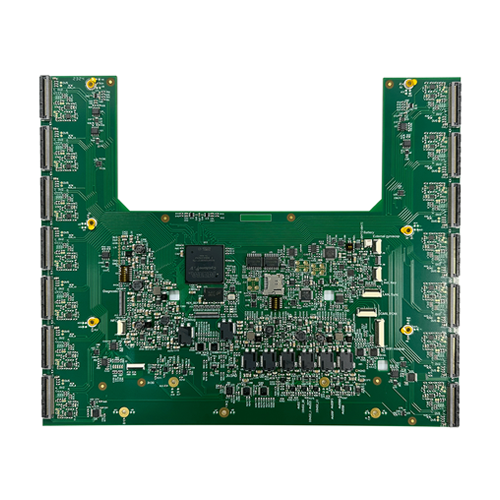

Q1: What makes this PCB suitable for automotive applications?

A: It complies with IPC J-STD-001H and IPC-A-610 HA, ensuring it meets high standards for durability, solder joint quality, and environmental resistance required in automotive systems.

Q2: Why is precious metal solder used?

A: Precious metal solders, such as high-purity gold or silver alloys, provide superior conductivity and long-term joint reliability, essential in high-vibration, high-temperature automotive environments.

Q3: Can this board be customized for specific ECU functions?

A: Yes. Layout, soldering requirements, and component selection can be tailored to meet different ECU applications (e.g., engine control, ADAS, infotainment).

Q4: Do you provide end-to-end assembly for automotive PCBs?

A: Yes. We offer full turnkey services including PCB fabrication, component sourcing, SMT assembly, and functional testing for automotive applications.

Q5: What testing standards do you follow for automotive PCBs?

A: Functional testing, ICT (In-Circuit Testing), and AOI (Automated Optical Inspection) are performed. Additional tests can be added based on customer requirements.