In the world of electronics manufacturing, the term "flip board PCB" can refer to two very different things. Some engineers use it when talking about flip-chip packaging technology and its integration with PCB designs. Others mean literally flipping or mirroring a PCB layout in their EDA software. This comprehensive guide covers both interpretations, delivering actionable insights, best practices, and expert-level checklists. Whether you're designing a high-density BGA with flip-chip dies or simply trying to mirror a board in KiCad, this guide has you covered.

What Does "Flip Board PCB" Really Mean?

When users search for "flip board PCB," they typically fall into one of two categories:

- Flip-Chip Packaging on PCB: Refers to the use of flip-chip ICs (integrated circuits mounted face-down) directly onto the PCB or an interposer. This approach is common in high-performance, high-density designs such as smartphones, networking equipment, and advanced computing.

- EDA-Based Board Flipping: Involves using software tools like KiCad or EasyEDA to mirror or flip the PCB layout during design or manufacturing prep.

This article addresses both topics, prioritizing flip-chip packaging while also providing practical EDA flipping tips at the end.

Flip-Chip on PCB: Concepts, Benefits, and When to Use

What is Flip-Chip?

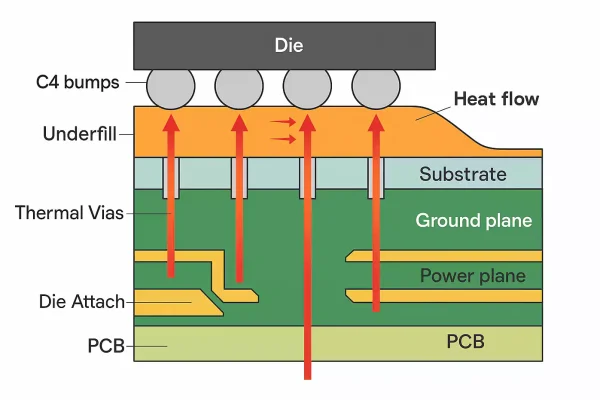

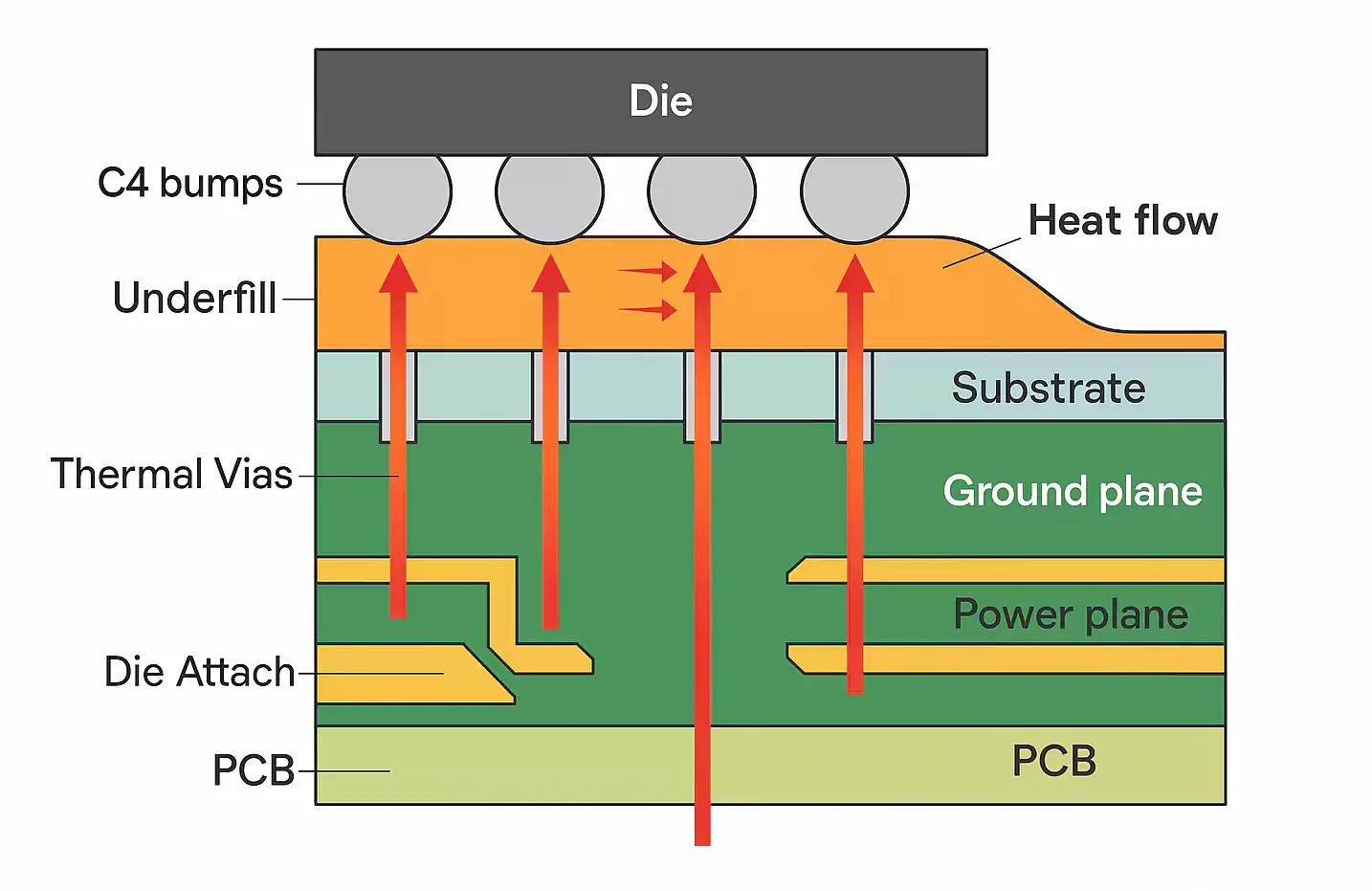

Flip-chip is a semiconductor packaging method where the silicon die is flipped and mounted face-down, allowing direct electrical connection between the die and substrate using solder bumps (also called C4 bumps). Instead of wire bonding, flip-chip provides short, high-density interconnections.

Benefits of Flip-Chip Packaging:

- Electrical Performance: Lower inductance and parasitics due to short interconnect paths.

- Thermal Management: Better heat dissipation through the substrate and die surface.

- Size Efficiency: Enables compact layouts with more I/O per unit area.

Common Use Cases:

- High-speed processors (CPU, GPU)

- RF components

- Advanced BGA and SiP (System-in-Package) designs

- Devices requiring fine pitch and miniaturization

Flip-Chip Assembly Flow on PCB

The typical flip-chip packaging process for PCB integration involves:

- Bump Deposition: The silicon die is fabricated with solder bumps.

- Die Placement: The die is flipped and aligned with the substrate.

- Reflow Soldering: Heat is applied to form permanent joints.

- Underfill Application: Epoxy is dispensed to fill the gap between the die and substrate, improving mechanical strength and reliability.

- Cleaning and Inspection: Excess materials are removed, and joints are inspected via X-ray or AOI.

The underfill is particularly important—it compensates for thermal mismatch and reduces stress on the solder bumps during thermal cycling.

PCB Layout Best Practices for Flip-Chip/FC-BGA

Designing a PCB that integrates flip-chip or FC-BGA components requires precision and attention to layout details. Here are the key best practices:

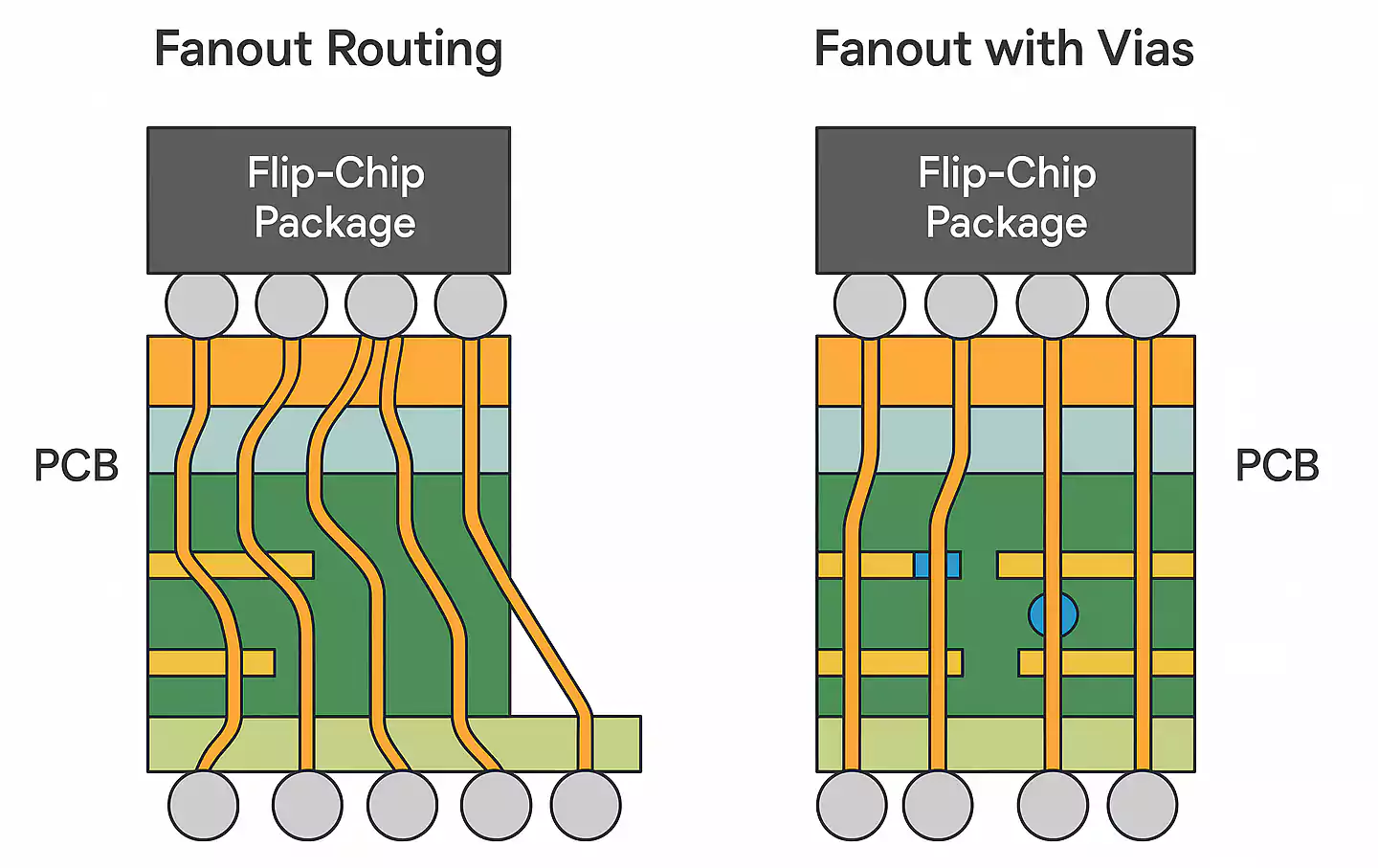

1. Fanout Strategy

- Use via-in-pad or microvia to reduce routing congestion.

- Employ HDI (High-Density Interconnect) stackups to support fine-pitch breakout.

- Avoid long trace lengths from the center die to outer ball pads.

2. Impedance and Signal Integrity

- Maintain consistent reference planes.

- Use differential pair routing and matched trace lengths for high-speed signals.

- Consider return paths and minimize stubs.

3. Power and Ground Planning

- Provide low-impedance power distribution with solid planes.

- Place decoupling capacitors close to power balls.

- Use multiple vias to minimize ESL/ESR in critical nets.

4. Thermal Design

- Increase copper thickness or area for heat dissipation.

- Utilize thermal vias to transfer heat to inner or bottom layers.

- Simulate thermal behavior if power exceeds 1–2 W/cm².

5. Material and Stackup Considerations

- Choose substrates with low CTE mismatch (e.g., BT, ABF).

- Balance layer count vs. routability.

- Ensure Dk/Df consistency for controlled impedance.

6. Footprint and Land Pattern

- Verify land pattern from manufacturer datasheet.

- Use IPC-7351 compliant libraries.

- Ensure accurate alignment for reflow profiles.

Flip-Chip vs. Wire-Bond vs. BGA: Decision Matrix

| Feature | Flip-Chip | Wire-Bond | BGA |

|---|---|---|---|

| Electrical Performance | Excellent | Moderate | Good |

| Thermal Dissipation | High | Low | Medium |

| Package Size | Very Compact | Larger | Compact |

| Assembly Complexity | High | Low | Medium |

| Cost | Higher | Lower | Medium |

| Application | High-end, RF, miniaturized | Low-cost ICs | General use |

When to use Flip-Chip:

- High-performance computing

- Fine-pitch or I/O-dense applications

- Thermal-critical designs

DFM/DFX Checklist for Manufacturing Success

To ensure the successful fabrication and assembly of flip-chip designs:

1.Design for Manufacturability (DFM):

- Confirm minimum trace width/spacing per vendor.

- Align pad sizes with stencil and bump dimensions.

- Avoid non-standard pad shapes unless required.

2.Design for Assembly (DFA):

- Use fiducials and global/local markers for alignment.

- Document underfill type and process parameters.

- Provide assembly drawing and reflow profile.

3.Design for Testability (DFT):

- Add test points for JTAG/functional validation.

- Allow for boundary scan access if possible.

4.Deliverables:

- Gerber or ODB++

- BOM with clear part numbers and alternatives

- Pick-and-Place file with exact coordinates

- Stackup drawing with impedance details

Troubleshooting & Reliability Concerns

Flip-chip assemblies introduce challenges in manufacturing and long-term reliability:

Common Issues:

- Open/shorted bumps

- Voids in underfill

- Warping of the die or PCB

- Inadequate cleaning under the die

Inspection Tools:

- 2D/3D X-ray

- Scanning Acoustic Microscopy (SAM)

- Automated Optical Inspection (AOI)

Reliability testing (thermal cycling, vibration, moisture sensitivity) is essential for high-stress environments.

How to "Flip" a PCB in EDA Tools (Secondary Intent)

While "flip board PCB" usually refers to flip-chip, some users simply want to flip their board layout in CAD software. Here's how:

KiCad:

- Press

Fto flip a component or board side. - Use

View > Flip Board Viewfor mirror inspection. - Ensure text is mirrored properly when flipping layers.

EasyEDA:

- Right-click and use Flip Horizontally/Vertically.

- Check pad orientation and net continuity after flipping.

- Use Gerber preview to verify mirror accuracy.

Important: Flipping a board for single-sided assembly or stencil production requires both layers and silkscreen to be mirrored—but netlist connections must remain intact.

FAQs

Q1: Is Flip-Chip the same as BGA?

A: No. Flip-chip refers to a die attachment method. BGA is the package form factor. A flip-chip can be used inside a BGA.

Q2: Do all Flip-Chip PCBs require underfill?

A: Most high-reliability or thermal-stress applications use underfill, but it's optional in low-stress environments.

Q3: Is Flip-Chip always more expensive?

A: Not always. For high-density, high-performance designs, flip-chip technology may reduce the number of board layers or size, thereby offsetting the cost.

Q4: Can I use standard PCB materials with Flip-Chip?

A: Only if the CTE and thermal properties match. Specialized materials (like ABF) are often required.

Summary and Takeaways

Flip-chip technology offers unparalleled performance for modern electronics, but it also introduces layout and manufacturing complexity. With careful planning, collaboration with manufacturers, and adherence to DFM/DFX principles, flip-chip PCBs can provide thermal, electrical, and space-saving benefits.

Meanwhile, for those using "flip board PCB" to refer to EDA tricks, understanding how to mirror designs properly ensures accurate manufacturing output.