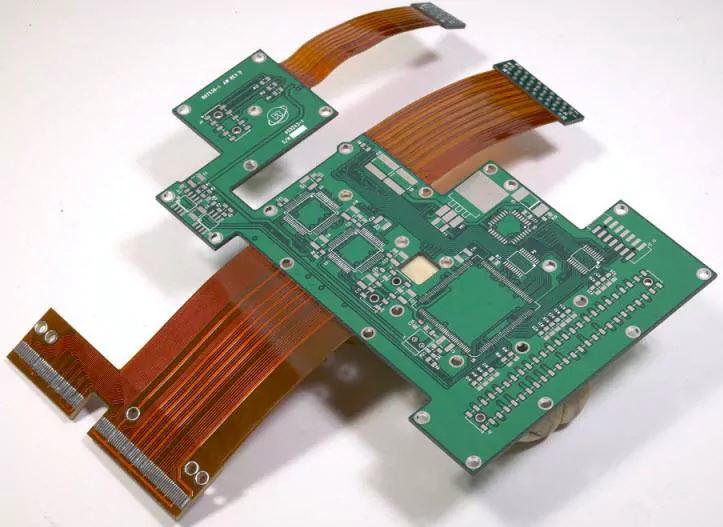

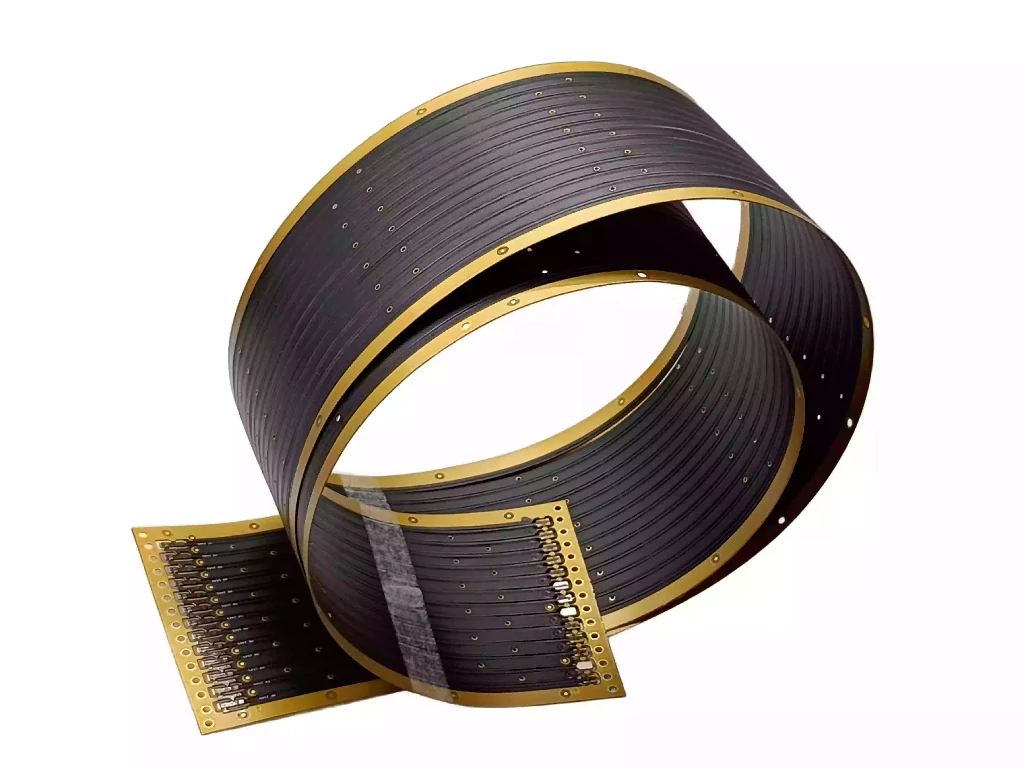

When designing modern electronic products, selecting the right type of PCB—FPC soft board or rigid PCB—is crucial for performance, reliability, and product innovation. In this blog, we’ll focus on the benefits and use cases of FPC flexible PCBs, and offer guidance on how to choose between flexible and rigid options depending on your needs.

What Is an FPC Flexible PCB?

FPC (Flexible Printed Circuit) boards are made of flexible polymer materials such as polyimide, allowing them to bend, twist, and fold without damaging the circuits. These boards are ideal for compact and space-constrained electronic designs.

Key Benefits of FPC Flexible PCBs

High Flexibility: Can be bent and folded to fit complex 3D spaces—perfect for wearable tech, foldable devices, and small electronics.

Lightweight & Thin: Enables ultra-thin product designs, helping reduce overall device weight.

Efficient Heat Dissipation: Promotes better thermal performance, especially in compact layouts.

Excellent Signal Integrity: Ideal for high-frequency signal transmission in high-density environments.

Reliable Connections: Used as dynamic connectors between moving parts or modules in complex systems.

Common Applications of FPC Soft Boards

FPCs are widely used in:

Smartphones and tablets

Wearable devices (smartwatches, fitness trackers)

Medical electronics (hearing aids, diagnostic tools)

Automotive electronics (airbag systems, dashboards)

Foldable or modular electronic products

Aerospace and military systems

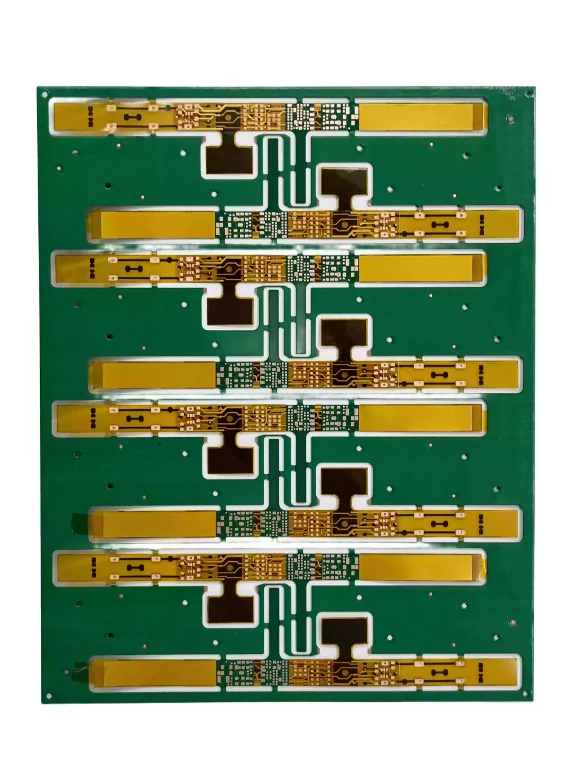

FPC vs. Rigid PCB: Key Differences

| Feature | FPC Flexible Board | PCB Rigid Board |

| Flexibility | High (can bend and twist) | None (rigid and fixed) |

| Weight & Thickness | Lightweight and ultra-thin | Heavier and thicker |

| Durability | Less mechanically robust | High mechanical strength |

| Heat Resistance | Excellent heat dissipation | Good, but depends on board thickness |

| Manufacturing Cost | Higher due to complex process | Lower and widely standardized |

| Best Used For | Compact, mobile, flexible devices | Desktop electronics, industrial use |

How to Choose the Right PCB for Your Project

Choose FPC Soft Boards If:

Your product requires folding, bending, or 3D layout

Lightweight and space-saving design is a priority

You need high flexibility between internal modules

Your device is portable, wearable, or modular

Choose Rigid PCBs If:

Mechanical strength and durability are key

The design is flat, simple, and space is not limited

You’re working within a tight budget

The product is industrial or desktop-grade electronics

Cost Considerations

While FPC boards offer more flexibility, they come with higher material and manufacturing costs due to the use of flexible substrates and a more delicate fabrication process. Rigid PCBs are more cost-effective for high-volume production with simpler designs.

Final Thoughts

PC soft boards are the ideal choice for high-performance, space-constrained, and portable electronic devices. Their ability to flex, fold, and withstand dynamic environments makes them essential in next-gen electronics. However, understanding the trade-offs in cost, durability, and design complexity is crucial when selecting between FPC and rigid boards.

Need expert advice for your next PCB design?

📩 Contact our team for custom FPC and rigid PCB solutions with fast turnaround times.