In modern electronics manufacturing, the structure of a rigid multilayer PCB (ML-PCB) directly affects product performance, reliability, and manufacturability.

Because multilayer boards come in many forms, the IPC Multilayer PCB classification system—established by the IPC (Institute for Printed Circuits)—provides a comprehensive set of design standards that define the grades and types of rigid printed circuit boards.

These standards give designers and manufacturers a common language for communicating stack-up configurations, via structures, and quality expectations.

This article explains how IPC-2221, IPC-2222, and IPC-2226 classify multilayer PCBs—and why understanding these IPC Multilayer PCB types helps you choose the right design and fabrication strategy for your next project.

The Role of IPC Standards in PCB Design

IPC is the world’s leading standards organization for the electronics manufacturing industry.

Its goal is to establish consistent rules and definitions across design, fabrication, assembly, and inspection, so everyone—from engineers to production teams—can speak the same technical language.

In multilayer PCB design, IPC standards do more than describe structure; they define how people communicate design intent.

When a drawing says “Type 3 Multilayer” or “HDI Type II”, both designers and fabricators immediately know the intended layer configuration from the structure and process requirements.

IPC-2221 — Generic Standard on Printed Board Design

IPC-2221 serves as the umbrella standard for all printed circuit designs.

It defines general design principles, including conductor spacing, annular ring width, dielectric clearance, material properties, and both electrical and mechanical considerations.

In multilayer PCB design, IPC-2221 acts as the foundation for all other standards.

It doesn’t classify specific board types itself; rather, it provides the framework for standards such as IPC-2222 and IPC-2226.

In short, IPC-2221 is the foundation—not the destination.

IPC-2222 — Sectional Design Standard for Rigid Organic Printed Boards

IPC-2222 focuses on traditional rigid multilayer PCBs with general-purpose feature sizes.

It defines two major structural types based on how vias connect internal layers.

IPC-2222 Classification

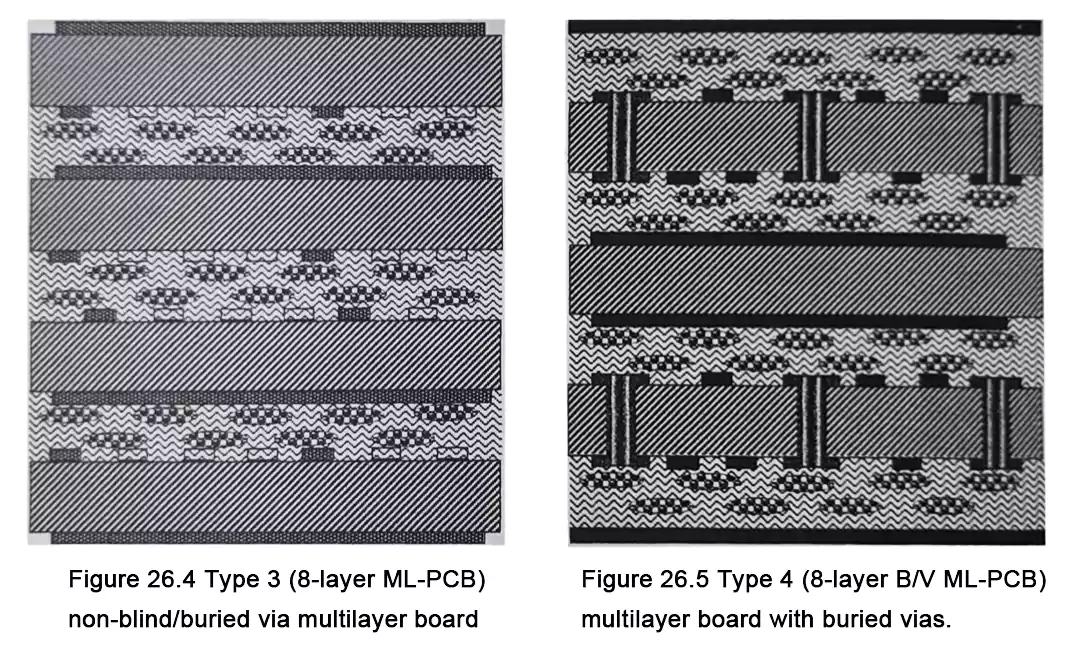

- Type 3 — Multilayer Board Without Blind or Buried Vias

This is the most common multilayer structure.

All layers are interconnected via plated-through holes (PTH), with no blind or buried vias.

Type 3 boards dominate general electronics, industrial control, and communication devices thanks to their low cost, high yield, and mature manufacturing processes. - Type 4 — Multilayer Board with Blind and/or Buried Vias

This structure adds blind or buried vias to improve routing density and save internal space.

It’s used when fine-pitch BGAs or high-density connectors require shorter interconnect paths.

Type 4 boards demand tighter layer registration, more complex lamination, and precise drilling, but they enable significantly denser routing.

IPC-2226 — Design Standard for High-Density Interconnect (HDI) PCBs

As electronics continue to shrink and I/O counts increase, traditional multilayer structures reach their limits.

That’s why IPC-2226 was introduced—to standardize HDI (High-Density Interconnect) PCBs that use microvias, blind/buried vias, and sequential lamination to achieve extreme wiring density.

IPC-2226 Classification

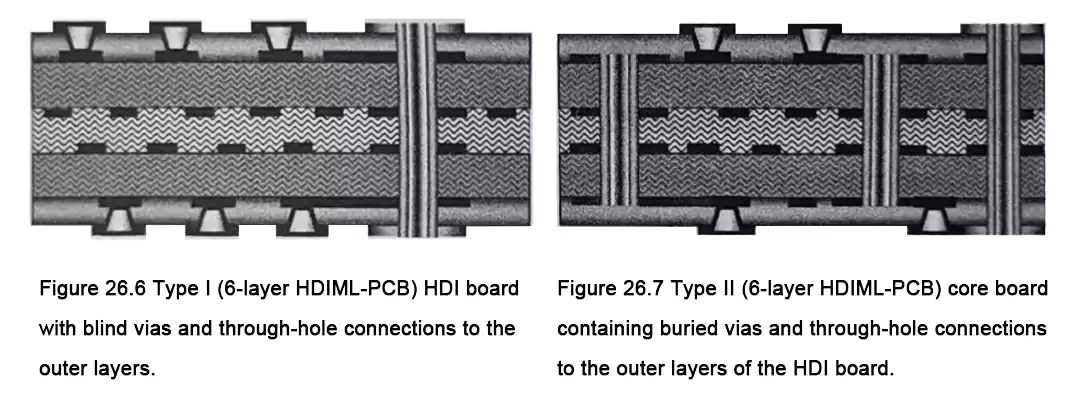

- Type I — 1[C]0 or 1[C]1 Structure

A single build-up layer with microvias connecting to the core.

Through-holes may also connect outer layers.

Type I is the simplest HDI form, commonly used in compact consumer devices. - Type II — 1[C]0 or 1[C] Core with Buried Vias

The core includes buried vias, and outer build-up layers use laser-drilled microvias.

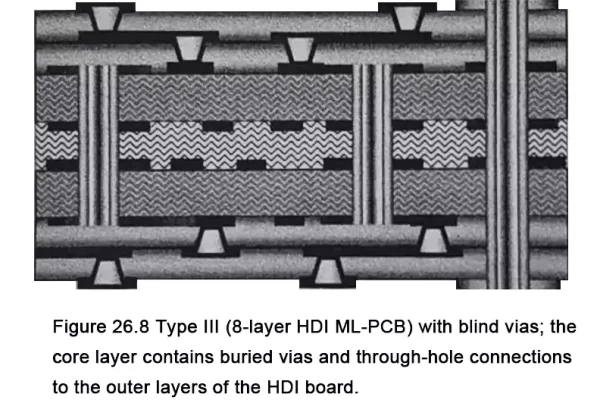

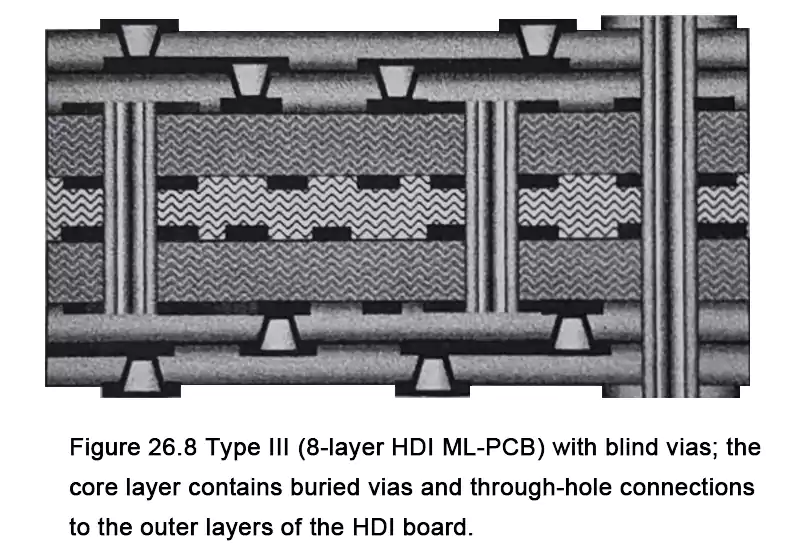

This hybrid approach balances the advantages of traditional multilayer and HDI technologies, making it ideal for smartphones, automotive electronics, and dense IoT modules. - Type III — >2[C]>0 Structure

Multiple sequential build-up layers with buried and/or through vias.

Type III is the hallmark of advanced HDI design, often requiring multiple laser drilling and lamination cycles.

It’s used in 5G communication modules, high-speed servers, and HPC (high-performance computing) boards.

IPC-2226 not only defines the classification but also specifies design and process requirements—such as microvia diameter limits, lamination order, copper thickness control, and interconnect reliability testing.

Why IPC Multilayer PCB Classification Matters in Engineering Practice

Understanding the differences among IPC-2221, 2222, and 2226 is not just academic—it directly impacts how boards are designed and built.

Key Engineering Impacts

- Design for Manufacturability (DFM)

Each IPC type implies a different manufacturing capability.

Type 3 boards can be built by almost any fabricator, while Type III HDI requires laser drilling, sequential lamination, and precise registration control. - Cost and Lead Time

As complexity increases—from Type 3 → Type 4 → HDI Type III—costs and production time rise dramatically.

Selecting the right IPC type helps balance performance, reliability, and budget. - Reliability and Performance

IPC standards define reliability expectations for via integrity, interlayer adhesion, warpage, and dielectric spacing.

Choosing the proper classification helps ensure consistent performance through thermal cycles and mechanical stress. - Universal Communication

IPC classification provides a standardized design language.

A note like “IPC-2226 Type II” instantly conveys stack-up intent to any global PCB supplier, eliminating ambiguity and reducing engineering revisions.

Conclusion

From IPC-2221’s general design framework to IPC-2222’s conventional multilayer structures and IPC-2226’s advanced HDI configurations, the IPC system builds a clear hierarchy for rigid PCB design.

For engineers, mastering IPC Multilayer PCB Classification means more than compliance—it’s the key to reliable, manufacturable, and cost-effective board design.

In the electronics industry, following IPC standards isn’t a constraint; it’s an engineering language shared across the global supply chain.