As technology advances, so does the demand for smaller, lighter, and more efficient devices. Engineers and designers are turning to Flexible Printed Circuits (FPCs) to meet these evolving demands. In this article, we explore the top six advantages of using flexible PCBs in product design and how they can significantly improve your projects.

Extreme Flexibility

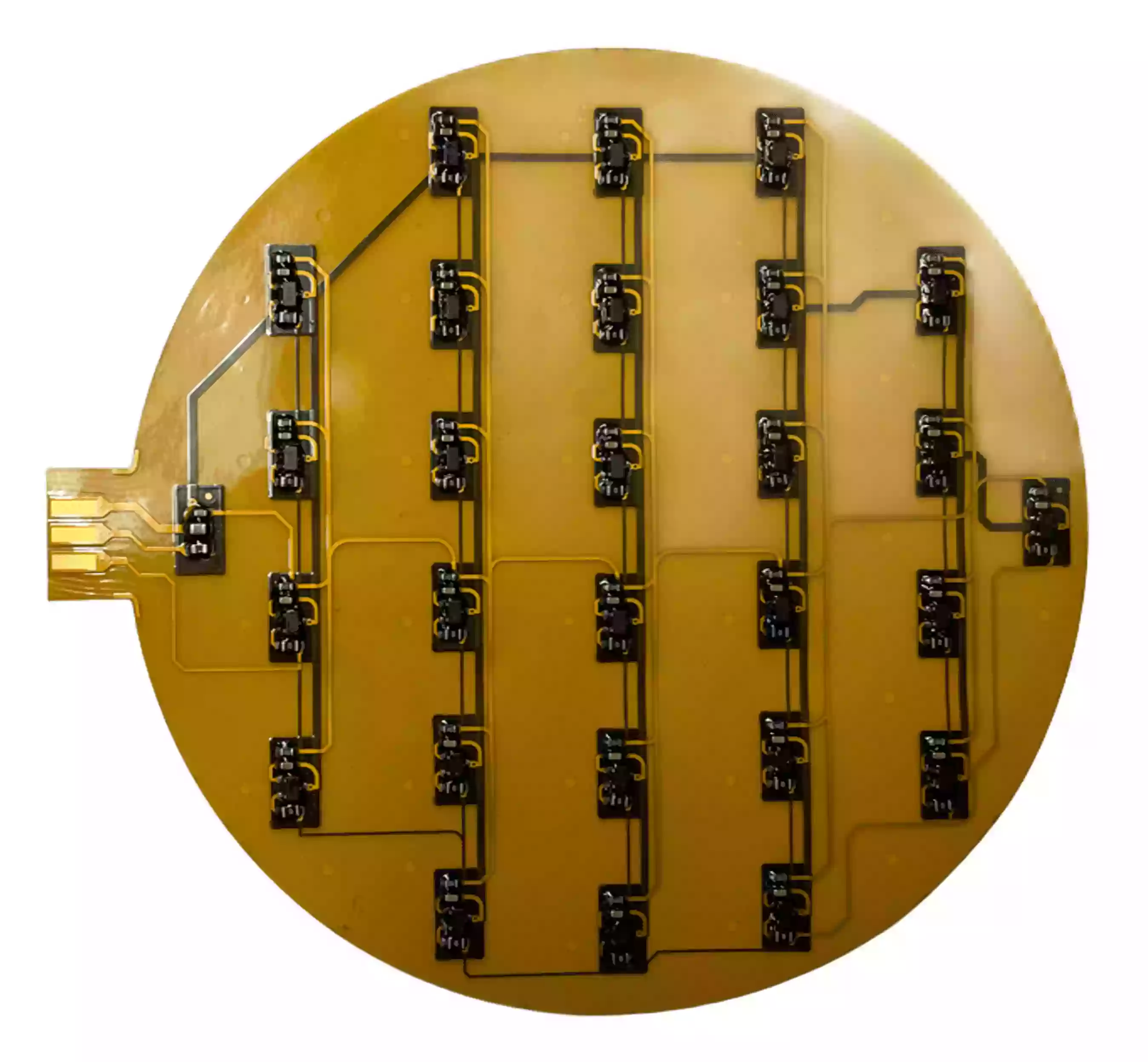

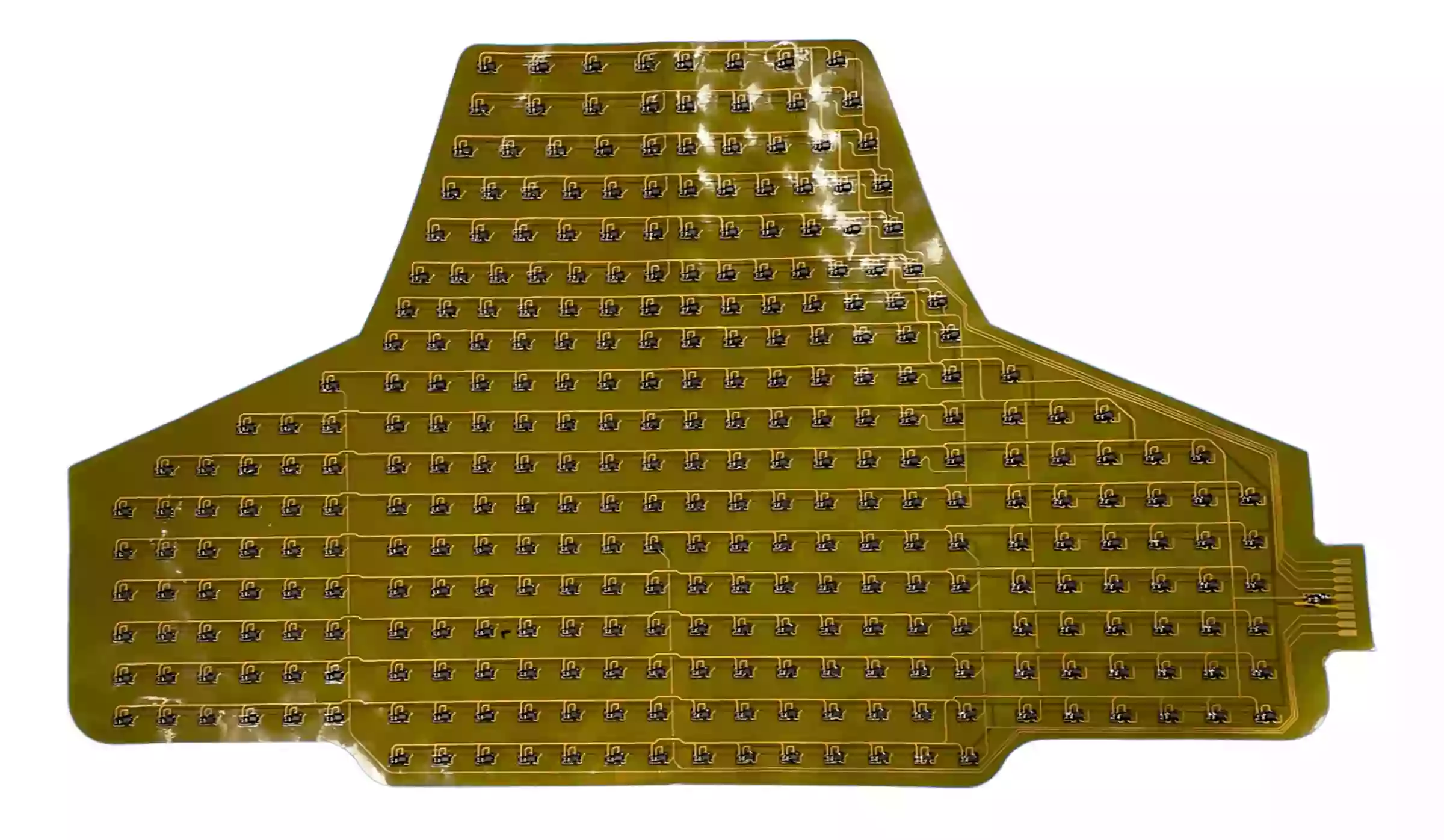

One of the most significant advantages of FPCs is their flexibility. Unlike traditional rigid PCBs, flexible circuits can be bent, twisted, or folded to fit into complex and confined spaces. This capability is essential for modern electronics, such as wearables, foldable phones, and flexible displays.

Lightweight and Thin

FPCs are extremely thin and lightweight, which makes them ideal for applications where size and weight are critical factors. These circuits can be as thin as 0.1mm, making them perfect for compact and portable devices like smartphones, laptops, and drones. In fact, flexible PCBs are up to 70% lighter than their rigid counterparts.

Space Optimization

FPCs allow for creative design solutions where space is at a premium. By integrating the circuit directly into the product’s structure, designers can eliminate bulky connectors and reduce the overall footprint of the device. In some cases, FPCs can even replace wiring and cables, reducing the need for additional components.

Enhanced Reliability

Flexible PCBs are more durable and reliable compared to traditional rigid PCBs. They can withstand constant bending, vibrations, and shock without cracking, which is essential for devices used in dynamic environments. The ability to endure these conditions makes FPCs ideal for automotive, aerospace, and medical applications.

Cost-Efficiency in Volume Production

Despite their advanced features, FPCs can be cost-effective for large-scale production. Their lightweight design leads to reduced material costs, and their ability to fit into tighter spaces means fewer components and assembly steps. This results in a more streamlined manufacturing process, which lowers costs in high-volume production.

Integrated Design Possibilities

Flexible PCBs open up new possibilities for integrated designs. They can be incorporated directly into the product, reducing the need for additional components and connectors. This can lead to cleaner, more efficient product designs with fewer points of failure, improving overall system performance and reliability.

Conclusion

Flexible PCBs are an essential tool for modern product design. From extreme flexibility and lightweight construction to space optimization and enhanced reliability, FPCs offer unparalleled benefits. As a result, engineers and designers are increasingly turning to flexible PCBs to create high-performance devices in smaller, more efficient packages.