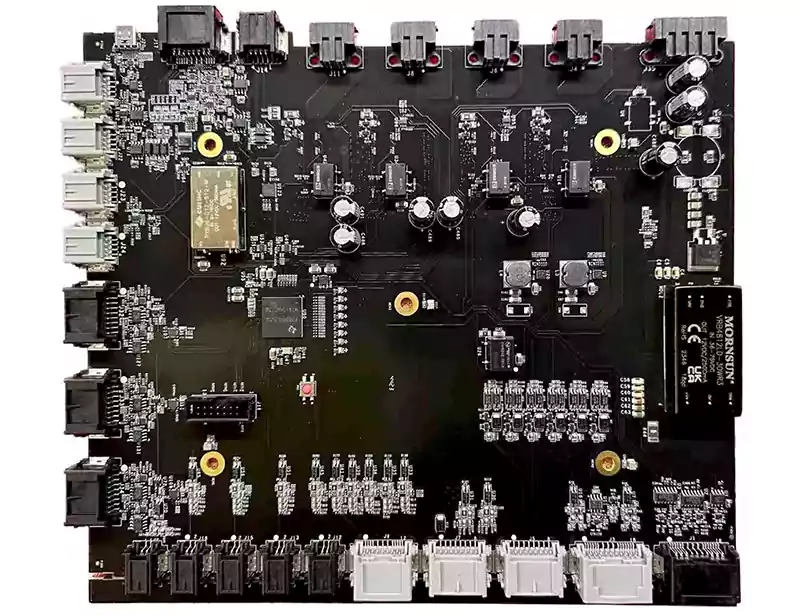

What Is a Black PCB? Black Solder Mask vs. Black Core FR-4, Pros, Cons, and Design Considerations

Learn what a black PCB is: black solder mask vs black-core FR-4, key pros and cons, AOI challenges, silkscreen readability, and ground-plane design tips.

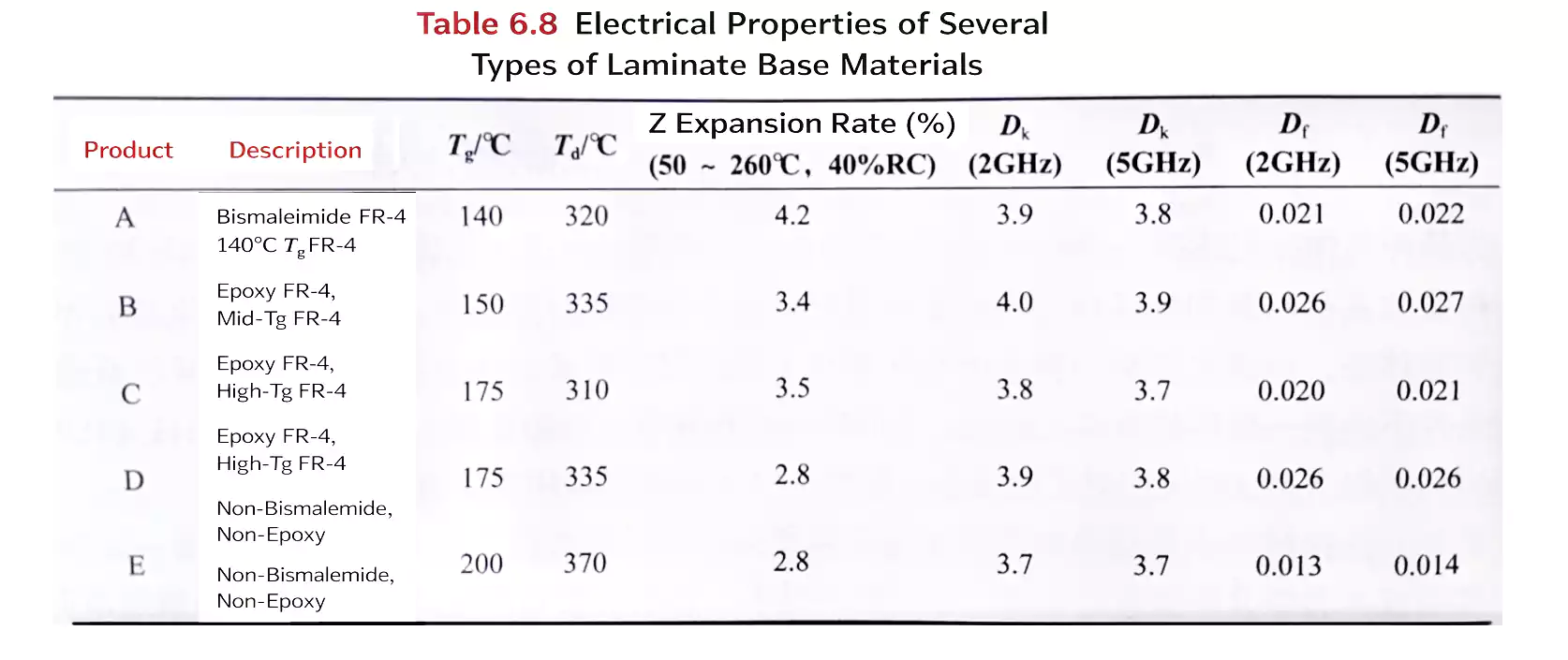

Lead-Free FR-4 Explained: High-Frequency Dk/Df for lead free solder

Understand lead-free FR-4 electrical performance for lead free solder: Dk/Df at GHz, phenolic vs DICY systems, resin content impact, and practical design tips.

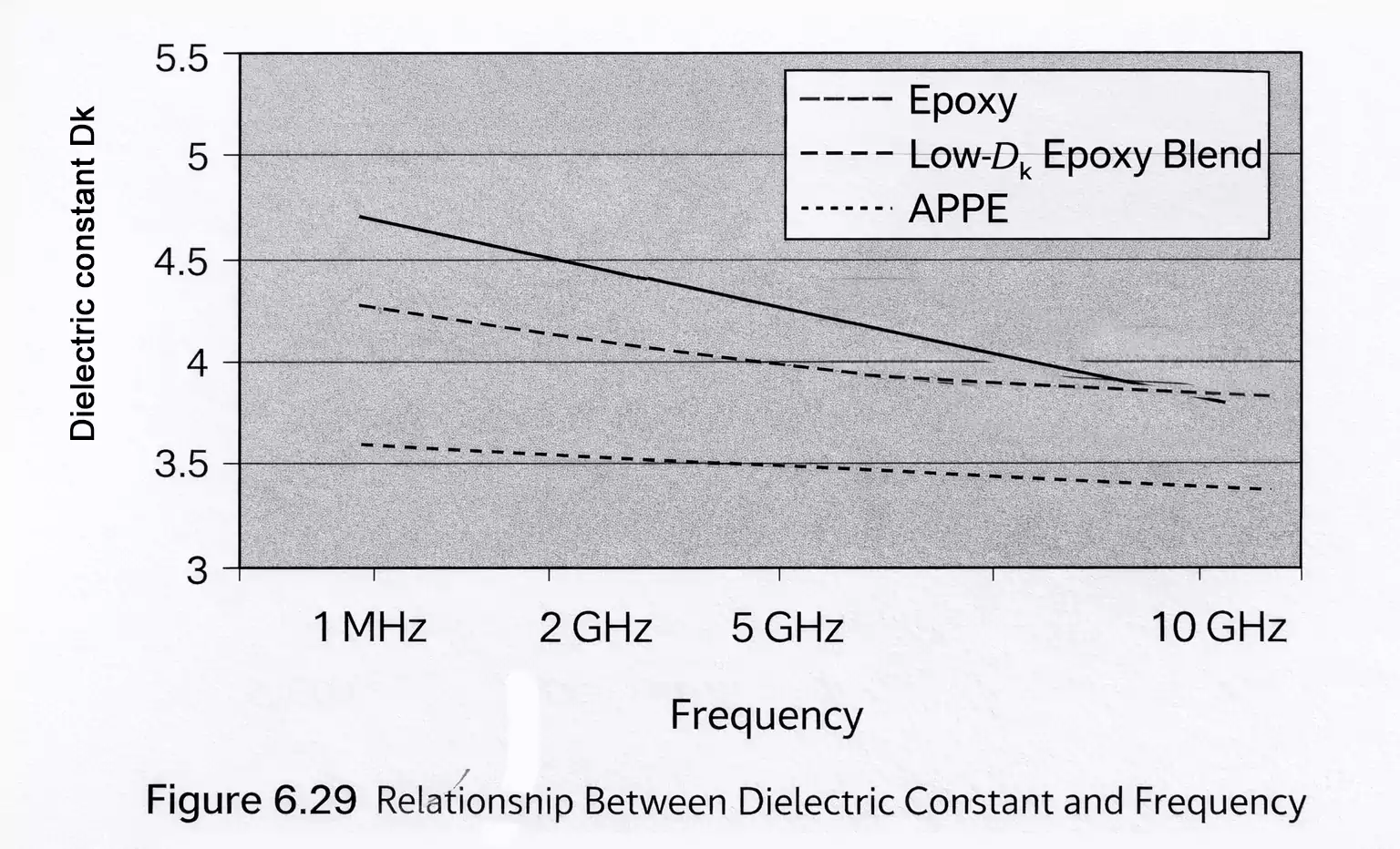

PCB Substrate Selection Guide: How to Choose the Best Material for High-Speed and RF PCB Performance

Choose the right PCB substrate for high-speed and RF designs. Understand Dk, Df, resin, reinforcement, moisture and frequency effects, plus cost and build trade-offs.

PCB Fabrication Low Cost Guide 2026: Save Without Sacrificing Quality

PCB fabrication low cost guide: smart choices on materials, thickness, finish, testing & lead time, plus 2026 supplier rankings—affordable boards without risk.

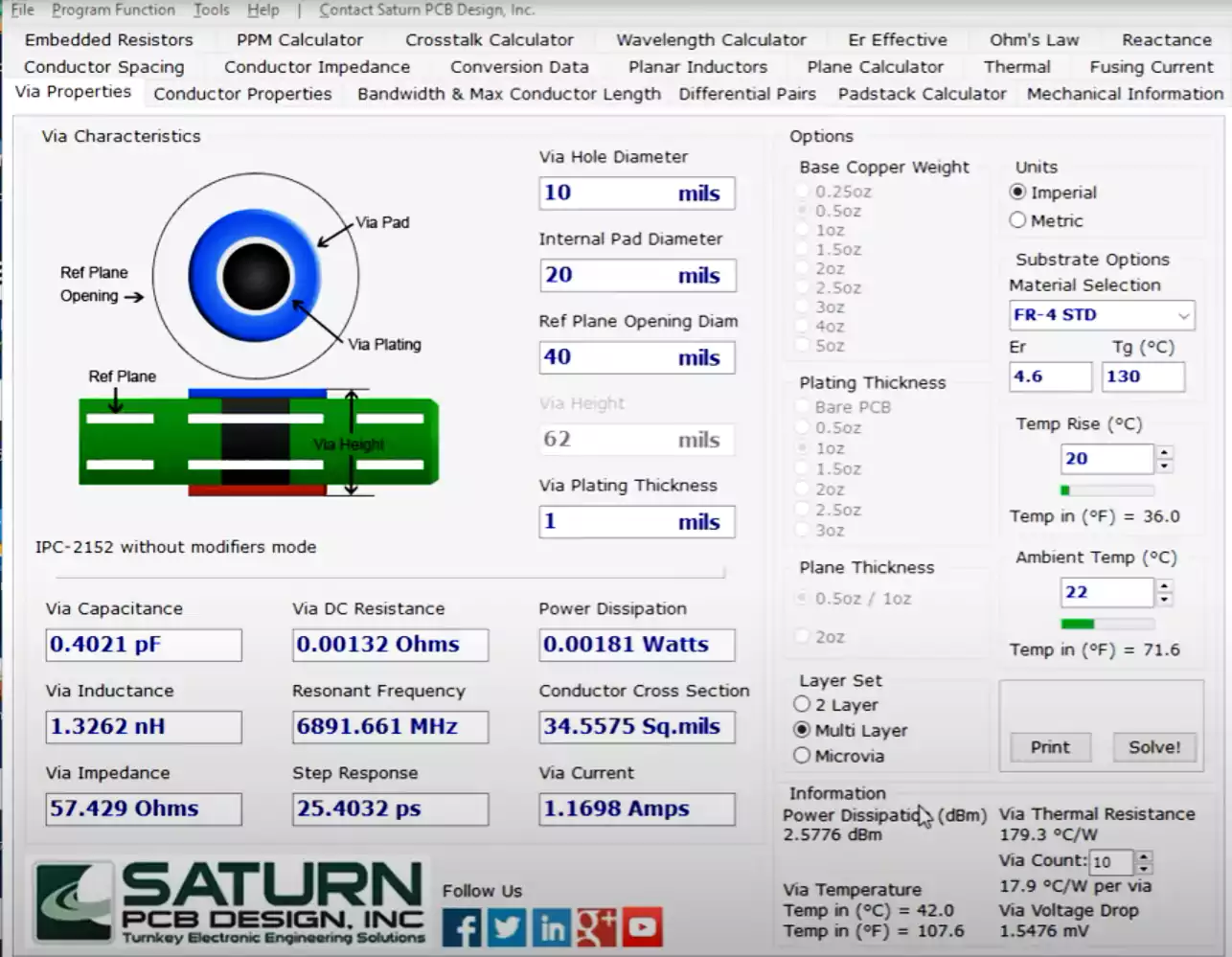

Saturn PCB Toolkit Guide: Impedance, Trace Width & Temp Rise

Learn how to use Saturn PCB Toolkit to calculate impedance, trace width, and temperature rise—plus fix Altium differences and avoid asymmetric stripline pitfalls.

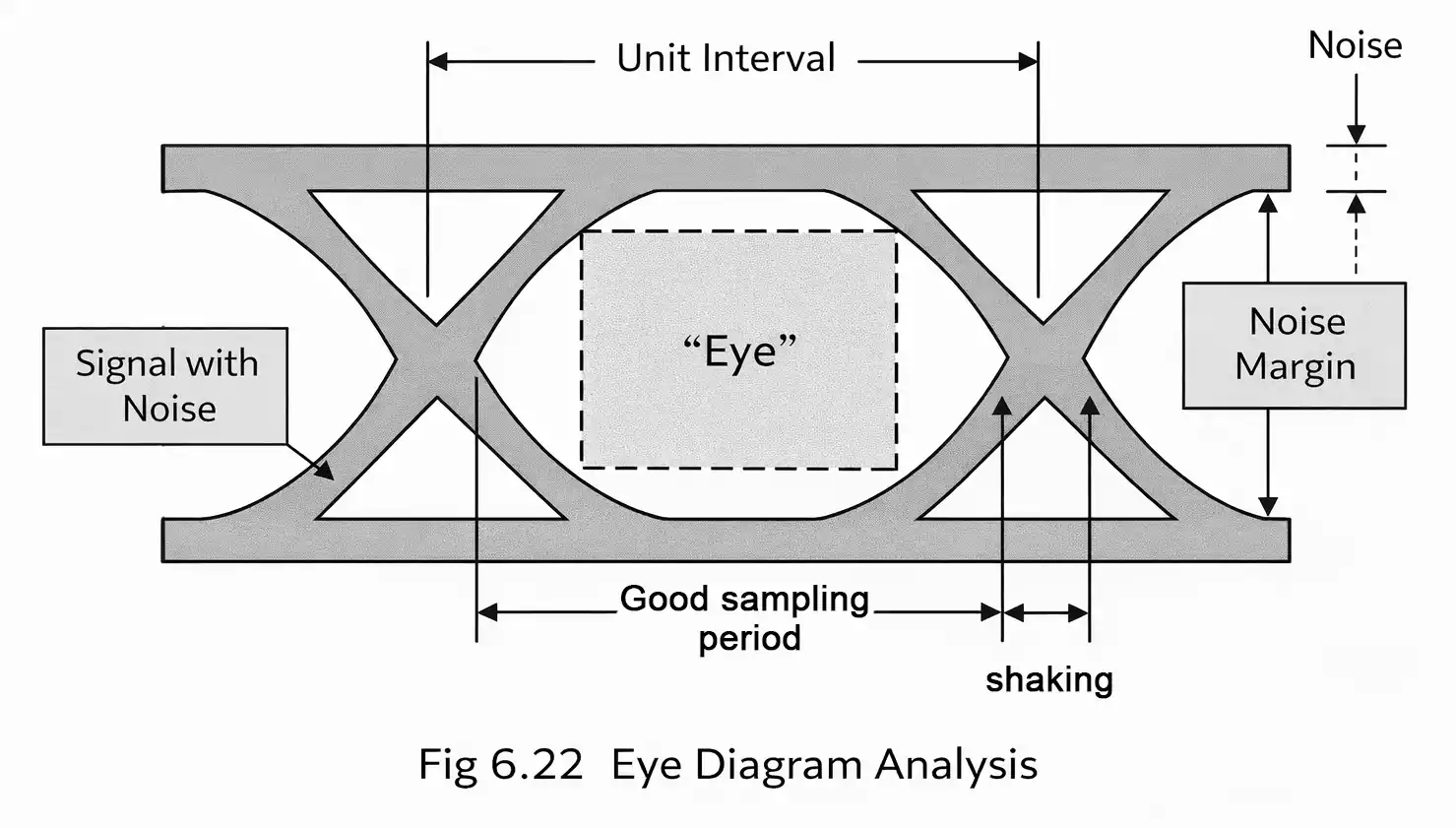

How PCB Dielectric Materials Impact High-Speed Signal Integrity: Rise Time, Eye Diagrams, and Loss Explained

How PCB dielectric materials (Dk/Df) shape high-speed signal integrity: rise time, bandwidth, eye diagrams and loss — plus material choices for 10+Gbps designs.

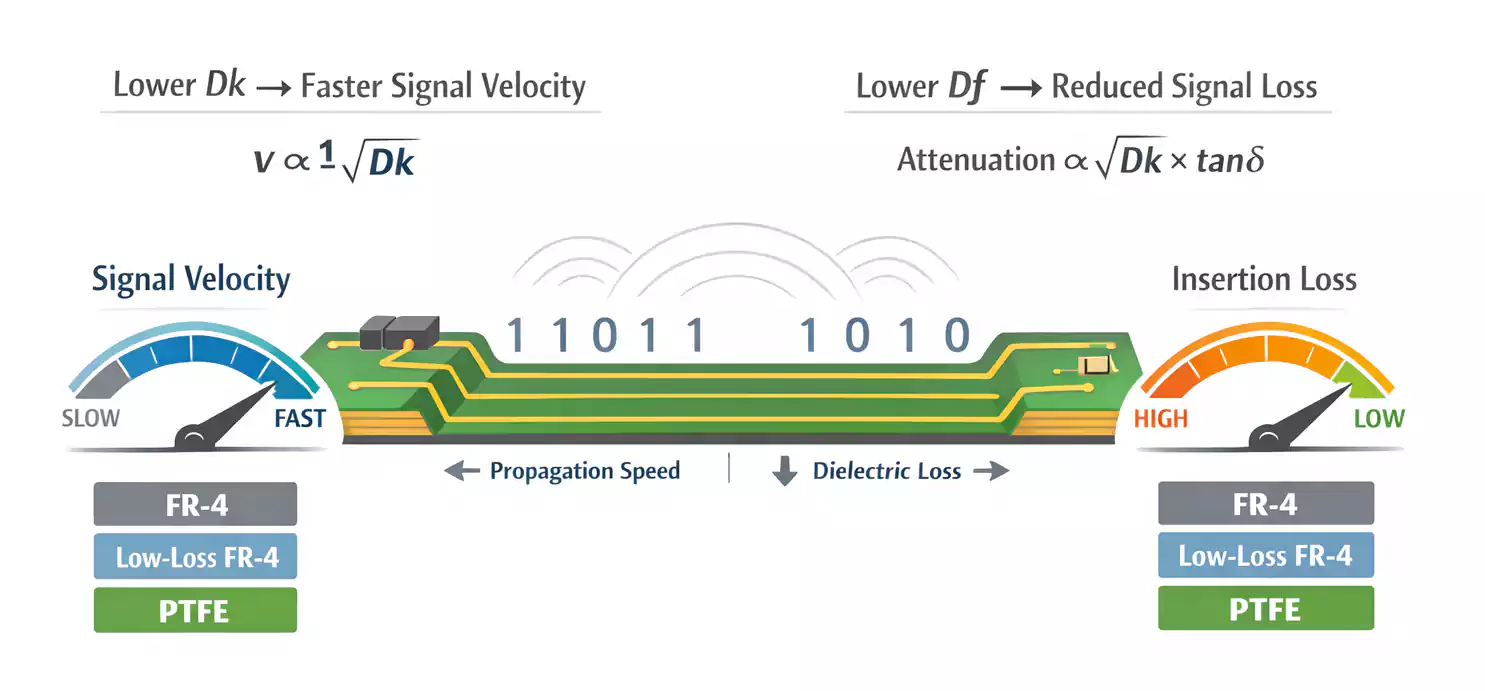

How Dielectric Constant and Dissipation Factor Impact High Speed PCB Design and Signal Integrity

Learn how dielectric constant (Dk) and dissipation factor (Df) impact high speed PCB signal integrity, loss, and design performance.

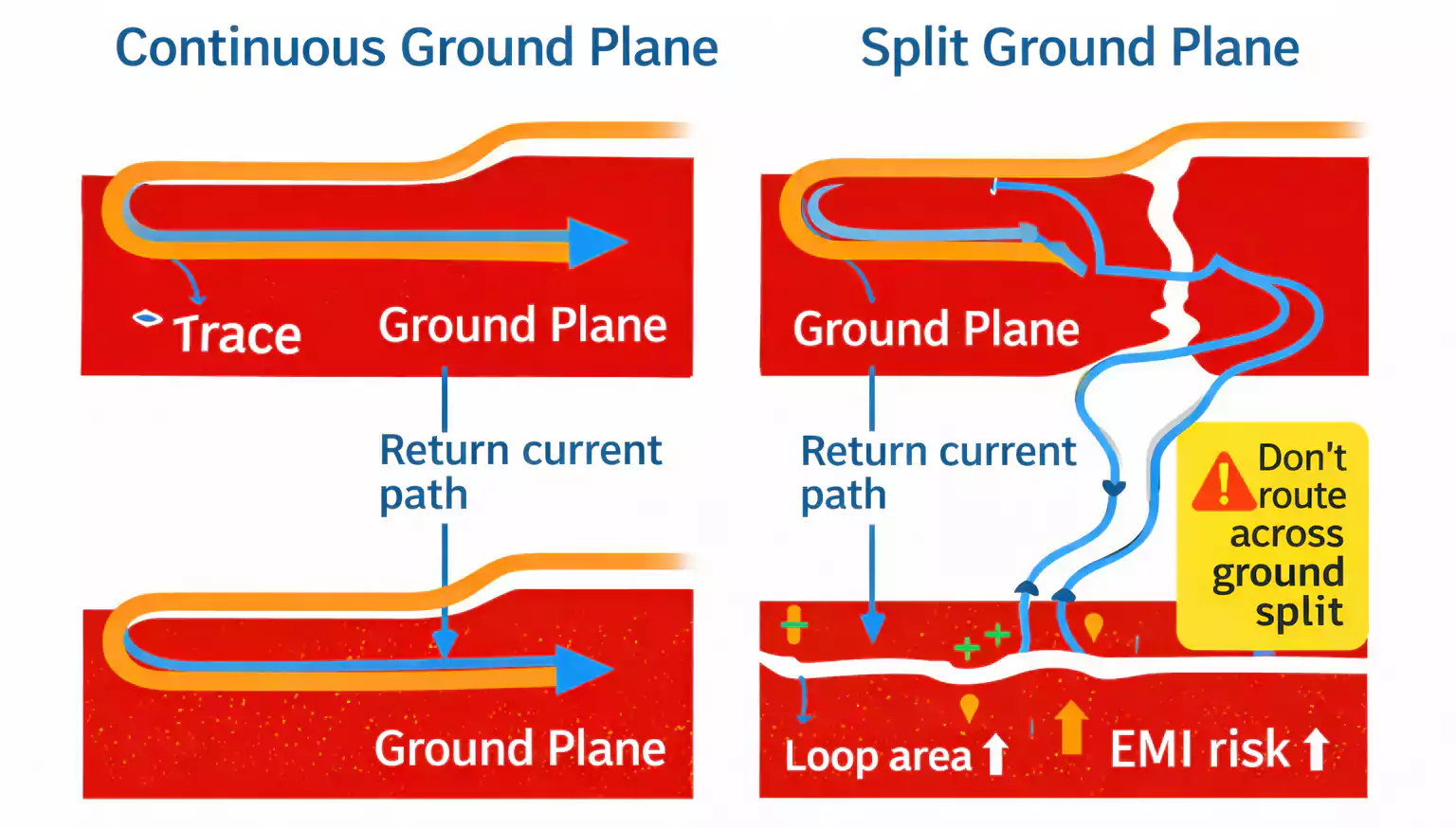

PCB Ground Plane Guide: Return Paths, Split Risks, EMI, and RF PCB Best Practices

Master PCB ground plane design—learn clear rules for return paths, avoid ground plane splits, fix EMI problems, and apply practical RF PCB tips to boost signal integrity and speed up debugging.

Quick Turn PCB & Assembly in the USA – 24–72 Hour Prototypes Done Right

Learn how to get reliable quick turn PCB and PCB assembly in the USA — 24–72 hour prototypes, turnkey options, practical DFM tips, and how to cut lead time without risking quality.

Arcade PCB Replacement & Reproduction Guide: JAMMA Compatibility, Buying Pitfalls, and Pac-Man/Arcade1Up Fixes

Learn how to replace or reproduce Arcade PCB with confidence — JAMMA compatibility, smart buying tips, common repairs, and step-by-step Arcade1Up Pac-Man fixes.

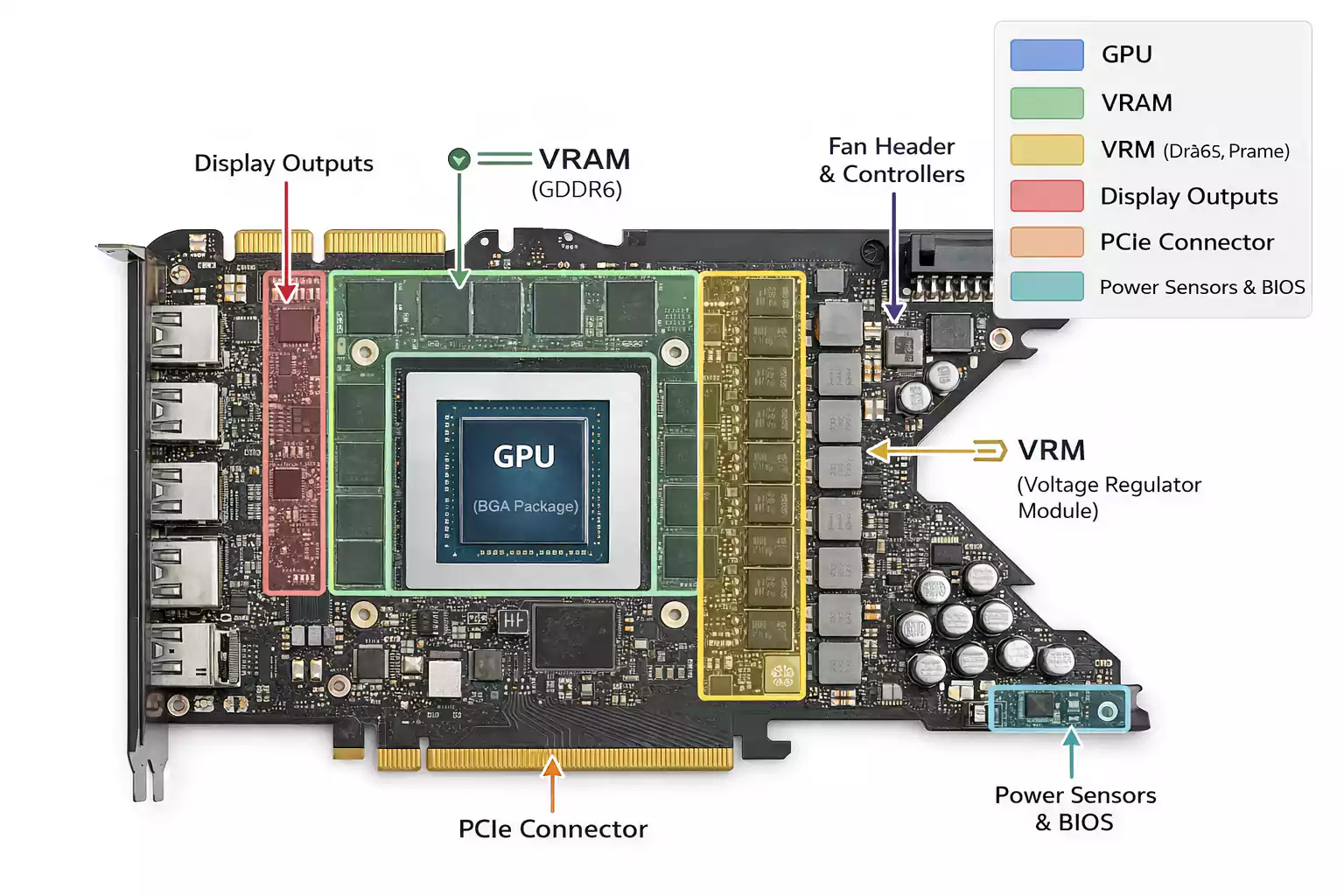

Graphics Card PCB Explained: Layers, Impedance, BGA Assembly & Thermal Design Guide

Discover how graphics card PCBs are engineered: layer stack-ups, impedance control, BGA assembly, and thermal solutions — plus real case notes and handy checklists.

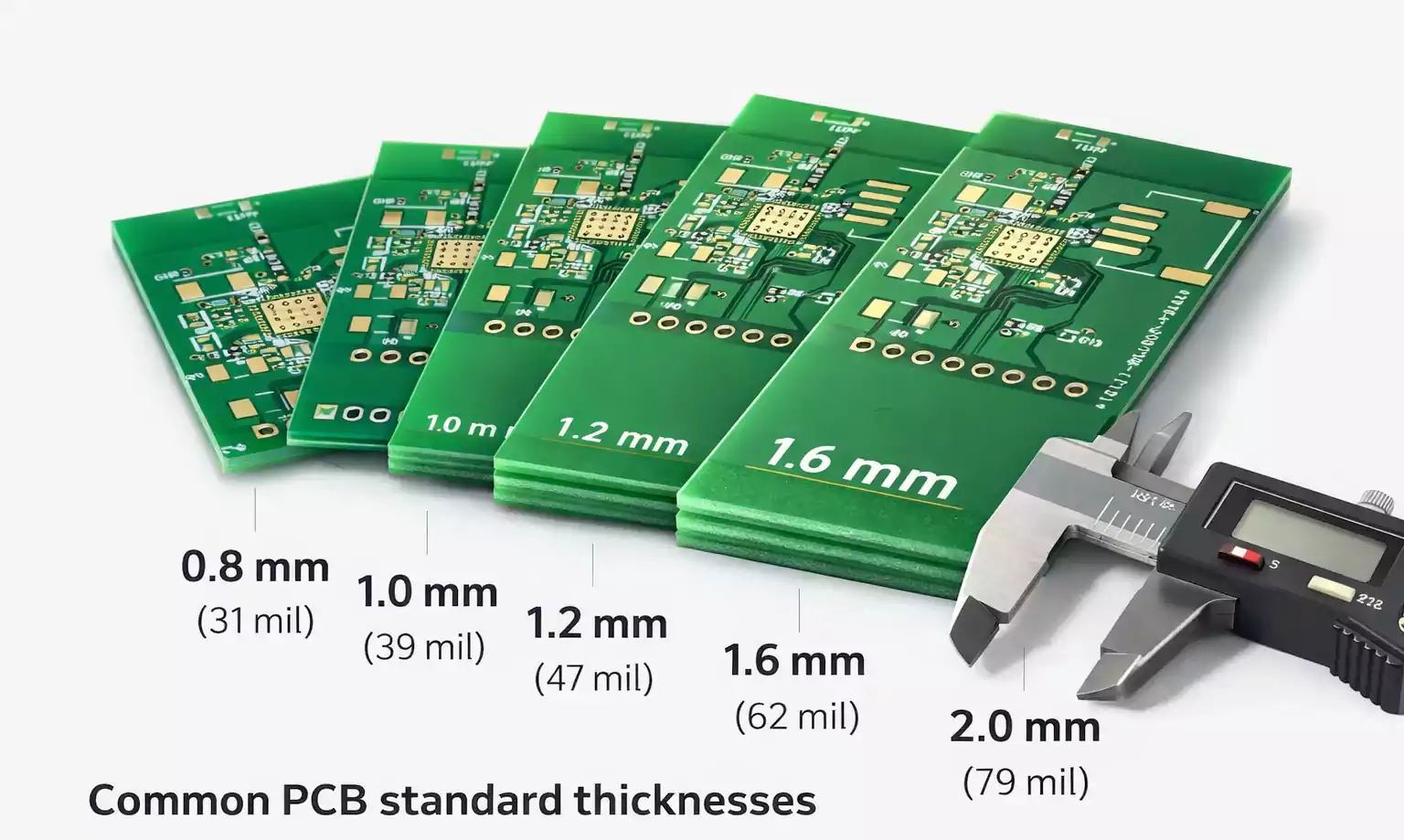

PCB Standard Thicknesses: How to Choose 0.8/1.0/1.2/1.6/2.0 mm for Cost, Impedance & Connector Fit

Choose the right PCB Standard Thicknesses: compare 0.8–2.0 mm options, applications, tolerances, stackup tips, and connector fit to reduce costs and accelerate production.