PCB Screw Terminal Blocks Explained: Types, Sizes, Pros & How to Choose

Discover what PCB screw terminal blocks are, how they work, key types, sizes, pros vs soldering, and how to choose the right one—with clear FAQs.

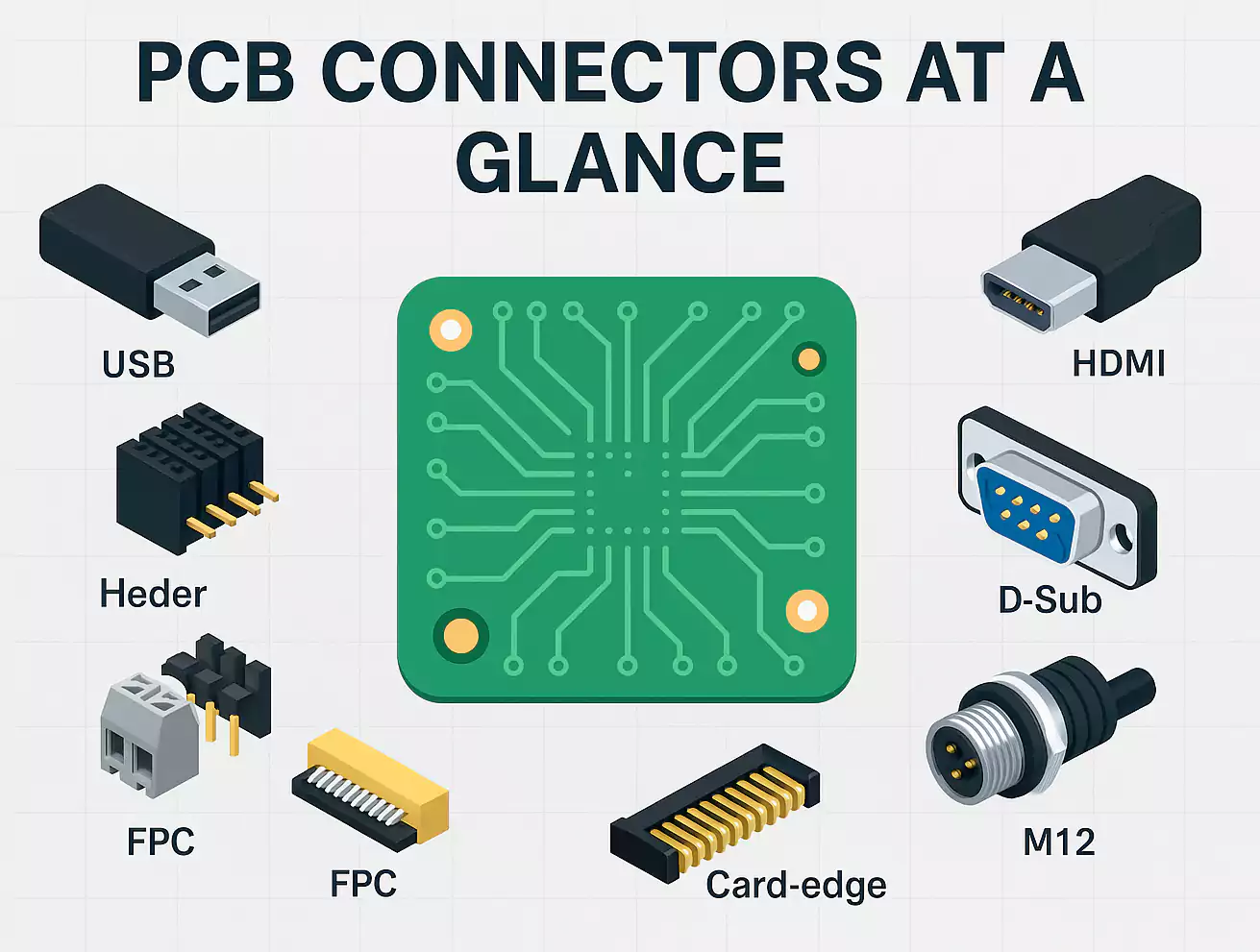

PCB Connectors Explained: Types, Edge vs Board-to-Board, and How to Choose the Right One

Practical PCB connectors guide: learn edge, board-to-board (BTB), wire-to-board (WTB), FPC and pogo types, plus quick selection tips to help you pick the right connector fast.

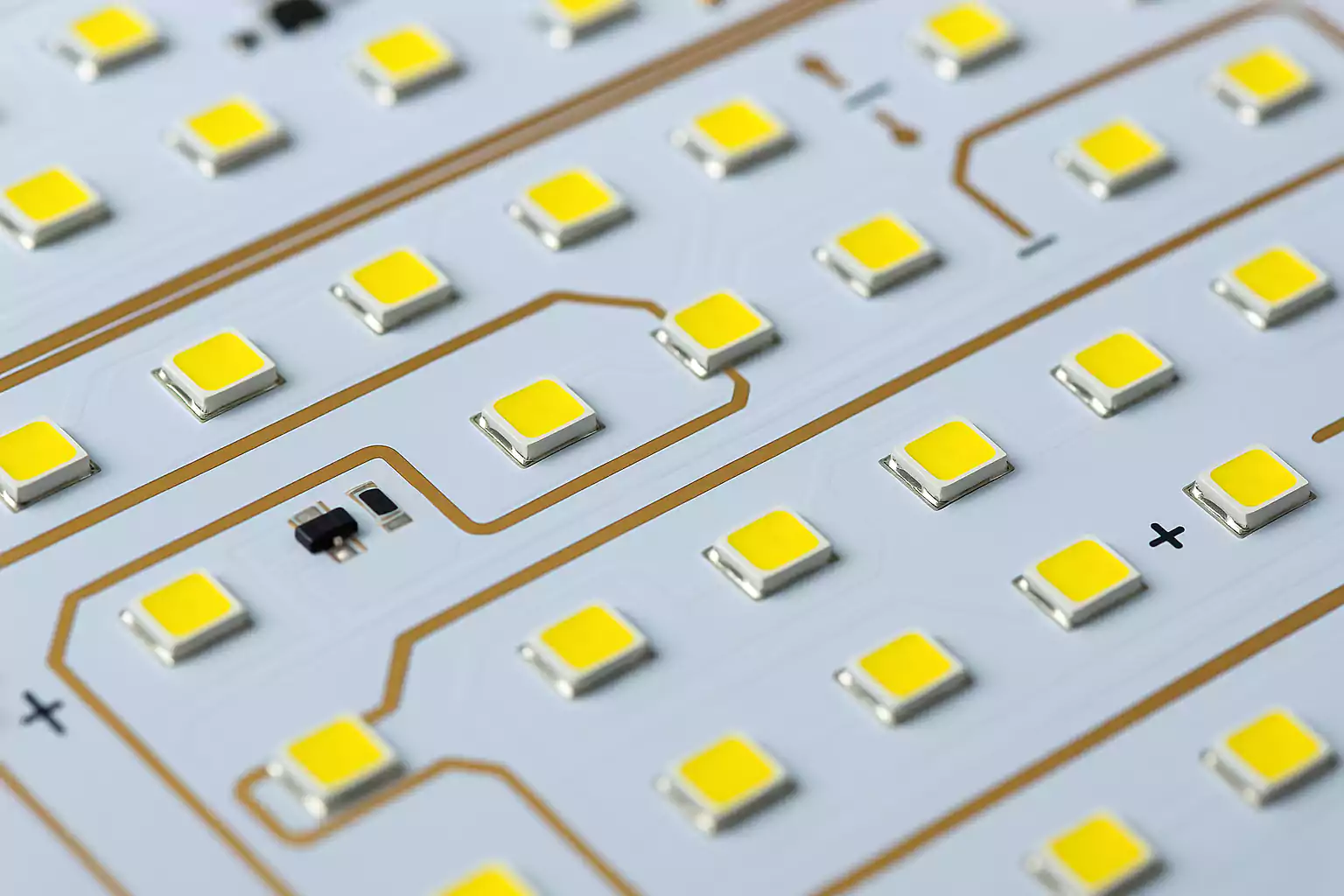

LED PCB Board Guide: Types, Design Tips, and How to Pick the Right One

Discover what an LED PCB board is, why aluminum MCPCBs are best for heat, and how to choose the right type for your LED lighting project. Simple guide with design tips, specs, and FAQs.

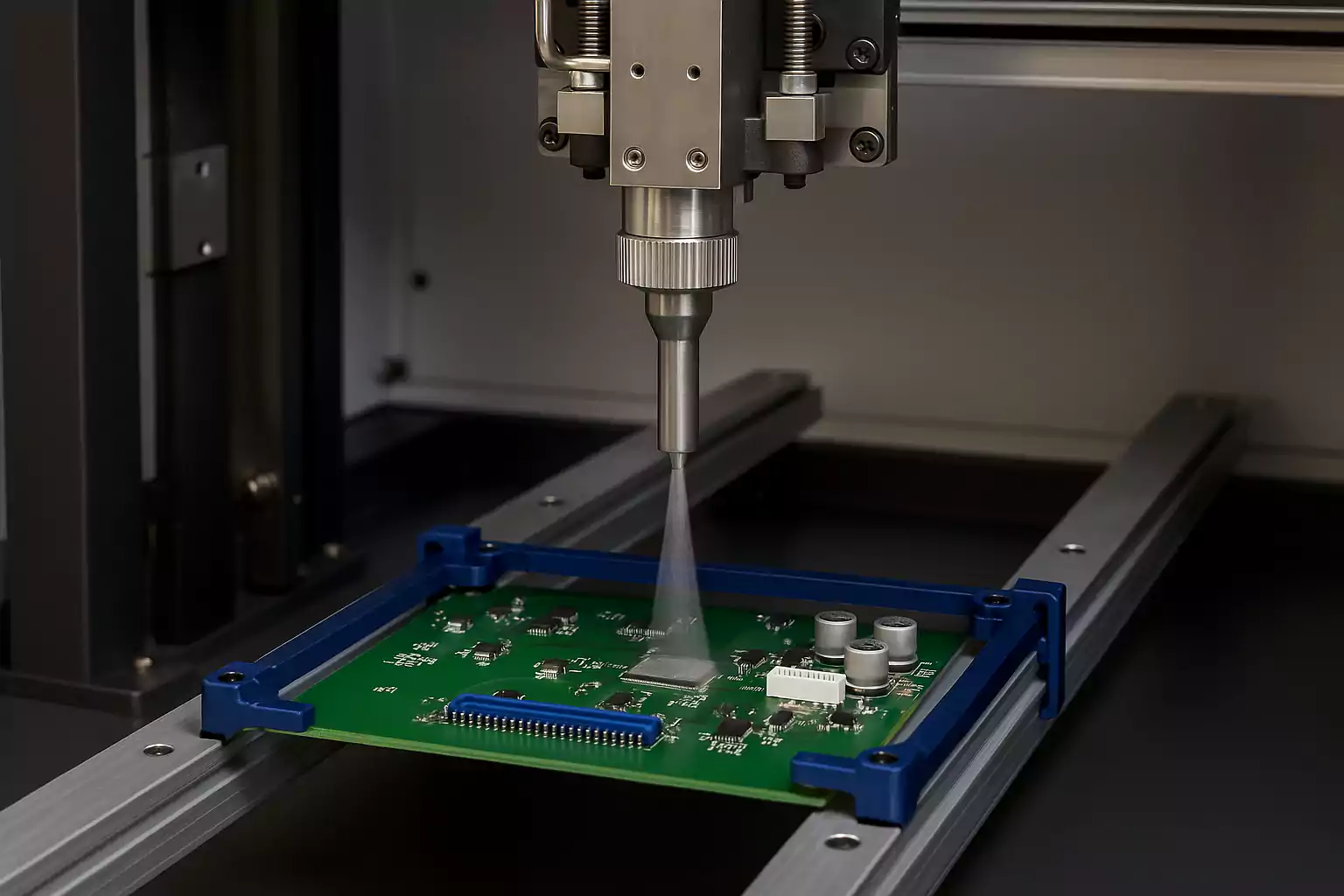

PCB Coating Guide for PCB Printer Users: Best Materials, Spray Methods, and Troubleshooting Tips

Discover the complete guide to PCB coating: learn the best coating types (acrylic, silicone, urethane, parylene), how to apply them (spray, dip, selective), ideal thickness, common defects, and how to choose the right protection for your circuit boards. Clear comparisons and expert tips inside!

Best PCB Testing Methods Explained: ICT, Flying Probe, FCT & More

Discover the best PCB testing methods—compare ICT, Flying Probe, AOI, FCT, costs, coverage, and when to use each. Clear guide for engineers & buyers.

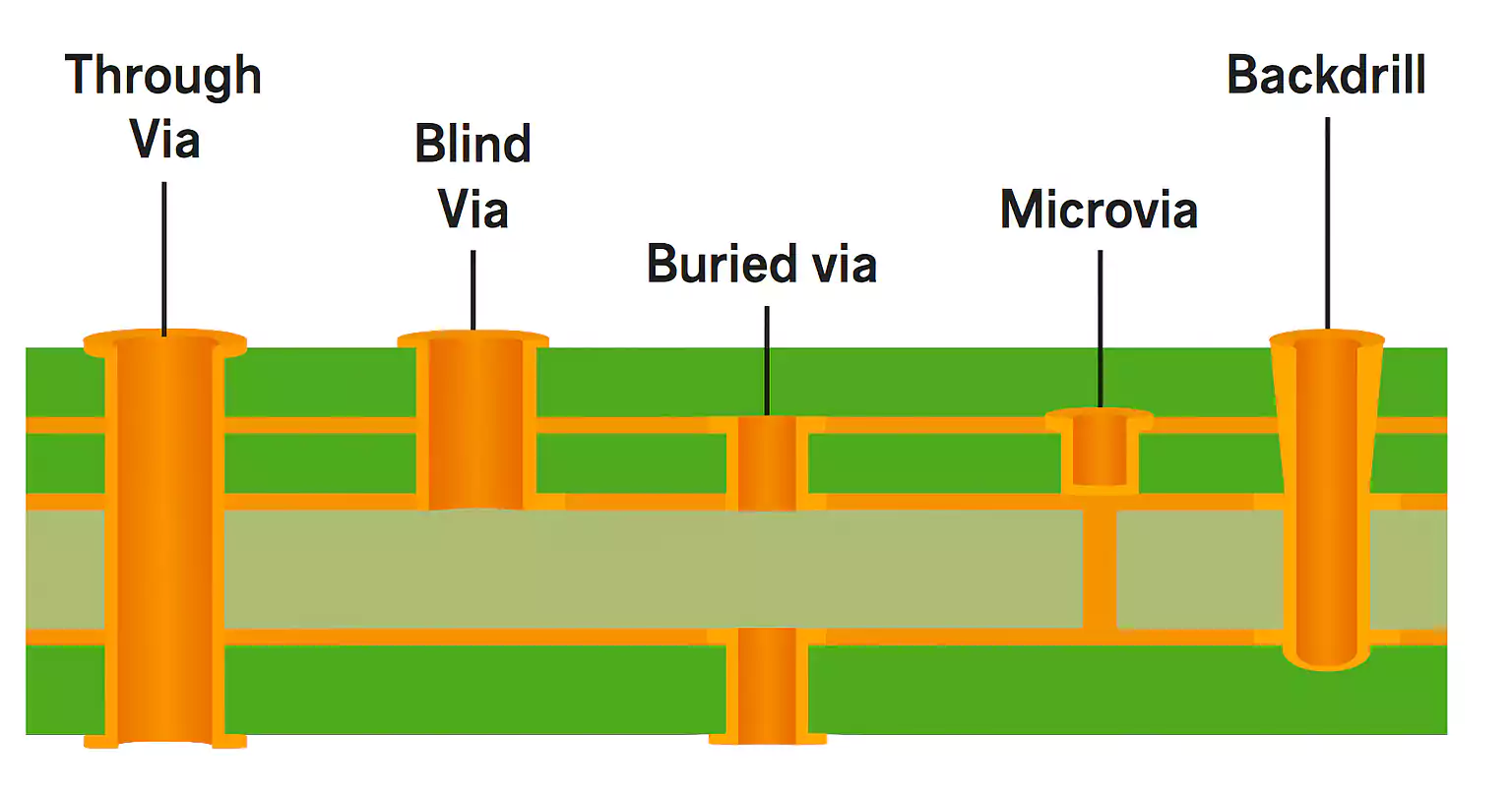

PCB Via Guide (2025): Types, Sizing, Aspect Ratio & Tenting — The Complete, Easy Guide

Quickly master PCB via design: types, sizing, aspect ratio, tenting & reliability — practical tips to avoid manufacturing mistakes and speed up your HDI builds in 2025.

PCB Printer & Thickness Guide (2025): How to Choose Standard PCB Thickness, Tolerances & Get Perfect Prints

PCB Printer & Thickness Guide — how PCB printers pick standard PCB thicknesses, tolerances, and stack-ups. Clear 3-step method, quick chart, and ordering checklist to get perfect boards.

PCB Printer Guide: PCB Layers & Stack-Ups Explained — How Many Layers to Use

Master PCB layers and stack-ups: when to use 2/4/6/8 layers, how to read stack diagrams, and how to identify layer counts. Practical tips for designers.

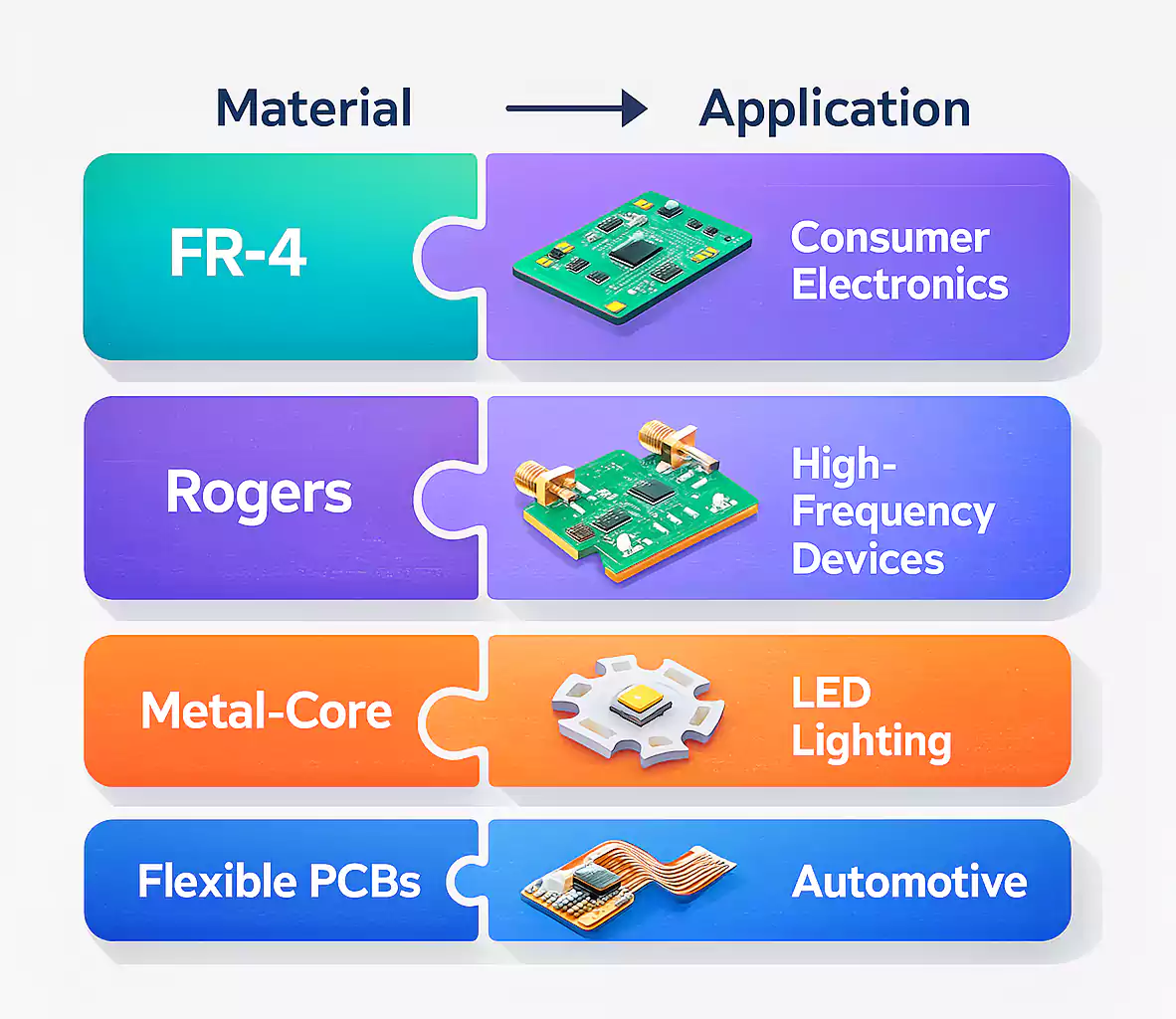

Ultimate PCB Material Guide: Types, Properties & How to Choose the Best PCB Material

PCB material explained: compare FR-4, Rogers, Polyimide, PTFE and metal-core. Learn Dk/Df/Tg differences, thermal and mechanical tradeoffs, and quick selection tips to pick the right substrate.

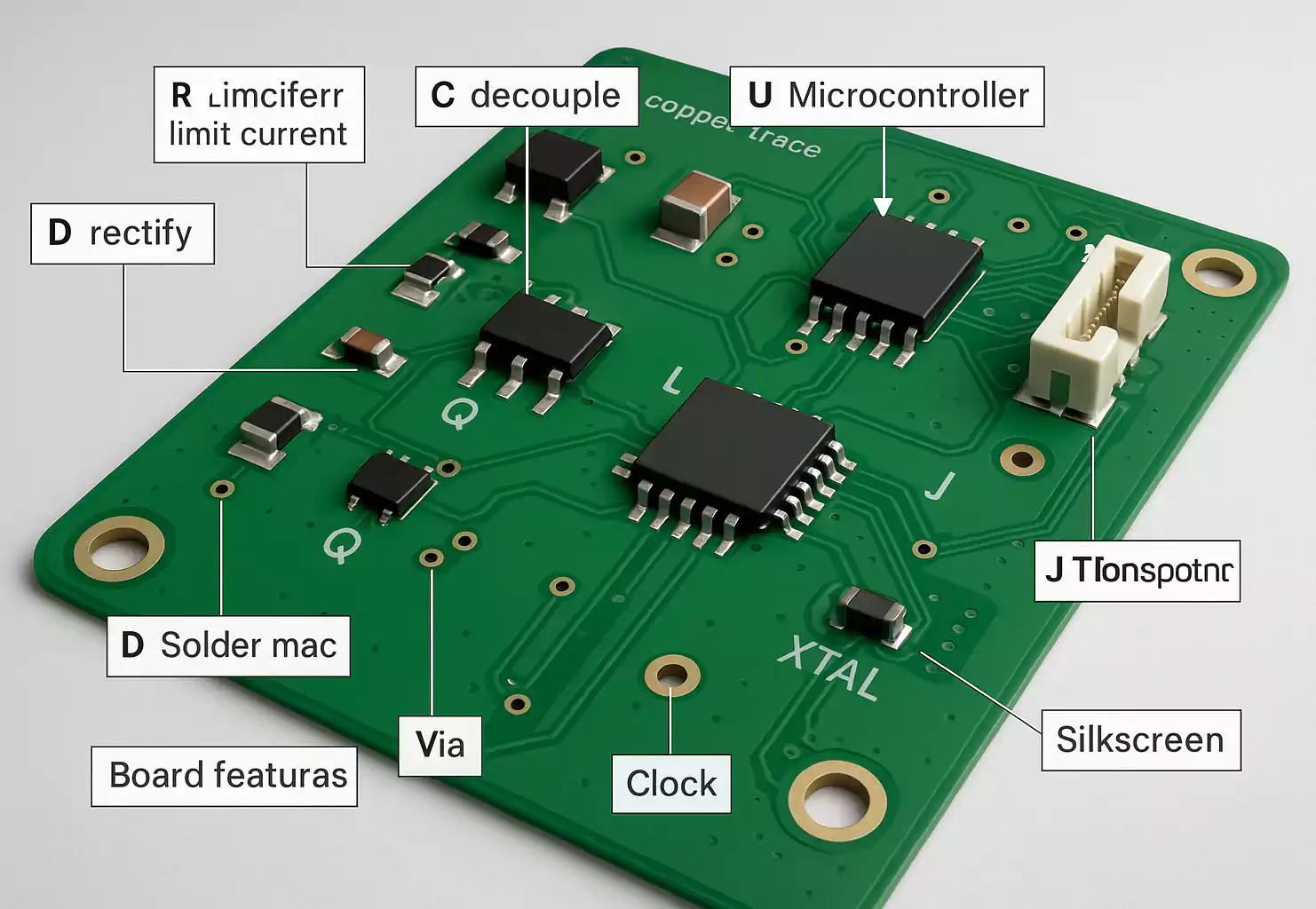

Parts of a PCB: Complete Beginner's Guide to Components

Learn the parts of a PCB—common components, board features, polarity tips, and quick ID tricks for beginners. A clear, image-friendly guide to help you identify, troubleshoot, and design circuits.

PCB Printer Buying Guide: Best Desktop Printers for Quick Prototyping

Looking to buy a pcb printer? This practical guide explains how PCB printers work, compares top desktop models, lists key specs, and helps you decide fast.

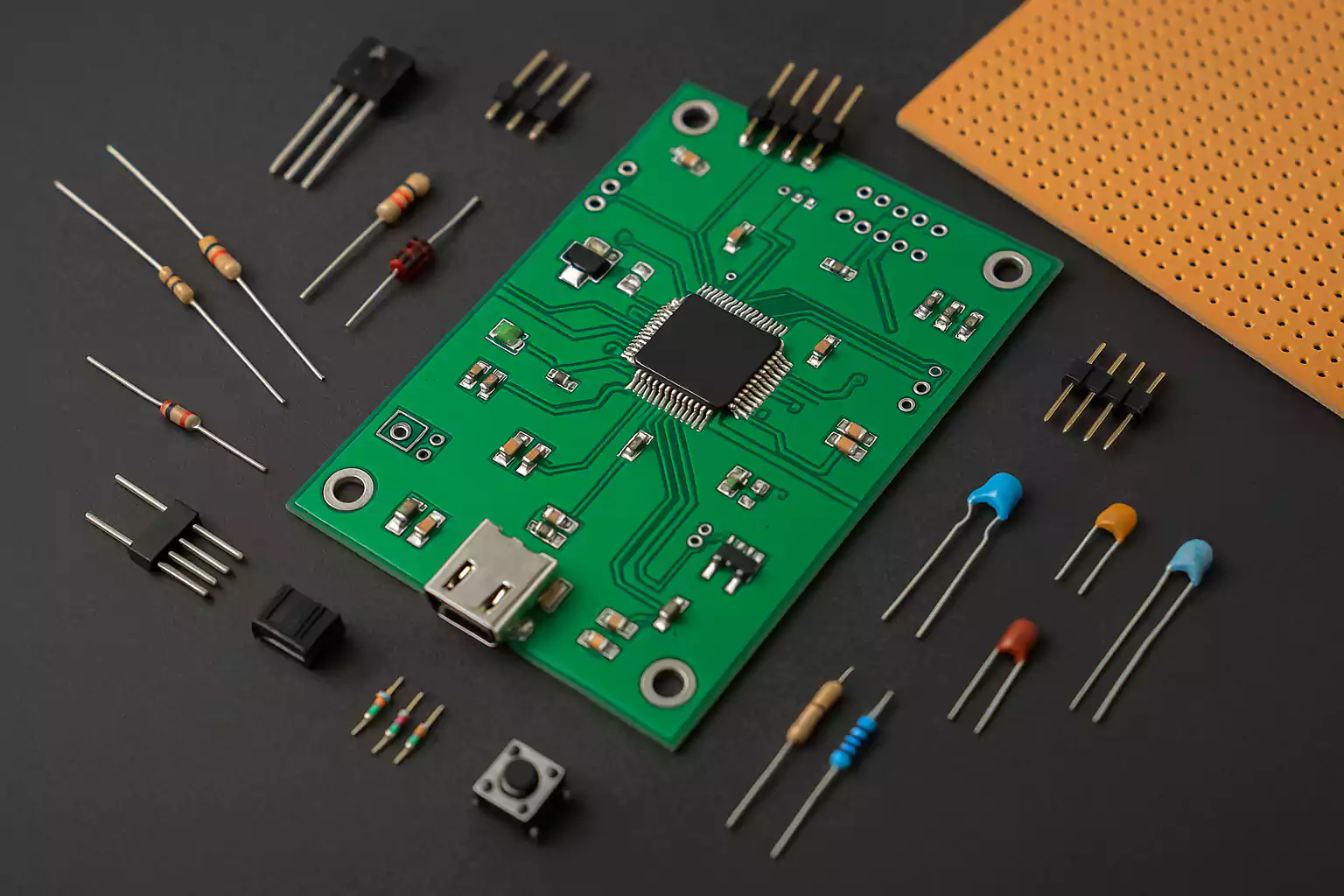

Blank PCB and Parts: The Ultimate 7-Step Guide to Buy, Build & Test

Turn Blank PCB and Parts into a working PCBA: a clear 7-step guide with parts list, sourcing & cost tips, assembly checklist, and fast prototyping advice.