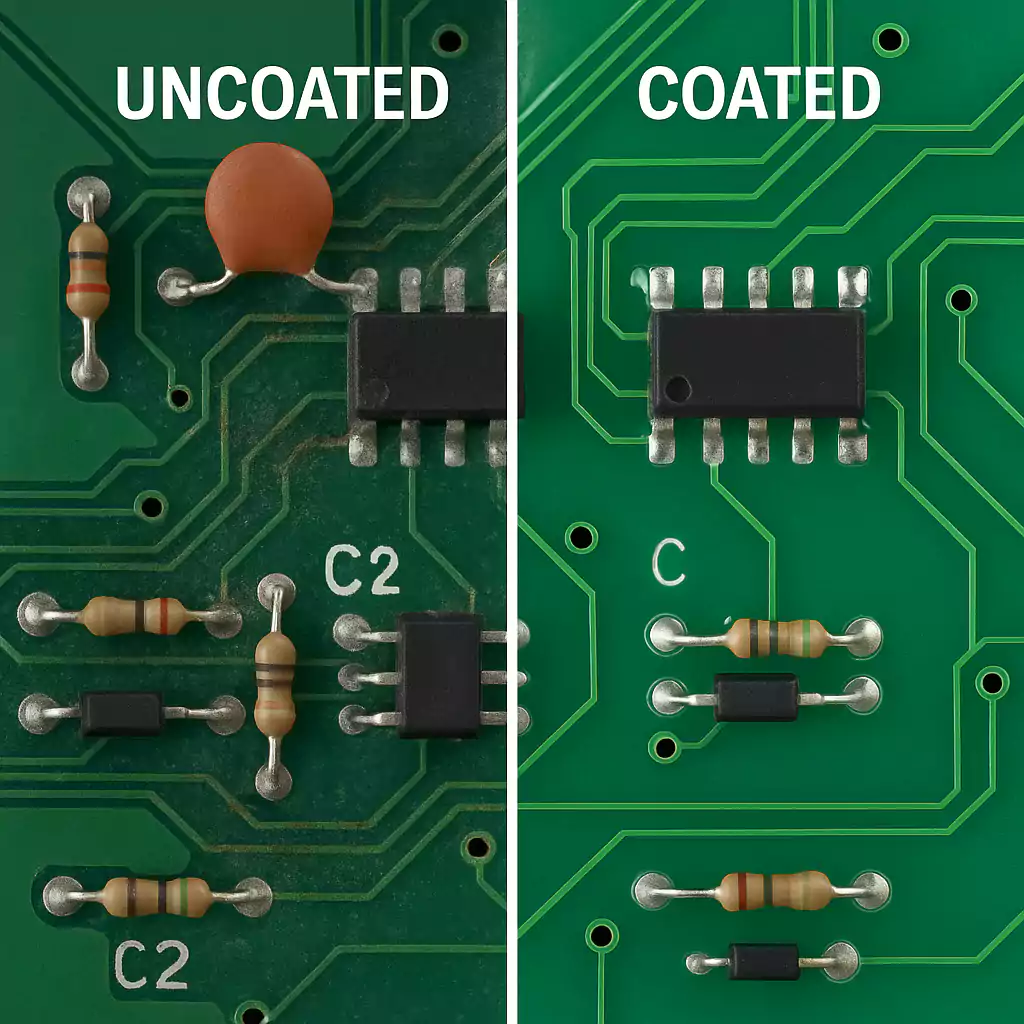

Conformal Coating for PCBs: Types, Benefits, Application Tips & How to Choose the Right One

Learn everything you need to know about conformal coating for PCBs—including coating types, key benefits, application methods, and how to choose the right material for your electronics. Improve reliability, prevent failures, and extend product life with expert tips.

Solder Paste Explained: What It Is, How to Use It, and How to Choose the Right Type

Learn what solder paste is, how it works in SMT and reflow soldering, and how to choose the right type for your PCB projects. Avoid common mistakes with expert tips on usage, storage, and flux selection.

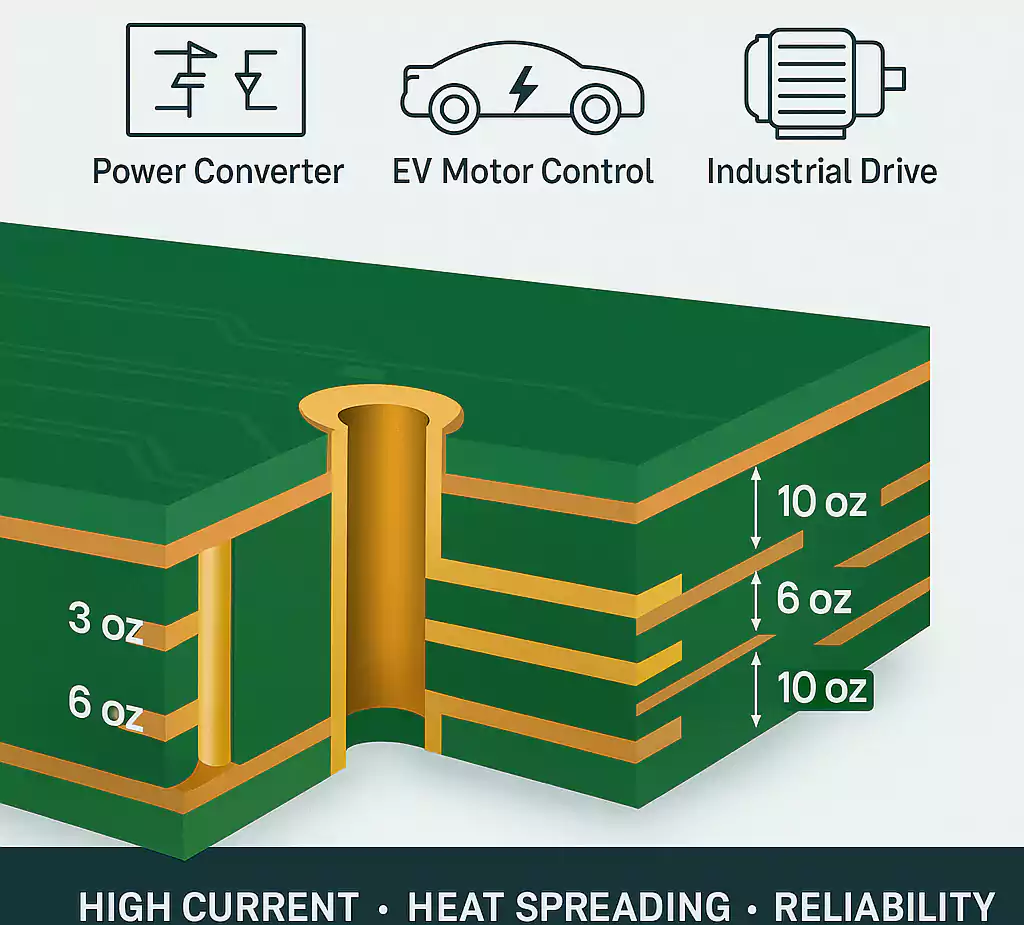

Thick Copper PCB Explained: 1 oz vs Heavy Copper, Benefits & How to Choose the Right Thickness

Learn how to choose the right thick copper PCB—1 oz vs heavy copper—plus clear design rules, stackup examples, thermal/current tips, and cost drivers in one practical guide.

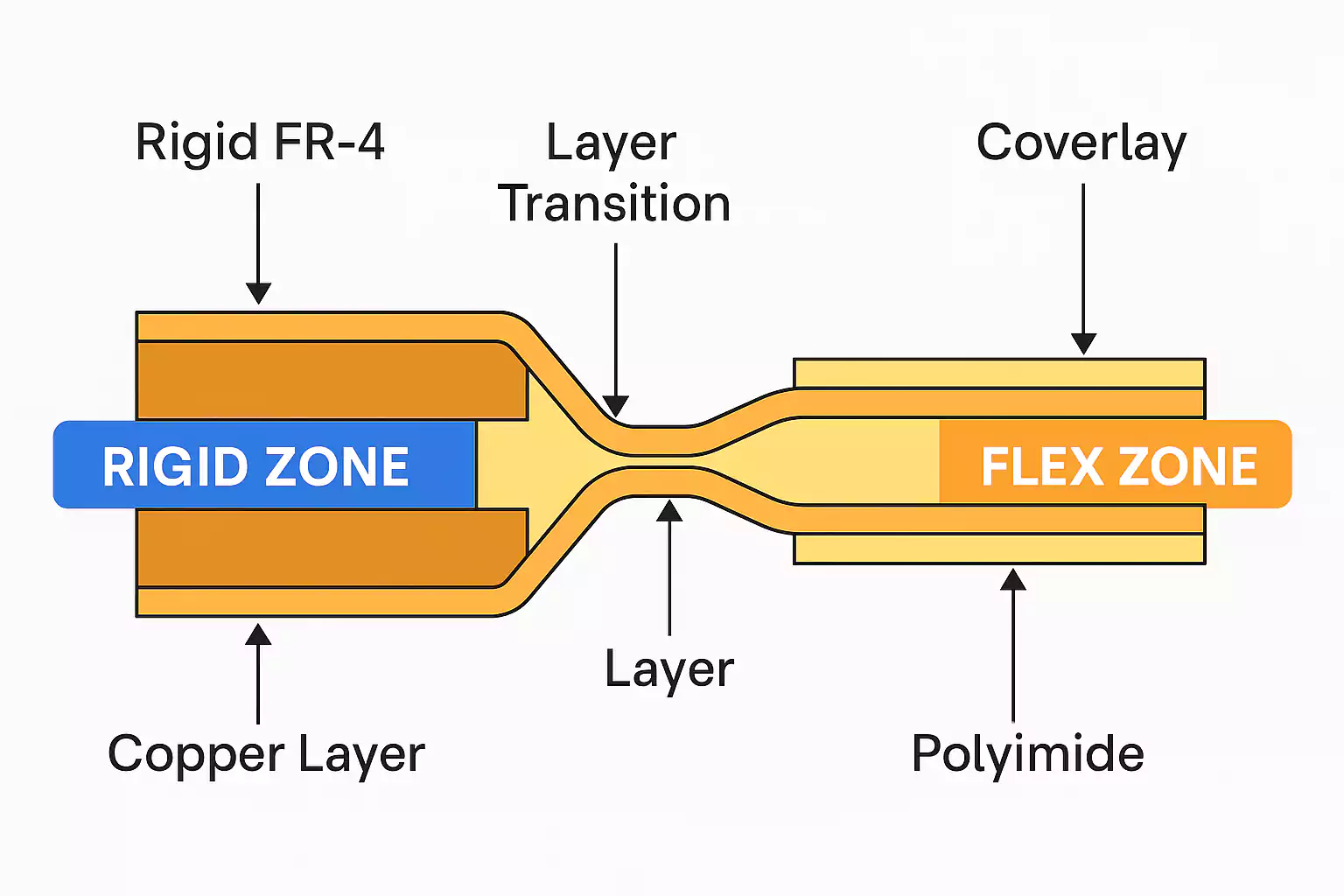

Rigid Flex PCB Explained: Benefits, Design Tips, and Applications for Modern Electronics

Explore how a Rigid Flex PCB offers space-saving, high-reliability performance for modern electronics. Learn key benefits, design tips, and common applications in aerospace, medical, and consumer devices.

High Frequency PCB: Materials, Design Tips, and Applications in Modern Communication Systems

Looking for a reliable high frequency PCB? Learn about low-loss materials, key design techniques, and how these boards power 5G, radar, and RF systems.

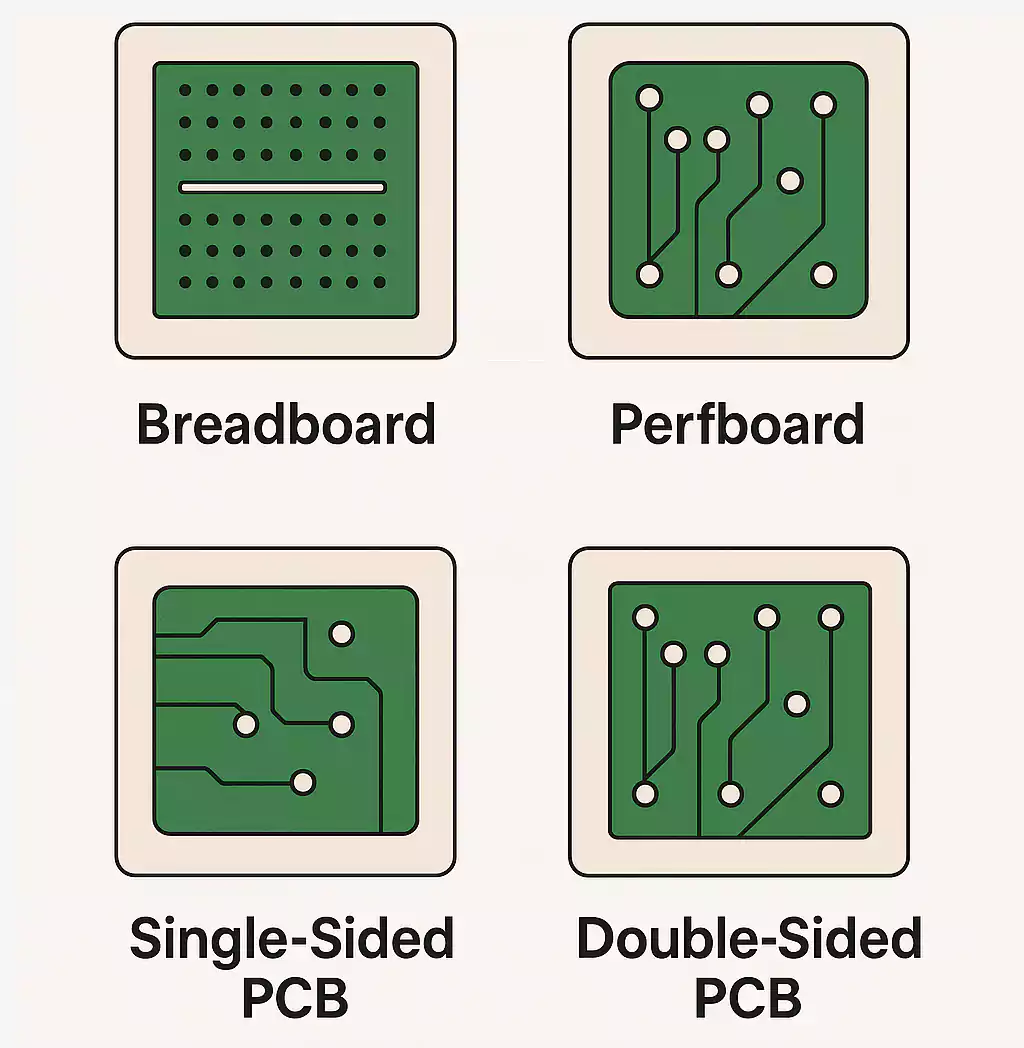

PCB Board Prototype: How to Design, Build, and Avoid Costly Mistakes

Discover how to design and build a PCB board prototype the right way. Learn key types, avoid common mistakes, and get faster, more reliable results.

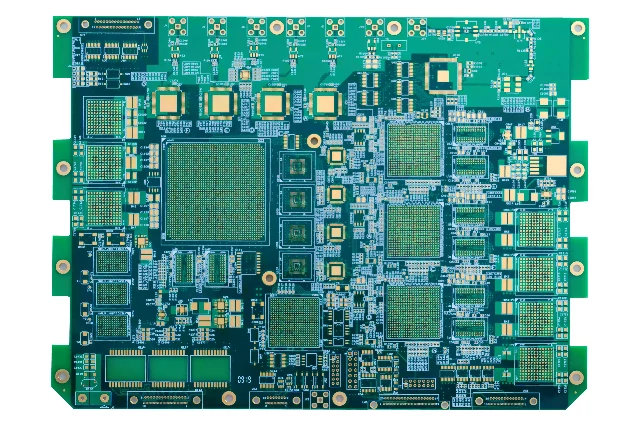

HDI PCB Explained: What It Is, Key Benefits, Stack-Up Types & Design Standards

Discover what HDI PCBs are, how they work, and why they're essential for compact, high-performance electronics. Learn about key benefits, stack-up types, and industry design standards in this complete HDI PCB guide.

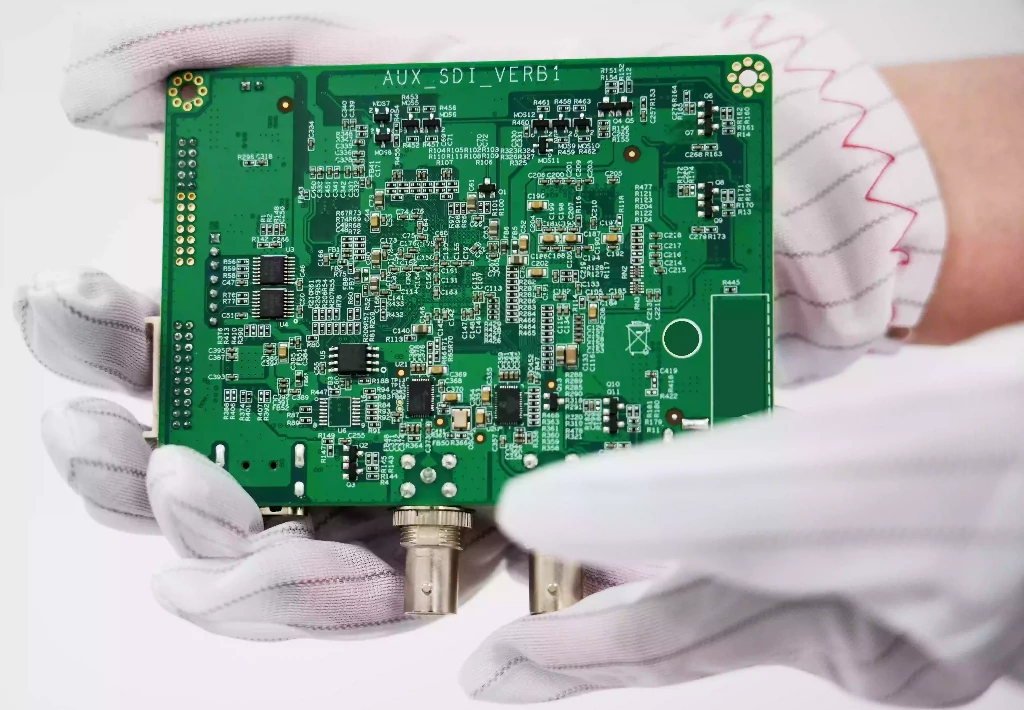

Full vs Partial Turnkey PCB Assembly: Key Differences, Benefits, and When to Use Each

Discover the key differences between full and partial turnkey PCB assembly, including their benefits, use cases, and how the process works. Learn how turnkey services can streamline your electronics manufacturing, reduce lead times, and simplify component sourcing—all in one efficient solution.

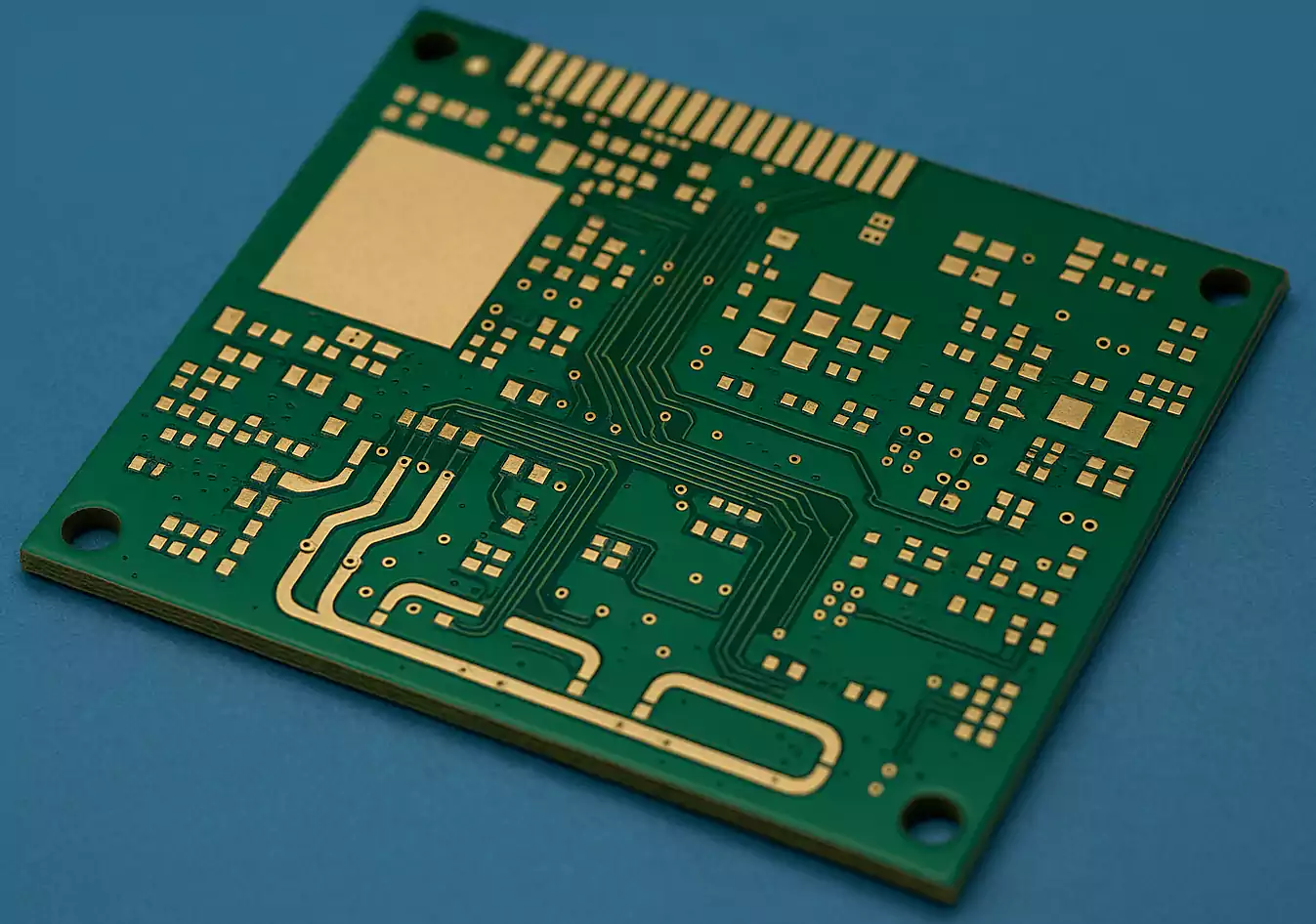

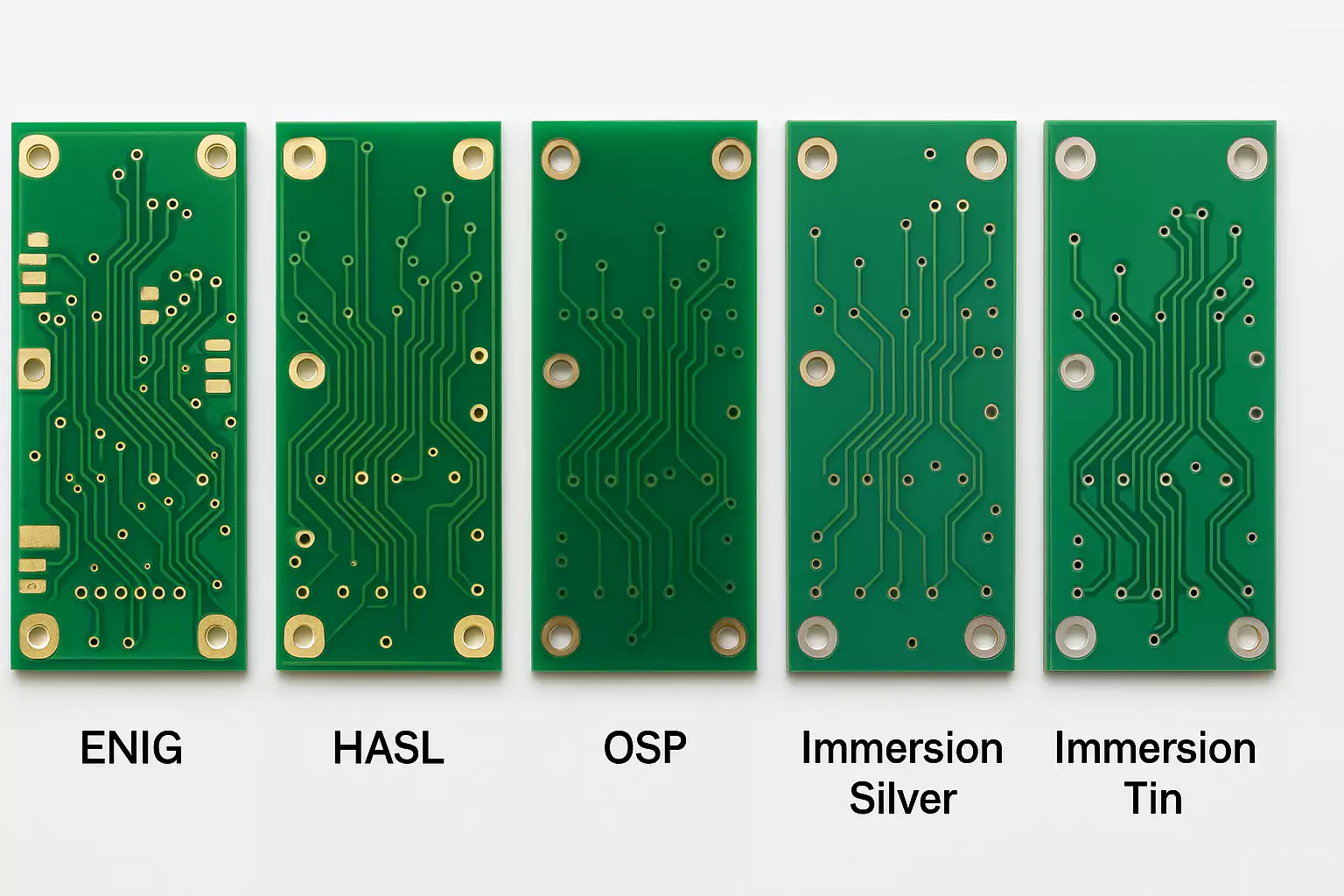

PCB Surface Finish: ENIG vs HASL vs OSP & More — Which Is Best for Your Board?

Compare the most common PCB surface finishes—ENIG, HASL, OSP, Immersion Silver, and Immersion Tin. Learn how each affects solderability, cost, reliability, and RoHS compliance to choose the best finish for your PCB design

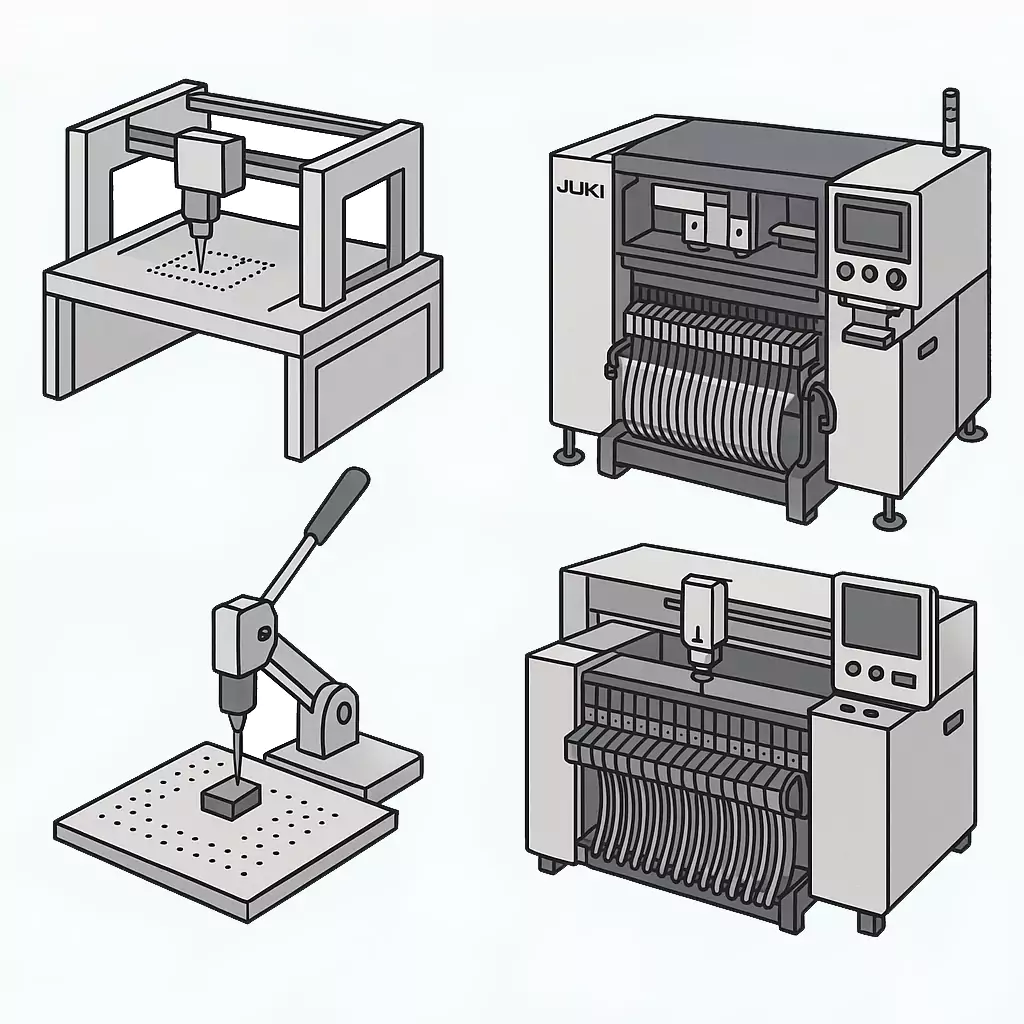

Types of SMT Pick-and-Place Machines and How to Choose the Right One

Discover the main types of SMT Pick-and-Place Machines and learn how to choose the right one for your production needs. This guide explains each machine’s features, advantages, and ideal applications to help you boost efficiency, precision, and ROI in your SMT assembly line

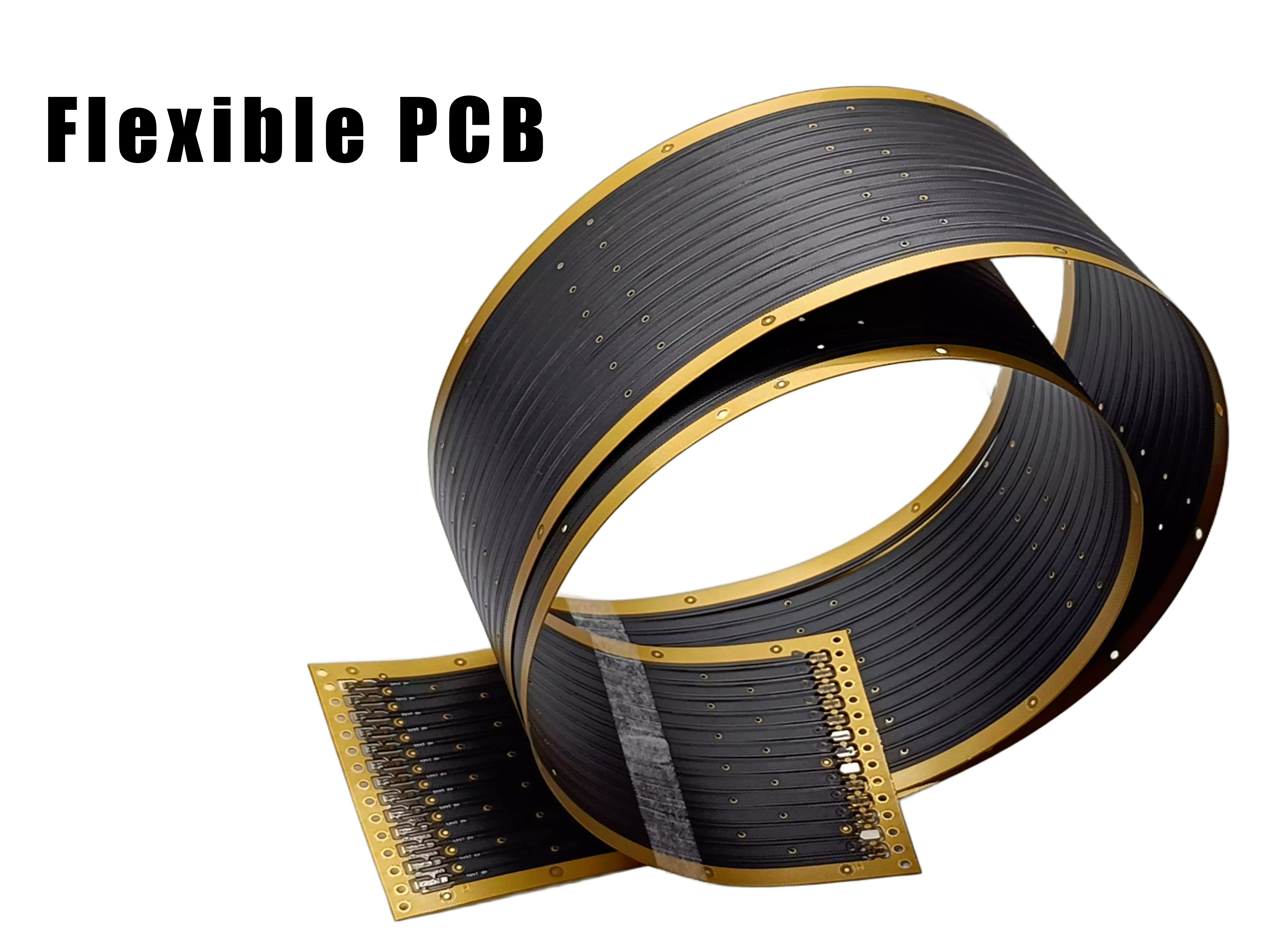

Flex PCB Design Guide: Materials, Bending Limits, Applications & Best Practices

Discover everything you need to know about Flex PCBs—what they are, how they work, and why they're essential in compact, high-performance electronics. This guide covers flex PCB types, design rules, bending limits, cost factors, and real-world applications in wearables, automotive systems, and medical devices. Learn best practices for material selection, layout, and manufacturing to improve reliability and reduce failure risks.

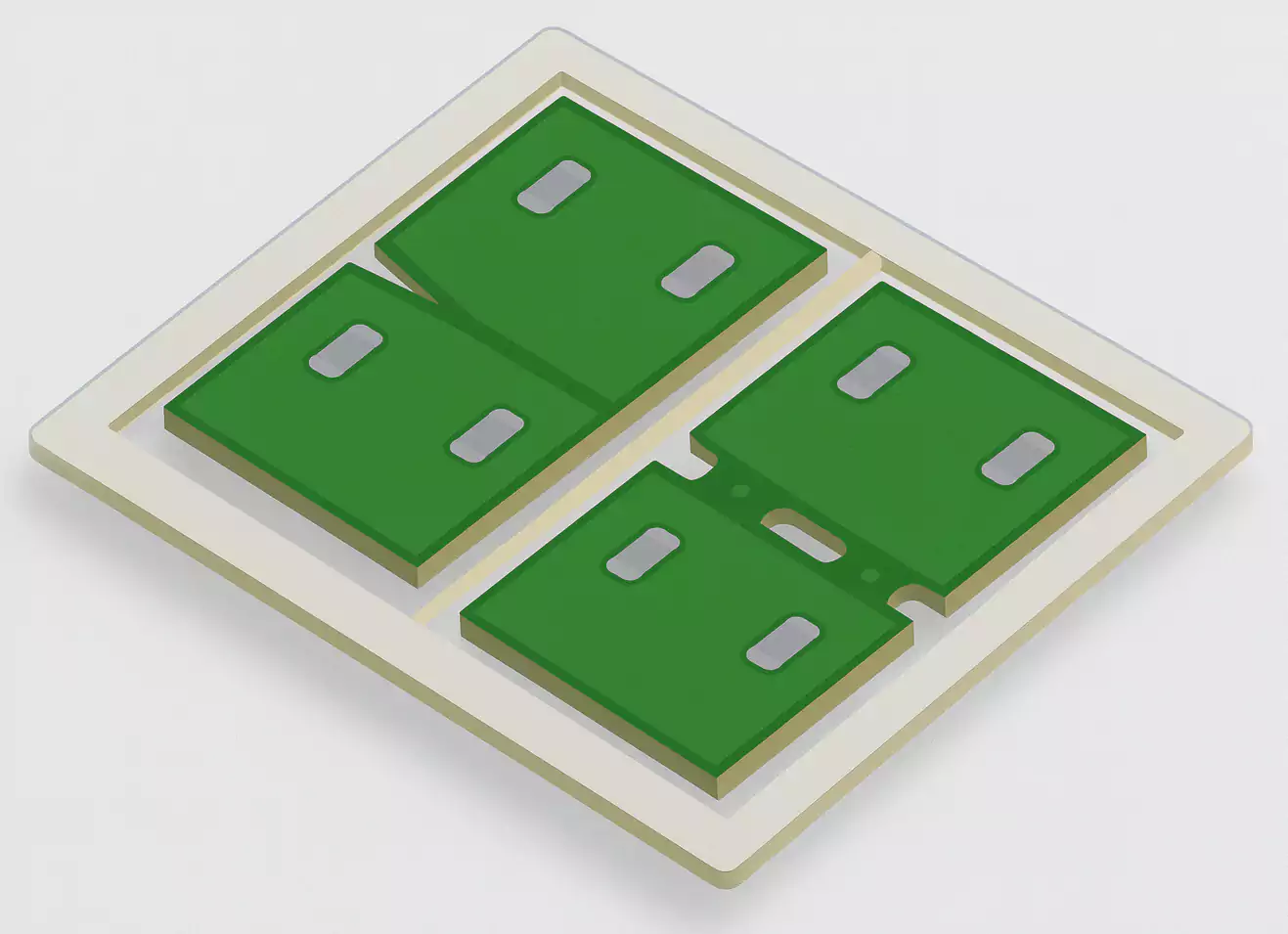

PCB Panelization Guide: Best Practices for Efficient Layout, V-Scoring, and Tab Routing

Learn everything you need to know about PCB Panelization—from V-scoring vs. tab-routing to array layout, fiducial placement, and edge rail design.