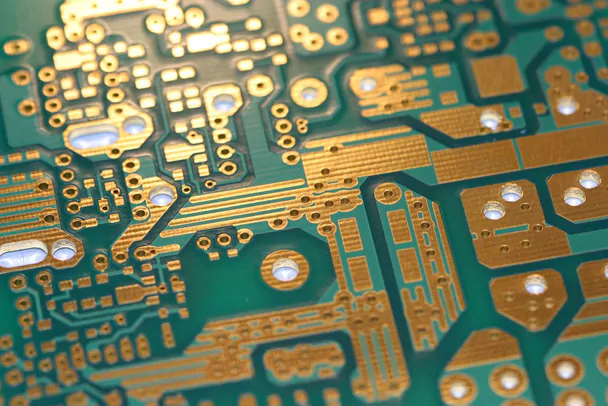

At Fast Turn PCB, we specialize in delivering cutting-edge surface treatment solutions that enhance the reliability and performance of your printed circuit boards (PCBs). One of our core competencies is Gold Finger plating, powered by the Electroless Nickel Immersion Gold (ENIG) process. This technology is essential for PCBs used in telecommunications, automotive electronics, medical equipment, and industrial control systems.

What Are Gold Fingers?

Gold Fingers are the gold-plated edge connectors found on PCBs. These serve as critical contact points between PCBs and their mating connectors, and must offer superior durability, conductivity, and corrosion resistance. Fast Turn PCB uses industry-proven ENIG surface finish to ensure every gold finger meets IPC standards and rigorous inspection criteria, such as:

No visible scratches or gouges

No discoloration or oxidation

No plating delamination (peel test compliant)

No surface contamination (e.g., adhesive or residue)

No dents or pits, especially in critical contact areas

No exposed copper

Why ENIG for Gold Fingers?

1.Excellent Solderability and Bonding

Our ENIG process creates a uniform gold layer over a nickel base, resulting in:

Strong, reliable solder joints

High production yield with fewer soldering issues

Consistent performance across batches

2.Exceptional Corrosion Resistance

The nickel layer acts as a barrier to oxidation, while the gold layer provides additional protection from humidity, moisture, and environmental exposure—perfect for aerospace, military, and medical electronics.

3.Reliable Electrical Conductivity

Gold offers one of the highest levels of electrical conductivity. Our ENIG-plated gold fingers ensure:

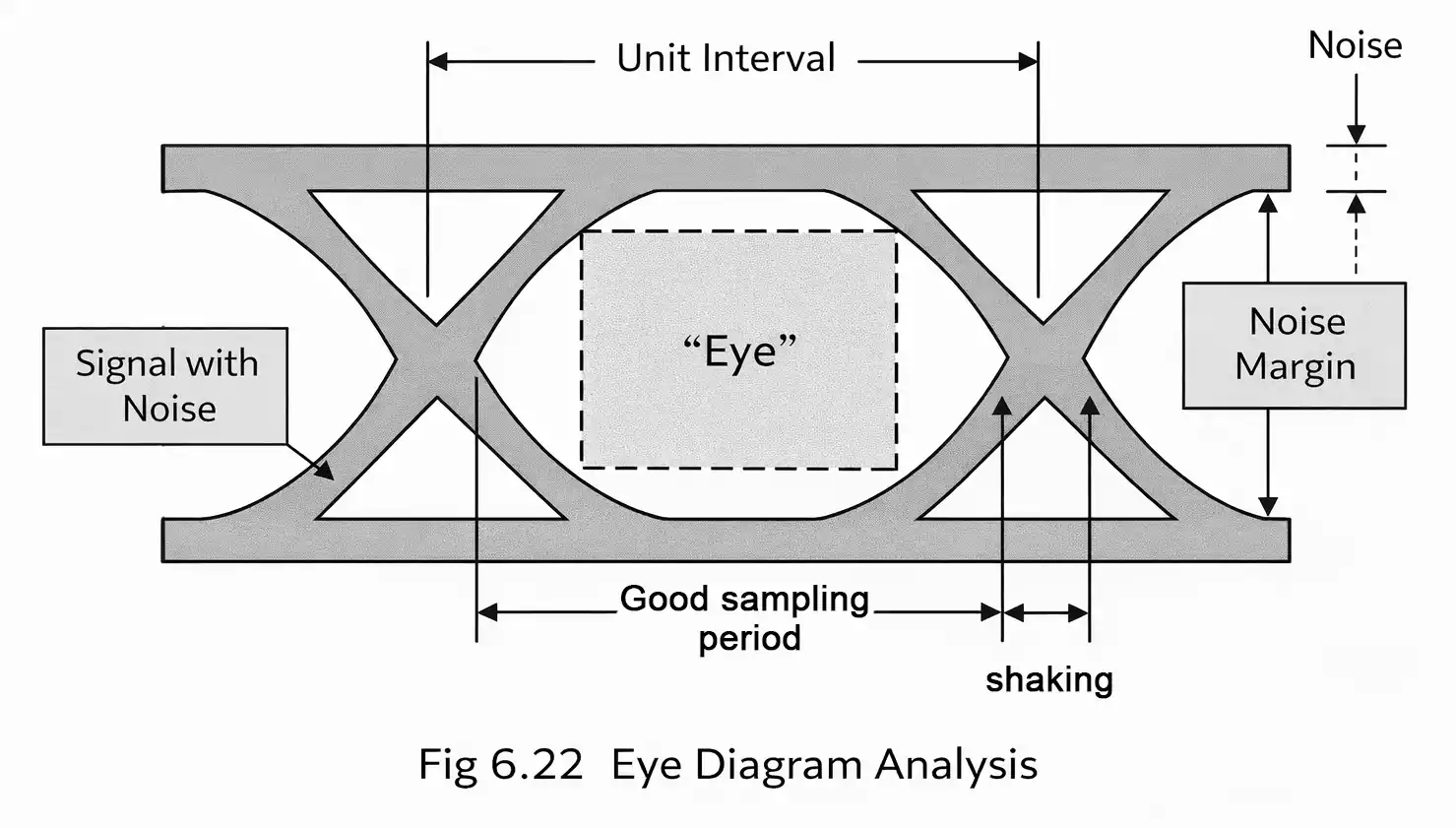

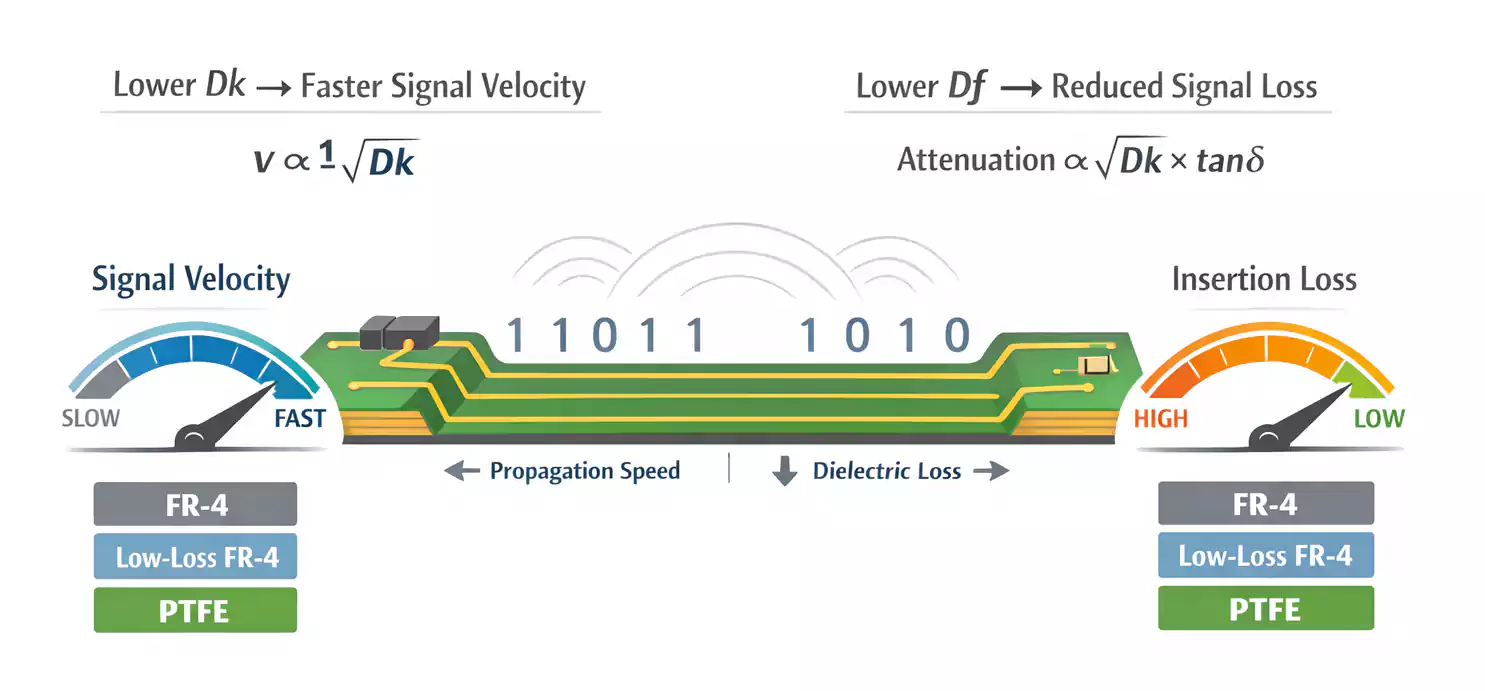

Stable signal transmission

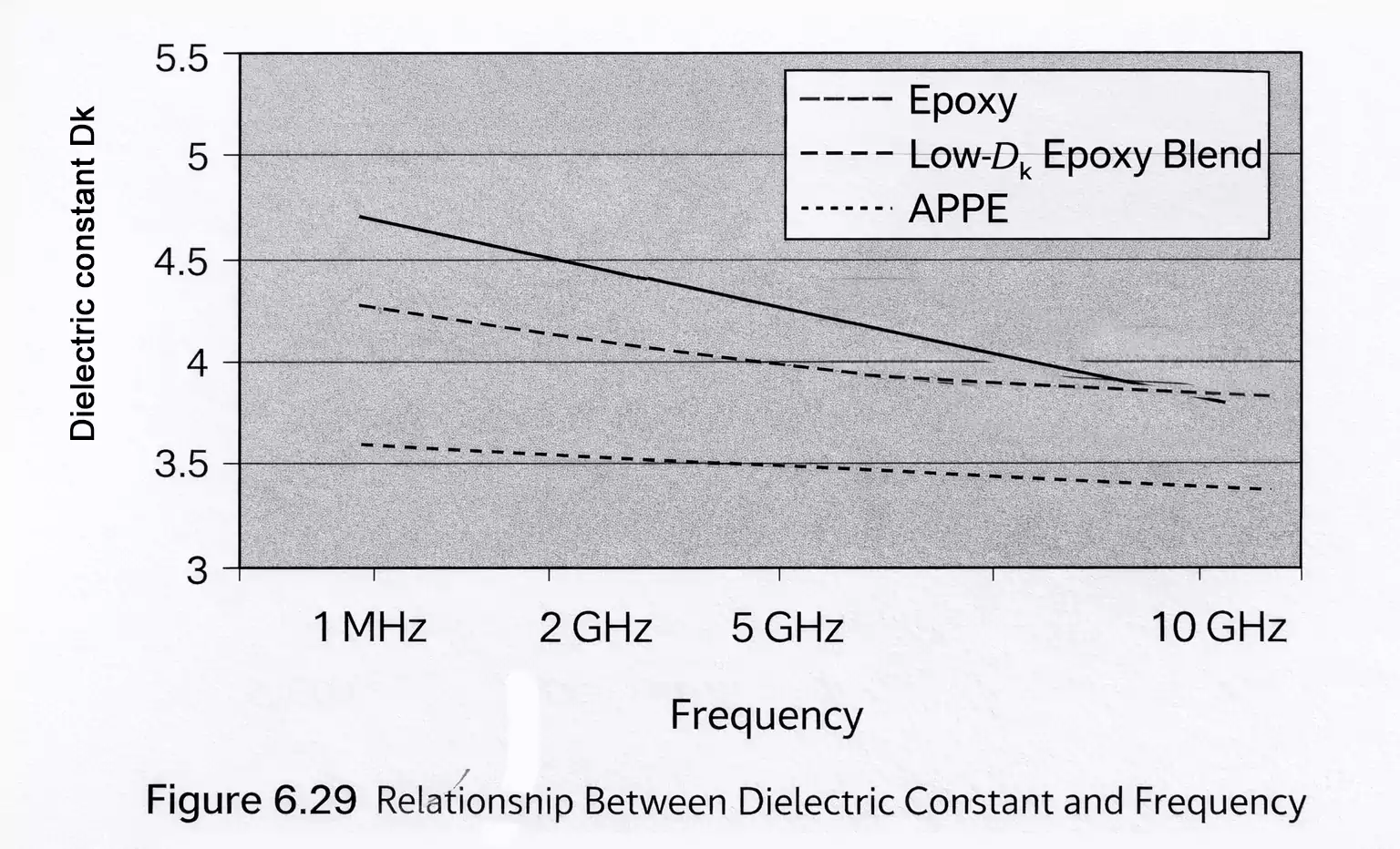

Minimal signal loss in high-frequency circuits

High performance in data-intensive applications

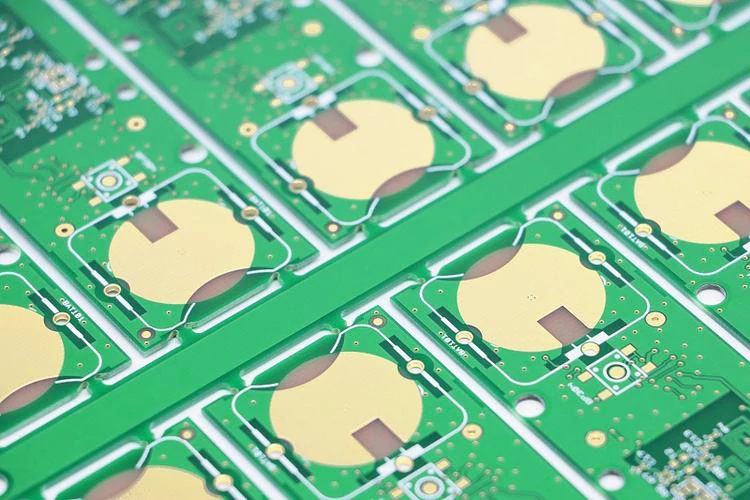

4.Flat, Clean, and Professional Surface Finish

The ENIG process ensures a smooth, bright, and flat finish that:

Supports automated assembly

Enhances insertion/removal durability

Reflects the high-quality manufacturing standard of Fast Turn PCB

Why Choose Fast Turn PCB?

✅ Expertise in ENIG & Gold Finger Processing

✅ Full compliance with IPC-A-600 inspection standards

✅ Fast turnaround with high precision and quality control

✅ 100% inspection for defects like copper exposure, surface contamination, delamination, and scratches (as per visual and magnified inspection guidelines)

Applications of Gold Finger PCBs

Gold Finger PCBs are widely used in:

Motherboards and graphics cards

Industrial controllers

High-speed data and communication devices

Consumer electronics requiring frequent insertion/removal

Partner with Fast Turn PCB for High-Performance Gold Finger Solutions

If your product demands high-reliability edge connectors and superior electrical performance, Fast Turn PCB is your trusted partner. Our ENIG process and gold finger expertise ensure your PCBs meet the most stringent technical and quality standards.

📩 Contact us today to learn more about our advanced surface finishing services and request a quote!