Introduction

FR-4 is the most commonly used material in printed circuit boards (PCBs), known for its balance of mechanical strength, electrical insulation, and low cost. It forms the backbone of most modern electronics—from consumer gadgets to industrial systems—thanks to its flame-retardant properties and dependable performance.

This guide explains exactly what FR-4 PCB material is, how it's made, and why it's so widely used in the electronics industry. It also covers the key properties that make FR-4 popular, the limitations that affect its performance in high-frequency or high-temperature environments, and how it compares to alternative materials like Rogers or polyimide.

What Is FR‑4?

FR‑4 is a widely used composite material made from woven fiberglass cloth and epoxy resin, engineered to be flame-retardant, durable, and electrically insulating. The term "FR" stands for "Flame Retardant", and the "4" refers to its classification under the NEMA (National Electrical Manufacturers Association) standard system.

NEMA defines a series of laminate grades used in electrical insulation and PCB manufacturing. Among them, FR‑4 has become the industry standard for rigid circuit boards due to its excellent balance of thermal, mechanical, and dielectric properties.

Naming Origin: What Does "FR‑4" Stand For?

- "FR" = Flame Retardant

- "4" = Grade number in the NEMA classification system

This differentiates it from other grades such as G‑10, which shares a similar fiberglass-epoxy construction but lacks flame-retardant properties.

FR‑4 vs. G‑10: Key Differences

| Property | FR‑4 | G‑10 |

|---|---|---|

| Flame Retardant | ✅ Yes (meets UL94‑V0 standards) | ❌ No (flammable under high heat) |

| NEMA Grade | FR‑4 | G‑10 |

| Composition | Woven fiberglass + epoxy resin | Woven fiberglass + epoxy resin |

| Thermal Resistance | Higher (suitable for PCB soldering) | Lower |

| Common Usage | Printed circuit boards, electrical insulators | Structural parts, mechanical insulation |

| Cost | Moderate | Slightly lower |

| Electrical Insulation | Excellent | Excellent |

| Availability | Industry standard | Less common in PCB manufacturing |

While G‑10 was widely used before FR‑4 was introduced, it has largely been phased out in the electronics industry due to its flammability and lower thermal resistance. FR‑4, with its UL94‑V0 flame rating, became the safer and more reliable option—especially for PCB applications requiring soldering or operation in higher-temperature environments.

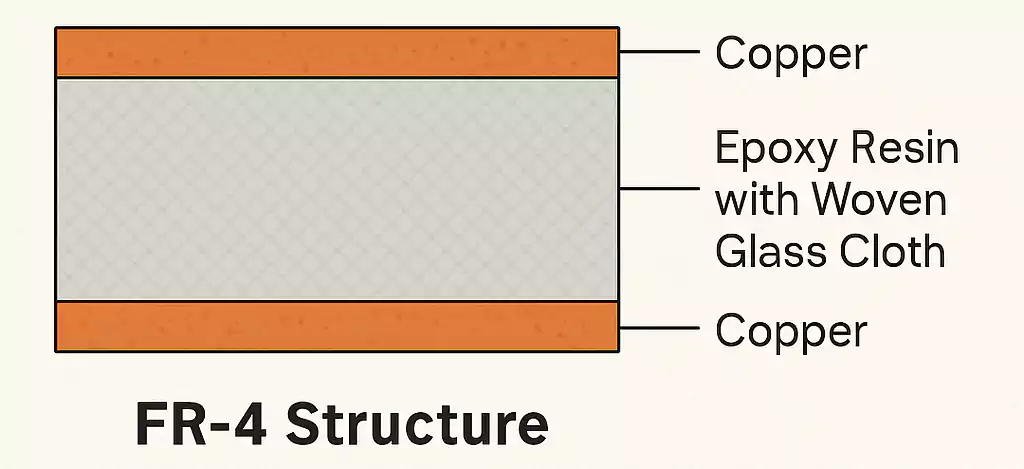

Material Composition of FR-4

FR-4 PCB material is a composite laminate made primarily of two key components:

- Woven fiberglass cloth (reinforcement)

- Epoxy resin (binder matrix)

Together, these materials form a strong, flame-retardant substrate that serves as the foundation for most rigid printed circuit boards (PCBs).

1. Woven Fiberglass Cloth

The fiberglass component provides mechanical strength and dimensional stability. It is typically made from E-glass fibers, which are non-conductive and resistant to moisture and corrosion. The woven structure ensures rigidity and a consistent thickness, which are crucial for multilayer PCB fabrication.

2. Epoxy Resin Binder

The epoxy resin binds the fiberglass layers together and contributes to the board's electrical insulation, chemical resistance, and thermal durability. The resin is thermosetting, meaning it cures permanently under heat and pressure, locking the fiberglass structure in place. This gives FR-4 its characteristic hardness and resistance to warping.

Layered Structure in PCB Use

In PCB manufacturing, multiple FR-4 sheets are laminated together with copper foil layers to form multi-layer boards. The inner core is typically FR-4 laminate, while outer layers may include prepreg (partially cured resin) for flexibility during pressing.

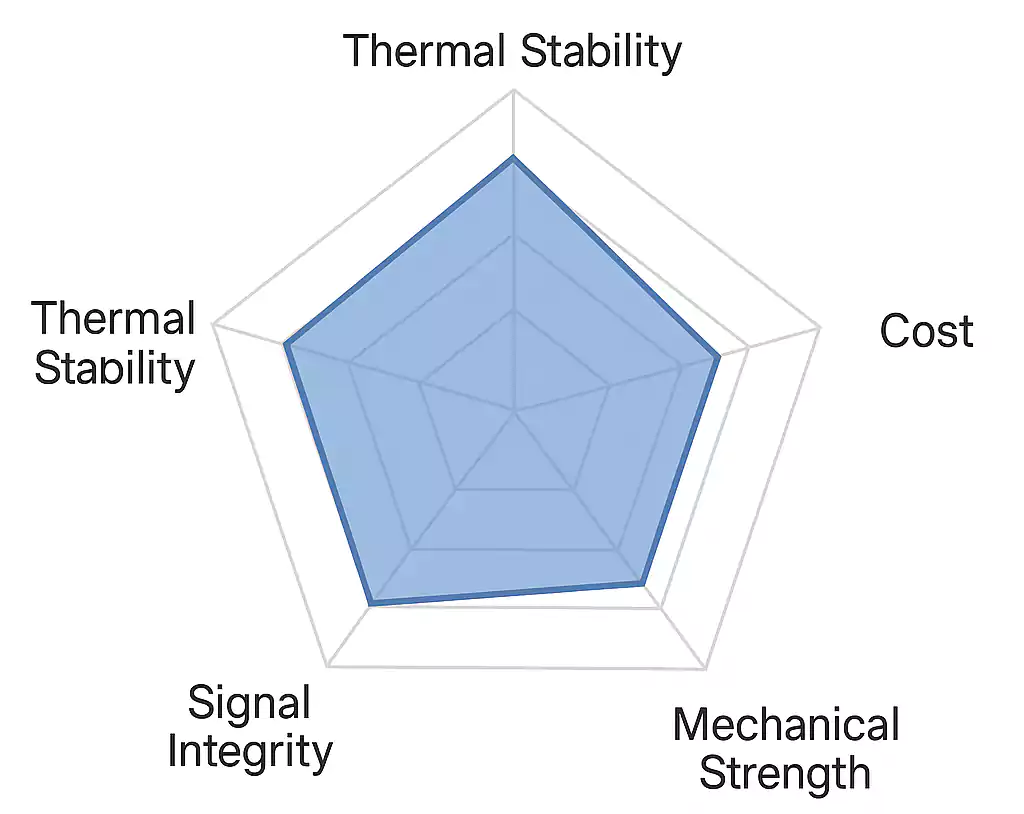

Key Performance Properties of FR-4

FR-4 is valued in the electronics industry for its balanced combination of electrical insulation, mechanical strength, thermal stability, and flame resistance. Understanding these performance parameters is essential for selecting the right substrate for PCB design, especially in environments involving thermal cycling, signal transmission, or mechanical stress.

The following table summarizes the most important characteristics of FR-4:

| Property | Typical Value | Description / Importance |

|---|---|---|

| Density | ~1.85 g/cm³ | Lightweight but structurally strong |

| Dielectric Constant (Dk) | 4.2 – 4.8 @ 1 MHz | Affects signal propagation speed and impedance; stable over frequency range |

| Dissipation Factor (Df) | 0.015 – 0.02 @ 1 MHz | Lower values mean less signal loss, important in high-speed circuits |

| Glass Transition Temperature (Tg) | 130°C to 180°C (standard) / >200°C (high Tg) | Indicates the temperature at which the material softens; affects thermal reliability |

| Thermal Conductivity | ~0.3 W/m·K | Determines heat dissipation capability |

| Flammability Rating | UL94 V-0 | Flame-retardant; self-extinguishing in vertical burn tests |

| Peel Strength | ≥1.4 N/mm | Adhesion strength between copper and laminate |

| Water Absorption | ≤0.10% | Low moisture uptake improves dimensional and electrical stability |

| Electrical Strength | ~20 kV/mm | High dielectric breakdown voltage; ensures insulation under high voltages |

| Flexural Strength | ~400 – 500 MPa | High mechanical strength; resists bending and deformation |

| Coefficient of Thermal Expansion (CTE) | ~14 – 17 ppm/°C (in-plane) | Important for multi-layer PCB dimensional stability |

Advantages of FR-4: Why It's the Most Popular PCB Material

FR-4 is the standard material for printed circuit boards due to its reliable performance, affordable cost, and versatile properties. It's used across consumer electronics, automotive systems, industrial equipment, and medical devices—proving its value in both everyday and critical applications.

Here are the core advantages of FR-4 in PCB manufacturing:

1. Flame Retardancy (UL94 V-0 Certified)

FR-4 meets the UL94 V-0 flammability rating, meaning it is self-extinguishing when exposed to flame. This is a critical safety feature for any device operating near heat or electricity.

2. Excellent Electrical Insulation

The epoxy-glass composite structure offers strong dielectric properties, maintaining high electrical resistance even under high voltage. This makes FR-4 ideal for densely packed multilayer PCBs and mixed-signal designs.

3. High Mechanical Strength

FR-4 has high flexural strength and rigidity, which helps it withstand handling, vibration, and mechanical stress without cracking or warping—crucial for both small consumer electronics and large industrial equipment.

4. Good Thermal Stability

With a glass transition temperature (Tg) typically between 130°C and 180°C, standard FR-4 can tolerate soldering processes and moderate thermal cycles. High-Tg variants can go beyond 200°C, suitable for lead-free and multilayer PCB assembly.

5. Low Water Absorption

FR-4 absorbs very little moisture (typically ≤0.10%), which enhances its dimensional stability and electrical reliability, even in humid or wet environments.

6. Cost-Effective and Widely Available

Compared to high-performance laminates (like Rogers or polyimide), FR-4 is significantly more affordable while offering enough performance for the vast majority of designs. Its global availability and standardization also simplify sourcing and manufacturing.

7. Excellent Copper Adhesion

The surface properties of FR-4 allow for strong bonding with copper layers, which is essential for multilayer PCB stack-ups and high-reliability designs.

8. Easy to Machine and Fabricate

FR-4 is compatible with standard PCB fabrication processes including drilling, milling, and etching. Its durability reduces fabrication defects and improves production yields.

Limitations and Considerations of FR-4

While FR-4 is a versatile and cost-effective material, it's not the best choice for every application. Designers working on high-speed, high-frequency, or high-temperature systems should be aware of FR-4's performance limitations.

Understanding these constraints is essential for avoiding signal integrity issues, thermal failures, or reduced product lifespan.

1. Not Ideal for High-Frequency Applications

FR-4 has a dielectric constant (Dk) in the range of 4.2–4.8 and a dissipation factor (Df) around 0.02. These values fluctuate with frequency and temperature, which can cause signal loss and impedance drift in RF and microwave circuits—typically above 1 GHz.

2. Limited Thermal Performance

Standard FR-4 has a glass transition temperature (Tg) of 130°C–180°C. Beyond this range, the material can soften, warp, or delaminate. It's not suitable for high-temperature or thermal cycling environments without switching to high-Tg FR-4 or specialized materials.

3. Variable Electrical Properties

FR-4's electrical characteristics can vary between batches or manufacturers. For high-reliability designs, this inconsistency may lead to signal distortion, especially in tightly controlled impedance systems like DDR, USB 3.0, or high-speed backplanes.

4. Not Suitable for Miniaturized or High-Density Designs

FR-4 has a higher CTE (coefficient of thermal expansion) compared to advanced materials, which can affect via reliability in fine-pitch or multilayer designs. It also may not perform well in very thin or flex-rigid boards.

5. Environmental Limitations

Although halogen-free FR-4 variants are available, standard FR-4 is not the most eco-friendly material. It contains halogens and epoxy compounds that may not meet strict RoHS/REACH requirements unless specified.

Applications of FR-4: Where It's Used

Thanks to its excellent balance of electrical insulation, mechanical strength, thermal stability, and cost-effectiveness, FR-4 is used in a wide range of PCB applications—from everyday consumer devices to mission-critical industrial systems.

Below is a breakdown of the most common and important use cases for FR-4:

1. Consumer Electronics

FR-4 is the backbone of mass-produced electronics such as:

- Smartphones and tablets

- Laptops and desktop computers

- Televisions and smart home devices

Its affordability and structural integrity make it ideal for compact, multi-layer boards used in modern gadgets.

2. Industrial Control Systems

In factory automation, robotics, and control panels, FR-4 PCBs are used for:

- Power supply boards

- Motor drivers

- PLCs and relay modules

Its mechanical rigidity and flame-retardant properties offer reliable performance in demanding industrial environments.

3. Automotive Electronics

While not suited for the hottest engine bay areas, FR-4 is widely used in:

- Dashboard and infotainment systems

- Rearview cameras and sensor modules

- Battery management systems (BMS)

High-Tg FR-4 variants are often selected to handle elevated temperatures and vibration.

4. Medical Devices

In non-implantable and diagnostic equipment, FR-4 is found in:

- ECG monitors and defibrillators

- Handheld imaging devices

- Wearable health trackers

Its stable dielectric performance supports accurate signal transmission in medical-grade electronics.

5. Aerospace and Defense

FR-4 is used in certain low-risk, non-flight-critical subsystems like:

- Ground-based radar systems

- Communication modules

- Power converters

For high-temperature or radiation-prone areas, FR-4 may be replaced with polyimide or ceramic laminates.

6. LED Lighting and Power Electronics

FR-4 serves as a low-cost base in:

- LED driver boards

- Light panels

- Inverters and converters

Although not as thermally conductive as aluminum-backed MCPCBs, FR-4 remains a common choice for moderate-power designs.

FR-4 Variants and Alternative Materials

Although standard FR-4 is suitable for a wide range of PCB applications, there are several specialized variants designed to meet more demanding requirements—such as higher thermal stability, stricter environmental compliance, or better electrical performance.

When standard FR-4 reaches its limits, especially in high-frequency, high-speed, or high-temperature environments, engineers often turn to alternative materials.

Common Variants of FR-4

| FR-4 Variant | Key Features | Best Use Cases |

|---|---|---|

| High Tg FR-4 | Glass transition temperature > 180°C | Lead-free soldering, automotive, multilayer PCBs |

| Halogen-Free FR-4 | Environmentally friendly, meets RoHS/REACH requirements | Eco-compliant products, medical, EU-regulated markets |

| Low Dk / Low Loss FR-4 | Improved signal integrity for high-speed digital signals | High-speed data (e.g., USB 3.0, HDMI, DDR4) |

| FR-4 with High CTI | High Comparative Tracking Index for better voltage isolation | Power supplies, industrial controls |

These variants retain the basic fiberglass and epoxy structure but are formulated to perform better under specific conditions.

Alternative Materials to FR-4

When FR-4's limitations—such as poor high-frequency behavior or thermal constraints—become critical, the following alternatives are commonly used:

| Material | Key Advantages | Typical Applications |

|---|---|---|

| PTFE (e.g., Rogers) | Ultra-low Dk/Df, excellent for RF/microwave | Antennas, 5G, radar, satellite communications |

| Polyimide | High thermal resistance, flexible or rigid-flex options | Aerospace, automotive under-hood, high-temp systems |

| Metal Core PCB (MCPCB) | Excellent heat dissipation, aluminum or copper base | LED lighting, power conversion, high-current circuits |

| Ceramic (Alumina, AlN) | Superior thermal conductivity and dimensional stability | Power modules, RF amplifiers, high-reliability electronics |

Material Selection Tips & Practical Guidelines

Choosing the right PCB substrate depends on performance requirements, environmental conditions, and cost targets. While FR-4 suits most general applications, selecting the right variant or alternative is key to ensuring long-term reliability.

Quick Selection Guidelines:

- Standard FR-4: Use for basic consumer electronics, low-speed digital, and general-purpose PCBs.

- High Tg FR-4: Choose when operating temperatures exceed 130–150°C or for lead-free soldering.

- Low Dk / Low Loss FR-4: Recommended for high-speed signals (e.g., USB 3.0, HDMI, Ethernet).

- Halogen-Free FR-4: Use when environmental regulations like RoHS or REACH apply.

- Switch to Rogers/PTFE: If your design operates above 1 GHz or demands tight signal integrity.

- Use Polyimide or Metal-Core: For extreme thermal or power-dense applications.

Future Trends & Advanced Research in PCB Materials

As electronics evolve toward faster, smaller, and hotter designs, the limitations of standard FR-4 are pushing innovation in both materials and manufacturing.

Key Trends to Watch:

- High-Frequency Readiness: Research focuses on modifying FR-4's resin systems to lower dielectric loss, extending its use into higher GHz ranges for cost-sensitive RF designs.

- Eco-Friendly Formulations: Halogen-free and recyclable laminates are gaining traction due to stricter global environmental regulations (RoHS, WEEE, REACH).

- Hybrid Stackups: Designers are combining FR-4 with high-performance cores (e.g. Rogers or polyimide) to balance cost and signal integrity in complex multilayer PCBs.

- Ultra-Thin & Flex Variants: Miniaturization and wearable tech are driving demand for ultra-thin and flexible FR-4 derivatives.

- Cryogenic & Quantum Research: In emerging applications like quantum computing and deep-space electronics, FR-4 is being studied for behavior under extreme low temperatures.

Frequently Asked Questions (FAQ) About FR-4

What does "FR-4" stand for?

FR-4 stands for Flame Retardant grade 4, a material classification under the NEMA (National Electrical Manufacturers Association) standard. It refers to a glass-reinforced epoxy laminate known for its flame resistance and electrical insulation.

What is the maximum temperature FR-4 can withstand?

Standard FR-4 has a glass transition temperature (Tg) between 130°C and 180°C. High-Tg variants can tolerate temperatures above 200°C, suitable for lead-free soldering and harsh thermal conditions.

Is FR-4 suitable for high-frequency PCB designs?

No. FR-4 is not ideal for high-frequency circuits above ~1 GHz due to its variable dielectric properties and higher signal loss. For RF or microwave designs, materials like Rogers, PTFE, or ceramic laminates are preferred.

What are the main advantages of FR-4?

FR-4 is widely used due to its low cost, good mechanical strength, electrical insulation, flame retardancy, and ease of processing—making it a go-to material for general-purpose PCB fabrication.

What is the difference between FR-4 and G-10?

Both are epoxy-glass laminates, but G-10 is not flame-retardant. FR-4 includes flame-resistant additives and meets the UL94 V-0 standard, making it safer and more suitable for electronic applications.

Can FR-4 be used in flexible PCBs?

No. FR-4 is a rigid laminate and not suitable for flex or rigid-flex PCBs. For flexibility, polyimide or PET-based materials are used instead.

Is FR-4 RoHS compliant?

Standard FR-4 may not be RoHS compliant due to halogen content, but halogen-free FR-4 variants are available and meet RoHS/REACH standards.

Conclusion

FR-4 remains the most widely used PCB material thanks to its excellent combination of mechanical strength, electrical insulation, thermal stability, and cost-efficiency. It's the default choice for countless applications—from consumer electronics and industrial equipment to automotive and medical devices.

However, like any material, FR-4 has its limitations. For high-frequency, high-speed, or high-temperature environments, selecting a high-Tg FR-4 variant or switching to advanced materials like PTFE or polyimide may be necessary.

Choosing the right PCB substrate is critical to ensuring performance, reliability, and compliance. Understanding FR-4's strengths and constraints allows engineers to design smarter, reduce failures, and optimize cost.