Introduction

PWB (printed wiring board) and PCB (printed circuit board) both refer to the basic circuit boards used in electronics manufacturing, but the difference between them can be confusing—especially as usage varies across regions, industries, and even eras.

In the United States and most of the global electronics industry, PCB has become the standard term. However, PWB is still widely used in countries like Japan or in niche documentation where clarity is needed to distinguish a bare board from a fully assembled one.

Understanding the differences between PWB and PCB is crucial for professionals working in electronics design, manufacturing, sourcing, or product development. Misinterpreting the terminology could lead to errors in procurement, documentation mismatches, or even quality control issues.

In this article, we'll clearly define what PWB vs PCB is, break down their key differences, explain how the terms have evolved, and offer practical advice on when to use which term.

Basic Definitions: What Is a PWB and What Is a PCB?

Before diving into the differences between PWB and PCB, it's essential to understand what each term actually means.

What Is a PWB (Printed Wiring Board)?

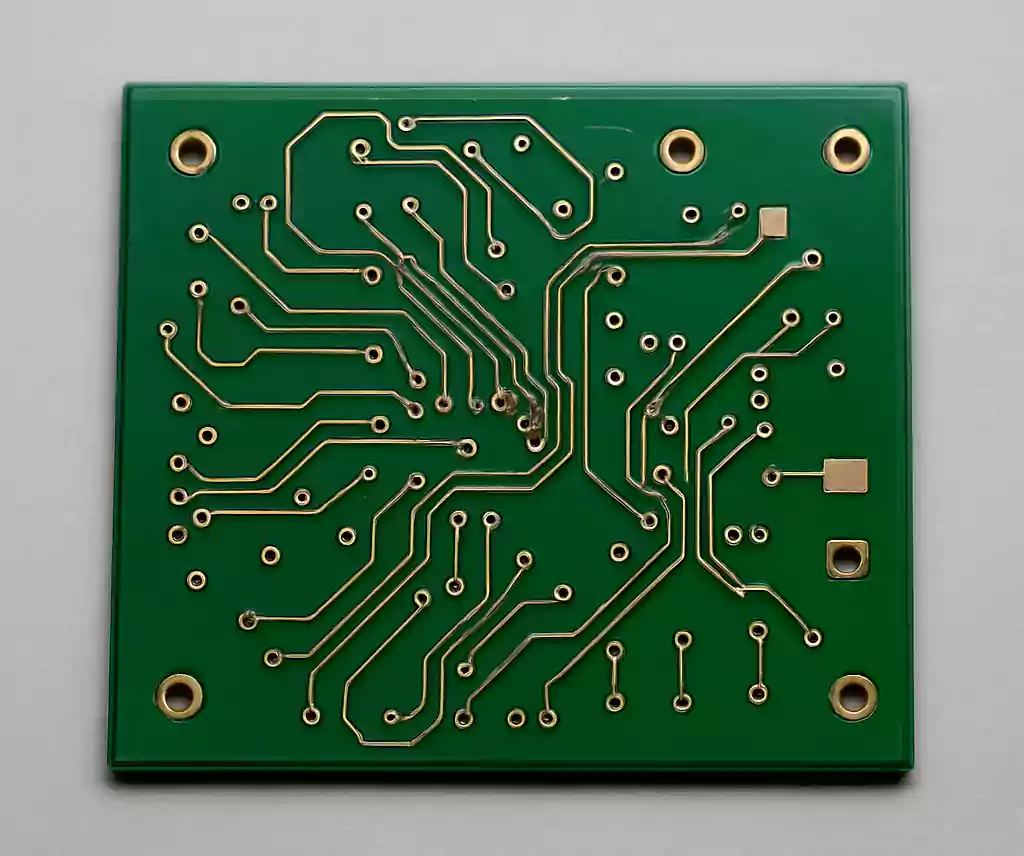

A PWB, or Printed Wiring Board, refers to a bare board that contains only the conductive pathways (traces) etched onto an insulating substrate. It does not include any electronic components. PWBs serve as the foundation for electronic assemblies, providing the physical structure and wiring necessary for connecting components.

In the early days of electronics manufacturing, the term PWB was commonly used to describe this basic wiring structure. The term helps distinguish a board that has no components (unpopulated) from one that is fully assembled.

Key characteristics of a PWB:

- No components mounted

- Includes only copper traces and pads

- Used in early production stages or prototyping

- Sometimes preferred in Japan to avoid confusion with toxic polychlorinated biphenyls (also abbreviated as PCB)

What Is a PCB (Printed Circuit Board)?

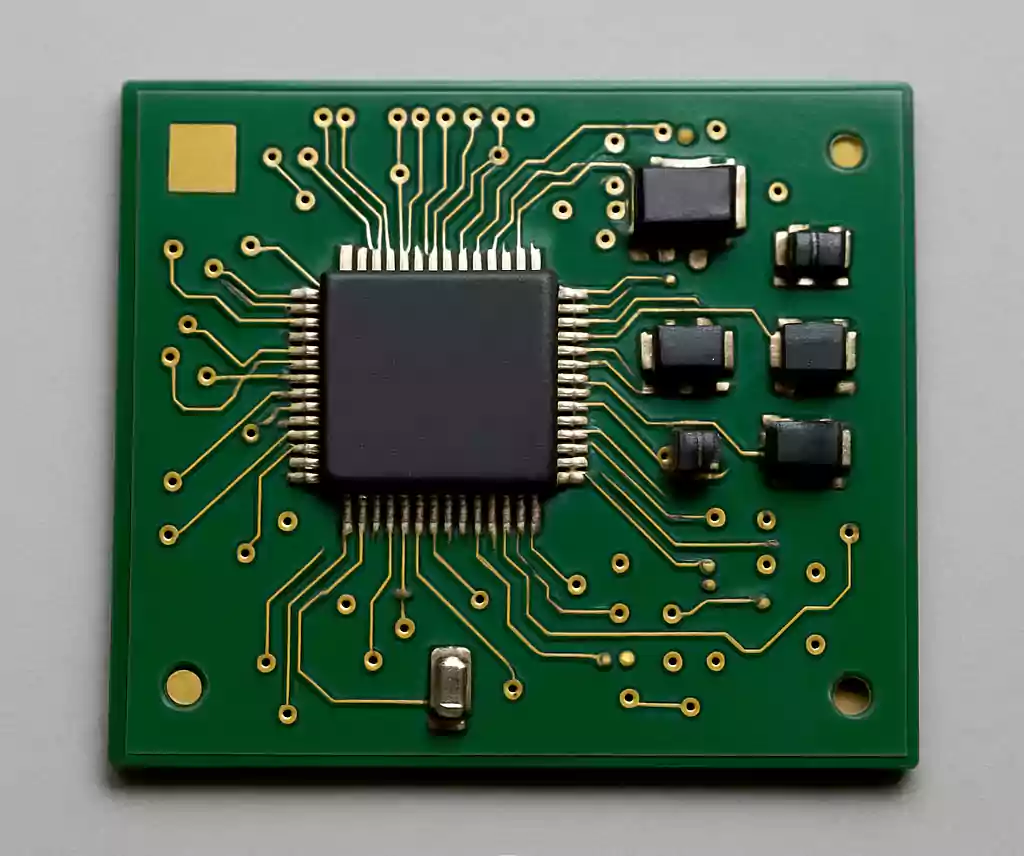

A PCB, or Printed Circuit Board, refers to the same physical board—but often implies a more complete and advanced stage of development. In modern usage, PCB is a broader term that includes:

- The copper-clad base board (same as a PWB)

- The integration of electronic components (in manufacturing or in context)

- Multi-layer routing, vias, and advanced material stacks

Key characteristics of a PCB:

- May refer to either a bare or assembled board (context matters)

- Most widely used industry term worldwide

- Often used interchangeably with "assembled PCB" (though technically different from PCBA)

Historical Background and Term Evolution

Understanding the historical background of PWB and PCB reveals how the meanings of these two terms have evolved over the decades, an evolution influenced not only by technology but also by standards bodies, regional preferences, and linguistic sensitivities.

Evolution Timeline of PWB vs PCB Terminology

| Time Period | Term Used | Context | Key Events & Industry Trends |

|---|---|---|---|

| 1940s–1950s | PWB (Printed Wiring Board) | Early electronics industry | PWB was the dominant term used to describe basic boards with printed copper wiring but no components. PCB was rarely used at this stage. |

| 1960s–1970s | PWB remains common | Military & aerospace sectors | High-reliability industries continued using "PWB" to refer strictly to bare boards, especially in defense documentation. |

| 1980s | PCB gains traction | Commercial electronics boom | As surface mount technology (SMT) and multilayer boards became mainstream, "PCB" started to replace "PWB" in general manufacturing. |

| 1990s | Transition period | IPC standards evolve | Industry associations like IPC began promoting unified terminology. "PCB" was adopted in most global documentation. |

| 2000s–Present | PCB becomes the standard | Global manufacturing | PCB is now the default term in English-speaking markets. However, PWB is still used in Japan and niche sectors. |

| Present (Region-Specific) | PWB in Japan | Language sensitivity | In Japan, "PWB" is preferred to avoid confusion with polychlorinated biphenyls (PCB), a toxic substance. |

| Present (Technical Standards) | PCB in IPC, ISO, and ANSI | International documentation | Most global standards and certifications (e.g., IPC-2221, ISO 9001) now use "PCB" as the official term. |

Key Takeaways:

- PWB was originally used to describe bare boards with etched wiring.

- PCB gradually became the industry-standard term as manufacturing and assembly advanced.

- Modern usage favors "PCB" globally, but PWB still appears in specific regions and older technical documents.

- Knowing the distinction helps professionals avoid confusion in procurement, documentation, and cross-border collaboration.

PWB vs PCB: Detailed Comparison

While PWB and PCB are often used interchangeably, they refer to different stages and scopes of board production in electronics. Understanding the core differences is essential for engineers, procurement teams, and electronics hobbyists alike.

Side-by-Side Comparison Table

| Category | PWB (Printed Wiring Board) | PCB (Printed Circuit Board) |

|---|---|---|

| Definition | A bare board with etched copper traces and no mounted components | A board that includes etched traces and may also have assembled components (may be bare or assembled) |

| Assembly Status | Unpopulated (no electronic parts mounted) | Can be either populated (assembled) or unpopulated |

| Typical Usage Stage | Early-stage development, prototyping, educational projects | Production-level electronics, final product integration |

| Complexity | Generally simpler—single or double-sided | Often complex—multi-layer, includes vias, thermal and signal integrity design |

| Applications | R&D, circuit testing, academic learning | Consumer electronics, industrial systems, automotive, aerospace, medical devices |

| Industry Adoption | Niche usage in Japan or in military legacy docs | Global industry standard across all sectors |

| Terminology Purpose | Used to differentiate between bare board and assembled board | Used as a general term for all circuit boards |

| Manufacturing Focus | Basic substrate fabrication, copper etching, no soldering involved | Full process including drilling, plating, SMT/THT assembly |

| Standardization | Rarely used in modern international standards | Official term in IPC, ISO, and ANSI standards (e.g., IPC-6012, ISO 9001) |

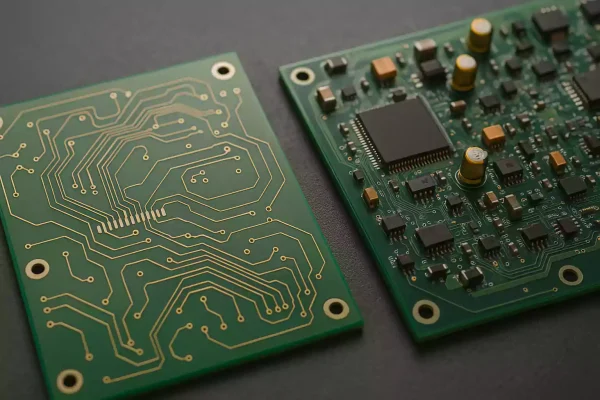

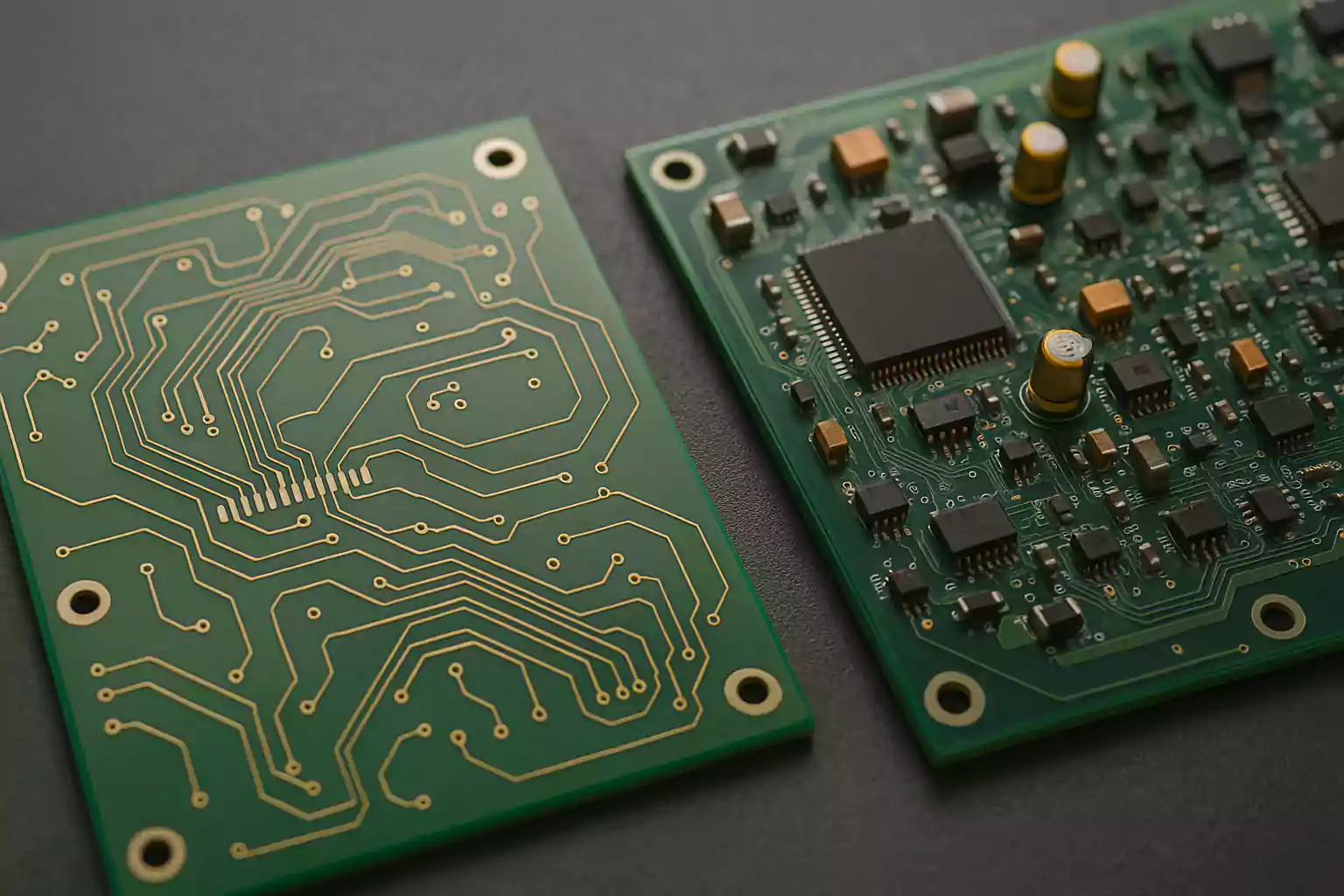

| Visual Appearance | Green or brown board with exposed copper pads and no components | May include chips, resistors, connectors, and other SMD/THT parts |

Terminology Overlap and Usage Recommendations

In the electronics industry, it's common to encounter both PWB (Printed Wiring Board) and PCB (Printed Circuit Board) in technical documents, supplier catalogs, and engineering discussions.

Why the Terms Are Often Confused

The confusion arises because:

- Both refer to circuit boards with conductive pathways.

- The only difference may be whether components are mounted.

- Some organizations or countries have legacy preferences for one term over the other.

Common Usage Scenarios

| Context | Preferred Term | Reason |

|---|---|---|

| Modern industry (global) | PCB | Universally recognized; aligns with IPC and ISO standards |

| Bare board procurement | PWB (or bare PCB) | Emphasizes that the board is unpopulated, avoiding confusion with PCBA |

| Fully assembled boards | PCB or PCBA | PCB when context is clear; PCBA (Printed Circuit Board Assembly) is specific |

| Japanese manufacturing docs | PWB | Avoids confusion with “PCB” as polychlorinated biphenyls (toxic chemical) |

| Military or aerospace legacy | PWB | Historically preferred in strict documentation practices |

| Internal team communication | Depends on convention | Use consistent language within teams and documentation |

Related Terms Explained and Expanded

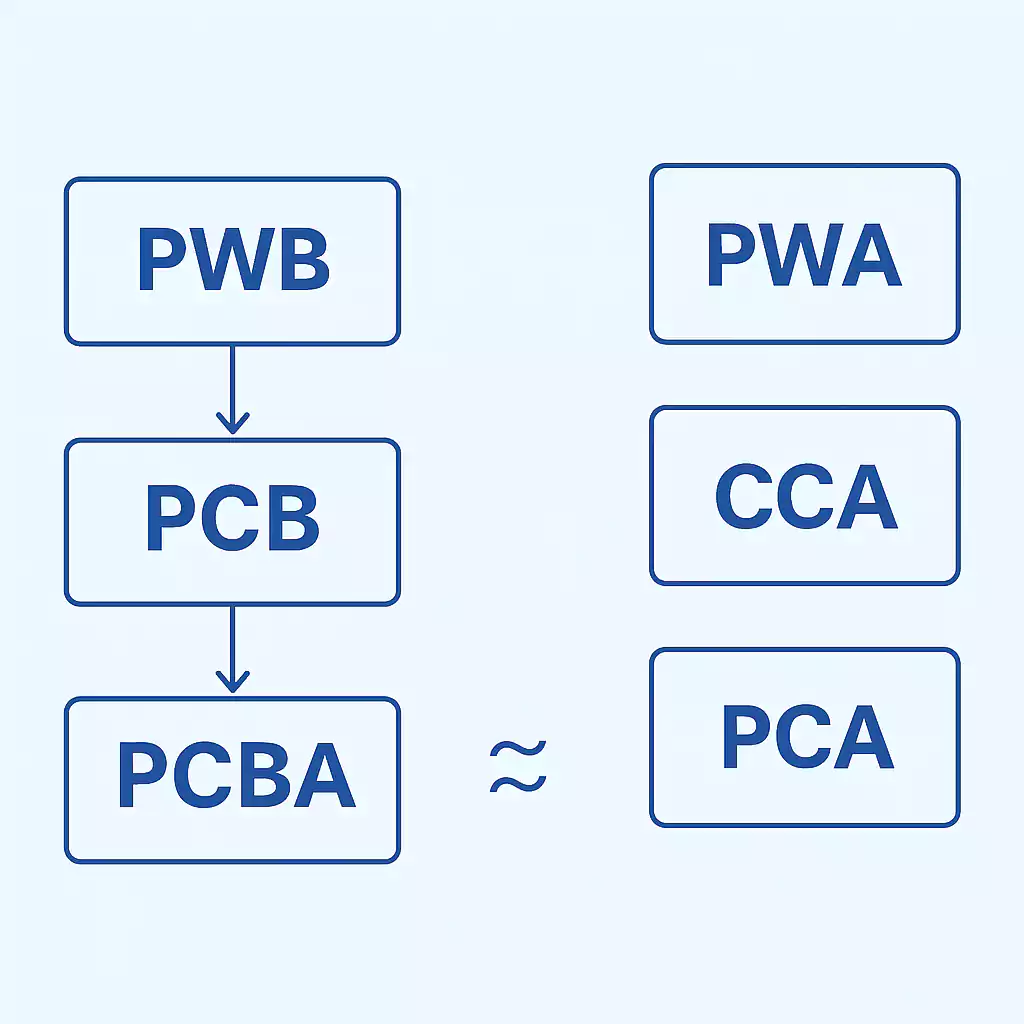

As you explore the differences between PWB and PCB, you'll likely encounter several related acronyms such as PCBA, PWA, CCA, and PCA. These terms describe different stages of board assembly or are used interchangeably in various industries. Understanding their definitions and differences helps eliminate ambiguity in communication, sourcing, and technical documentation.

Commonly Confused Terms in PCB Manufacturing

| Term | Full Form | Meaning | Common Usage |

|---|---|---|---|

| PCB | Printed Circuit Board | A circuit board that may be bare or populated with components | Industry-standard term for all types of circuit boards |

| PWB | Printed Wiring Board | A bare board with copper traces but no components | Often used to emphasize unpopulated boards; legacy or regional use |

| PCBA | Printed Circuit Board Assembly | A PCB that has been fully assembled with components (ICs, resistors, etc.) | Common in manufacturing, BOMs, and final product specs |

| PWA | Printed Wiring Assembly | Equivalent to PCBA; used mostly in military and aerospace documentation | Legacy terminology, mostly U.S. Department of Defense and contractors |

| CCA | Circuit Card Assembly | Another synonym for an assembled board | Used in aerospace, avionics, and some legacy systems |

| PCA | Printed Circuit Assembly | Also refers to a fully assembled board (less common today) | Occasional use in older documents or niche industries |

Practical Selection Guide: When to Choose PWB or PCB

Choosing the right terminology—and understanding the correct board type—can save time, reduce procurement errors, and improve collaboration between engineers, manufacturers, and suppliers. Whether you're in prototyping, mass production, or global sourcing, knowing when to use PWB or PCB is essential.

Key Considerations for Choosing Between PWB and PCB

| Criteria | Use PWB (Printed Wiring Board) | Use PCB (Printed Circuit Board) |

|---|---|---|

| Assembly Stage | When the board is unpopulated and used for prototyping or testing | When referring to both bare or assembled boards; PCB is the general industry term |

| Project Phase | Early R&D, prototyping, design validation | Production, product launch, or client-facing documentation |

| Procurement Purpose | When ordering bare boards only | When sourcing completed or ready-to-assemble boards |

| Audience or Context | Internal engineering teams, educational use | External clients, suppliers, global partners |

| Industry Standards Usage | In legacy systems, some aerospace/military documentation | Recommended by IPC, ISO, ANSI; standard in modern electronics manufacturing |

| Region (e.g., Japan) | Preferred to avoid confusion with chemical PCBs (polychlorinated biphenyls) | Common in North America, Europe, China, and most global markets |

| Terminology Sensitivity | If the audience needs clarity between bare board and assembled board | If clear context is provided or when following universal naming conventions |

FAQs

Is PWB the same as PCB?

Not exactly.

While both refer to circuit boards, a PWB (Printed Wiring Board) typically describes an unpopulated board, whereas a PCB (Printed Circuit Board) may refer to either a bare or assembled board. In modern usage, “PCB” has become the global standard.

Why is PWB still used in Japan?

In Japan, the term PWB is commonly used to avoid confusion with "PCB", which can also stand for polychlorinated biphenyls, a toxic chemical compound banned worldwide. Japanese manufacturers and documentation often favor "PWB" to maintain clarity and avoid regulatory misinterpretations.

Can I use PCB and PCBA interchangeably?

No.

•PCB refers to the board itself—either bare or sometimes partially assembled.

•PCBA (Printed Circuit Board Assembly) specifically refers to a fully assembled board with all components soldered on.

•Use PCBA when emphasizing the completed electronic assembly.

What's the difference between PCB and PWA or CCA?

These are all terms for assembled circuit boards, but used in different industries:

•PCB = Printed Circuit Board (general)

•PWA = Printed Wiring Assembly (used in military/aerospace)

•CCA = Circuit Card Assembly (used in aerospace/avionics)

Is PWB outdated?

Not entirely.

While PWB is less common in modern global standards (like IPC or ISO), it is still valid in:

•Military and aerospace documentation

•Japanese electronics manufacturing

•Educational settings that require stage-specific terminology

How do I know which term to use in my documentation?

Use PCB as the default, unless:

•You’re working with Japanese suppliers

•You're dealing with legacy systems or government documentation

•You need to clearly distinguish between a bare board (PWB) and an assembled one (PCBA)

Does "bare PCB" mean the same thing as PWB?

Yes, in most contexts.

The term "bare PCB" is often used interchangeably with PWB to refer to an unpopulated circuit board. It helps modernize language while maintaining technical clarity.

What terminology do IPC and ISO standards recommend?

Global standards such as IPC-2221 and ISO 6012 officially use the term PCB (Printed Circuit Board). If you're creating documentation or specifications that must adhere to international norms, "PCB" is the correct choice.

Conclusion

The terms PWB (Printed Wiring Board) and PCB (Printed Circuit Board) may seem interchangeable, but they reflect different stages, regional preferences, and historical usage in the electronics industry. Understanding these subtle distinctions is not only useful for engineers and procurement teams — it's essential for accurate documentation, effective global communication, and efficient manufacturing.