Introduction

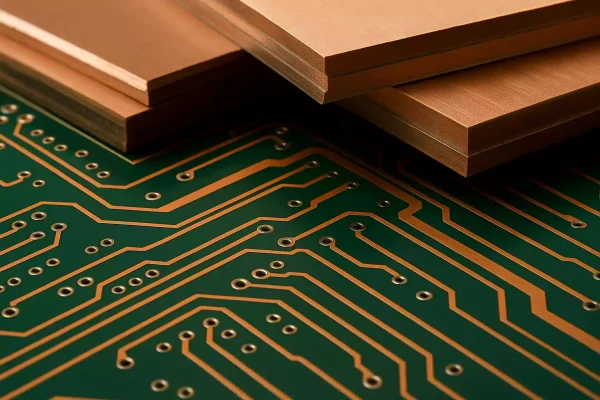

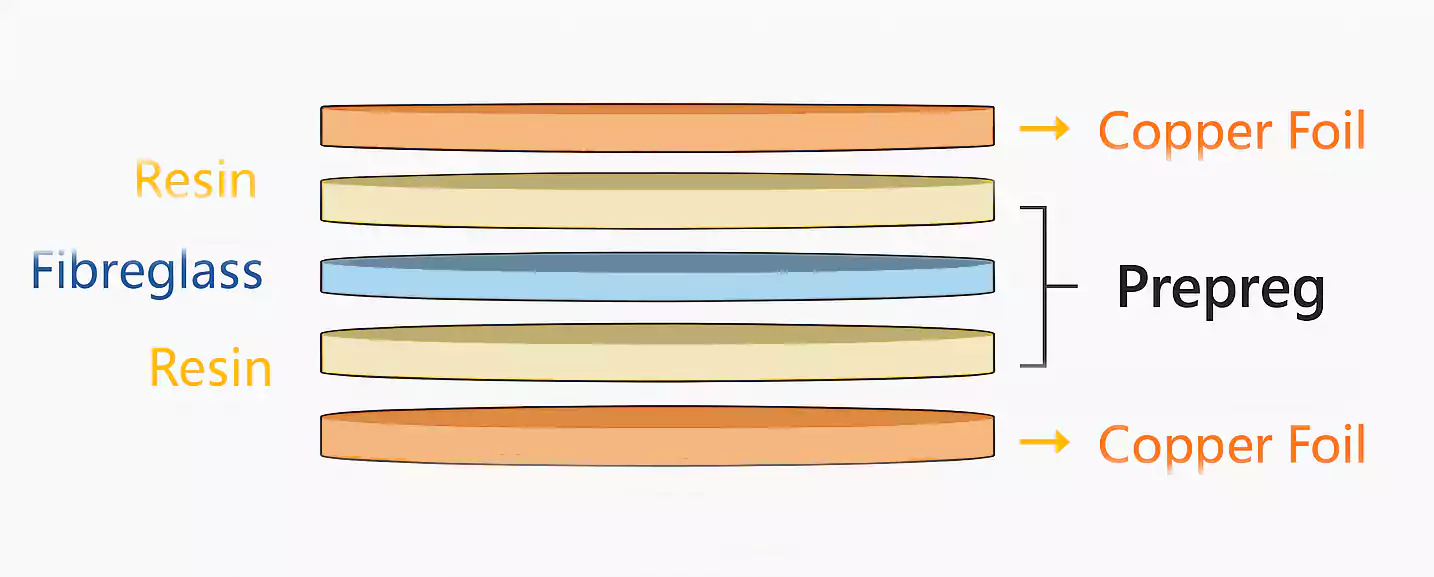

Copper Clad Laminate (CCL) is the core material used to manufacture printed circuit boards (PCBs), which serve as the foundation of all modern electronic devices. It consists of a non-conductive substrate laminated with a thin layer of copper foil on one or both sides. This copper layer is later etched to form conductive circuits.

As electronics become smaller and more powerful, the demand for high-performance PCB materials like CCL continues to rise. Choosing the right type of CCL directly impacts the board’s electrical performance, heat resistance, and long-term reliability.

In this article, you’ll learn what copper-clad laminates are, the most common types, their key properties, and how to select the best material for your specific application.

What Is Copper Clad Laminate?

Copper Clad Laminate (CCL) is a flat, rigid, or flexible sheet material used as the base for manufacturing printed circuit boards (PCBs). It is made by bonding a layer of copper foil onto one or both sides of an insulating substrate—typically composed of glass fiber-reinforced epoxy resin, paper, or composite materials.

The copper layer provides the conductive surface that is later patterned into traces and pads during PCB fabrication. The substrate underneath offers mechanical support and electrical insulation between layers or components.

CCL comes in a variety of types and thicknesses to suit different performance needs. Its composition, quality, and performance characteristics directly affect the functionality, reliability, and durability of the final electronic product.

Main Types of Copper Clad Laminate (CCL)

Copper-clad laminates can be classified in several ways, depending on their material composition, electrical properties, and mechanical characteristics. Below are the most common classification methods used in the PCB industry:

1. By Base Material

- Paper-based CCL (e.g., XPC): Low-cost, used for simple, low-frequency circuits. Rare in modern high-performance electronics.

- Glass fiber cloth base CCL (e.g., FR-4): The most widely used type, ideal for multilayer PCBs requiring good mechanical and electrical properties.

- Composite materials (e.g., CEM-1, CEM-3): Combine paper and fiberglass; suitable for mid-range applications.

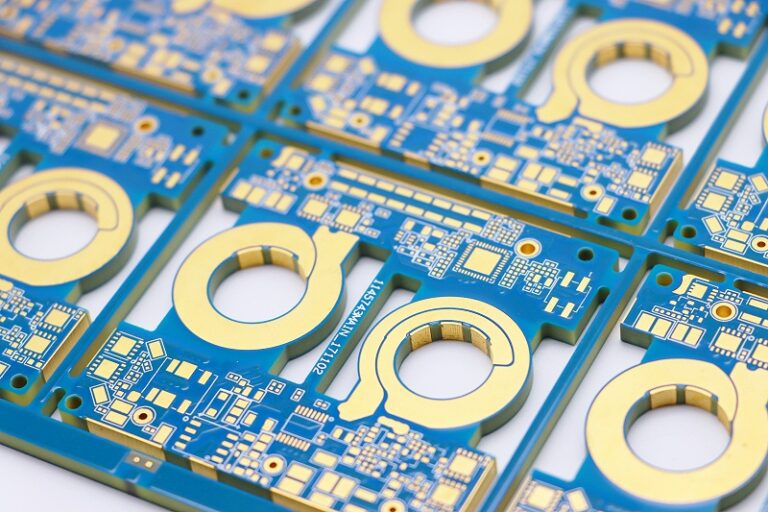

- Special materials (e.g., metal-base, ceramic-base): Used in high-power or high-frequency applications that demand thermal conductivity or RF stability.

2. By Insulating Resin

- Phenolic resin CCL: Low-cost and low-performance, mostly obsolete.

- Epoxy resin CCL (FR-4): The industry standard for rigid boards, offering balanced electrical and thermal properties.

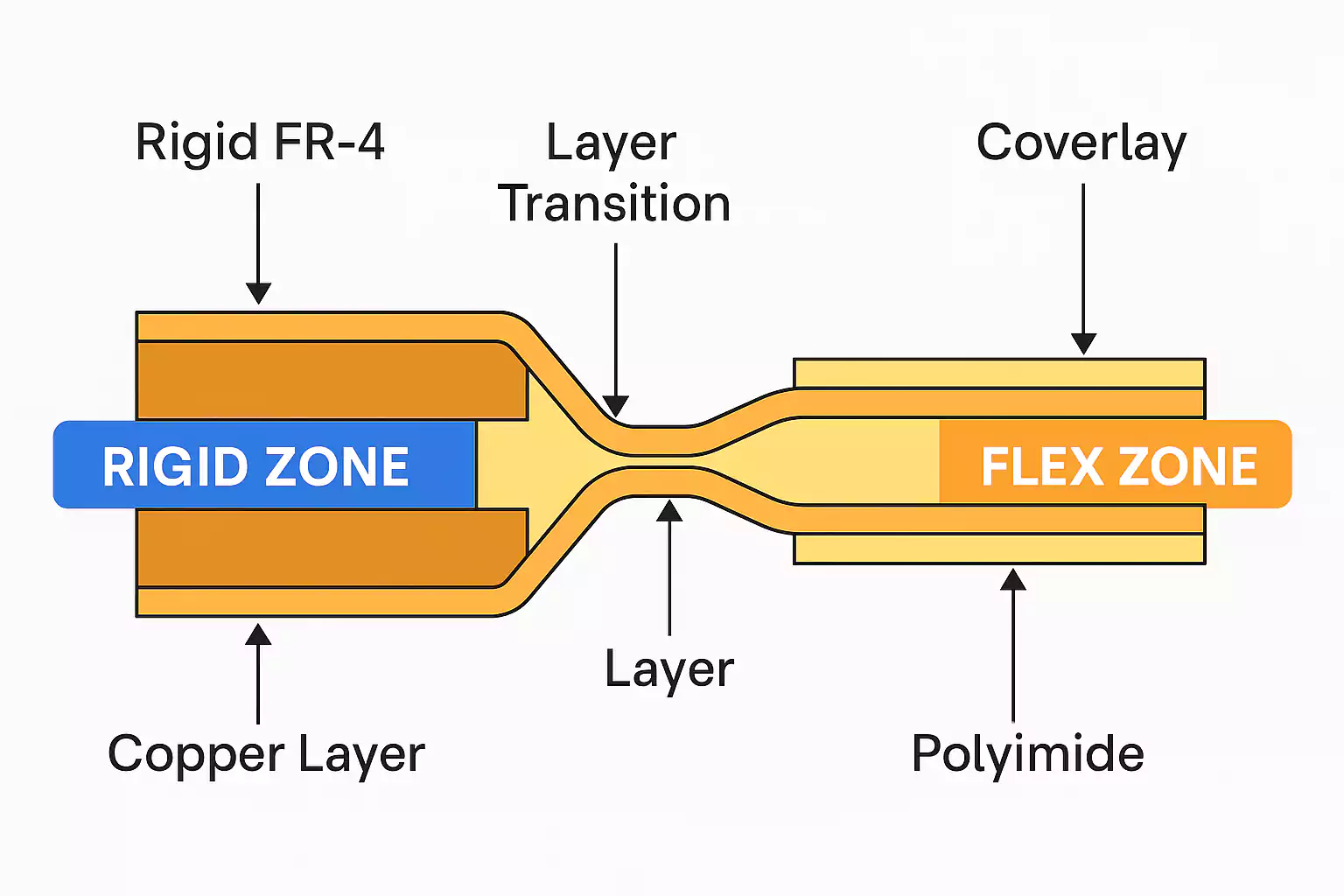

- Polyester or polyimide resin (for FCCL): Used in flexible copper clad laminates.

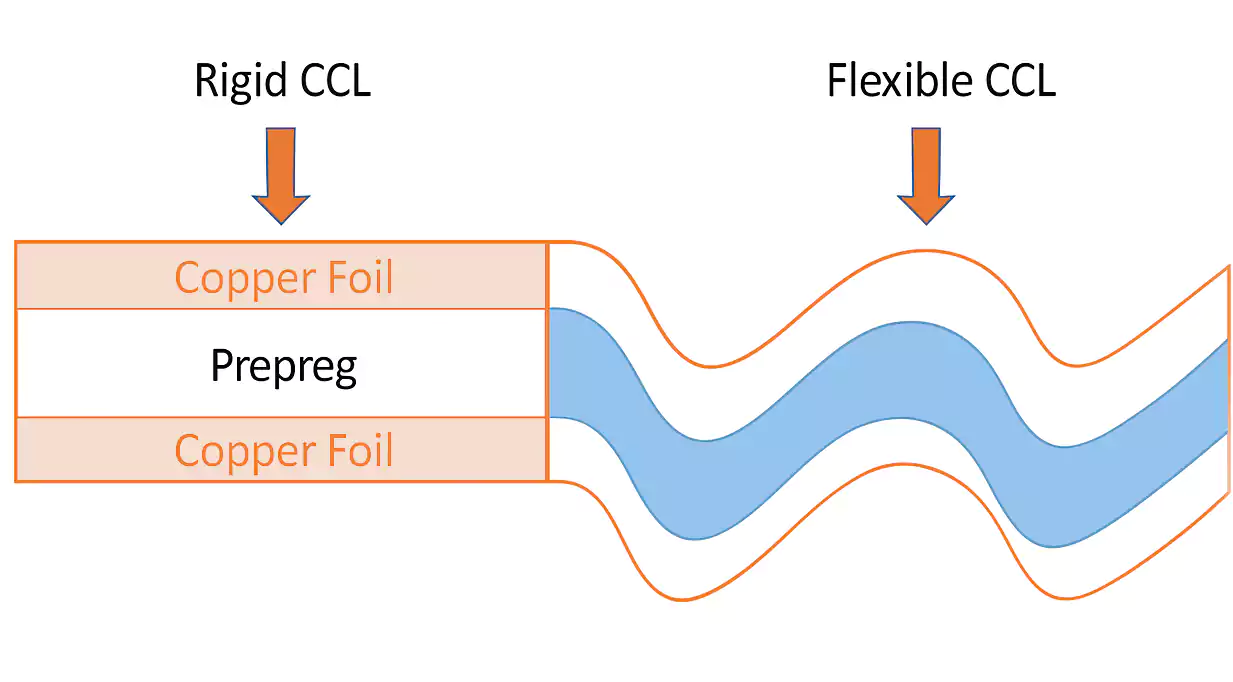

3. By Mechanical Rigidity

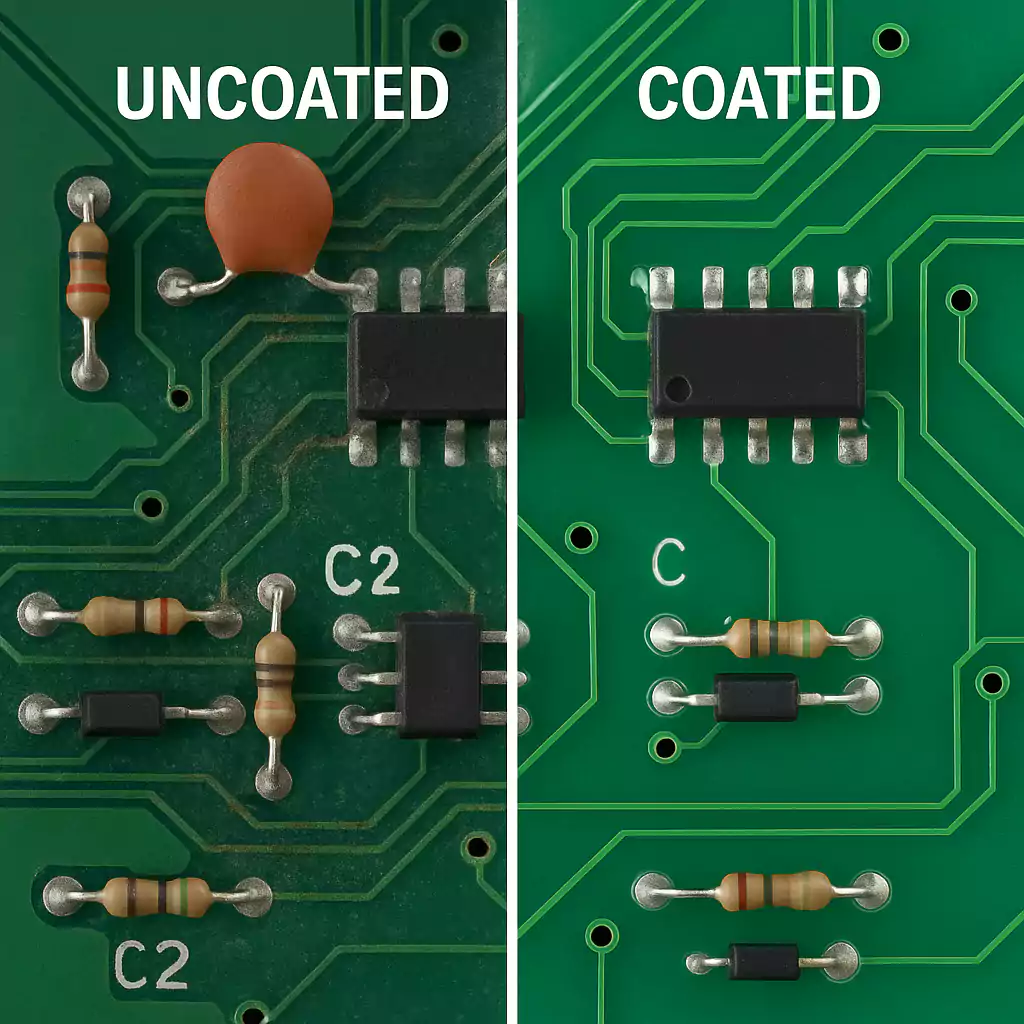

- Rigid CCL: Common in desktop electronics, servers, and industrial control systems.

- Flexible CCL (FCCL): Used in mobile phones, wearables, and foldable electronics.

4. By Performance Characteristics

- General-purpose CCL: Standard dielectric and thermal behavior for low to medium-frequency circuits.

- High heat resistance CCL: Withstands elevated temperatures during soldering or operation.

- Low dielectric constant (Dk) and low loss (Df): Ideal for high-frequency or RF applications such as 5G or microwave systems.

- Low CTE (Coefficient of Thermal Expansion): Critical for multilayer or high-reliability PCBs to prevent delamination.

Key Properties of Copper Clad Laminates

| Property | Description | Typical Range |

|---|---|---|

| Dielectric Constant (Dk) | Signal speed, impedance control | 4.2–4.8 (FR-4), <3.0 (RF CCL) |

| Dissipation Factor (Df) | Signal loss, high-frequency performance | ~0.02 (FR-4), <0.005 (low-loss) |

| Thermal Conductivity | Heat dissipation | 0.3 W/m·K (FR-4), >1.0 (MCPCB) |

| Glass Transition Temp (Tg) | Heat resistance, soldering process | 130–180 °C |

| CTE (Z-axis) | Dimensional stability, via reliability | 40–70 ppm/°C |

| Peel Strength | Copper adhesion strength | ≥1.0 N/mm |

| Moisture Absorption | Electrical stability in humid conditions | ≤0.2% |

| Flame Rating | Safety compliance | UL 94 V-0 |

Common Applications of Copper Clad Laminates

Copper clad laminates (CCLs) are essential to nearly every sector of the electronics industry. Below are the most common use cases:

1. Consumer Electronics

- Smartphones, tablets, laptops, TVs

- Use FR-4 and flexible CCLs for high-density, compact layouts

- Emphasis on low cost, signal integrity, and multilayer capability

2. Automotive Electronics

- Engine control units (ECUs), LED lighting, ADAS systems

- Require high-Tg, high thermal conductivity, and vibration resistance

- Metal-based and high-temperature CCLs are commonly used

3. Communication Equipment

- Routers, 5G base stations, antennas, RF modules

- Demand low-Dk and low-Df laminates for high-frequency performance

- PTFE, ceramic-based, or hydrocarbon CCLs are preferred

4. Industrial and Power Electronics

- Power supplies, motor drivers, sensors, PLCs

- Applications demand strong heat dissipation and electrical insulation

- Aluminum-based or thick copper CCLs are often used

5. LED Lighting

- Backlight modules, streetlights, automotive lamps

- Require high thermal conductivity to manage heat

- Metal core PCBs (MCPCBs) with aluminum CCLs are widely adopted

6. Medical Devices (Low- to Mid-Frequency)

- Imaging systems, monitoring equipment

- Emphasis on electrical reliability and moisture resistance

- FR-4 and composite CCLs are typically sufficient

Conclusion

Copper clad laminates (CCLs) form the foundation of every printed circuit board. Their material properties—such as dielectric performance, thermal stability, and mechanical strength—play a critical role in ensuring signal integrity, reliability, and long-term durability in electronic devices.

From standard FR-4 to high-frequency PTFE and metal-based laminates, choosing the right CCL depends on your application’s specific needs, including power density, operating frequency, temperature conditions, and budget. Engineers and sourcing professionals should always evaluate key specifications like Dk, Df, Tg, and thermal conductivity when selecting a laminate.

At Fast Turn PCB, we offer quick-turn and small-to-medium volume PCB manufacturing with a full range of copper clad laminate (CCL) options, including FR-4, high-frequency, and metal-based materials. For expert support or a fast quote, contact us at service@fastturnpcb.com.