In the world of Printed Circuit Board Assembly (PCBA), the Bill of Materials (BOM) table plays an essential role throughout the manufacturing process. Serving as the backbone of component procurement, production planning, quality control, cost management, and maintenance, a well-structured BOM ensures that everything runs smoothly from start to finish.

In this blog, we’ll explore the various roles a BOM table plays in PCBA processing and how it helps optimize procurement and production processes. Whether you are a seasoned manufacturer or new to the industry, understanding the full scope of BOM’s impact will help streamline your operations.

What is a BOM Table and Why is it Crucial for PCBA?

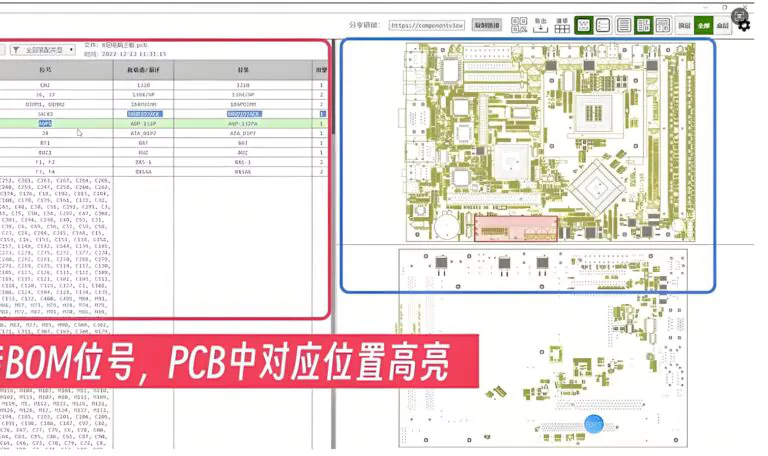

A BOM (Bill of Materials) table is a comprehensive list of all the components required to produce a PCB assembly. It includes detailed specifications, part numbers, quantities, and supplier information for each component. The BOM acts as a roadmap for procurement, assembly, and quality control, ensuring that every part is sourced and assembled correctly. Without a well-structured BOM, the production process can encounter delays, errors, and cost overruns.

Key Roles of the BOM Table in PCBA Processing

Accurate Guidelines for Component Procurement

The BOM table serves as a detailed shopping list for procurement teams. It includes the exact part numbers, quantities, and supplier details, ensuring that manufacturers procure the correct components in the right amounts. By eliminating ambiguity in the procurement process, the BOM prevents material shortages, purchasing errors, and unnecessary delays—ensuring that the production line operates without interruption.

Scientific Basis for Production Planning

For assembly engineers, the BOM table acts as a roadmap for the entire production process. It outlines the sequence of assembly, specifying which components should be placed on the PCB and when. This ensures that the assembly process is carried out in an efficient and error-free manner. Think of it as a detailed guide that helps engineers complete each step of the process with precision.

Strict Standards for Quality Control

A BOM table is also a critical tool for quality control (QC). By listing the specifications and quality standards for each component, it provides QC personnel with a clear benchmark for inspecting components. Comparing the actual components to those listed in the BOM ensures that only high-quality parts are used, leading to reliable and consistent PCBA production. This is essential for maintaining the performance and durability of the final product.

Precise Tools for Cost Control

Cost management is a major concern for any manufacturer, and the BOM table provides transparency into the cost of each component. It includes cost information for each part, which can be used to estimate production costs and adjust budgets accordingly. By optimizing the BOM for cost efficiency, manufacturers can better control their expenses, maximize profit margins, and reduce waste.

Convenient Manual for Maintenance and Repair

Once the PCBA is in use, the BOM table proves invaluable for maintenance and repair. If a component fails or requires replacement, the BOM provides detailed information on the exact part needed, including the model number and reference details. This ensures that maintenance teams can quickly identify and replace faulty components, minimizing downtime and maintaining operational efficiency.

Essential Document for Change Management

In the fast-paced world of electronics, changes and upgrades are inevitable. The BOM table plays a key role in tracking and managing these changes. When modifications are made to the PCBA design, the BOM records these revisions, ensuring that different versions of the PCBA are properly managed. This version control helps maintain consistency and avoid errors during production, even when upgrades or changes are implemented.

How a Standardized BOM Improves PCBA Efficiency

By standardizing the BOM process, manufacturers can achieve greater transparency, streamline procurement, and reduce errors in production. A clear and accurate BOM table serves as a foundation for every aspect of PCBA processing, from purchasing components to quality assurance and post-production maintenance. This leads to faster production times, fewer defects, and a higher overall product quality.

Conclusion: Why You Need a Well-Structured BOM Table in Your PCBA Manufacturing Process

The BOM table is not just a list of components; it’s an essential tool that drives efficiency, reduces errors, and ensures quality throughout the entire PCBA production process. From procurement and assembly to cost management and change tracking, a comprehensive BOM table plays a critical role in achieving high-quality results. As the foundation of PCBA manufacturing, a well-organized BOM table can help your business reduce costs, improve production efficiency, and ensure product reliability.

If you’re looking to streamline your PCBA process, consider reviewing your BOM table and making sure it’s as detailed and accurate as possible. It’s the first step toward achieving better procurement practices, improved assembly processes, and a smoother path to high-quality PCBA production.