The manufacturing of Flexible Printed Circuits (FPC) involves several intricate steps, each ensuring the final product meets the desired performance and quality standards. Understanding the FPC manufacturing process is essential for making informed decisions when choosing a supplier for your project. In this article, we’ll walk you through the entire process of creating an FPC, from design to production.

Material Selection

The journey of FPC manufacturing begins with material selection. The base material, typically polyimide, is chosen for its excellent flexibility and high-temperature resistance, making it an ideal choice for flexible circuit boards. Copper foil is then selected to create the conductive pathways that carry electrical signals. The choice of materials at this stage directly impacts the performance and durability of the final product.

Circuit Pattern Formation

Once the materials are selected, the next step is to define the circuit pattern. This is achieved through photo imaging and etching processes, where the copper foil is selectively removed to form the intricate circuit design. The precision with which this is done is essential to ensure that the FPC can handle the required electrical loads and function as intended.

Lamination & Adhesive Bonding

In this stage, the circuit layers are laminated together using specialized adhesives to create the final multi-layered structure. The adhesives used must be chosen with care, as they need to balance both strength and flexibility. The lamination process also determines the overall durability and mechanical properties of the FPC.

Coverlay Application

To ensure protection from environmental factors and mechanical damage, a coverlay is applied over the copper traces. The coverlay, usually made of polyimide or another durable material, serves as a shield, preventing external elements like moisture or dust from affecting the integrity of the circuit. This layer also plays a role in providing electrical insulation between layers.

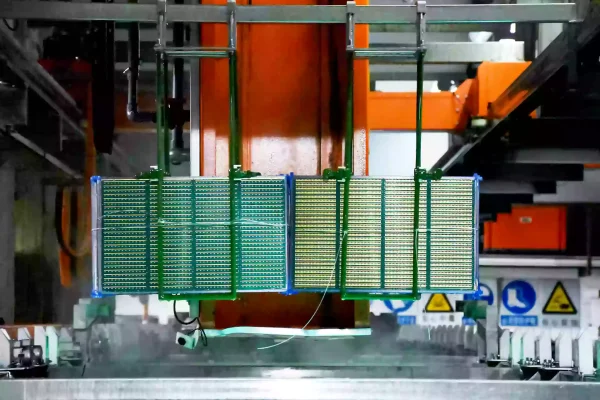

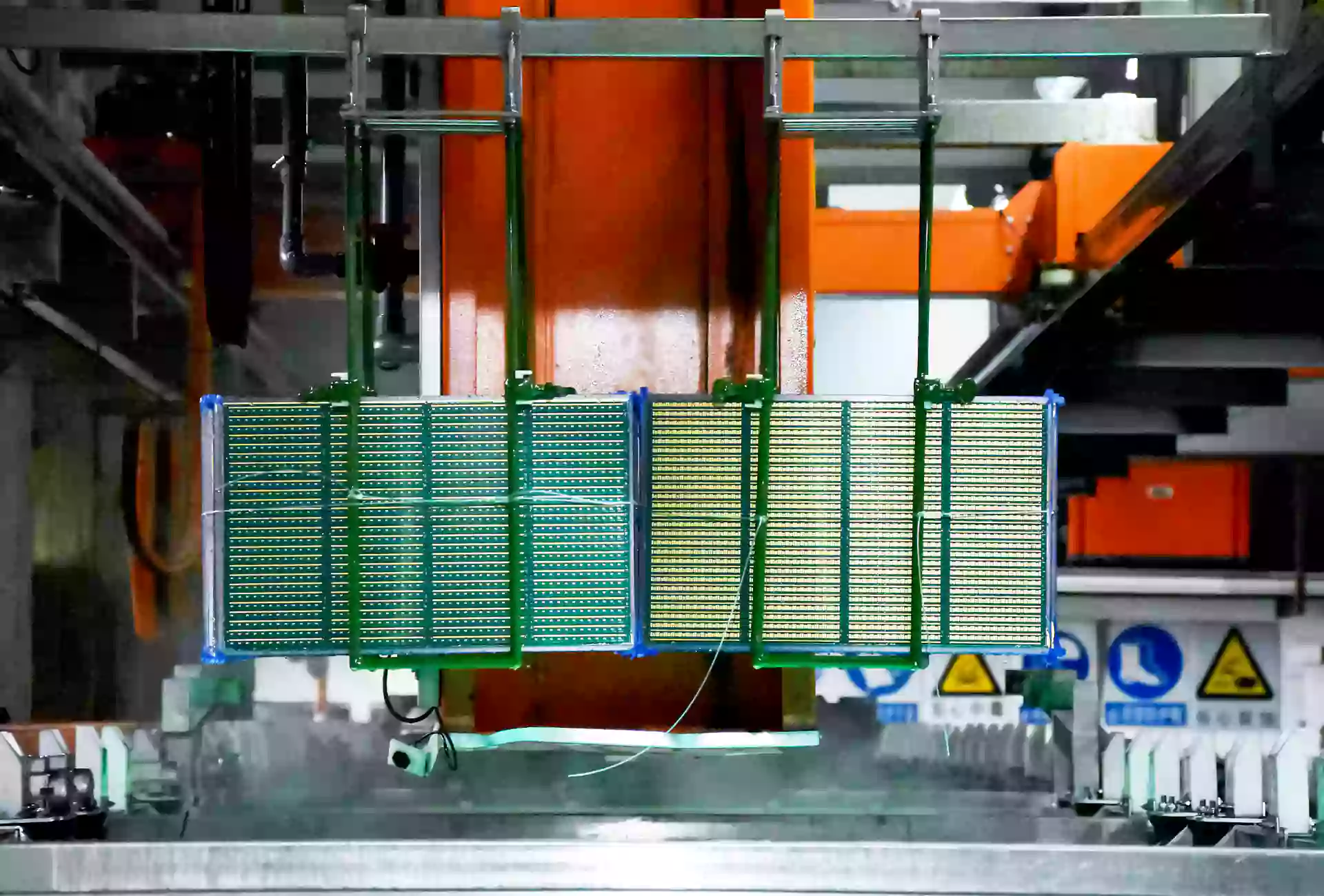

Surface Finish for Enhanced Reliability

To enhance the performance and longevity of the FPC, a surface finish is applied to the copper traces. The most common finishes include Electroless Nickel Immersion Gold (ENIG) and Organic Solderability Preservative (OSP). These finishes not only improve solderability but also provide superior corrosion resistance, ensuring that the FPC can withstand harsh operating conditions.

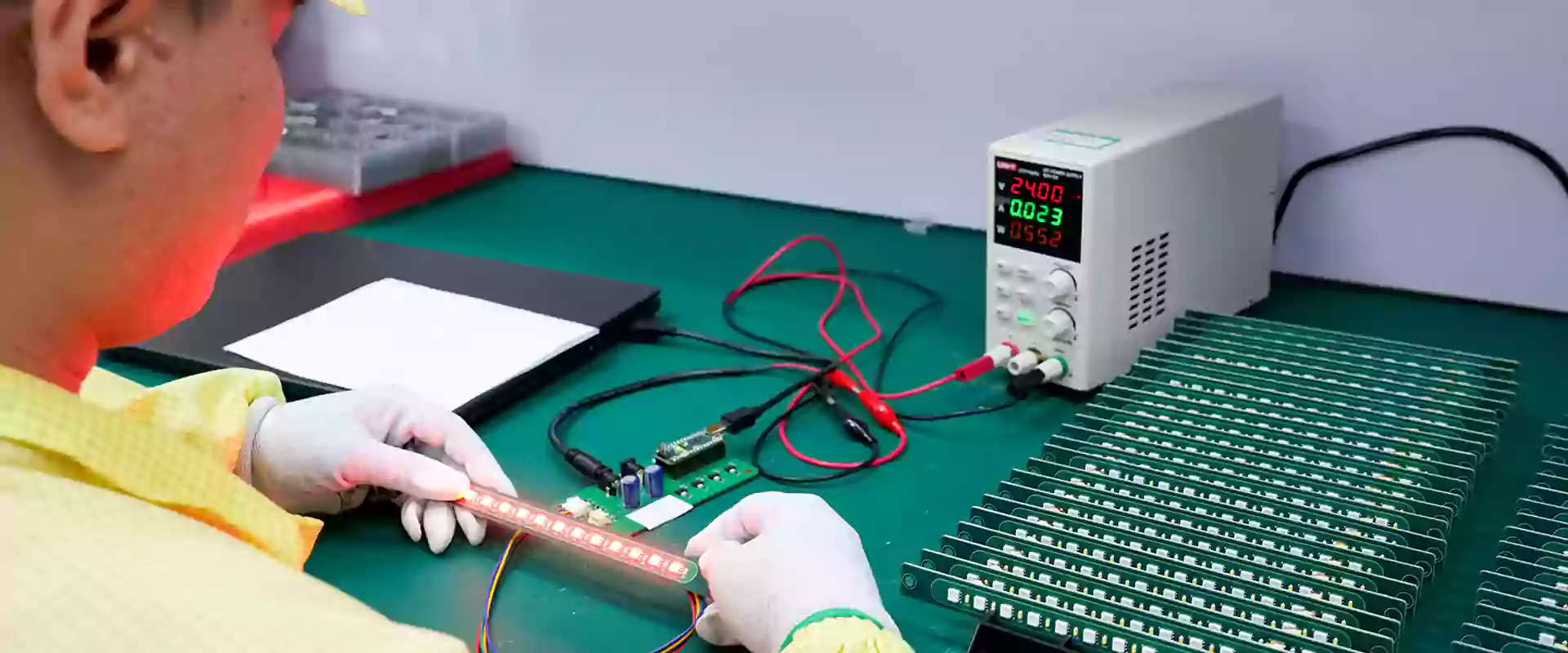

Electrical Testing

Once the FPC is fabricated, it undergoes rigorous electrical testing to confirm its functionality. This involves testing for continuity, checking for any short circuits, and ensuring that the electrical signals flow correctly through the designed paths. Testing is a critical step in identifying and resolving any potential issues before the FPC is delivered to the client.

Final Inspection & Quality Assurance

Before the FPC is shipped out, it undergoes a final inspection process to ensure it meets all quality standards. This inspection checks for visual defects, ensures that the dimensions are accurate, and confirms that all electrical properties are functioning correctly. Only after passing this quality assurance check is the FPC ready for delivery to the client.

Why Partner with a One-Stop FPC Manufacturer?

Selecting a reliable FPC manufacturer is essential to ensure that your product is built to meet industry standards. When choosing a supplier, look for certifications such as IATF 16949, ISO 9001, and UL to guarantee the highest quality and reliability. A one-stop manufacturer, which manages both the design and production processes, can offer seamless coordination, reduce lead times, and minimize the risk of errors during production.

The Importance of Precision in FPC Manufacturing

The FPC manufacturing process is intricate and requires attention to detail at every step. By understanding the key stages of production, you can make more informed decisions when choosing an FPC manufacturer. Partnering with an experienced supplier ensures that the final product not only meets your expectations but also performs reliably in its intended application.

Choosing the right manufacturer with the expertise and certifications to handle every aspect of FPC design and production is the key to a successful outcome.