What Is a PCB Printer?

A PCB printer—also called a circuit board printer or PCB board printer—is a compact machine that builds electrical circuits directly onto a substrate using conductive inks or pastes.

Instead of waiting days for a fab house to ship your prototype, you can print a working circuit in a few hours right on your bench.

This process is different from 3D printing, which builds plastic parts layer by layer. PCB printing focuses on functional electronics, not mechanical structures. The goal is to form conductive traces, pads, and, in some cases, vias that connect components electrically.

PCB Printing vs. 3D Printing

Although they sound similar, PCB printing and 3D printing are very different. The table below shows the main contrasts:

| Purpose | Creates electrical circuits | Builds 3D structures or enclosures |

| Materials | Conductive inks, pastes, or metal nanoparticle materials | PLA, ABS, resin, nylon, etc. |

| Substrate | FR-1, FR-4, PET, paper, or flexible film | Printed plastic part itself |

| Precision | ~100 µm trace/space (model dependent) | ±0.1–0.5 mm geometric accuracy |

| Layers | Usually 1–2 (some hybrid multi-layer options) | Many physical layers |

| Output | Functional prototype circuit | Physical shape, non-conductive |

| Price Range | $3,000 – $25,000 + | $200 – $2,500 |

PCB printers are all about speed, control, and privacy. Engineers can design, print, test, and fix boards the same day—without exposing IP or paying shipping costs. 3D printers, on the other hand, are great for mechanical housings and test fixtures, not working circuits.

How a Desktop PCB Printer Works

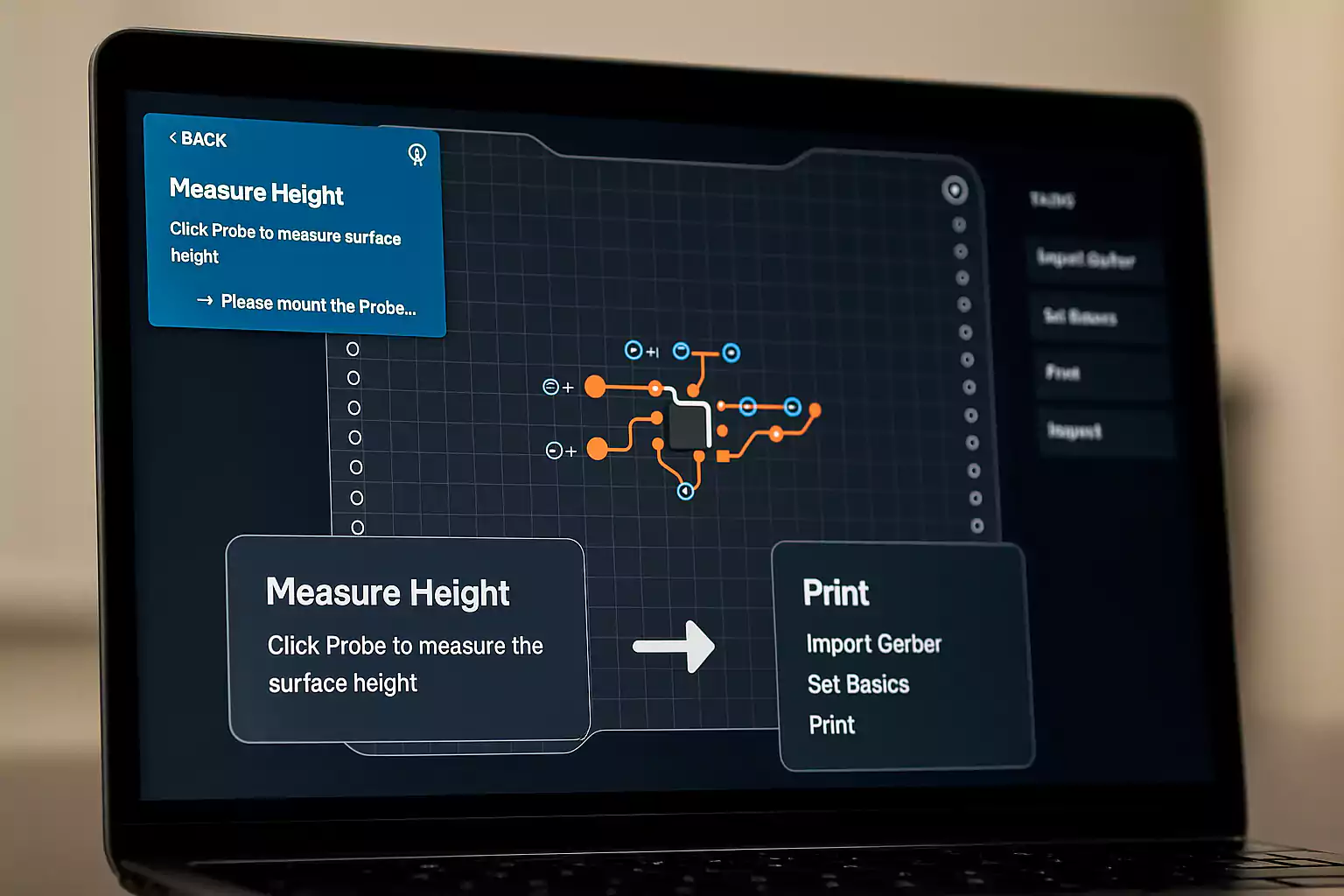

The workflow is surprisingly simple once you set it up:

- Design your circuit using ECAD software (E.g., KiCad, Altium, Eagle).

- Export Gerber files—the standard manufacturing format.

- Import those files into the printer’s software.

- The machine deposits conductive ink through a fine nozzle, often referred to as DIW (Direct Ink Writing).

- The traces are cured or sintered, typically by controlled heating.

- Optional: Dispense solder paste and reflow components right on the same platform.

- Test and repair with probes or a multimeter.

For example, the Voltera V-One combines printing, solder paste dispensing, and reflow into a single device. It even offers a small drilling attachment for through-hole parts.

Who Uses PCB Printers?

PCB printers aren’t meant for mass production. They excel in specific environments where time and flexibility are more important than unit cost.

1. Universities and Labs

Educators use them for hands-on electronics classes and research experiments. Students can design and print small circuits in a single lab session.

2. Hardware Startups and R&D Teams

When you’re iterating daily, waiting two or three days for every prototype slows you down. A desktop PCB printer enables teams to test new layouts immediately and pivot more quickly.

3. Confidential or Sensitive Projects

Some designs simply can’t be sent to outside vendors due to IP or security restrictions. Printing in-house keeps data offline and within your own lab.

In all these cases, the value isn’t just speed—it’s also independence and control over your prototyping pipeline.

Key Specifications to Check Before You Buy

Not all PCB printers are created equal. Here are the specs that actually matter when comparing machines:

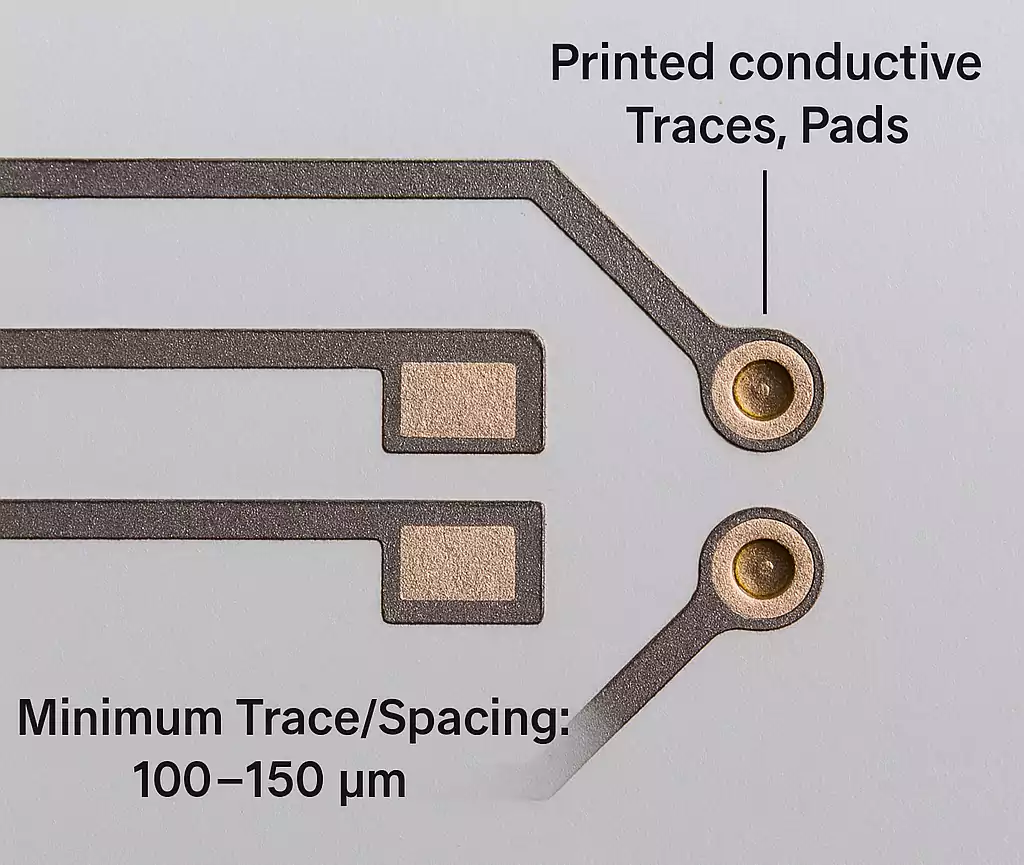

- Minimum trace width/spacing: Determines how dense your circuits can be. Typical hobby models print at around 150 µm; advanced systems can achieve resolutions below 100 µm.

- Number of layers supported: Most desktop printers handle single or double-sided boards only.

- Substrate compatibility: FR-1, FR-4, Kapton, PET, paper, or even fabric—verify which materials the printer can handle safely.

- Conductive ink properties: Look for low resistivity (high conductivity), good adhesion, and compatible curing temperatures for your substrate.

- Through-hole and via methods: Some use conductive epoxy dots or tiny rivets to connect top and bottom layers.

- Solder paste and reflow capability: A significant advantage if you require one-stop printing and assembly.

- Working area: Check the maximum printable board size.

- Software compatibility: Ensure it supports Gerber, Excellon, or standard ECAD file formats.

- Maintenance and consumables: Conductive ink cartridges can be costly—factor that into your running expenses.

- Support and training: Machines like the Voltera V-One come with detailed tutorials and responsive technical support, which can save hours of frustration.

Cost and TCO: Owning vs. Outsourcing

Let’s be honest—PCB printers aren’t cheap. Entry-level models start around $3,000–$4,000, while advanced multi-material systems exceed $25,000. On top of that, you’ll pay for:

- Ink or paste refills (often $50–$100 per cartridge)

- Substrate panels

- Maintenance kits or print heads

- Calibration time and operator labor

In comparison, outsourced prototypes from a quick-turn PCB service can cost as little as $5 to $20 per board, depending on size, layer count, and finish. Shipping takes 2–4 days for express orders.

So, when does a PCB printer make financial sense?

- If you print dozens of iterations each month, the machine eventually pays for itself.

- If your designs require same-day testing or IP confidentiality, speed and security outweigh raw cost.

- For occasional prototypes, outsourcing remains significantly more economical.

In other words, treat it as an investment in development velocity, rather than a replacement for full-scale manufacturing.

Common Misunderstandings and Limitations

PCB printers are amazing tools, but they have clear limits. Expecting too much often leads to disappointment.

1. They don’t replace full-scale PCB fabs

Complex boards—such as multi-layer, high-speed, or impedance-controlled—still require professional fabrication lines with copper plating, solder mask, and ENIG finishes.

2. Surface finish and durability differ

Printed traces are typically thicker and less uniform than etched copper. Conductive inks can oxidize more quickly and exhibit higher resistance.

3. Vias and double-sided alignment are tricky

Manual via filling or conductive rivets adds steps and can increase failure rates if not done carefully.

4. Consumables matter

Different inks have different curing temperatures and shelf lives. Using incompatible materials may lead to delamination or poor conductivity.

Is a PCB Printer Worth It? Real-World Pros and Cons

Like any engineering tool, a PCB printer comes with clear strengths and trade-offs. Understanding both sides helps you decide whether it fits your workflow.

Advantages

- Same-day prototyping and testing: Go from design to a working board in hours instead of days.

- Full control and data privacy: Keep your design files in-house with no external uploads.

- Creative material options: Print on flexible, transparent, or textile substrates for unique projects.

- Faster iteration: Test, tweak, and reprint easily without waiting for shipments to arrive.

Drawbacks

- High upfront cost: Desktop PCB printers range from a few thousand to tens of thousands of dollars.

- Limited complexity: Best for simple, low-layer boards rather than dense, multilayer designs.

- Ongoing maintenance: Consumables, such as conductive ink and nozzles, incur recurring costs.

- Lack of advanced finishes: No solder mask, plating, or professional-grade surface treatments.

The Bottom Line

If you treat a PCB printer as a rapid-prototyping tool, it can be a game-changer for speed and creativity.

If you expect it to replace a full PCB fabrication process, you’ll likely be disappointed.

For most teams, the best approach is a hybrid one: print early iterations in-house to test ideas quickly, then outsource the final version for high-quality production. That balance delivers the flexibility and control modern hardware design demands.

Frequently Asked Questions (FAQ)

1. Can a PCB printer make multilayer boards?

Some high-end systems can print limited multi-layer structures using insulating and conductive inks, but complexity and reliability drop quickly beyond two layers. For anything advanced, outsourcing is often the better option.

2. What’s the minimum trace width or spacing?

It depends on the printer and the type of ink. Most desktop models achieve a resolution of about 100–150 µm, while industrial machines can achieve finer resolutions.

3. Can it print solder mask or plated holes?

Not yet. Most desktop units only handle traces and pads. You can manually apply protective coatings afterward if needed.

4. Can PCB printing be combined with 3D printing?

Yes! Many labs 3D-print a base or enclosure, then print conductive traces on top. It’s a great way to explore embedded or wearable electronics.

5. What’s the best choice on a tight budget?

If you prototype only occasionally, use a quick-turn fab service. If you iterate multiple times per week or need on-site confidentiality, investing in a desktop PCB printer makes sense.

Conclusion

A PCB printer is one of the most exciting tools in modern hardware design. It brings electronics fabrication closer to the engineer’s desk—just like 3D printers did for mechanical parts a decade ago.

But remember its real purpose: speed and exploration, not mass production. Use it to test ideas instantly, to teach, to innovate, and to fail faster on your way to success. For finished, multilayer, production-grade boards, your favorite PCB manufacturer is still here to cover you.

With the right expectations, a PCB printer can transform your workflow and make prototyping as quick and creative as hitting “Print.”