Introduction – What Is Conformal Coating?

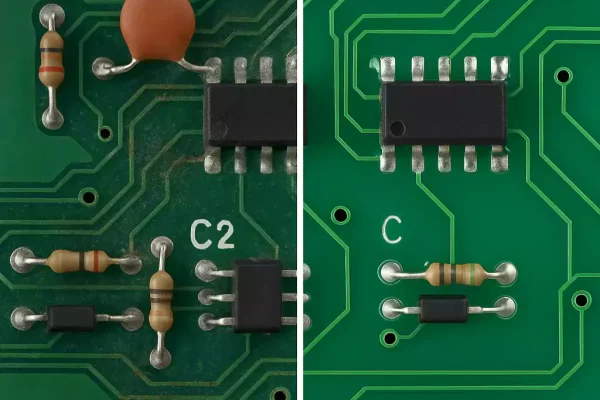

Conformal coating is a protective, non-conductive film applied to printed circuit boards (PCBs) to shield them from environmental stressors, including moisture, dust, corrosion, and chemical contaminants. Unlike traditional coatings, conformal coatings “conform” to the contours of the board and its components, forming a thin, invisible layer that preserves functionality without adding significant weight or volume.

In today’s electronics—especially in automotive, aerospace, industrial, and outdoor applications—PCBs are exposed to tough operating environments. Without proper protection, issues like corrosion, short circuits, or component failure can occur. That’s where conformal coating comes in: it helps extend the life of your electronics and reduces the risk of costly failures.

In this guide, we’ll break down the different types of conformal coatings, how to choose the right one for your project, and best practices for applying and inspecting them.

Benefits of Conformal Coating on PCBs

Conformal coating offers a wide range of benefits that help protect and extend the life of printed circuit boards (PCBs), especially in harsh or high-performance environments. Here are the key advantages:

- Moisture and Corrosion Protection

It creates a moisture-resistant barrier that prevents corrosion, oxidation, and electrical leakage caused by humidity, condensation, or salt spray. - Improved Electrical Insulation

By adding a thin, non-conductive layer over components and traces, conformal coating helps prevent short circuits, arcing, and unwanted current paths. - Resistance to Chemicals and Contaminants

The coating shields sensitive electronics from chemicals, solvents, and airborne contaminants that can damage or degrade circuitry over time. - Enhanced Mechanical Durability

It provides an added layer of protection against vibration, mechanical stress, and impact—especially useful in automotive, aerospace, and industrial applications. - Prevention of Tin Whiskers and Electrical Migration

Conformal coating can help reduce the growth of tin whiskers and inhibit electrochemical migration, both of which can lead to failures in fine-pitch and high-density designs.

By protecting PCBs from environmental and mechanical threats, conformal coating increases product reliability, reduces field failures, and minimizes costly repairs or replacements.

Main Types of Conformal Coating Materials

Here are the five most common types of conformal coating materials used in electronics:

1. Acrylic (AR)

Acrylic coatings are widely used due to their ease of application, fast drying time, and excellent moisture resistance. They’re ideal for general-purpose protection and are easily removable for rework.

2. Silicone (SR)

Silicone coatings offer excellent flexibility and high-temperature resistance, making them suitable for extreme environments. They perform well under thermal cycling and vibration.

3. Urethane / Polyurethane (UR)

Urethane coatings provide strong resistance to chemicals, moisture, and abrasion. They form a tough, durable barrier but are more difficult to rework.

4. Epoxy (ER)

Epoxy coatings create a very hard, protective layer with superior adhesion. However, they’re typically not used when rework or inspection is needed.

5. Parylene (XY)

Parylene is vapor-deposited in a vacuum chamber, producing an ultra-thin, uniform, pinhole-free coating with excellent dielectric strength. It offers the highest level of protection but at a higher cost.

Comparison Table

| Coating Type | Key Strengths | Key Limitations |

|---|---|---|

| Acrylic (AR) | Easy to apply/rework, affordable | Lower chemical resistance |

| Silicone (SR) | High temp resistance, flexible | Harder to remove, slower cure |

| Urethane (UR) | Chemical/moisture durability | Difficult to rework |

| Epoxy (ER) | Strong and rigid protection | Brittle, non-reworkable |

| Parylene (XY) | Superior protection, ultra-thin | Costly, complex application |

How to Choose the Right Conformal Coating

Here are the key factors to consider:

1.Operating Environment

Match the coating to the environment:

- High humidity or condensation → Use urethane (UR) or parylene (XY)

- Extreme temperatures → Use silicone (SR)

- Chemical exposure → Use urethane or epoxy (ER)

- Salt spray or corrosion → Use parylene

2.Need for Rework

If you may need to inspect or replace components:

Acrylic (AR) is the easiest to remove and reapply

3.Application Process

- Spray or brush → Acrylic or silicone

- Dip coating → Urethane or acrylic

- Vacuum deposition → Parylene (requires special equipment)

4.Cost and Use Case

- General electronics → Acrylic (affordable and versatile)

- Automotive / aerospace → Silicone or parylene (high-performance)

- Medical or mission-critical → Parylene (biocompatible, ultra-reliable)

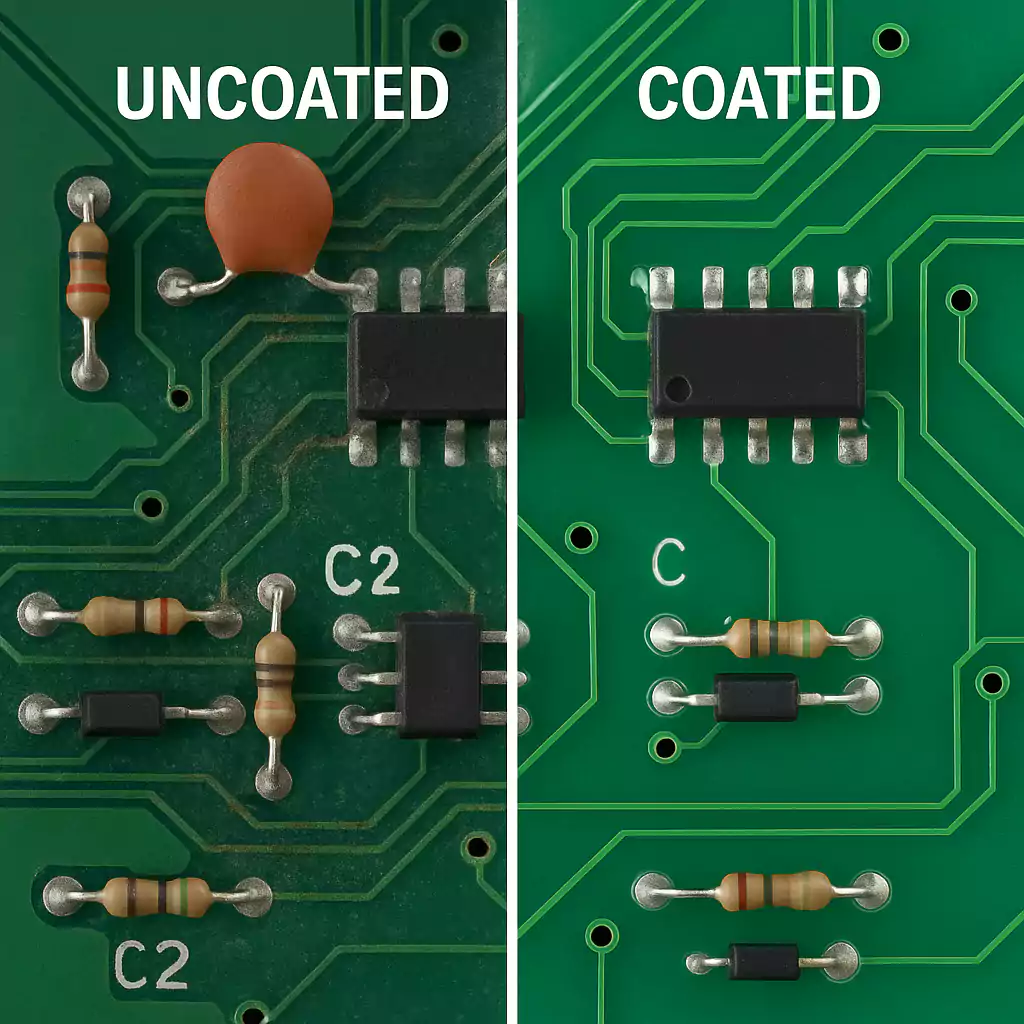

Application Methods

Applying conformal coating correctly is just as important as choosing the right material. Poor application can lead to coating defects, uneven protection, or even component damage. Below are the most common application methods and essential tips to ensure a successful coating process.

1.Brushing

- Simple and low-cost

- Best for prototypes or small batches

- May result in uneven thickness or air bubbles

2.Spraying (Manual or Automated)

- Provides consistent coverage

- Ideal for medium to high-volume production

- Requires masking to protect connectors and keep-out zones

3.Dip Coating

- Boards are dipped into the coating material for full coverage

- Efficient for high-volume production

- Not suitable for boards with tall or sensitive components

4.Selective Coating (Automated)

- High-precision, no-overspray method using robotic systems

- Excellent for complex PCBs with critical uncoated areas

- Higher equipment cost but minimal waste

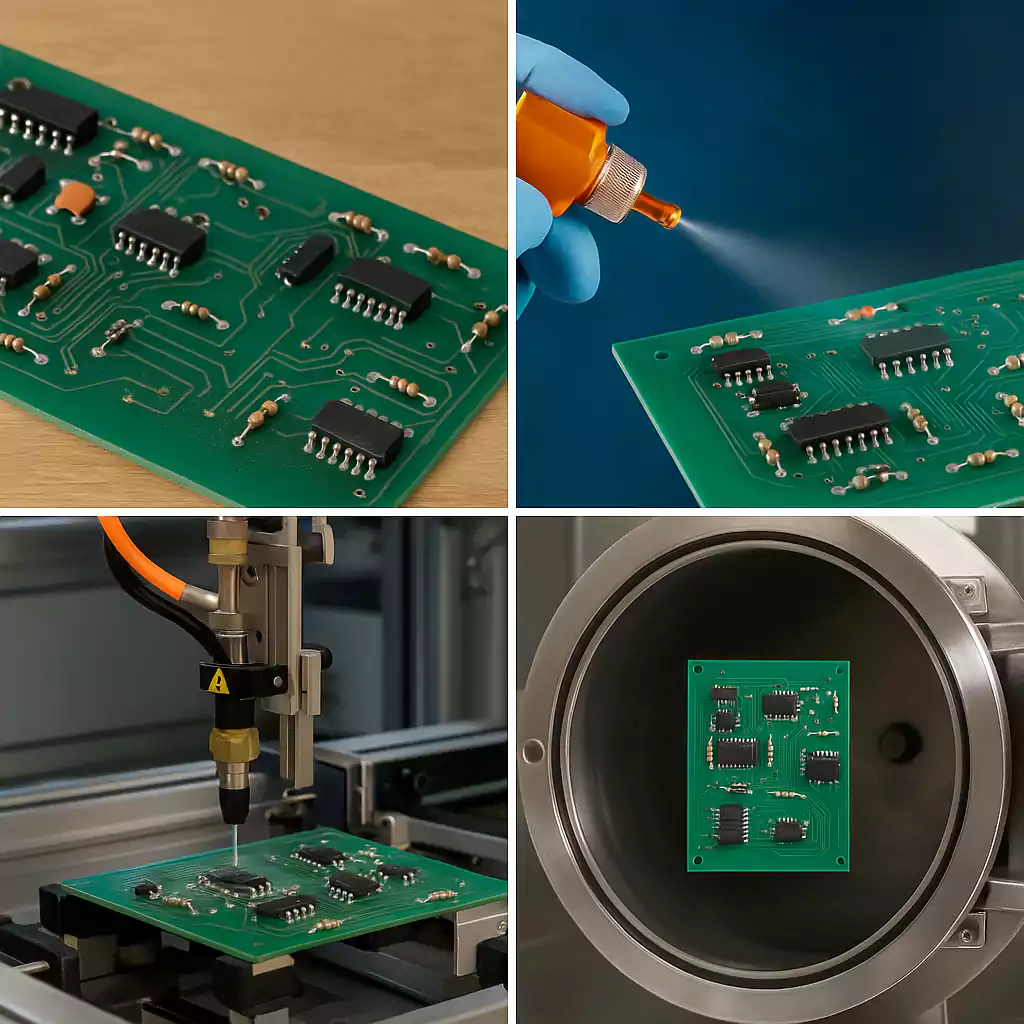

5.Parylene Coating (Vapor Deposition)

- Applied in a vacuum chamber as a gas

- Delivers ultra-thin, pinhole-free, uniform protection

- Requires specialized equipment and cleanroom conditions

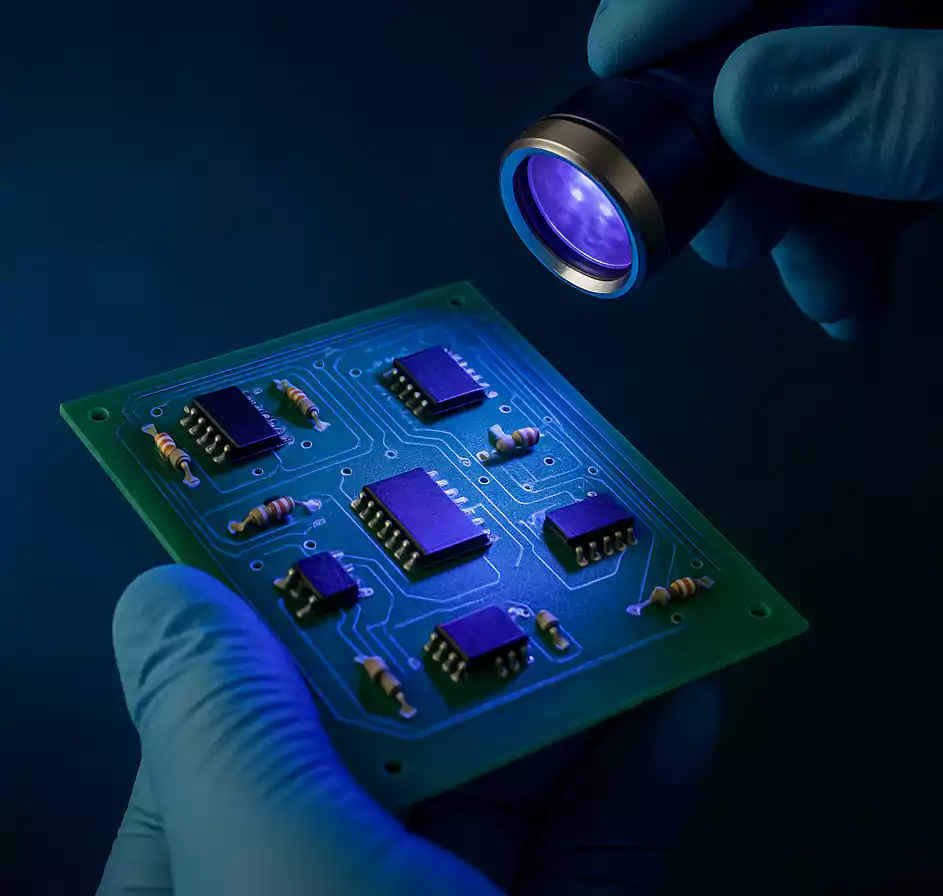

Common Issues

- Delamination

Often caused by poor surface prep or contamination. Always clean boards thoroughly before coating. - Bubbles or Voids

Typically result from incorrect spray distance or fast drying. Adjust application method and control ambient conditions. - Cracking

Happens when coatings are too thick or face frequent thermal cycling. Stay within the recommended thickness range. - Incomplete Coverage

Missed areas can lead to corrosion or electrical shorts. Always inspect with UV light or AOI tools after coating.

Conclusion

Conformal coating is a proven solution for protecting PCBs in harsh environments—offering defense against moisture, dust, chemicals, and electrical failures. By understanding the different coating types, selecting the right material for your application, and following proper application and inspection techniques, you can greatly improve the reliability and longevity of your electronic products.