As global semiconductor manufacturing shifts toward Southeast Asia, the capability and automation level of PCBA equipment has become a crucial benchmark of competitiveness. In an environment challenged by labor shortages and unstable supply chains, having advanced PCBA facilities is the key to delivering quality and speed.

Malaysia’s Semiconductor Industry Faces Labor Shortages

According to industry reports, Malaysia hosts over 50 semiconductor companies, including major players such as STMicroelectronics, Texas Instruments, Intel, Renesas, and more. Many of these companies operate assembly and wafer fabrication plants locally.

Malaysia is also a global hub for passive component manufacturing, with Japanese and Taiwanese giants like Murata, Toshiba, Wintek, and Huaxin Technology setting up production lines. Despite this industrial base, labor shortages are putting pressure on local semiconductor supply chains, particularly in power devices like MOSFETs, where lead times are worsening.

With Malaysia contributing to 13.5% of global semiconductor testing and packaging capacity, any further labor constraints could trigger new global supply bottlenecks.

Our Strength: High-Speed, Integrated PCBA Equipment & Services

At Fast Turn PCB, founded in 2015, we focus on delivering quick-turn, high-end PCB samples and small-to-medium batch PCBA services. We offer end-to-end solutions from PCB design to procurement and final assembly—all under one roof.

Here’s a closer look at our core PCBA equipment and production capabilities:

SMT (Surface Mount Technology) Assembly Lines

High-speed Pick-and-Place Machines (Yamaha, Juki, ASM)

Supports ultra-fine components like 01005, BGA, QFN with precision placement.

Solder Paste Inspection (SPI)

Ensures solder paste quality before reflow.

10+ Zone Reflow Ovens

Lead-free and leaded solder profiles with precise thermal control.

DIP Insertion & Wave Soldering

Automatic Wave Soldering Systems

Ideal for large components and through-hole assemblies.

Selective Soldering Machines

Suitable for complex and mixed-technology boards.

Advanced Inspection & Quality Control

AOI (Automated Optical Inspection)

Detects component misalignment, polarity, tombstoning, etc.

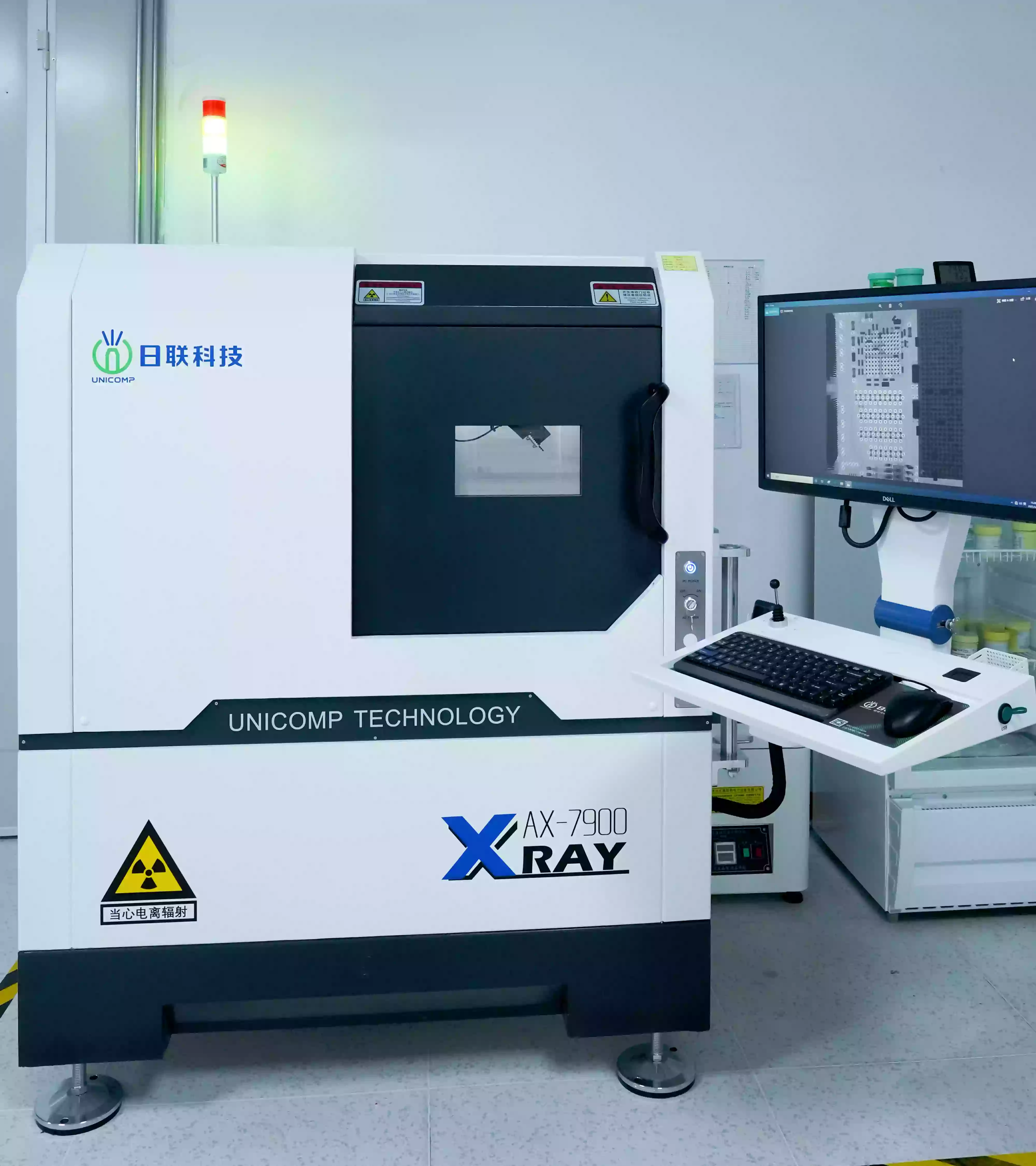

X-Ray Inspection System

For invisible solder joints such as BGA, LGA, QFN.

Functional Testing (FCT)

Customized to customer requirements, ensuring electrical performance.

One-Stop PCBA Services from Design to Delivery

| Service Module | Scope | Lead Time |

|---|---|---|

| PCB Design | Stack-up design, impedance calculation | Free Support |

| PCB Manufacturing | 1–48 layers, blind/buried vias, up to 12 oz copper | 24h turnaround |

| BOM Procurement | Fast global sourcing | Within 3 days |

| PCB Assembly | Prototypes & batch assembly | 1–3 days |

| Functional Testing | Custom test fixtures and protocols | Upon request |

| Global Logistics | International delivery support | Rapid shipment |

We Support a Wide Range of PCB Types:

Single-sided, Double-sided, Multilayer (up to 48 layers)

Rigid PCBs, Flexible Circuits, Rigid-Flex Boards

HDI Boards, Aluminum Substrates, High-Frequency Boards

Why Choose Us?

✅ Fast Delivery: 1–3 day turnaround for PCBA prototypes and small batches

✅ End-to-End Integration: From design, sourcing, to testing and delivery

✅ Smart Factory: MES-enabled production with full traceability

✅ Zero-Defect Quality Assurance: AOI + X-ray + FCT inspections throughout

✅ Dedicated Engineering Support: DFM reviews and layout optimization included

Final Thoughts

In a world of supply chain disruption and labor uncertainty, your choice of PCBA partner matters more than ever. At Fast Turn PCB, we combine speed, precision, and full-process integration to support your product innovation from idea to delivery.

📩 Contact us today to request a free DFM review, sample quote, or arrange a factory tour!