The PCBA One-Stop Service refers to a comprehensive solution where a professional PCBA manufacturer manages the entire process—from design and procurement to assembly, testing, and final delivery. By entrusting the full spectrum of PCBA services to an experienced manufacturer, companies can streamline operations, reduce costs, enhance quality control, and benefit from flexible production options and technological advancements. Below are the seven key benefits of opting for a PCBA One-Stop Service:

Streamlined Procurement Process

Traditional PCBA services often require customers to handle the procurement of materials, manage inventories, and coordinate with multiple suppliers. In contrast, a one-stop service simplifies this by centralizing material procurement and production processes under a single roof. Customers only need to provide product design files and technical specifications, significantly reducing the complexity of managing multiple suppliers and saving valuable time and resources.

Reduction in Inventory Costs

With the one-stop service model, the responsibility for material procurement and inventory management is transferred to the PCBA manufacturer. This eliminates the need for customers to maintain large inventories, reducing storage costs and minimizing capital tied up in unsold stock. This shift not only lowers operational costs but also alleviates financial pressure by ensuring more efficient material usage.

Assured Product Quality & Timely Delivery

PCBA manufacturers that offer one-stop services typically have optimized internal processes and integrated supply chains. By controlling the procurement of components, production scheduling, and quality testing, these manufacturers can guarantee consistent product quality and on-time delivery. This results in more reliable products and a predictable timeline for your business, giving you confidence in meeting customer expectations.

Convenient Small Batch Order Fulfillment

One of the standout advantages of a PCBA one-stop service is the ability to accommodate small or low-volume production runs. Many small or startup businesses face challenges when ordering small quantities due to higher costs and logistical inefficiencies. A one-stop service consolidates several small orders into larger batches, making it easier to fulfill smaller orders without incurring prohibitive costs, offering a more efficient solution for low-volume production.

Optimized Supply Chain Management

By transferring the responsibility for supply chain management to a PCBA manufacturer, companies can achieve improved operational efficiency and reduced risks. The manufacturer can leverage its established relationships with suppliers, enabling better resource integration, optimized material management, and more responsive supply chain solutions. This ultimately reduces the cost of materials and ensures a smoother, faster production process.

Increased Flexibility for Startups and Small Businesses

For small businesses or startups that may not have the resources to manage large-scale production or detailed supply chain operations, the PCBA one-stop service model offers the ideal solution. This model accommodates the flexibility required for product development and small batch trials. Startups can adjust quantities as needed without worrying about maintaining inventory or managing complex procurement processes.

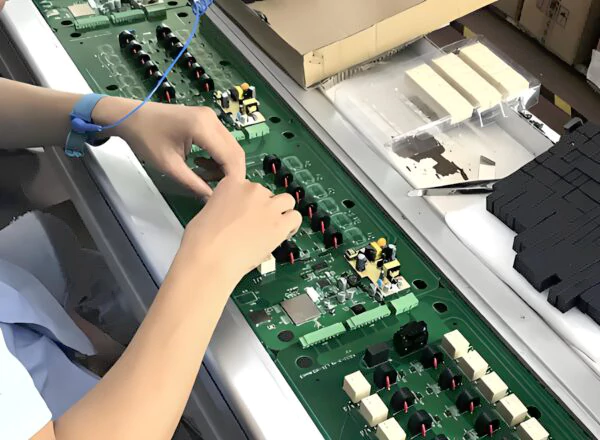

Technological Innovation and Automation Integration

As the electronics manufacturing industry evolves, technological innovation and automation have become critical in enhancing production efficiency and maintaining product quality. PCBA factories offering one-stop services are increasingly adopting cutting-edge technologies and automated processes to improve precision, speed, and cost-effectiveness. With these advancements, customers benefit from higher-quality PCBs, reduced production times, and the ability to quickly adapt to market demands.

Why Choose a PCBA One-Stop Service?

In today's competitive market, efficiency, cost savings, and quality control are paramount to a successful electronic manufacturing process. By opting for a PCBA one-stop service, businesses can streamline their operations, reduce financial risks, and leverage technological advancements, making it the ideal choice for companies seeking comprehensive solutions in PCB assembly.

Whether you’re a small startup or an established business looking to optimize your manufacturing process, the PCBA one-stop service provides a robust solution that enhances your supply chain, accelerates product development, and ensures timely, high-quality deliveries.

Conclusion

Adopting a PCBA one-stop service model provides a range of advantages, from simplified procurement to enhanced flexibility and technological innovation. By outsourcing the full range of PCB assembly and manufacturing tasks to a trusted service provider, businesses can focus on core activities, reduce operational complexities, and stay ahead of the competition with high-quality, cost-efficient products.