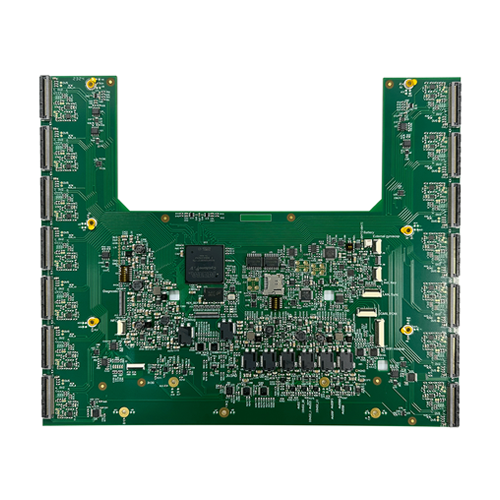

Q1: What is the main advantage of using a 32-layer PCB?

A: It allows for highly complex routing, better EMI performance, and separation of high-speed signals, power, and ground planes, essential in communication systems.

Q2: Why is impedance control critical in this board?

A: High-speed signals in communication devices require stable impedance to minimize signal distortion, crosstalk, and losses.

Q3: What challenges are associated with a 22:1 aspect ratio?

A: It demands precision in drilling and plating processes to maintain via reliability and overall board integrity.

Q4: Is back drilling essential?

A: Yes. Back drilling removes unused stubs from vias, which is crucial for signal integrity in high-speed designs.

Q5: Can this PCB be used in RF applications?

A: While it’s optimized for digital high-speed communication, with appropriate materials and layout, it can support certain RF applications as well.