Introduction

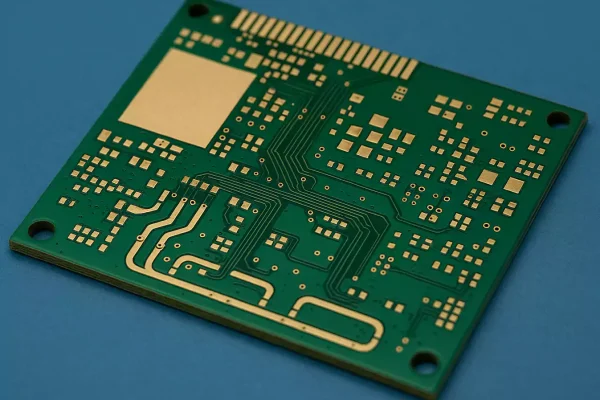

High frequency PCB is specialized circuit boards designed to operate at frequencies above 500 MHz, often reaching into the gigahertz (GHz) range. They are essential for high-speed applications such as 5G communications, RF systems, automotive radar, and satellite technology—where signal accuracy, low loss, and consistent performance are critical.

Compared to standard PCBs, high-frequency boards utilize advanced materials with low dielectric loss and stable electrical properties. They also require precise impedance control and well-managed signal paths to minimize interference and ensure reliable transmission at high frequencies.

In this article, we’ll take a closer look at what distinguishes high frequency PCB, the materials used in their construction, and their common applications in modern communication and electronic systems.

Why High-Frequency PCB Matter in Communication Circuits

In modern communication systems, signals are transmitted at extremely high frequencies to support fast data transfer, low latency, and reliable wireless connections. As operating frequencies increase—especially in applications like 5G, satellite links, radar, and RF front-end modules—maintaining signal integrity becomes significantly more challenging.

This is where high frequency PCB play a vital role. These boards are engineered to minimize signal loss, electromagnetic interference (EMI), and timing delays that can disrupt communication performance. Their precise impedance control and low dielectric loss materials help ensure that high-speed signals travel cleanly from point to point without distortion or degradation.

In high-frequency communication circuits, even minor inconsistencies in board layout or material properties can lead to reflection, crosstalk, or phase shifts—issues that severely impact transmission quality. A well-designed high-frequency PCB addresses these challenges through controlled stack-up, optimized routing, and proper grounding techniques.

Whether you’re building a 77 GHz automotive radar or a 3.5 GHz 5G antenna array, selecting the right high-frequency PCB is essential for reliable, high-performance signal transmission in today’s advanced communication technologies.

Key Material Properties and Laminate Types

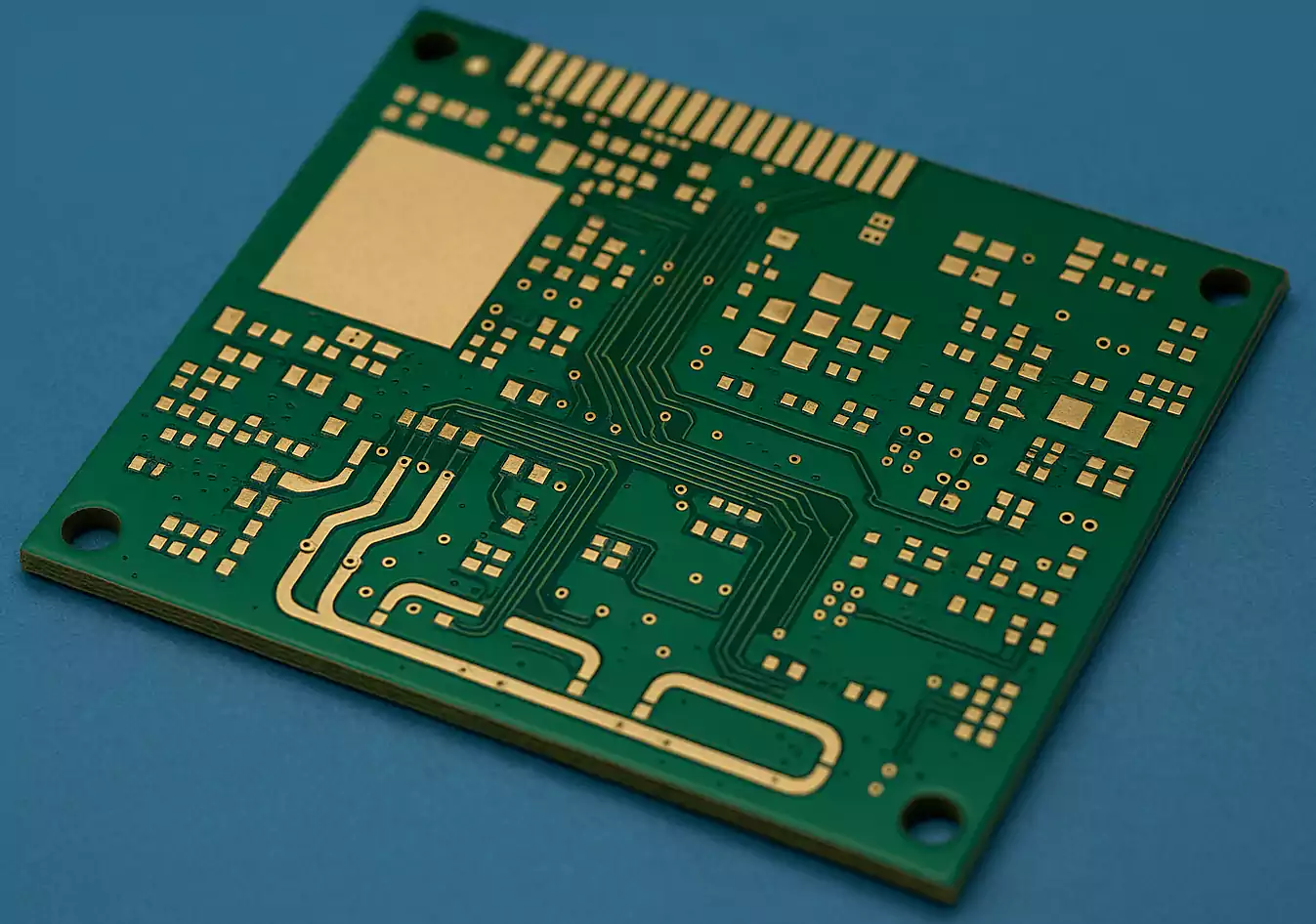

Selecting the right base material is crucial in high-frequency PCB design, especially for applications that demand low signal loss and consistent electrical performance. Unlike standard FR4 boards, high-frequency PCBs require advanced laminates with precise dielectric properties to ensure stable impedance and minimal signal distortion at GHz frequencies.

The most important material characteristics for high-frequency PCBs include:

- Low Dielectric Constant (Dk): Ensures consistent signal speed and minimizes impedance variation. Ideal Dk values for high-frequency designs typically range from 2.2 to 3.5.

- Low Dissipation Factor (Df): Reduces dielectric losses, which is critical in high-speed RF and microwave circuits.

- Thermal Stability: Materials must withstand temperature variations without degrading electrical performance.

- Moisture Resistance: Important for long-term reliability in harsh or variable environments.

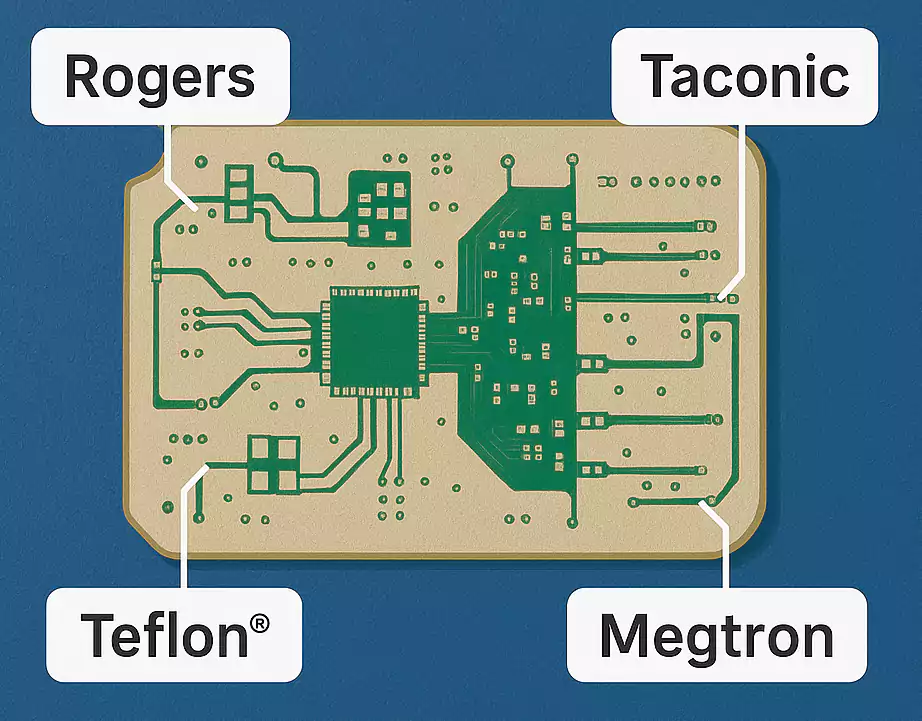

At Fast Turn PCB, we support a range of high-frequency laminates tailored for RF, 5G, and satellite communication circuits. Popular options include:

| Material | Key Features | Typical Applications |

|---|---|---|

| RO4003C / RO4350B | Low Dk (~3.38), low Df, excellent dimensional stability | RF modules, base stations |

| RO3003 / RO3010 | Ultra-low Dk (~3.0 to 10.2), low loss at mmWave | Satellite, radar systems |

| RT5880 | Extremely low Dk (~2.2), minimal Df, PTFE-based | High-end RF, aerospace |

| Taconic / Isola | Reliable thermal & electrical balance | General microwave circuits |

These materials—especially PTFE-based laminates such as Rogers and Taconic—are engineered to perform reliably under demanding electrical and thermal conditions. They help maintain signal integrity even in high-speed digital and mixed-signal analog environments.

Manufacturing Capabilities for High-Frequency PCBs

At Fast Turn PCB, we understand that high-frequency PCB manufacturing requires tight tolerances, specialized materials, and advanced fabrication techniques to ensure reliable signal transmission in GHz-range applications.

We offer a comprehensive range of manufacturing capabilities tailored for RF and microwave circuit performance. Our production supports ultra-fine trace widths and spacing down to 3/3 mil, and drilled hole sizes as small as 0.15 mm—ideal for high-density layouts and controlled impedance routing.

We work with premium high-frequency laminates such as RO4003C, RO4350B, RO3003, RT5880, and other PTFE-based substrates from Rogers®, Taconic®, and Isola®. These materials provide excellent electrical performance, low dielectric loss (Df), and minimal signal distortion—crucial for high-speed digital and RF circuits.

To meet diverse performance and assembly needs, we offer multiple surface finish options, including ENIG (Electroless Nickel Immersion Gold), Immersion Silver, Hard Gold, OSP, and ENEPIG—all suitable for high-frequency signal integrity and extended shelf life.

Additional capabilities include:

- Copper weights ranging from 0.5 oz to 13 oz, with finished copper up to 2 oz.

- Board thickness options from 0.2 mm to 3.2 mm, customizable to fit application-specific requirements.

- Multicolor solder mask and silkscreen choices for identification, branding, or aesthetics.

- Via processing options such as tented vias, plugged vias, or open vias to support complex stack-ups and RF shielding.

- Testing services including Flying Probe and AOI inspection to ensure every board meets strict performance standards.

Most high-frequency PCB orders can be manufactured within 7–10 days, with lead times as short as 2–3 days for urgent projects. This enables engineers to meet tight development schedules without sacrificing precision or quality.

Typical Applications in High‑Frequency Communication Circuits

High‑frequency PCBs are indispensable in modern communication systems where fast, clean, and low‑loss signal transmission is required. As wireless technologies advance into the millimeter‑wave and multi‑GHz bands, PCB materials and stack-ups must support stable impedance, low dielectric loss, and excellent thermal reliability.

- 5G and mmWave Communication Modules

High‑frequency PCBs are widely used in 5G base station antennas, small cells, and customer-premises equipment (CPE). These boards support beamforming networks, RF front‑end modules (FEM), and phased‑array antennas operating from sub‑6 GHz to 28 GHz+ mmWave frequencies. Consistent dielectric performance ensures low insertion loss and reliable data throughput. - Radar Systems (Automotive & Industrial)

Automotive radar (24 GHz / 77 GHz) relies on PTFE- and ceramic-based laminates to maintain phase accuracy and minimize signal distortion. Industrial and security radar systems also use high-frequency PCBs to detect objects precisely under varying environmental conditions. - Satellite and Aerospace Communication

Satellite communication devices, low‑earth‑orbit (LEO) transceivers, and avionics RF modules require high-frequency PCBs for stable performance in high-temperature and high-vibration environments. Low-loss laminates help preserve signal integrity across long-distance transmission paths. - Medical & IoT Wireless Equipment

Medical imaging systems, telemetry devices, and IoT wireless modules utilize high-frequency PCBs for clean RF signaling and compact antenna integration, supporting BLE, Wi‑Fi 6E, GPS, and UWB communication.

Conclusion

In all these applications, the right combination of dielectric materials, controlled impedance routing, and precision manufacturing ensures optimal RF performance and system reliability.

High‑frequency PCBs are fundamental to next‑generation communication and radar technologies, where clean signal transmission and low loss define system performance. As operating frequencies rise, choosing the right materials and manufacturing partner becomes critical to achieving stable, high‑reliability results.

Fast Turn PCB provides advanced high‑frequency fabrication capabilities with precision impedance control, low‑loss laminates such as Rogers®, Taconic®, and PTFE‑based materials, and fast turnaround lead times. Whether you're developing RF front‑end modules, 5G antenna boards, or high‑frequency radar systems, our engineering team can help you accelerate time‑to‑market with consistent quality and dependable performance.

Ready to build your high‑frequency PCB?

Contact Fast Turn PCB today for expert support and a fast quote.