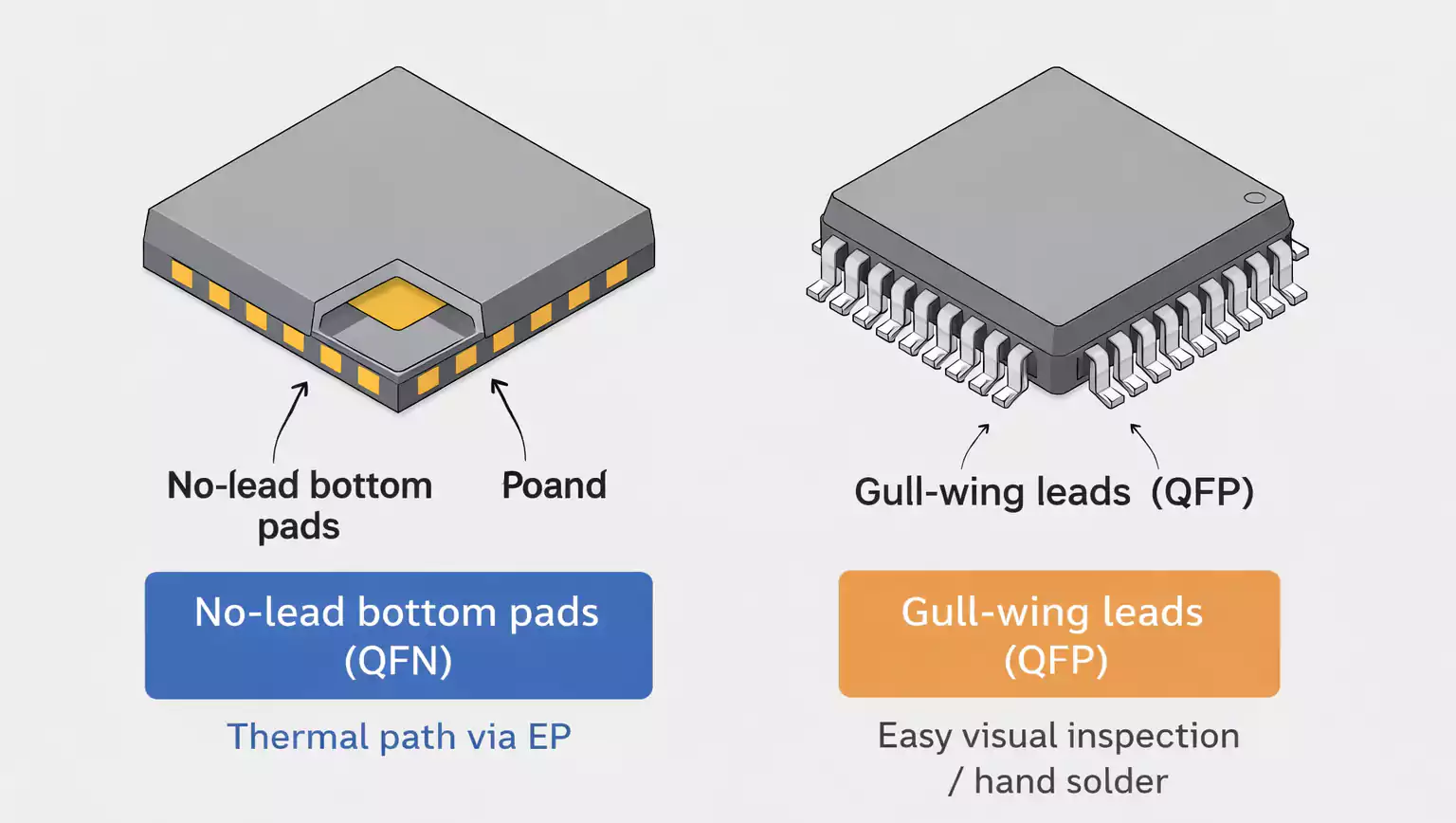

QFN Package Explained: Types, Structure, QFN With Lid, and How to Solder QFN Step-by-Step

Discover what a QFN package is, its types and structure, when to use a QFN with lid, and step-by-step tips on how to solder QFN packages perfectly.

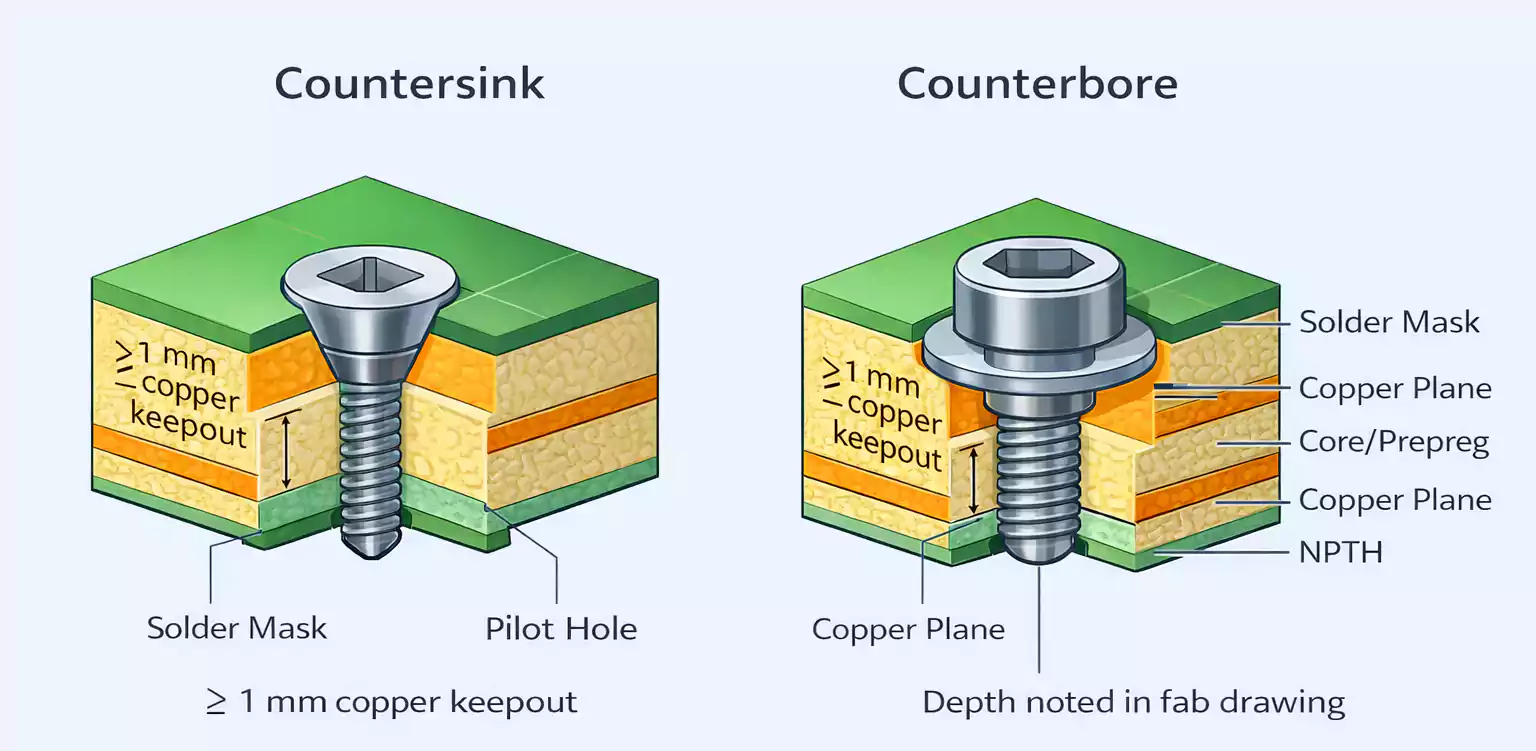

What Is a Counterbore and How Is It Different From a Countersink?

Discover what a counterbore is, how it differs from a countersink, and when to use each. Learn key design tips, symbols, and common mistakes to avoid.

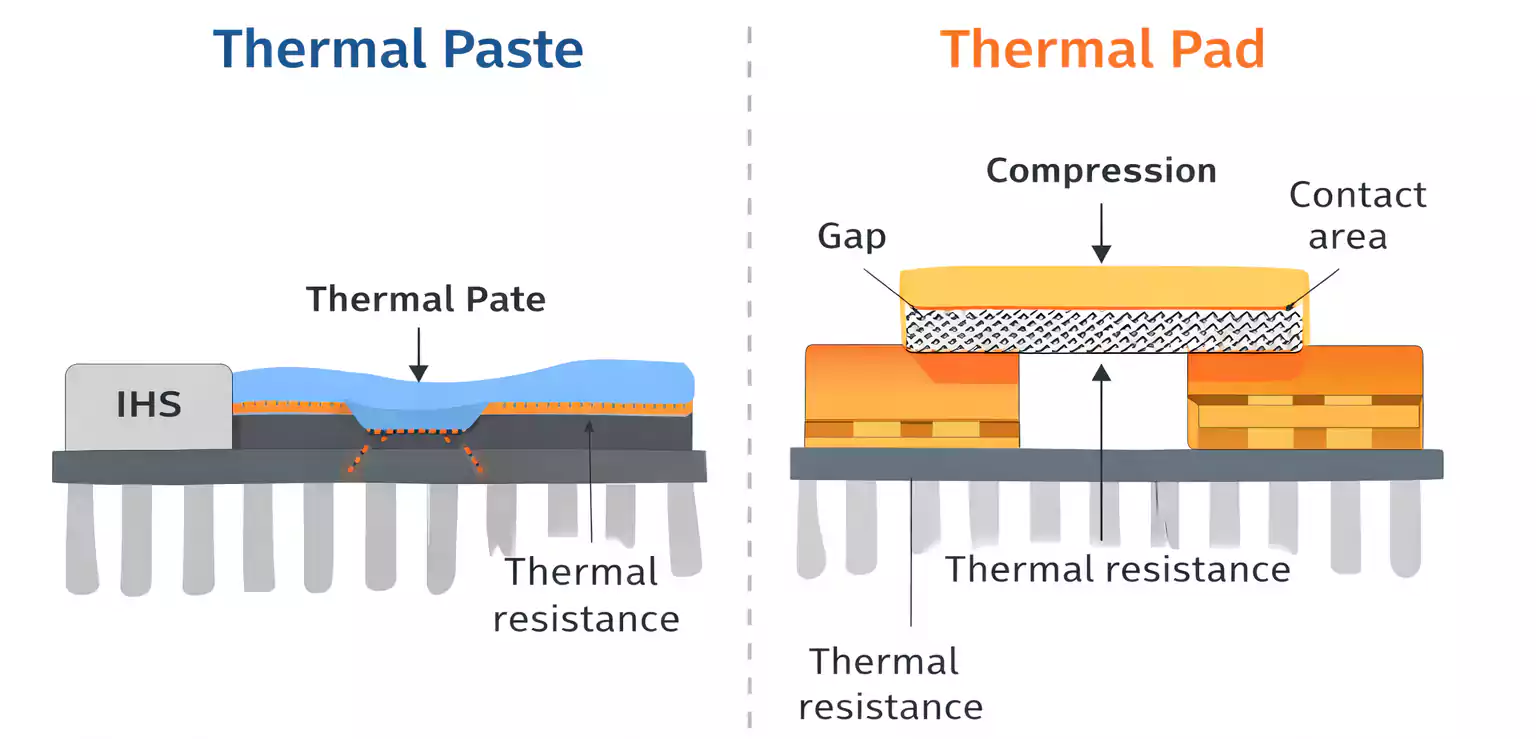

What Is Pad Thermal and How Does It Work – Thermal Pad vs Paste, IC Pad, and PCB Thermal Relief Explained

Learn what Pad Thermal really means in electronics and how it works in different contexts. This guide explains the differences between thermal pads and paste, how IC thermal pads improve chip cooling, and how PCB thermal relief pads enhance solderability — with practical design tips for better heat dissipation and reliability.

Latching Relay Explained: How It Works, 12V Wiring Diagrams, and Why It’s Better Than a Regular Relay

Discover what a latching relay is, how it works, and how to wire a 12V latching relay step-by-step. Learn the difference between latching and non-latching relays, key selection tips, and troubleshooting methods for reliable low-power switching.

Electroless Copper Plating in PCB Manufacturing: Process, Mechanisms

Electroless copper plating for PCBs explained: step-by-step process, activation methods, micro-etching reactions, and key mechanisms for reliable hole metallization.

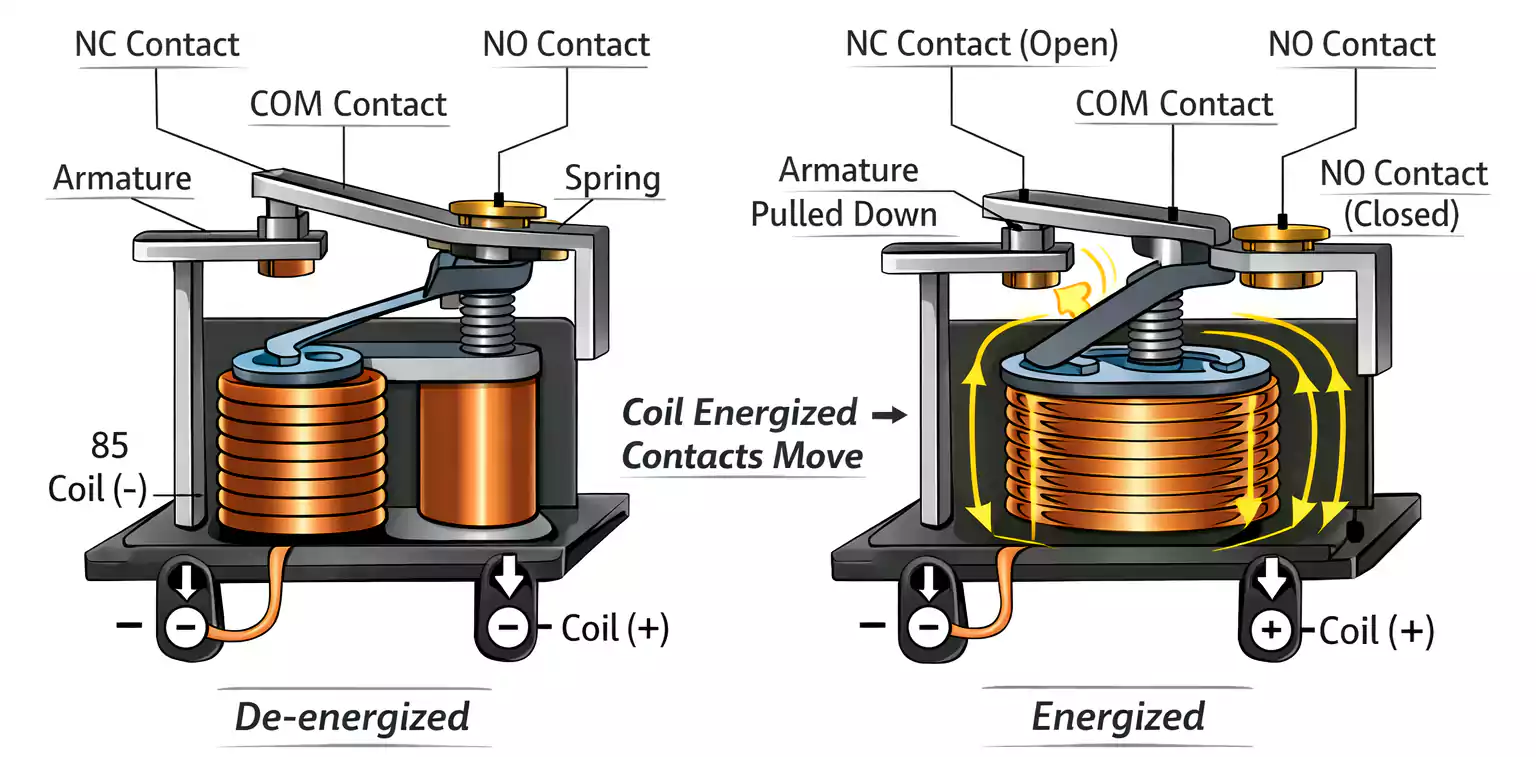

What Is a Relay and How Does It Work? Wiring Diagrams, DPDT Schematic, and How to Test a Relay Explained

Learn what a relay is, how it works, and how to wire & test 4/5-pin and DPDT relays. Clear diagrams, step-by-step testing, relay tester tips, and pro PCB advice.

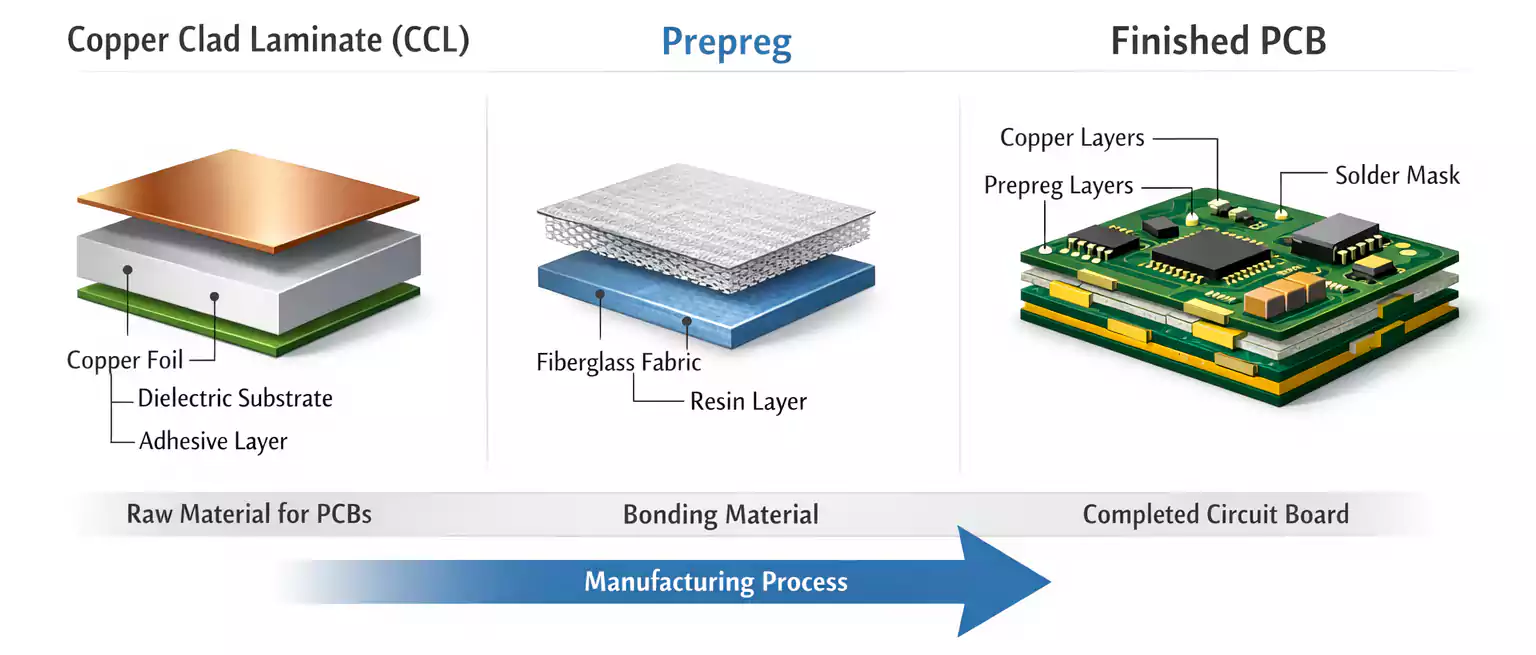

Copper Clad Laminate (CCL) Explained: What It Is, Types, Selection Guide & Price Factors

Learn what copper clad laminate (CCL) is, key types and properties, how to choose the right material, and the factors behind price—plus expert cost-saving tips.

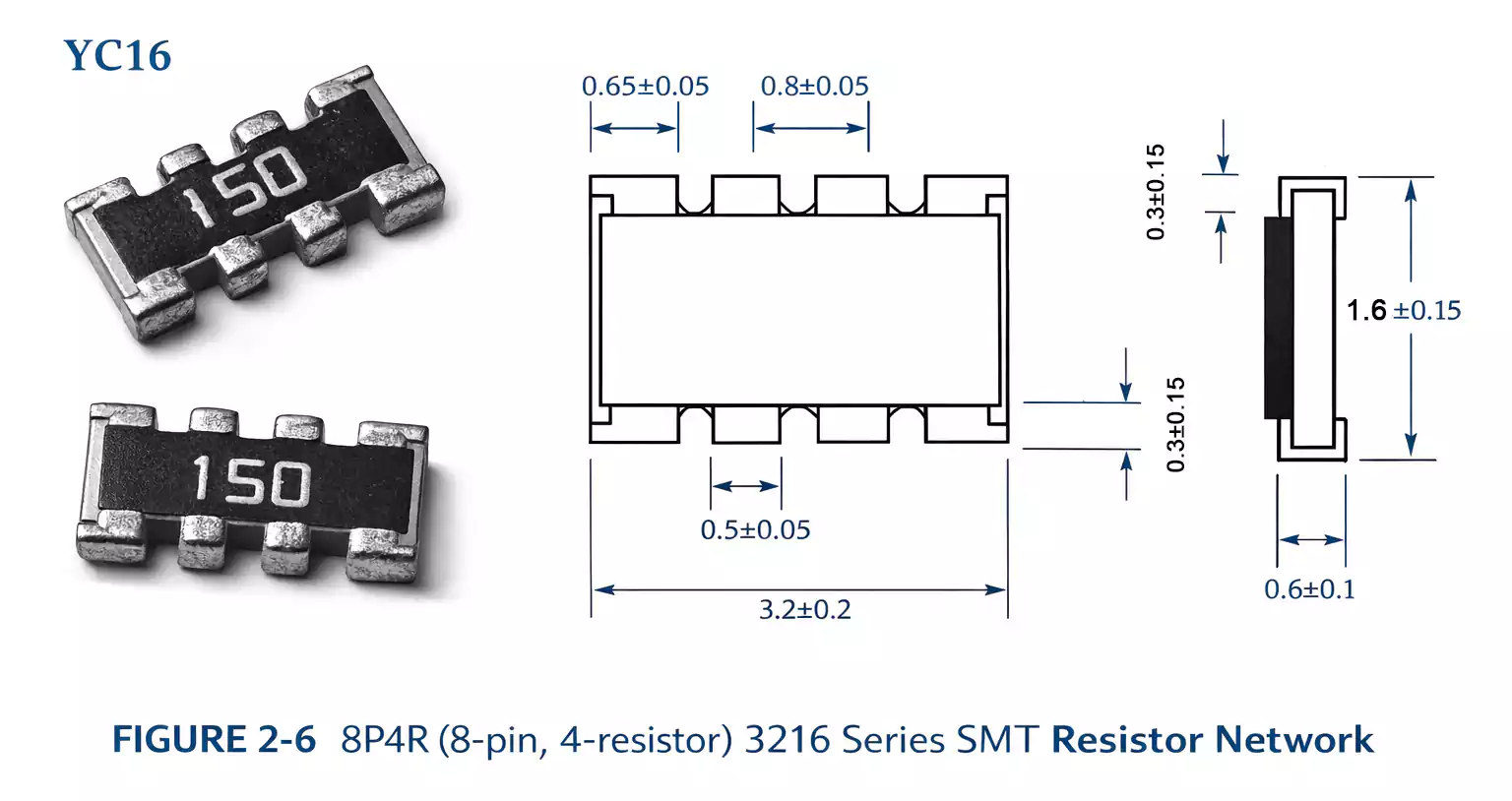

SMT Resistor Network Explained: Types, Packages, and How Resistor Array Simplify PCB Design

Learn what an SMT resistor network (resistor array) is—types, packages, circuit options, and applications—to optimize PCB design, reliability, and assembly.

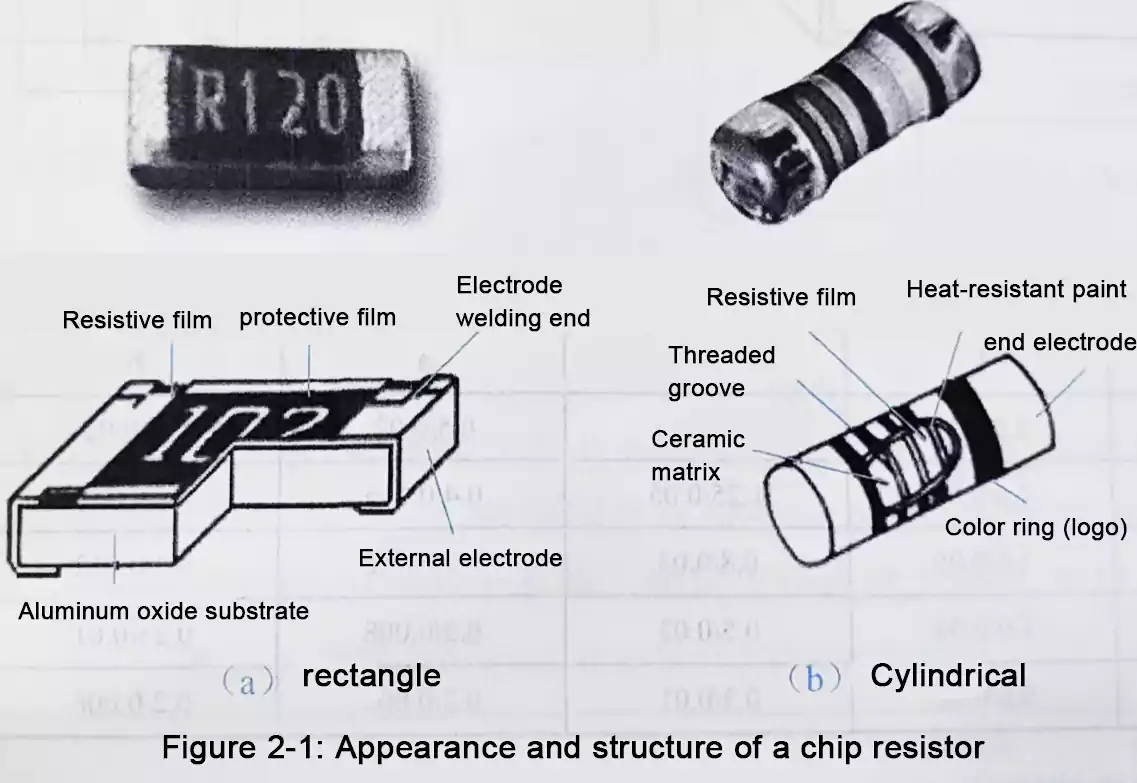

Chip Resistor Explained: Types, Sizes, and How to Read SMD Resistor Codes Like a Pro

Chip resistor demystified: SMD types, sizes, power ratings, terminal structure, and how to read SMD resistor codes—clear tips to improve solder reliability and PCB design.

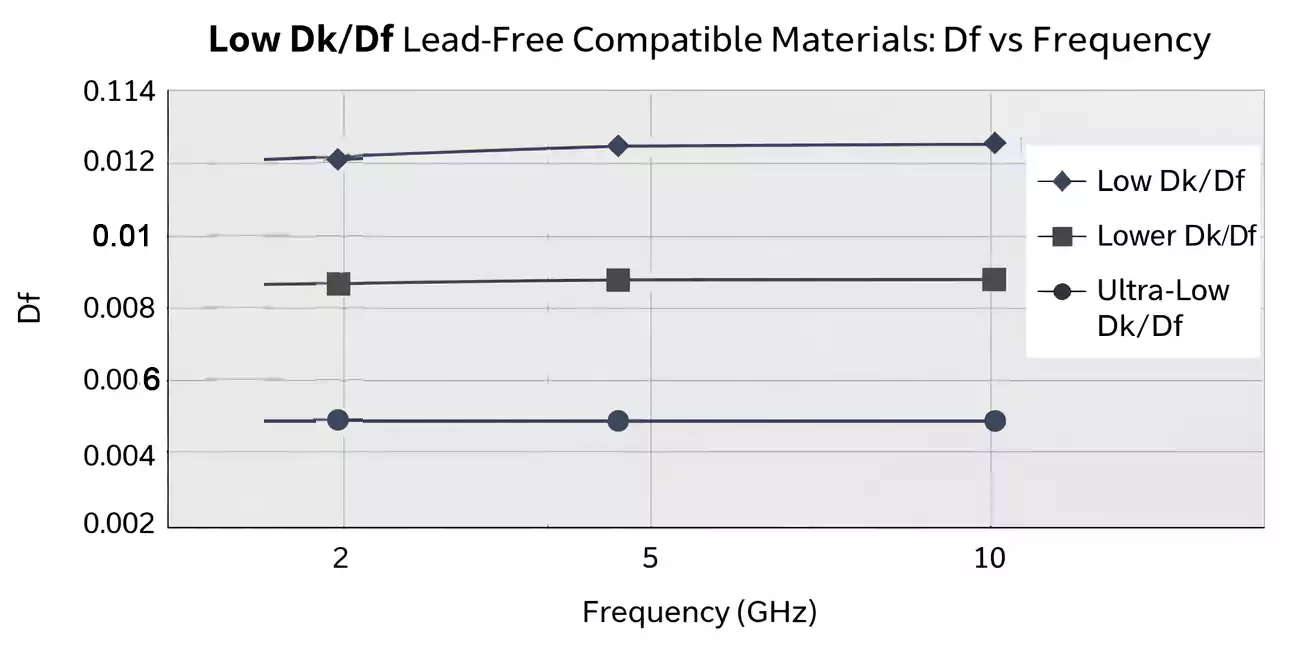

Low Dk Df PCB Materials Explained: Boost Signal Integrity and Lead-Free Reliability

Learn how low Dk Df PCB materials boost signal integrity and lead-free reliability. Practical tips on resin content, frequency effects, and stackup selection.

Silkscreen PCB Guide: What It Is, Minimum Text Height, Pad Clearance, and Labeling Best Practices

Silkscreen PCB guide: what it is, minimum text height, pad clearance, color contrast, QR labels, fiducials, and multicolor tips for error-free assembly.

What Is a Purple PCB? Advantages, Solder Mask Guide, and Design Tips You Should Know

Purple PCB explained: what it is and how solder-mask color affects readability, inspection, and yield—plus ground-plane tips to know when to choose purple vs green.