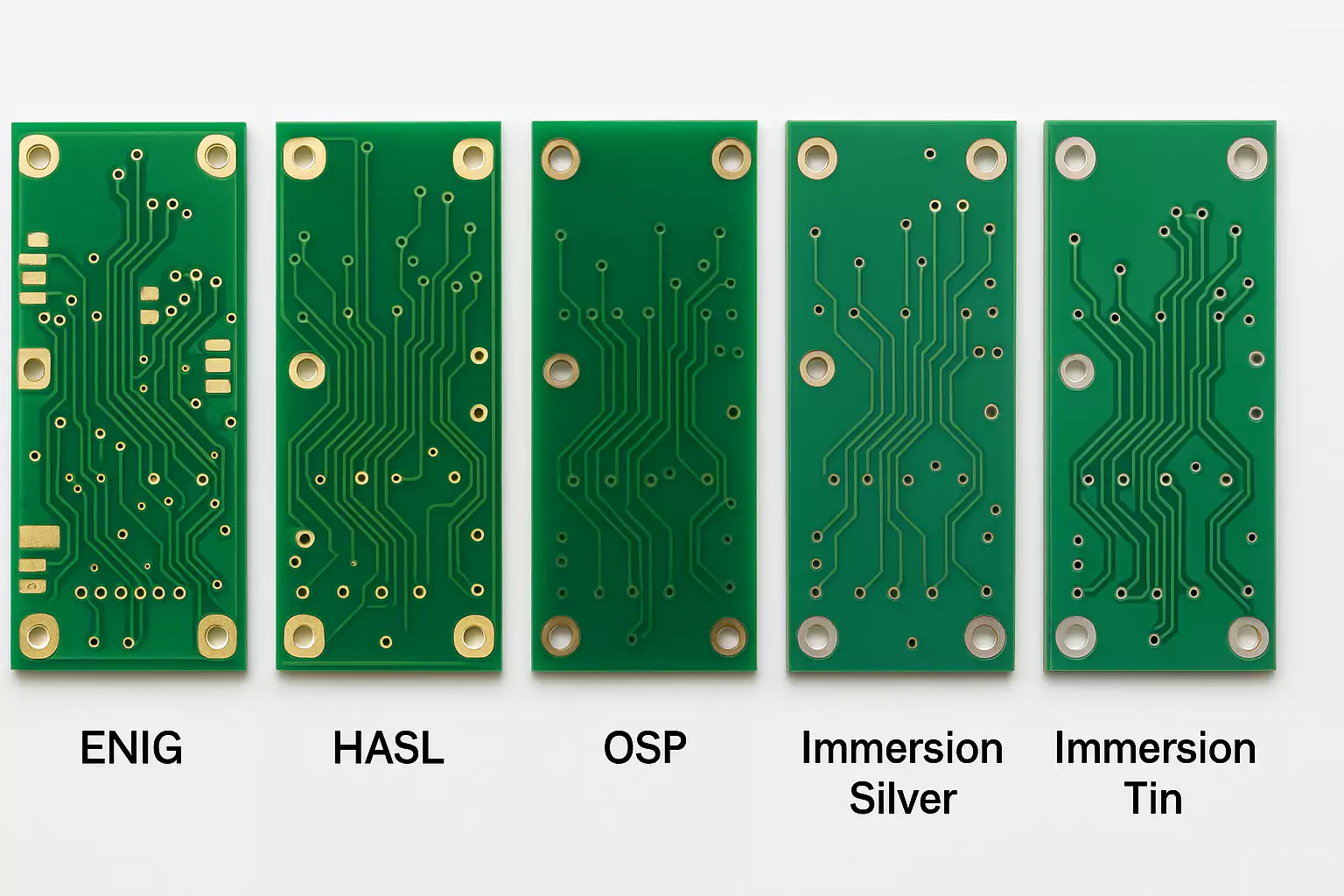

3. Wrong Material or Stack-Up Choice

Using the wrong substrate or layer configuration can compromise signal integrity, heat dissipation, or mechanical fit. Choose materials and stack-ups that align with your product’s performance needs.

4. Overlooking Assembly Constraints

Prototypes that aren’t designed with component spacing, solder mask clearance, or test access in mind can create problems during assembly. Planning for assembly early avoids delays later.

Conclusion

A solid PCB prototype is essential to any successful hardware development process. It allows you to verify your design, identify issues early, and avoid costly mistakes before moving to full production.

By choosing the right prototype type, following best practices, and partnering with a trusted manufacturer, you can streamline development and bring your product to market faster.

At Fast Turn PCB, we support you at every step—from quick-turn fabrication to expert DFM reviews. Upload your files today to get started with a fast, reliable PCB prototype you can count on.