In today's fast-paced electronics industry, one-stop PCBA services have become a game-changer for businesses looking to optimize their PCB production. These comprehensive services provide customers with an all-inclusive solution, ensuring higher efficiency, cost-effectiveness, and quicker turnaround times.

Rather than coordinating with multiple suppliers for different stages of production, businesses can rely on a single provider to manage the entire process. This results in reduced communication errors, faster decision-making, and improved production timelines. Below, we’ll dive into the key stages of one-stop PCBA (Printed Circuit Board Assembly) services and how they add value to your production pipeline.

PCB Design: Tailored for Your Needs

The first crucial step in any PCBA project is the PCB design phase. A professional team of electronic engineers typically handles this stage. From initial schematic design to PCB layout and circuit simulation, every step is carefully crafted to meet your product’s specific needs. With a deep understanding of electrical engineering principles, service providers ensure that your PCB design is both efficient and error-free. This attention to detail prevents costly design revisions down the line, helping you save both time and money.

High-Quality PCB Manufacturing

Once the design is confirmed, the next step is PCB manufacturing. One-stop services handle everything from selecting the right base material to the lamination, drilling, electroplating, and etching processes. These stages are crucial in ensuring that the final PCB meets stringent industry standards for durability, conductivity, and reliability. A high-quality PCB is the foundation for a successful PCBA project, and top-tier service providers are skilled at ensuring that the finished product meets your specifications.

Component Procurement: Quality and Timeliness

Component procurement is an essential part of the process. One-stop PCBA service providers work with trusted global suppliers to source high-quality electronic components that align with the circuit design. The service ensures that components are readily available, helping to avoid any delays in the assembly process. A streamlined procurement process means that all parts arrive on time, reducing lead times and ensuring that the production process can proceed without interruptions.

SMT Processing: Precision and Accuracy

Surface-mount technology (SMT) is a critical part of the assembly process. During this phase, SMT machines and reflow soldering techniques are used to precisely mount components onto the PCB. This stage is vital to ensuring that the components are properly soldered without defects. Strict quality control and automated inspection ensure that every solder joint is robust, making the final product more reliable and durable.

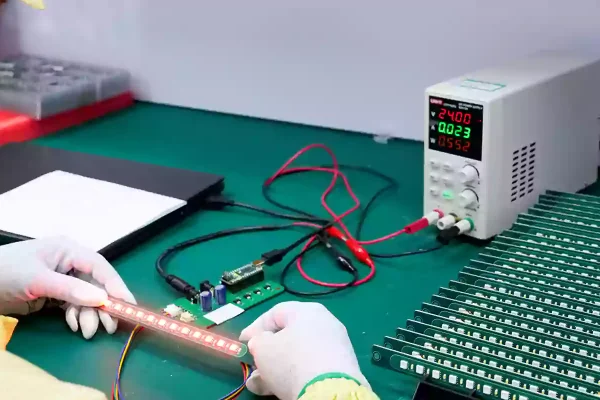

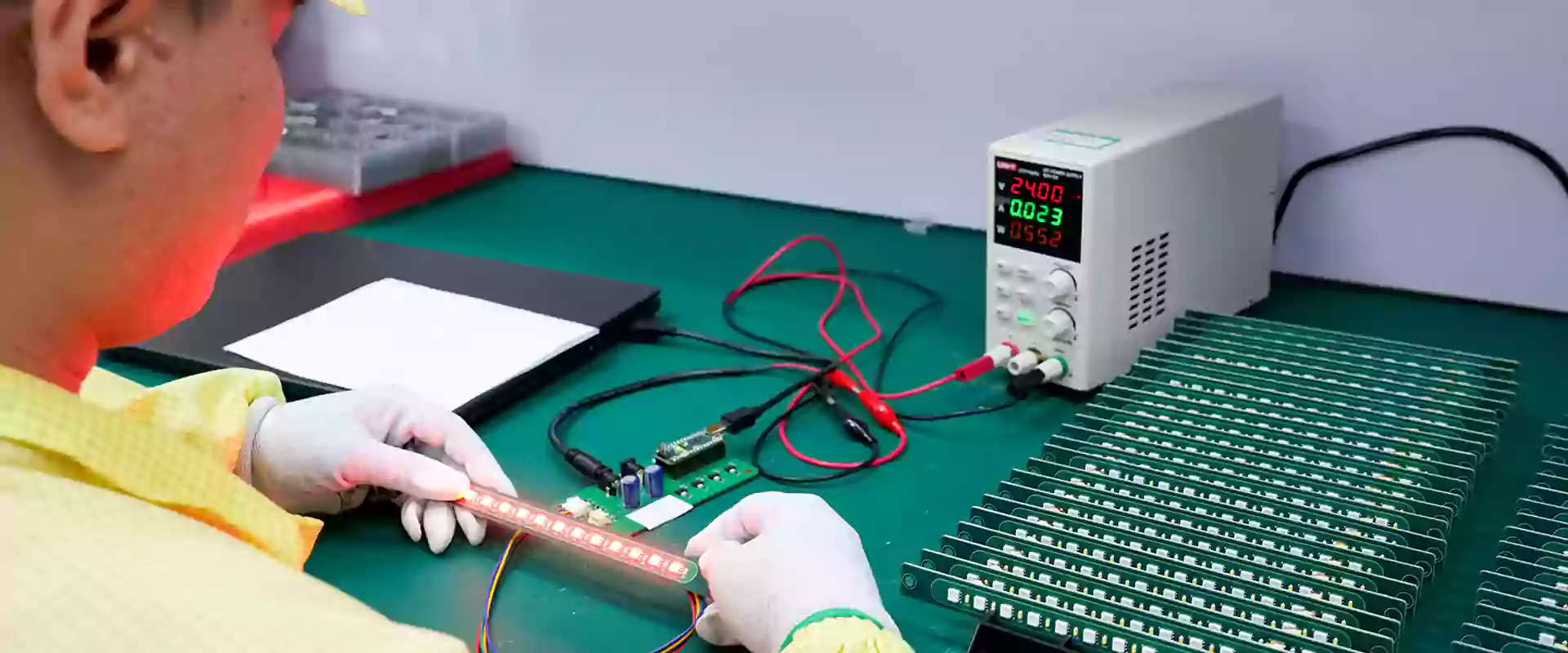

Testing and Quality Control: Ensuring Reliability

Before the final assembly, rigorous testing is conducted to ensure the PCB's functionality. This typically includes functional testing, aging tests, and environmental testing. One-stop PCBA service providers maintain stringent quality control protocols throughout the production process, minimizing the risk of defects and ensuring that the final product is stable and reliable. With in-depth testing, any issues are identified and rectified before they can reach the consumer, ensuring high-quality standards.

Assembly and Packaging: Ready for Shipment

For products requiring further assembly, one-stop PCBA services also offer assembly and packaging solutions. Whether it’s assembling the entire unit or just adding specific components, service providers ensure that everything is correctly integrated. Packaging is just as important—carefully designed packaging ensures that the final product remains safe during transportation and storage, preventing any damage before it reaches the customer.

Why Choose One-Stop PCBA Services?

By opting for one-stop PCBA services, you streamline the entire manufacturing process, reduce costs, and minimize the complexity of working with multiple suppliers. These services ensure that every step of the PCB production process is well-coordinated and controlled. From initial design to final assembly, everything is taken care of in one package.

One-stop service providers not only save you time but also help you scale your operations, maintain product quality, and meet tight deadlines. Ultimately, this leads to higher customer satisfaction and greater operational efficiency.