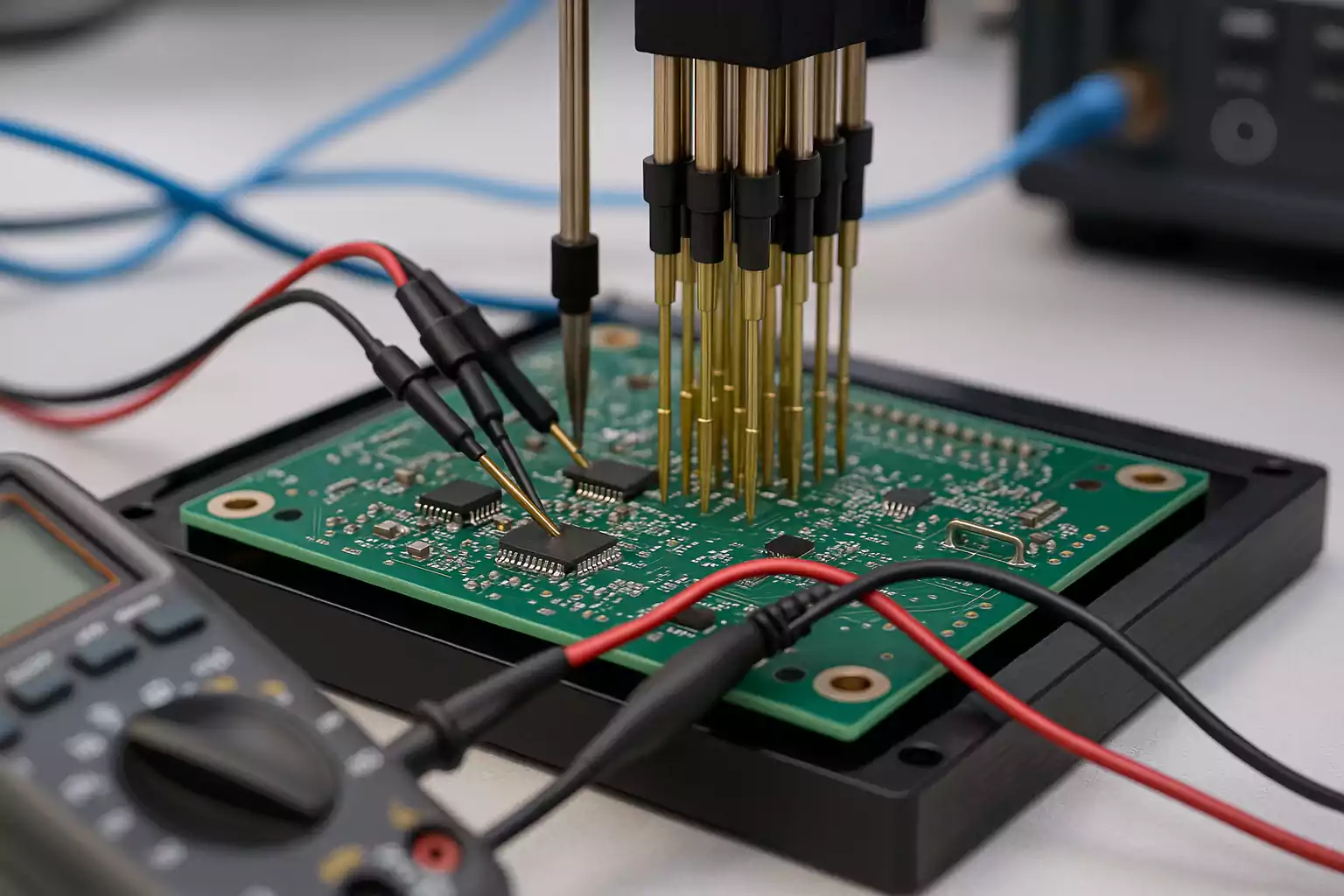

Understanding Functional Circuit Testing (FCT) for PCBs – Ensuring Your Board Works Before Deployment

Discover how Functional Circuit Testing (FCT) ensures your PCB works before deployment. Learn its benefits, how it compares to ICT and AOI, key equipment, real-world use cases, and best practices for reliable, defect-free electronics.

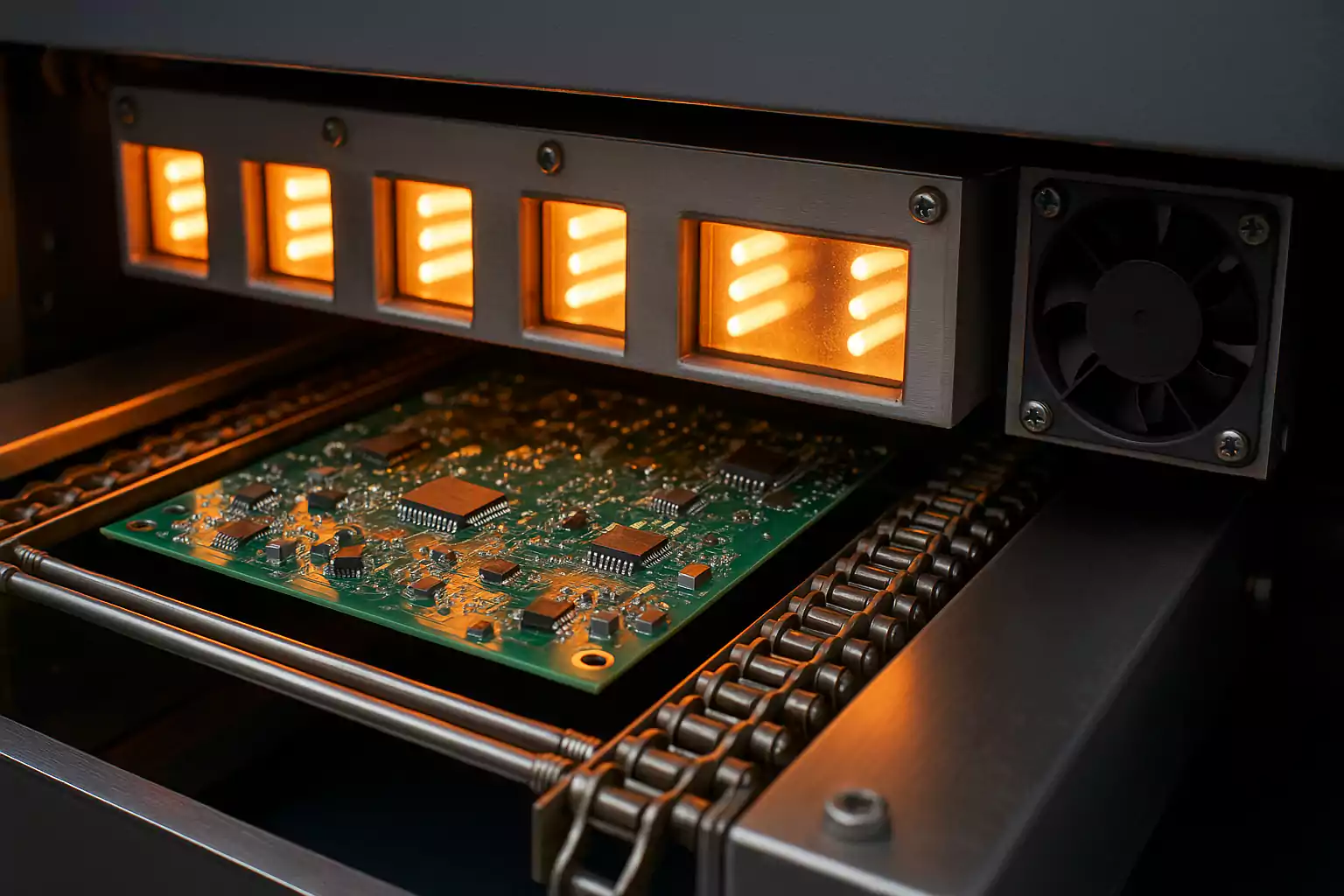

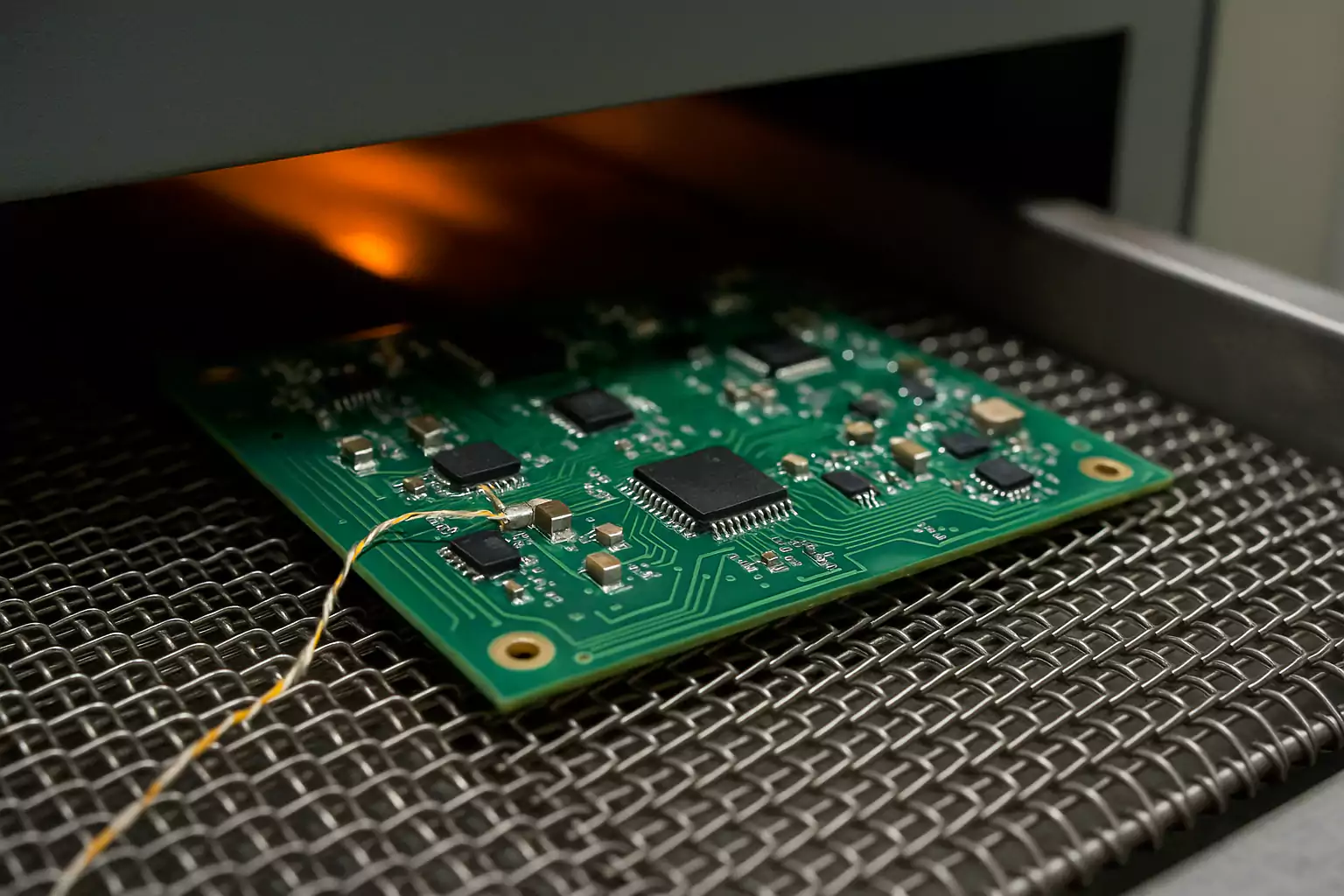

An in-depth piece on reflow soldering process and best practices

Learn everything about the reflow soldering process in SMT—from temperature profiles and oven types to common defects and best practices. This expert guide helps you master reliable, lead-free soldering and boost your PCB assembly yield.

An Invitation Letter from Russia

Fast Turn PCB will participate in this September’s RADEL electronics trade fair in St. Petersburg, Russia!

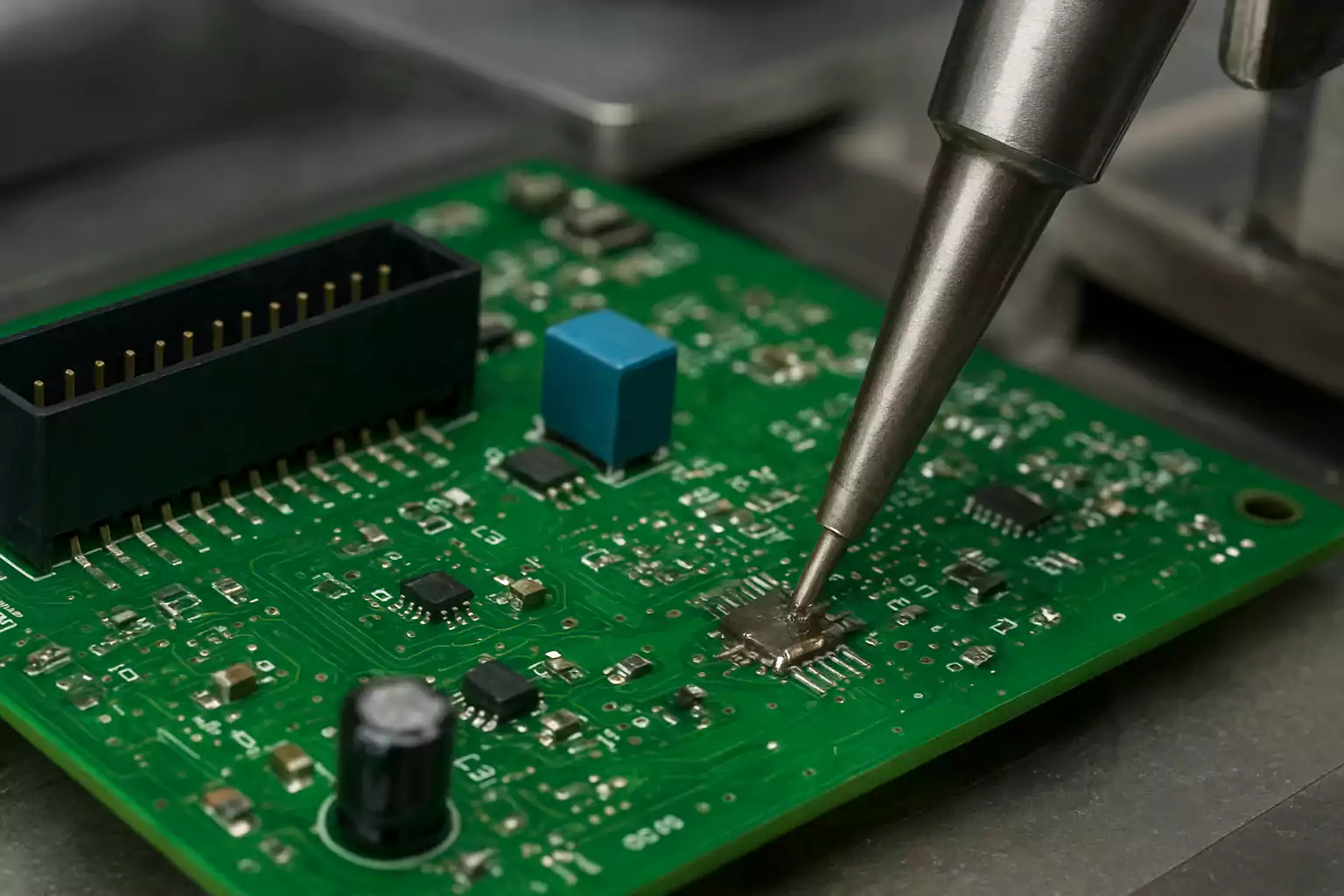

Selective Soldering vs Wave Soldering: When to Use Which?

Selective Soldering vs Wave Soldering : practical comparison for THT assemblies — when to use each, with key differences, pros and cons, cost factors, and PCB design guidelines to ensure efficient, high-quality manufacturing.

Guide to PCB Plating: Through-Hole Copper Plating and Surface Finishes

Discover how PCB plating works—from through-hole copper plating to ENIG and OSP finishes. Learn key steps, materials, and tips to improve solderability and reliability.

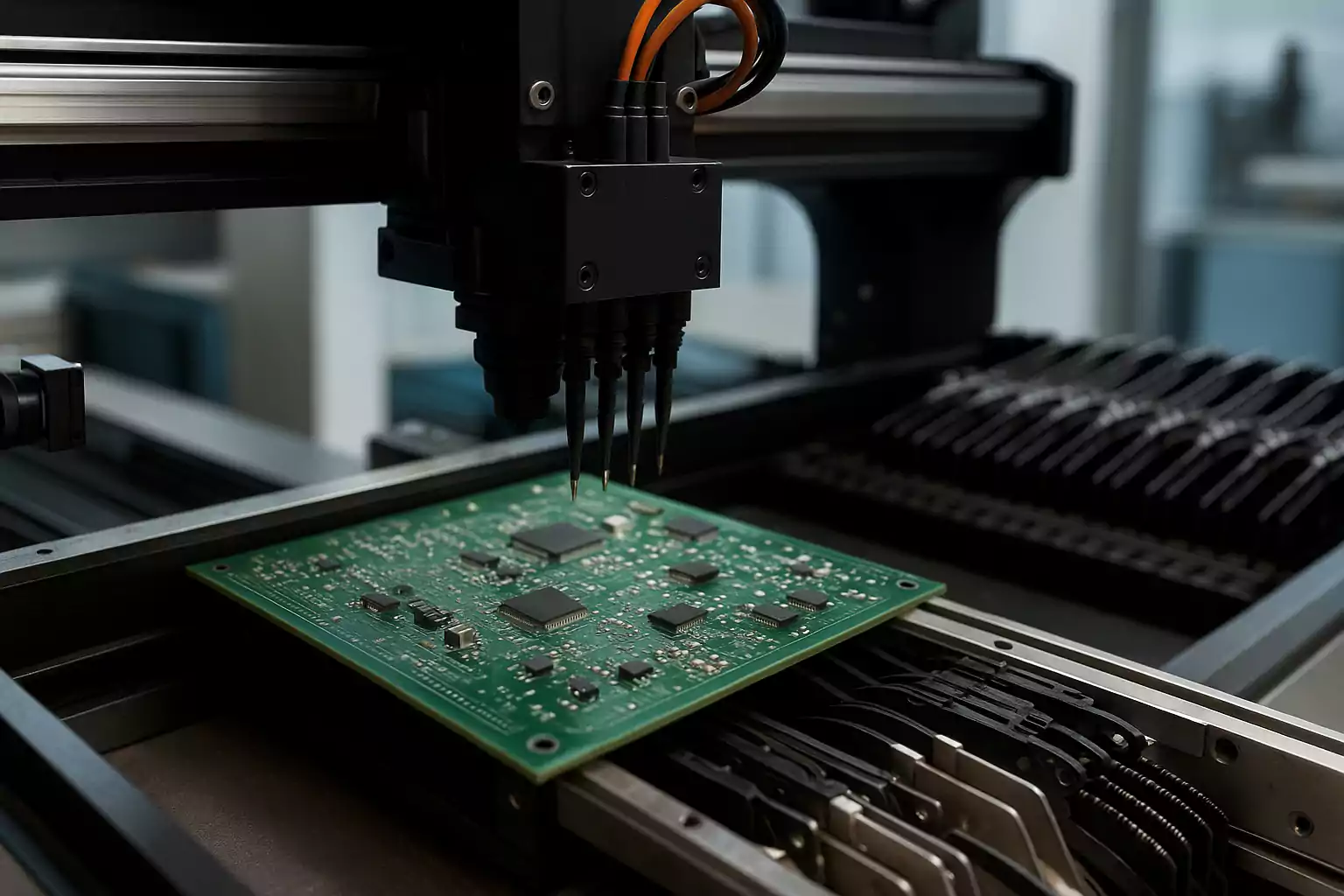

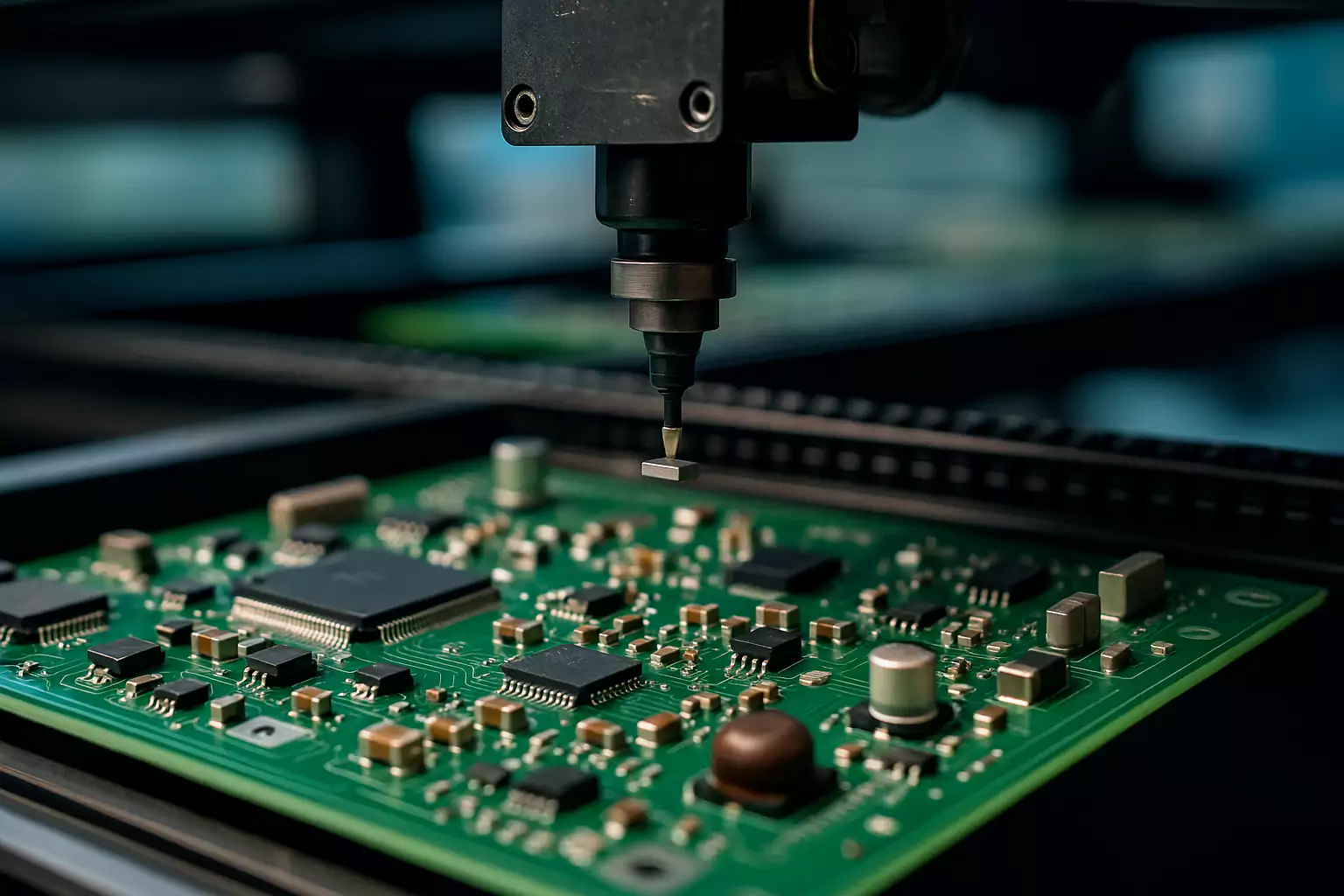

Pick-and-Place Machines Explained: A Complete Guide for PCB Assembly

Discover how pick-and-place machines power modern PCB assembly with unmatched speed and precision. Learn key types, core features, and expert tips to choose and optimize the right SMT solution for your production needs.

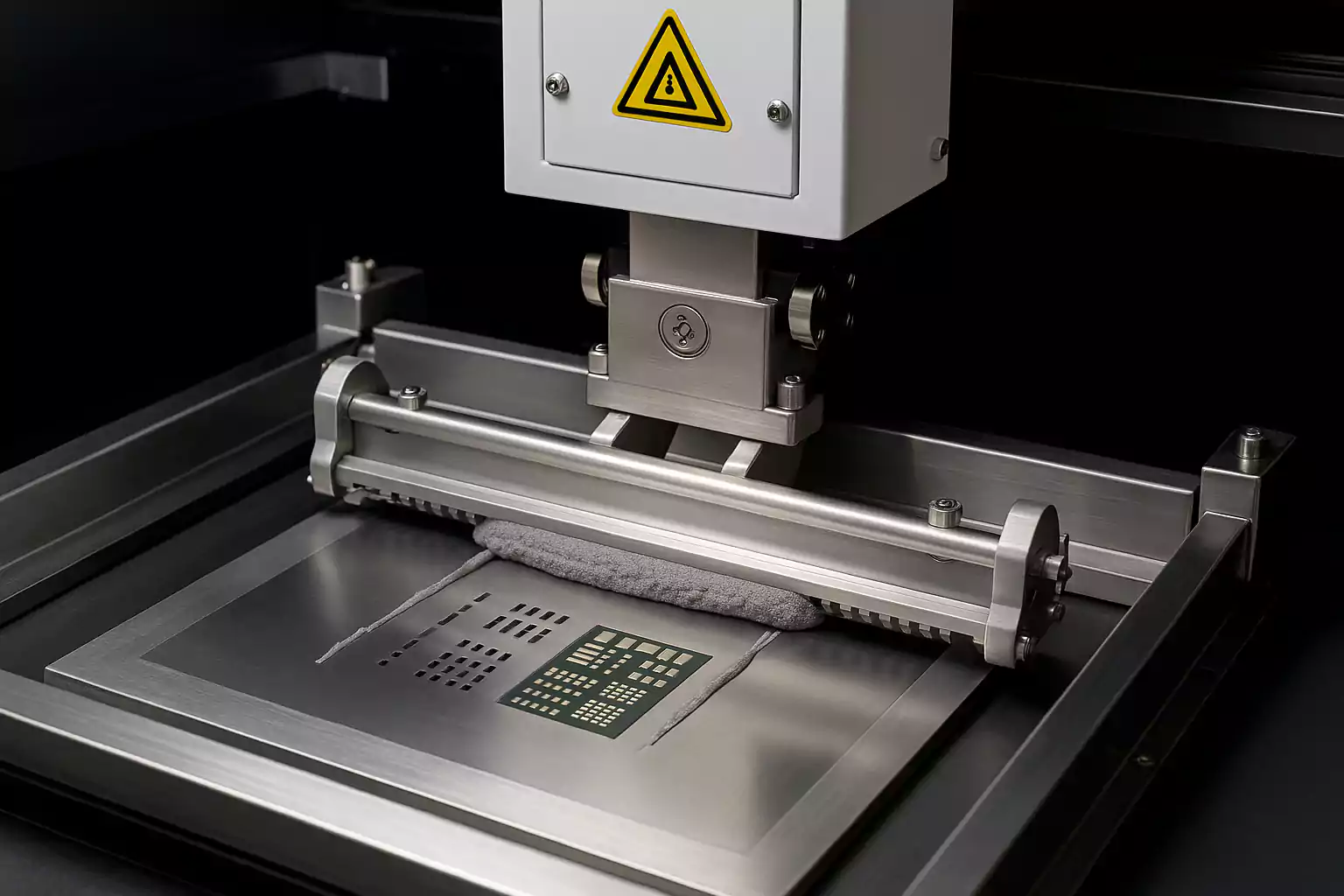

A comprehensive guide on solder paste stencil printing in SMT assembly

A complete guide to solder paste stencil printing in SMT assembly. Learn stencil design, print parameters, defect control, and best practices for high-yield PCBs.

Full Overview of PCB Manufacturing Process

Explore the complete PCB manufacturing process—from design files to finished boards. Learn every key step including imaging, drilling, plating, solder mask, and testing. Ideal for engineers and teams seeking reliable, high-quality PCB production.

Understanding PCB Lamination: How Multilayer Boards Are Bonded & Avoiding Delamination

Learn how multilayer PCBs are bonded through the lamination process and discover expert tips to avoid delamination. This complete guide covers materials, process steps, and reliability best practices for high-performance PCB fabrication.

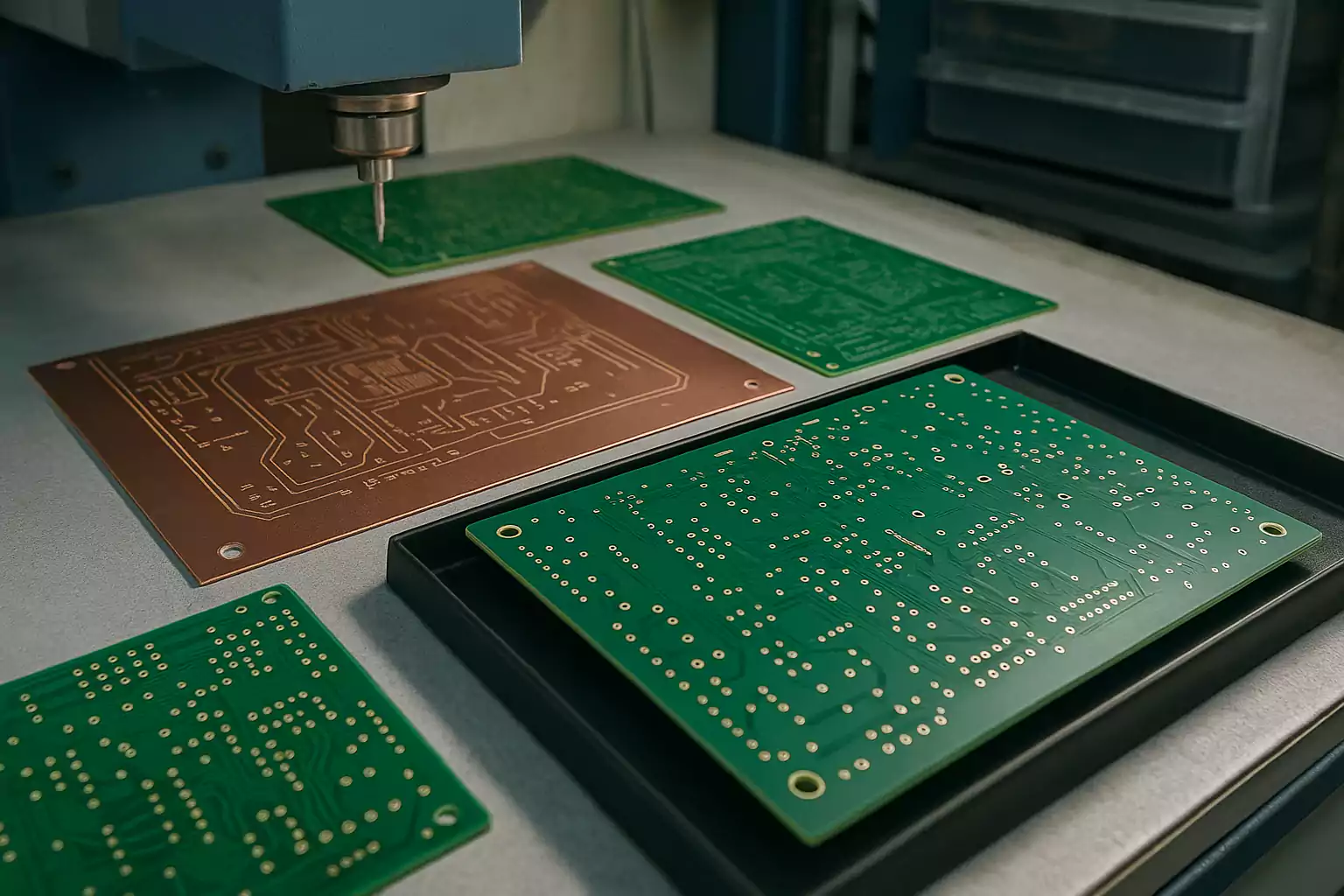

PCB Etching Process Explained: DIY Methods vs. Industrial Techniques

Discover the complete PCB etching process—compare DIY methods with industrial techniques, explore step-by-step workflows, safety tips, and future trends. Choose the best etching method for your project with this expert guide.

Reflow Soldering 101: Temperature Profile Optimization

Learn how to optimize your reflow soldering temperature profile for leaded and lead-free SMT assembly. This guide covers preheat rates, TAL, cooling, defect prevention, and profiling techniques like PWI and DOE for high-reliability PCB production.

From Bare Board to Assembled PCBA: A Step-by-Step Overview

Introduction PCB assembly (PCBA) is the process of mounting electronic components onto a bare printed circuit board to create a functional hardware system. By integrating both surface-mount (SMT) and through-hole (THT) components onto a fabricated board, PCBA transforms raw materials into functional circuits ready for testing, deployment, or enclosure. Whether it's a medical sensor, industrial […]