Introduction

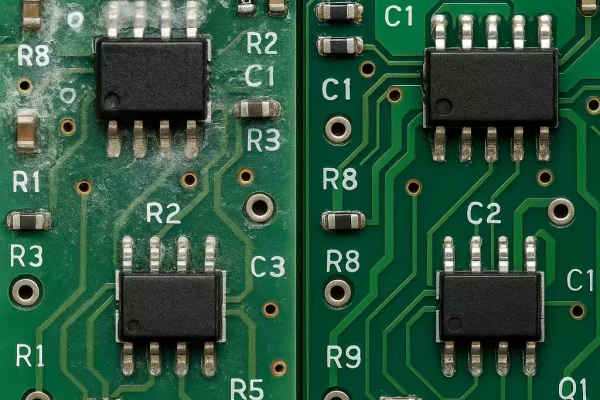

Flux residue is a common byproduct of the soldering process on printed circuit boards (PCBs). Although flux plays a critical role in promoting solder adhesion and preventing oxidation, its leftover residue—if not properly removed—can compromise both the performance and appearance of the finished assembly.

Cleaning flux off a PCB is an essential step in electronics manufacturing, repair, and prototyping. Residues left on the board can lead to corrosion, electrical leakage, signal interference, and failure of conformal coatings. These risks are especially critical in high-reliability applications such as medical devices, aerospace systems, and industrial controls, but they also affect consumer electronics and DIY projects.

This article provides a detailed guide on how to clean flux off PCB surfaces, covering different types of flux—including rosin-based, no-clean, and water-soluble—and the appropriate cleaning methods for each.

Types of Flux and Residue Characteristics

Understanding the type of flux used during soldering is essential when determining the most effective method for cleaning printed circuit boards (PCBs). Each flux type leaves behind different residues, some of which require aggressive cleaning methods, while others are marketed as "no-clean" but may still cause issues under specific conditions. Below are the most common types of flux and their associated residue characteristics:

1. Rosin-Based Flux (R-Type)

Rosin-based flux is derived from natural resin and is widely used in both hobbyist and industrial applications. It provides excellent soldering performance but leaves behind sticky or glossy amber-colored residues that can attract moisture and dust.

Residue Characteristics:

- Non-conductive when dry, but mildly corrosive over time if not removed

- Leaves visible deposits that can degrade PCB appearance

- Can interfere with conformal coatings or cause signal interference in high-frequency circuits

2. No-Clean Flux (NC-Type)

No-clean flux is formulated to leave minimal residue that is supposedly safe to remain on the board. It is commonly used in mass production to reduce cleaning steps. However, the term "no-clean" can be misleading.

Residue Characteristics:

- Thin, hard-to-see residues that may still be conductive under high humidity

- Can affect high-impedance or RF circuits

- Often incompatible with conformal coating or long-term reliability standards

3. Water-Soluble Flux (WS-Type)

Water-soluble fluxes are designed for easy removal using water, making them popular in environments that require rigorous post-soldering cleaning.

Residue Characteristics:

- Highly conductive and corrosive if left on the board

- Attracts moisture, leading to oxidation or short circuits

- Easily visible residues that can be removed with deionized (DI) water

Safety and Preparation Before Cleaning Flux from a PCB

Before you begin cleaning flux residue off a printed circuit board (PCB), it's important to set up a safe, organized, and well-equipped work environment. Many cleaning agents—such as high-purity isopropyl alcohol (IPA), acetone, and commercial flux removers—are flammable, volatile, or irritating to the skin and eyes. Taking the proper safety precautions not only protects you and your workspace but also helps ensure that your cleaning process is efficient and effective.

1. Work in a Well-Ventilated Area

Most flux removers and solvents produce fumes that can be harmful if inhaled in enclosed spaces. Always clean PCBs in a well-ventilated room or under a fume hood. If possible, work near an open window or use a small fan to direct fumes away from your face.

2. Wear Protective Equipment

To minimize exposure to chemicals and prevent electrostatic damage, wear the following personal protective equipment (PPE):

- Nitrile gloves: Protects your hands from solvents and flux chemicals

- Safety glasses or goggles: Prevents splashes from reaching your eyes

- Antistatic wrist strap: Avoids electrostatic discharge (ESD), which can damage sensitive electronic components

3. Power Down and Disconnect the PCB

Always turn off power and disconnect all power sources before cleaning. Removing the battery or unplugging the device is essential to avoid short circuits, electrical shocks, or damage during the cleaning process.

4. Prepare Your Cleaning Tools and Supplies

- High-purity isopropyl alcohol (IPA) (90–99% concentration)

- Commercial flux remover spray (optional for no-clean or rosin flux)

- Antistatic brushes, acid brushes, or soft-bristle toothbrushes

- Lint-free wipes (e.g., Kimwipes or microfiber cloths)

- Compressed air or a heat gun for drying

- ESD-safe work mat or surface

- Small containers for soaking (if needed)

5. Avoid Open Flames and Static Sources

Many cleaning solvents are flammable. Keep your workspace away from open flames, sparks, or high-heat sources. Additionally, avoid using cleaning materials that generate static electricity, such as paper towels or cotton swabs.

6. Organize Your Workspace

A clutter-free workspace allows for better handling of delicate components and reduces the risk of spills or damage. Place your tools and cleaning agents within easy reach, and make sure the board is positioned on a non-slip, ESD-safe surface.

Recommended Cleaners and Tools for Removing Flux from PCB

Choosing the right cleaning agents and tools is essential for effectively removing flux residue without damaging your PCB. Different flux types—such as rosin-based, no-clean, and water-soluble—respond best to specific solvents and application methods. Below are the most recommended products and tools for safe and thorough PCB cleaning.

1. Isopropyl Alcohol (IPA)

- Use high-purity (≥90%, ideally 99%) IPA for dissolving rosin and no-clean flux residues.

- It evaporates quickly and leaves no residue, making it ideal for sensitive electronics.

- Available in spray bottles or bulk for manual cleaning and soaking.

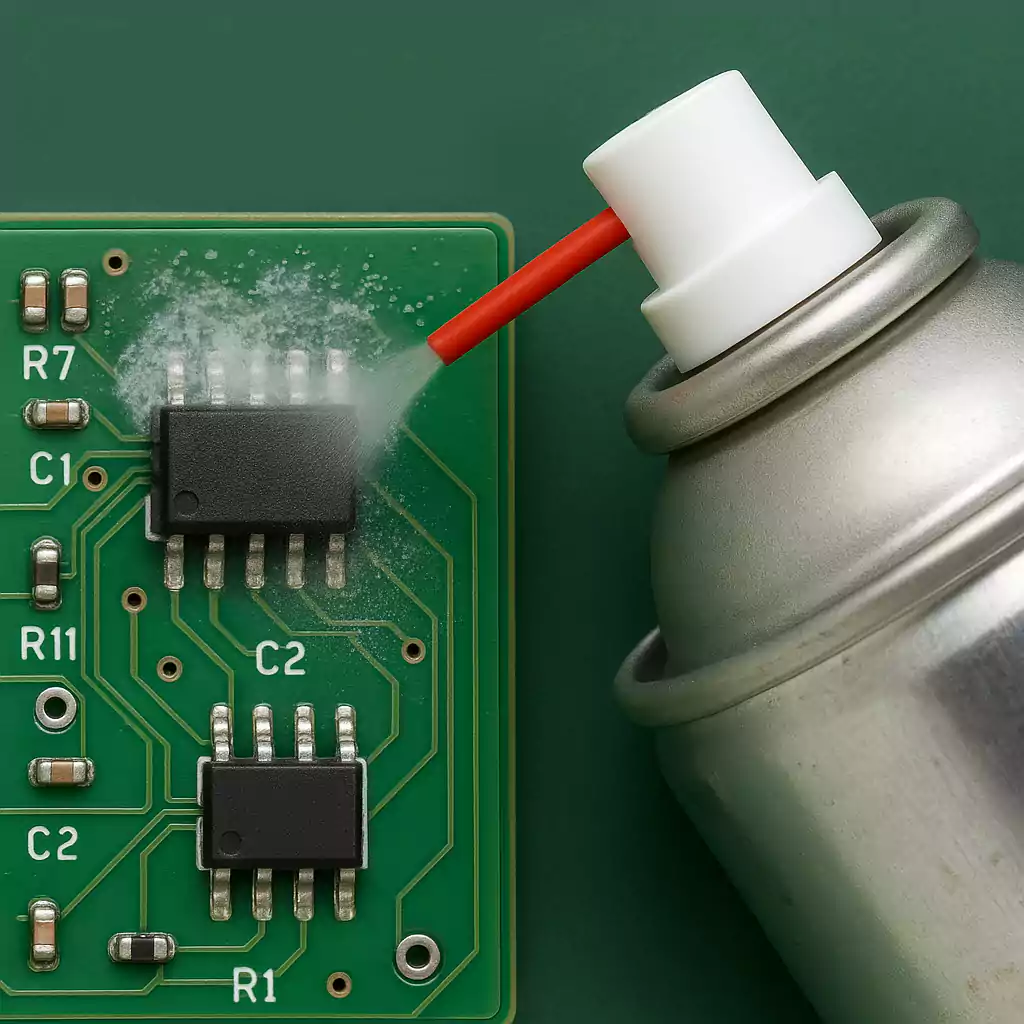

2. Commercial Flux Removers

- Specialized cleaning sprays (e.g., Techspray®, MG Chemicals®, Chemtronics®) are formulated to break down stubborn no-clean or rosin flux.

- Most include a directional straw or brush attachment for precision cleaning.

- Effective in both manual and automated cleaning workflows.

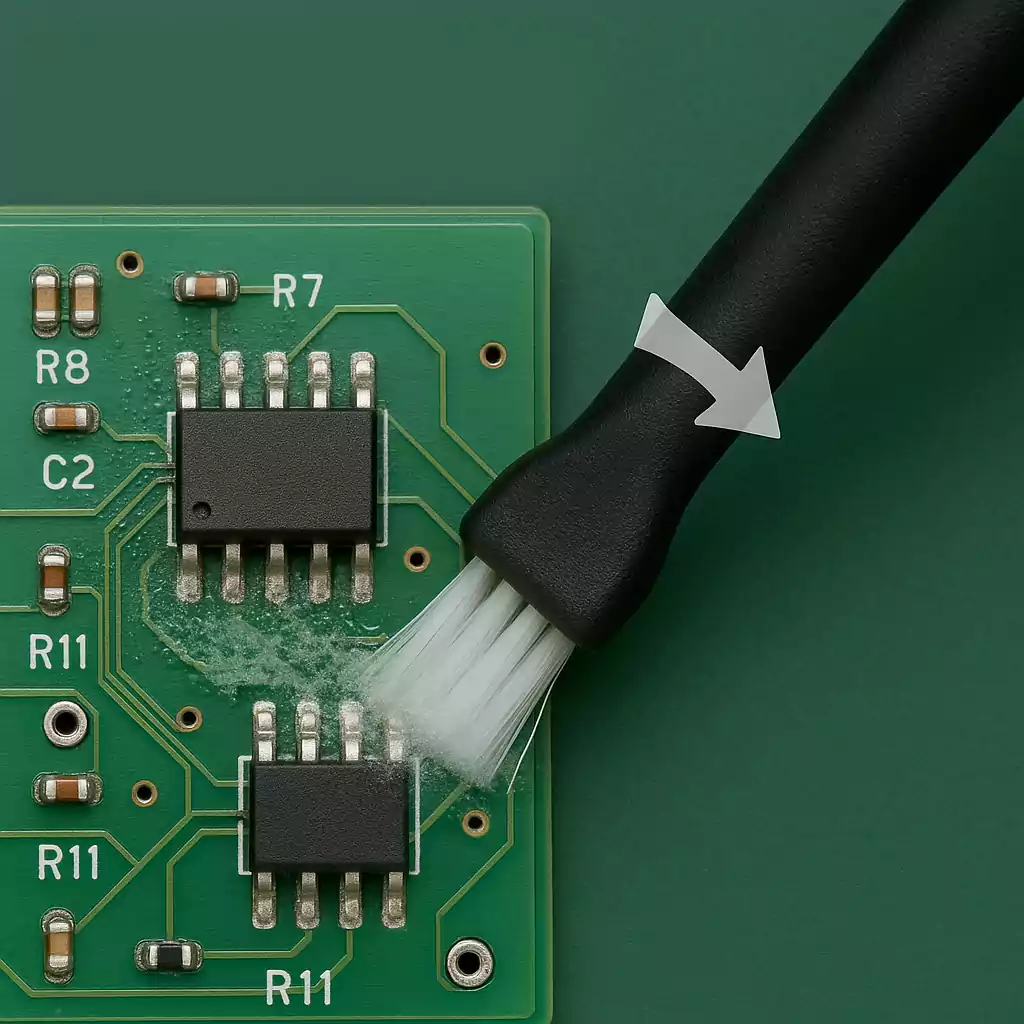

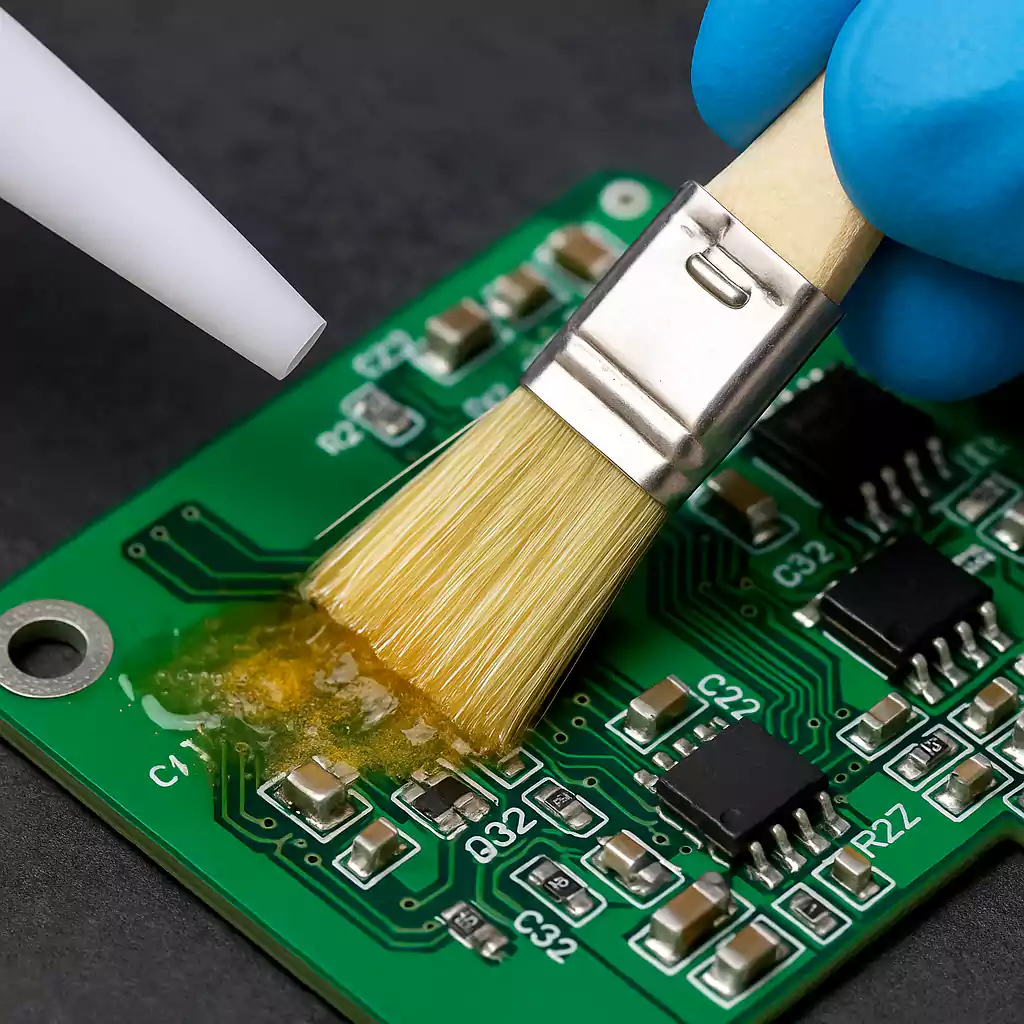

3. Cleaning Brushes

- Use ESD-safe brushes, acid brushes, or soft-bristle toothbrushes to agitate and lift flux.

- Antistatic brushes are recommended to avoid static discharge during cleaning.

4. Lint-Free Wipes and Swabs

- Kimwipes, microfiber cloths, or foam-tipped swabs are ideal for wiping off dissolved flux without leaving fibers or particles behind.

- Avoid using paper towels or cotton swabs, which can shed debris.

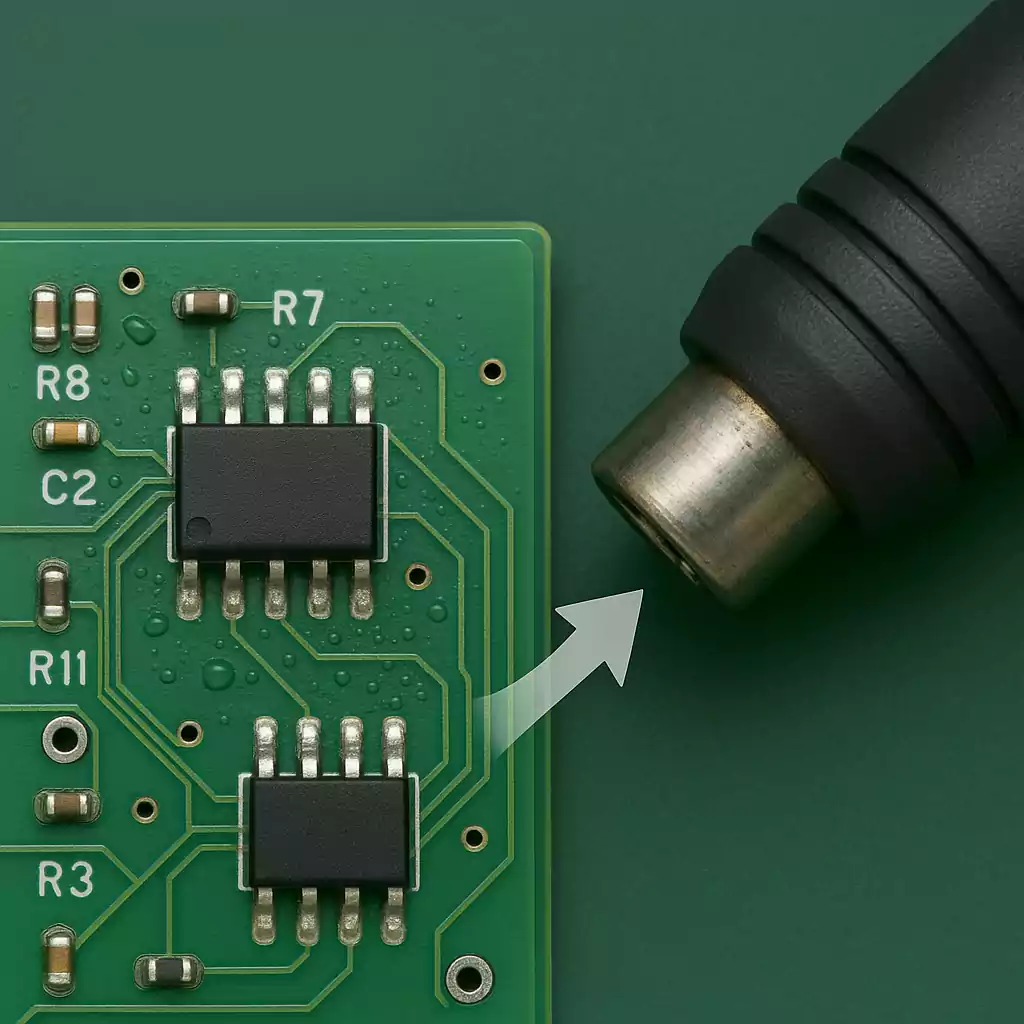

5. Compressed Air or Heat Gun

- Use canned air or a low-temperature heat gun to blow away solvent and dry the PCB quickly.

- This helps prevent residue from resettling and avoids moisture buildup.

6. Optional: Ultrasonic Cleaner

- Suitable for cleaning water-soluble flux or for batch cleaning in industrial settings.

- Only use with compatible components and follow manufacturer guidelines.

Step-by-Step Cleaning Process for Removing Flux from PCBs

Whether you're cleaning rosin-based, no-clean, or water-soluble flux, following a structured process ensures better results and reduces the risk of damage. Below is a proven step-by-step method for safely removing flux residue from printed circuit boards (PCBs).

Step 1: Power Down and Prepare the PCB

- Disconnect all power sources, batteries, and cables.

- Place the PCB on a flat, ESD-safe surface.

- Wear antistatic gloves or wrist straps and ensure proper ventilation.

Step 2: Identify the Type of Flux

- Check solder labels or documentation to determine if you're dealing with rosin, no-clean, or water-soluble flux.

- This helps you choose the right solvent and cleaning method.

Step 3: Apply Cleaning Agent

- For rosin or no-clean flux, spray or dab high-purity isopropyl alcohol (IPA) or a commercial flux remover directly onto the affected area.

- For water-soluble flux, use warm deionized water or a water-based cleaning solution.

Step 4: Agitate with a Brush

- Use an ESD-safe brush (e.g., acid brush or soft toothbrush) to gently scrub the flux residue.

- Brush in one direction to avoid redepositing residue.

- Reapply solvent as needed to keep the area wet and loosen stubborn buildup.

Step 5: Wipe or Rinse Away Residue

- Use lint-free wipes or foam-tipped swabs to blot and wipe away dissolved flux.

- For water-soluble flux, rinse thoroughly with deionized water after brushing.

Step 6: Dry the PCB Completely

- Use compressed air or a low-heat gun to remove moisture or remaining solvent.

- Make sure no liquid remains under components or connectors.

- Let the board sit for 10–30 minutes in a warm, dry place to ensure full evaporation.

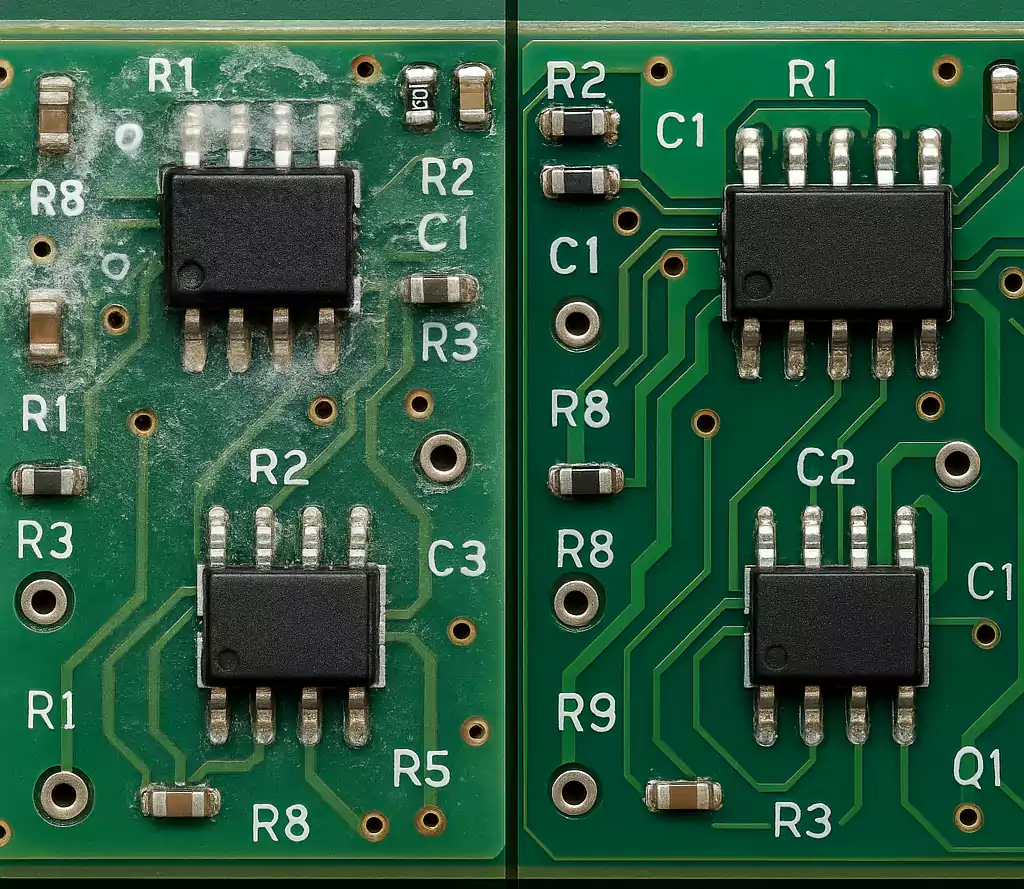

Step 7: Inspect and Repeat if Necessary

- Use a magnifying glass or microscope to inspect solder joints and component pads.

- Repeat the process if any visible residue remains.

Recommended Cleaning Methods by Flux Type

Choosing the right cleaning approach depends heavily on the type of flux used during soldering. Each type leaves behind residues with different properties, and using the wrong method can lead to ineffective cleaning or even damage. The table below summarizes the best practices for cleaning each flux type:

| Flux Type | Cleaning Agent | Water Rinse Needed | Residue Risk | Recommended Tools | Special Notes |

|---|---|---|---|---|---|

| Rosin-Based | 99% Isopropyl Alcohol (IPA) or flux remover | ❌ No | Mildly corrosive over time; visible buildup | Antistatic brush, lint-free wipes | Scrub thoroughly; may leave white residue if not fully removed |

| No-Clean | Specialized no-clean flux remover or IPA | ❌ No (in most cases) | Often invisible; may cause leakage in humidity | Brush + targeted spray; dry thoroughly | Removal recommended before conformal coating or in high-reliability circuits |

| Water-Soluble | Warm DI (deionized) water + neutral detergent | ✅ Yes | Highly conductive and corrosive if not cleaned | Soft brush, rinse tank, compressed air or heat gun | Must be cleaned immediately after soldering; ensure full drying to avoid damage |

Common Mistakes When Cleaning Flux—and How to Avoid Them

Cleaning flux residue from a printed circuit board (PCB) may seem simple, but even small mistakes can lead to poor results, component damage, or long-term reliability issues. Below are the most common flux cleaning errors—and how to avoid them for a safe, effective cleaning process.

Mistake 1: Using 70% Isopropyl Alcohol

70% IPA contains too much water, which can leave behind moisture and reduce the solvent’s ability to dissolve flux effectively.

Solution:

Always use high-purity IPA (90% or higher), ideally 99%, especially for rosin or no-clean flux. It evaporates faster, leaves no residue, and is safe for electronics.

Mistake 2: Using Cotton Swabs or Paper Towels

Cotton and paper products can shed fibers and leave lint behind, potentially causing shorts or signal interference.

Solution:

Use lint-free wipes, foam-tipped swabs, or Kimwipes designed for electronics cleaning.

Mistake 3: Spraying Without Agitation

Solvents can dissolve flux, but without brushing or wiping, the loosened residue may re-deposit elsewhere on the board.

Solution:

Always use an antistatic brush to gently agitate the area while the flux remover or IPA is applied. This helps fully lift and remove the residue.

Mistake 4: Leaving Water-Soluble Flux Unwashed

Water-soluble flux is highly corrosive and conductive if left on the board, potentially causing short circuits or rapid degradation.

Solution:

Immediately clean water-soluble flux after soldering using warm deionized water, followed by thorough drying with compressed air or a heat gun.

Mistake 5: Not Drying the PCB Completely

Residual moisture or solvent under components can lead to corrosion, malfunction, or long-term damage.

Solution:

After cleaning, use compressed air or a heat gun to dry the board thoroughly—especially under connectors and between fine-pitch pins.

Mistake 6: Assuming No-Clean Flux Never Needs Cleaning

Despite its name, no-clean flux can still cause issues in high-impedance, RF, or humid environments, and interfere with conformal coatings.

Solution:

Clean no-clean flux when working on critical applications, before applying protective coatings, or when visible residue remains.

Frequently Asked Questions (FAQ)

How to Clean Flux Off PCB?

Despite its name, no-clean flux can still leave behind residues that affect performance in high-impedance or high-frequency circuits. To remove it:

•Use a specialized no-clean flux remover or 99% IPA

•Apply the solvent directly and gently scrub with an ESD-safe brush

•Wipe away dissolved flux with a lint-free cloth or foam swab

Is 70% isopropyl alcohol good for cleaning PCBs?

No.

70% IPA contains too much water, which can leave moisture on the board and reduce cleaning effectiveness. For best results, always use 90–99% isopropyl alcohol, preferably 99%, especially on delicate electronics.

Can I use acetone to remove flux residue?

Yes, but with caution.

Acetone is a powerful solvent that can dissolve rosin and some no-clean fluxes. However, it may:

•Damage plastic connectors or PCB coatings

•Evaporate too quickly

•Leave residue if not wiped thoroughly

What's the best way to dry a PCB after cleaning?

After cleaning:

•Use compressed air to blow out solvent from under components

•Follow with a low-heat gun or air-dry the board in a clean, dry area

•Ensure the board is completely dry before powering on—especially if water-based cleaning was used

Is it necessary to clean flux if I'm not applying conformal coating?

Yes, in many cases.

Even without a coating step, flux residue can absorb moisture, cause corrosion, or interfere with high-frequency signals. Cleaning is especially important for:

•High-reliability electronics

•RF circuits

•Any application in humid or harsh environments

Can I use a toothbrush to clean flux off a PCB?

Yes—but choose wisely.

Use a soft-bristle or antistatic brush. Regular household toothbrushes may generate static or shed bristles. For best results:

•Use acid brushes or ESD-safe brushes

•Always brush while the solvent is wet to avoid re-depositing residue

How do I know if all the flux is removed?

Check for:

•No visible residue or white haze under bright light or magnification

•Consistent, shiny solder joints

•No stickiness when wiping with a dry lint-free cloth

Conclusion

Proper flux removal is essential—not optional—for maintaining the electrical performance, reliability, and longevity of your PCB. Leftover residue can cause corrosion, signal degradation, and interfere with coatings or high-frequency applications.

By identifying the type of flux used, choosing the right cleaning agent (such as high-purity IPA or a dedicated flux remover), and following a safe, structured cleaning process, you ensure your circuit boards meet both functional and professional standards.

Clean boards don't just look better—they perform better.