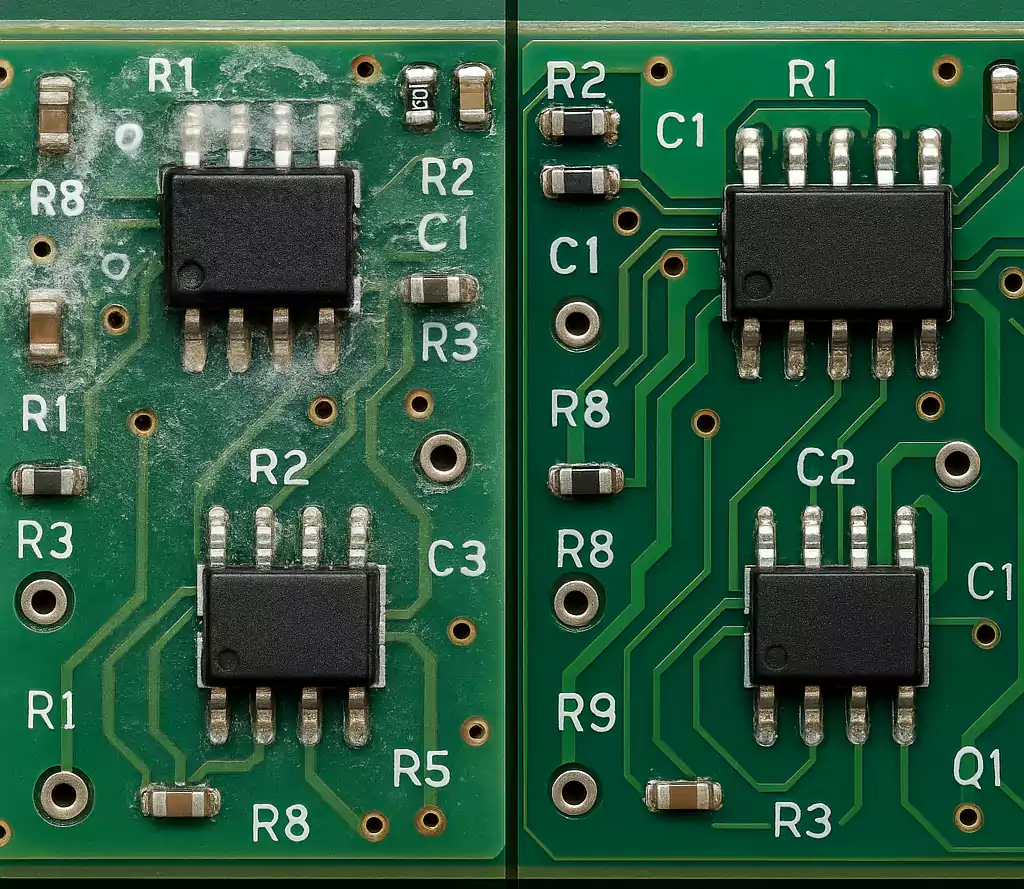

PCB Open Circuit & Broken Trace Repair Guide | Step-by-Step Fixes

Learn how to identify and repair PCB open circuits and broken traces with step-by-step methods, tools, safety tips, and preventive measures.

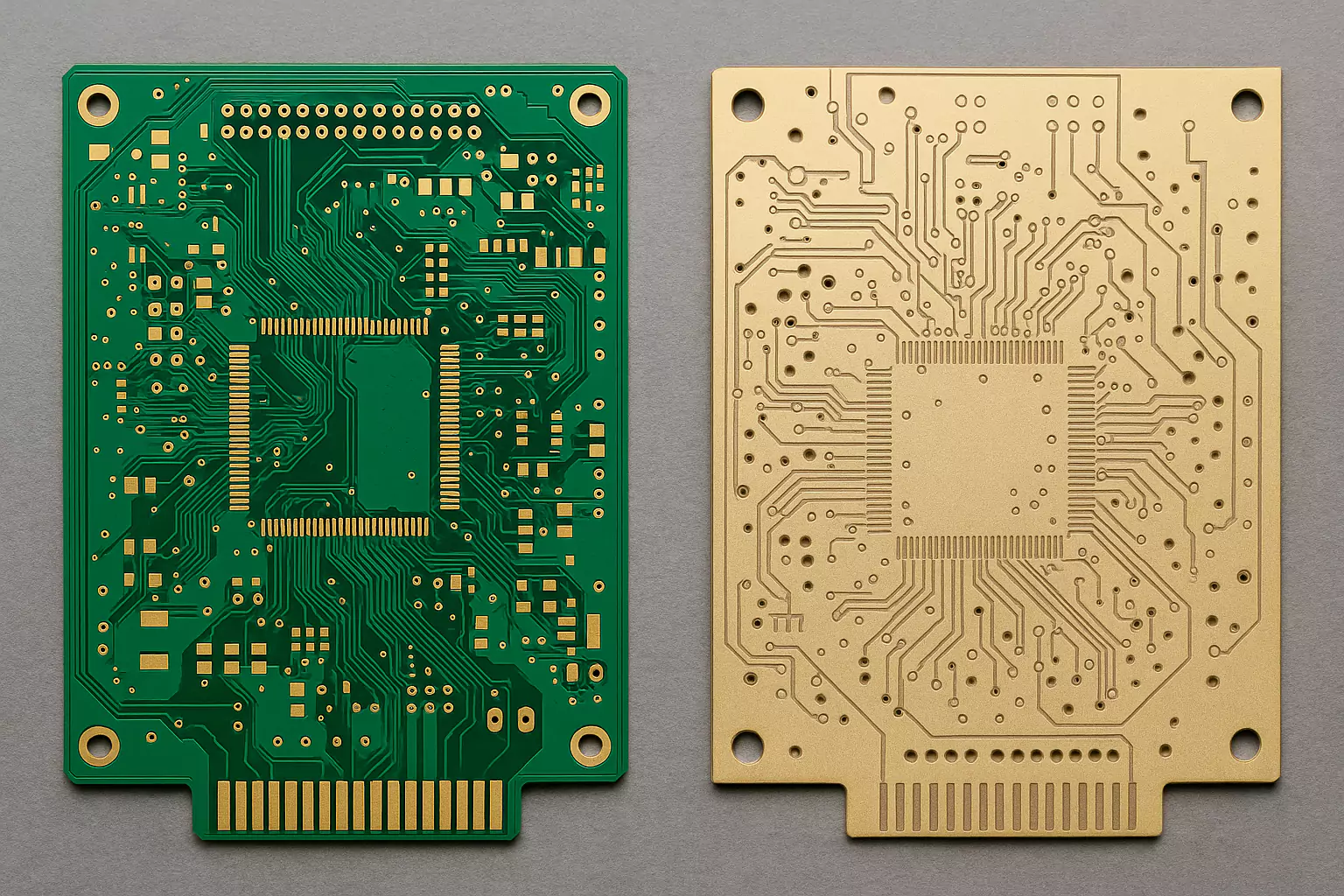

FR4 vs Rogers PCB Materials: Key Differences, Use Cases & How to Choose the Right One

Compare FR4 and Rogers PCB materials in terms of cost, dielectric performance, signal loss, and real-world applications. Learn which material is best for your RF, 5G, or high-speed design needs in this practical engineering guide.

What Is FR-4 PCB Material? Properties, Benefits, Limitations & When to Use It

Learn what FR-4 PCB material is, how it works, and why it’s the most widely used substrate in electronics. Discover its properties, advantages, limitations, and when to choose alternatives for high-performance designs.

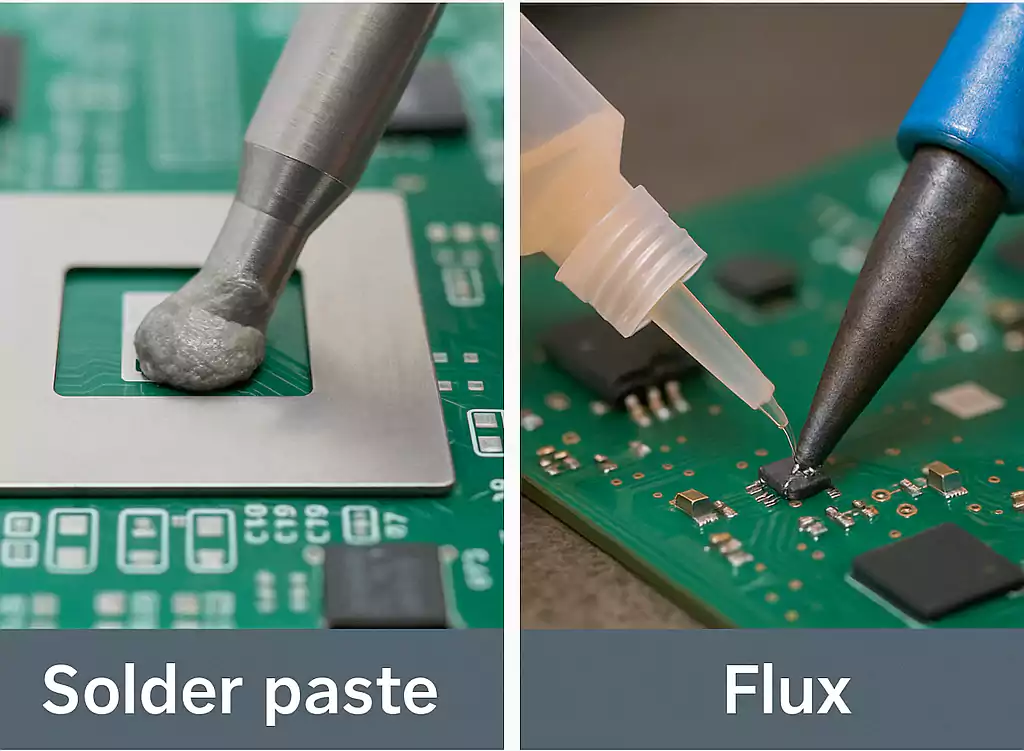

Solder Paste vs Flux: Key Differences, Uses, and Pro Tips for Perfect Soldering

Learn the key differences between solder paste and flux, including their composition, functions, and best use cases. This expert guide compares SMT and manual soldering workflows with visuals, tips, and common mistakes to help you choose the right material for perfect solder joints.

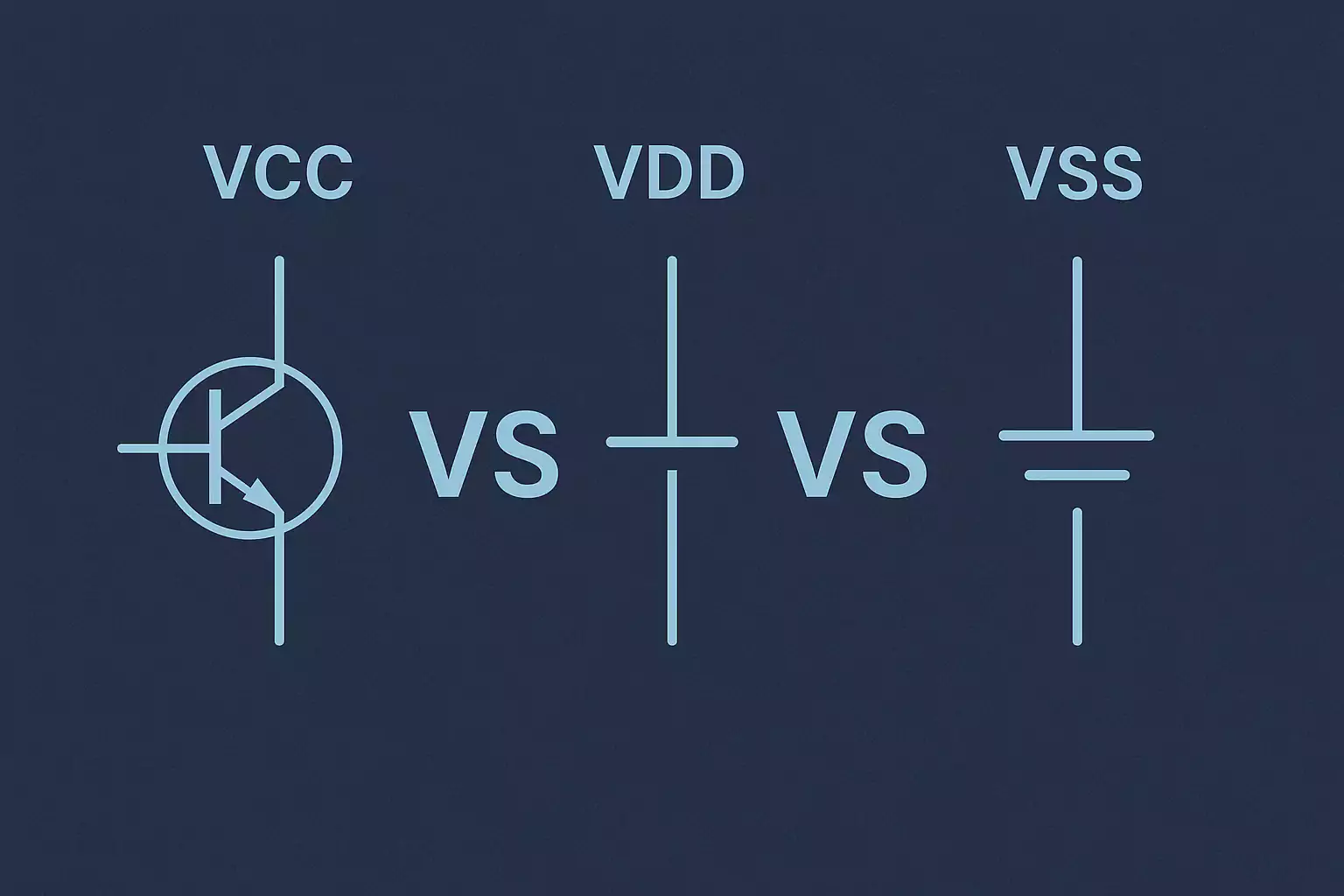

VCC vs VDD vs VSS Explained: Key Differences, Usage, and Practical Design Tips

Learn the key differences between VCC, VDD, VSS, and VEE in electronic circuits. This clear, practical guide explains each term's origin, usage, and meaning—plus real-world examples, diagrams, and expert tips to avoid common mistakes.

Cold Solder Joints: How to Identify, Fix, and Prevent the #1 Hidden Cause of Electronics Failure

Discover what cold solder joints are, how to detect them, and proven methods to fix and prevent failures. This complete guide helps improve circuit reliability and avoid costly rework in electronics.

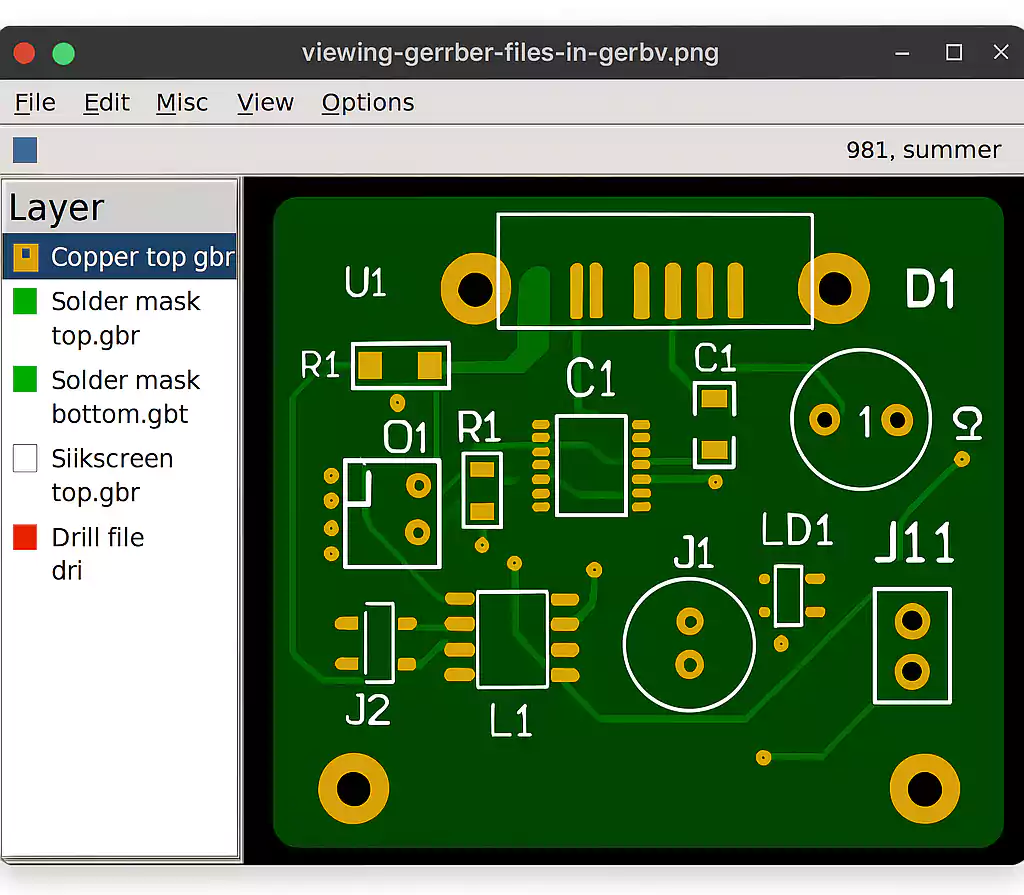

What Is a GBR File? Complete Guide to Gerber Files, Formats, Viewers, and Common Errors

Learn what a GBR file is, how it’s used in PCB design, and how to open, convert, validate, and fix Gerber files. This complete guide covers file types, common errors, tools, and best practices for reliable manufacturing.

What Is a PCB? Complete Beginner-to-Pro Guide to Printed Circuit Boards

Discover what a PCB (Printed Circuit Board) is, how it works, and why it powers nearly all modern electronics. This complete guide covers PCB types, structure, design, manufacturing, applications, FAQs, and key performance tips—perfect for beginners and engineers alike.

How to Clean Flux Off PCB: Step-by-Step Guide for Rosin, No-Clean & Water-Soluble Flux

Learn how to clean flux off PCB effectively with this professional guide. Explore cleaning techniques for rosin, no-clean, and water-soluble flux, along with the best tools, solvents, and methods to prevent corrosion, enhance circuit performance, and extend board lifespan.

PWB vs PCB: What’s the Difference and Which Term Should You Use

Confused about PWB vs PCB? Discover the real difference between Printed Wiring Boards and Printed Circuit Boards, when to use each term, and why it matters in electronics design, manufacturing, and documentation.

Typical PCB Thickness Explained: Standards, Stack-Up Design & Application Best Practices

Learn everything about typical PCB thickness — from industry standards and stack-up design to application-specific recommendations. This complete guide helps you choose the right board thickness for performance, cost, and reliability.

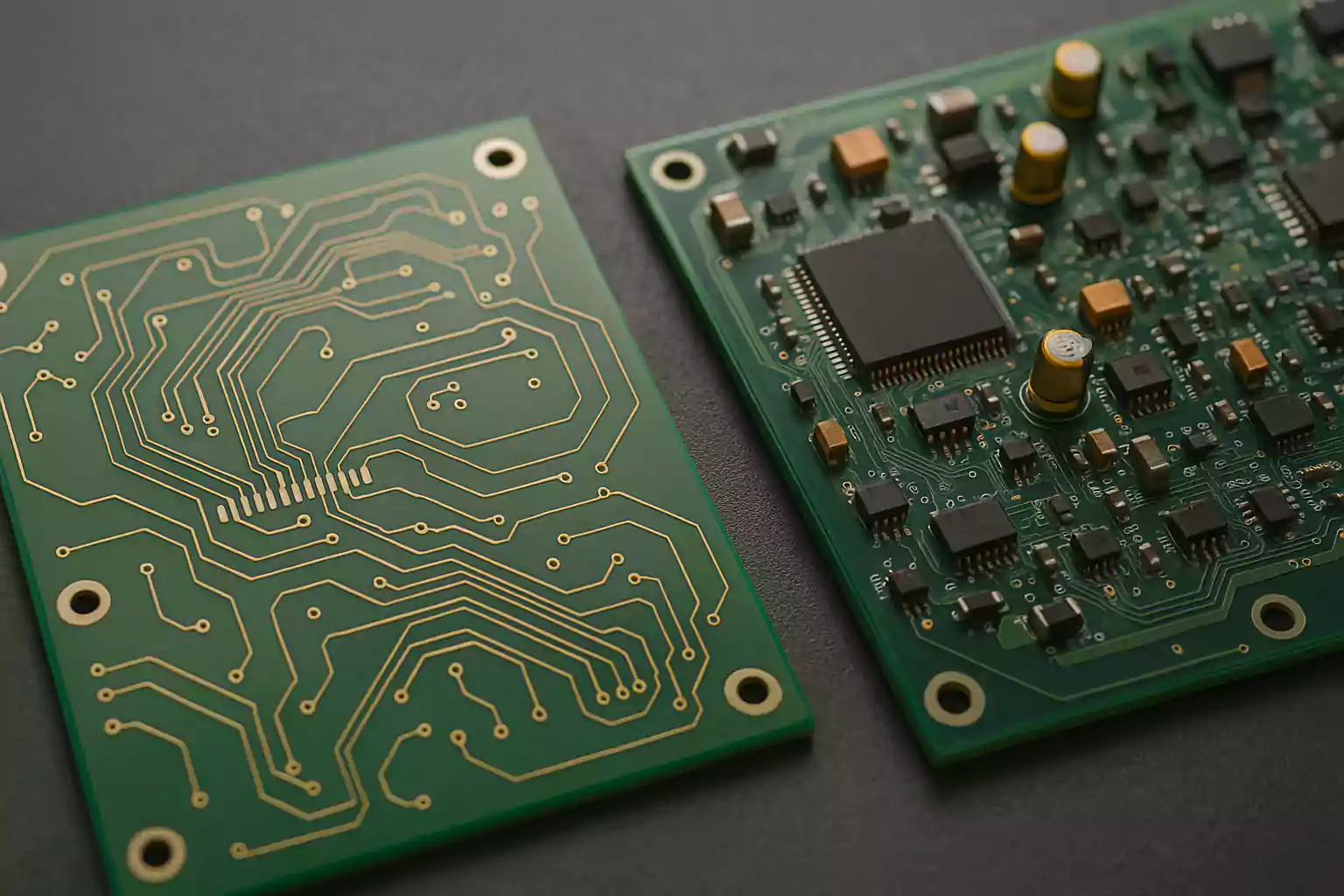

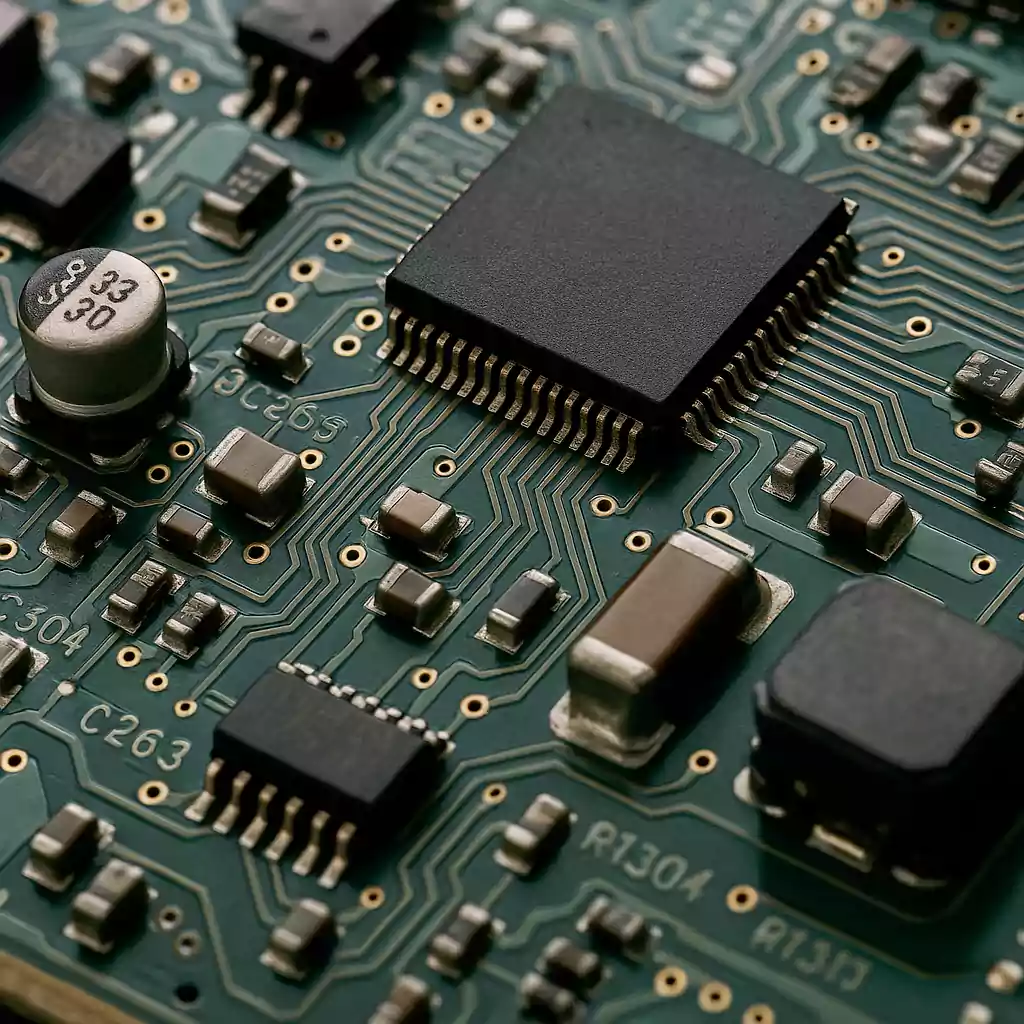

PCB Components Explained: The Complete Guide to Circuit Board Parts, Functions, and Design Best Practices

Introduction Printed Circuit Boards (PCBs) are the foundational backbone of virtually all modern electronic devices—from smartphones and laptops to industrial machinery and medical equipment. But what makes a PCB truly function are its components—the active, passive, and electromechanical parts that bring a circuit to life. Understanding the components of a PCB is essential not only […]