Home - Services - PCB Manufacturing - High TG PCB Manufacturing Services

High TG PCB Manufacturer

High TG PCB designed for high-temperature stability and long-term reliability. Using high-Tg FR-4 materials, controlled lamination, and IPC-based fabrication processes, we deliver low-warpage, lead-free reflow-ready boards for automotive, industrial, power, and other mission-critical applications.

- All uploads are secure and confidential.

Precision High TG PCB Manufacturing Overview

High TG PCB fabrication remains a preferred choice for electronics that must maintain dimensional stability, via integrity, and electrical performance under elevated temperatures and repeated thermal stress. By using high-Tg FR-4 materials and tightly controlled fabrication processes, High TG PCBs help reduce warpage, lower delamination risk, and minimize Z-axis expansion—especially in lead-free assembly environments.

High Tg materials stay mechanically stable at higher temperatures, helping boards resist softening and deformation during lead-free reflow, extended operating heat, and thermal cycling. The result is improved hole/via reliability, more consistent impedance behavior, and stronger long-term performance in demanding use cases.

High TG PCBs are commonly specified when designs face multiple lead-free reflow cycles, repeated thermal cycling, high power density, or high-reliability requirements where mechanical stability and via robustness are critical.

FastTurn’s workflows support a smooth scale-up from prototype builds to small/medium runs and production ramp, with engineering-driven execution for high-mix programs. High TG PCB manufacturing can also be integrated with bare PCB fabrication, controlled impedance builds, and assembly-ready manufacturing.

What Is a High TG PCB ?

A High TG PCB is a printed circuit board manufactured with a laminate that has a higher glass transition temperature (Tg) than standard FR-4. Tg is the temperature at which the resin system begins to transition from a rigid, “glassy” state to a softer, more rubber-like state. When a board operates near or repeatedly crosses this transition point, material stability can drop, increasing the risk of warpage, Z-axis expansion, and reliability issues.

By using high-Tg FR-4 materials, High TG PCBs maintain better mechanical strength and dimensional stability at elevated temperatures. This is especially important for lead-free reflow soldering, where higher peak temperatures and multiple reflow cycles can stress standard materials. High TG PCBs are commonly selected to improve through-hole/via reliability, reduce heat-related deformation, and support consistent performance over long service lifecycles.

High TG PCB materials are widely used in automotive electronics, industrial control, power electronics, telecom/network equipment, and other applications where boards experience high operating temperatures, thermal cycling, or stringent reliability requirements.

Key Benefits & Performance Advantages

High-TG PCBs are chosen when designs must remain stable during lead-free reflow, elevated operating temperatures, and repeated thermal cycling. Compared with standard FR-4, high-Tg materials help reduce heat-related deformation and improve long-term reliability in demanding environments.

- Enhanced thermal stability & heat resistance

Maintains rigidity at higher temperatures, helping boards tolerate lead-free soldering profiles and high operating heat.

- Improved dimensional stability

Better stability during heating and cooling reduces warpage and alignment issues across multiple reflow cycles.

- Stronger via/PTH reliability under thermal stress

Helps minimize Z-axis expansion effects, supporting more reliable plated-through holes and via structures over time.

- Improved mechanical strength under stress and strain

Better resistance to cracking and fatigue in applications exposed to vibration, shock, or temperature swings.

- Better moisture and chemical resistance in harsh environments

Supports more stable performance, even in environments where humidity, contaminants, or industrial exposure can accelerate material aging.

- Higher long-term reliability for mission-critical electronics

Designed to help reduce heat-driven failure modes such as deformation and delamination, improving lifecycle stability.

High TG vs Standard FR-4

High TG vs Standard FR-4: When to Choose High TG

Use a High TG PCB when your board must stay stable under higher heat and repeated thermal stress, such as:

- Lead-free reflow and multiple reflow cycles

- Thermal cycling or higher operating temperatures

- High-reliability designs where lower warpage and stronger via/PTH reliability matter

High-Tg FR-4 helps maintain dimensional stability and reduce warpage compared with standard FR-4 in these conditions.

Tg vs Td: Quick Difference

- Tg (Glass Transition Temperature): the point where the resin softens, affecting stability and Z-axis expansion.

- Td (Decomposition Temperature): the point where the material begins to break down.

Tg impacts reflow/thermal cycling stability; Td indicates high-heat tolerance margin.

High Tg PCB Materials & Key Properties

Key Properties

- Thermal Stability

Maintains mechanical/electrical stability at elevated temperatures. - Lower Z-Axis Expansion (Better Via/PTH Reliability)

Reduces through-thickness expansion during heating to protect vias and plated through-holes. - Dimensional Stability (Lower Warpage Risk)

Helps reduce warpage and registration shift across multiple reflow cycles.

Material Options (Tg Levels)

- Standard Tg FR-4 — general-purpose

- Mid Tg FR-4 — improved thermal performance

- High Tg FR-4 — preferred for lead-free reflow and higher-reliability requirements

High TG PCB Fabrication Capabilities

FastTurn manufactures High TG PCBs for designs that require improved thermal stability, lower warpage risk, and dependable performance through lead-free reflow and thermal cycling. Below is a capability overview for High Tg FR-4 PCB fabrication.

- Build Options

- Layer count

Prototype to production multilayer builds - Board thickness

Standard and custom thickness options based on stackup requirements - Copper weight

Signal and power copper options to support current, thermal, and reliability needs

- Fine Feature & Drill Capabilities

- Minimum trace/space

Available for standard and advanced designs - Minimum hole size

Supported for production drill rules

- Surface Finishes

- ENIG— common for fine-pitch and assembly-ready boards

- HASL / Lead-Free HASL

- OSP

- Via Structures

- Through viasfor standard multilayer High TG PCBs

- Blind/buried vias for HDI & High TG PCB solutions

- Warpage Control & Dimensional Stability

- Stackup balancing guidance and lamination controls to reduce

- Process controls to support registration accuracy across reflow cycles.

- DFM checks focused on via integrity, Z-axis behavior, and heat-stress reliability

- Quality & Verification

- AOIand electrical testing (E-test)

- Controlled impedance verification

- Additional reliability-oriented inspection options are available upon request

Advanced Testing for Maximum Reliability

FastTurn prioritizes reliability and performance across every High TG PCB build. Because high-temperature applications and lead-free reflow place greater thermal stress on laminate systems and vias, inspection and testing are essential to verify structural integrity, electrical continuity, and build consistency before shipment.

Testing and inspection are integrated into our High Tg FR-4 PCB fabrication workflow to detect issues early and reduce field risks. Based on your design complexity and reliability requirements, we apply the appropriate verification methods to support both prototypes and small-to-medium production runs.

Testing & Inspection Capabilities

- AOI (Automated Optical Inspection)

Inspects outer-layer features for pattern accuracy, defects, and artistry consistency. - Electrical Testing (E-Test)

Verifies circuit connectivity by checking for opens, shorts, and net-to-net isolation. - Controlled Impedance Verification

Confirms impedance targets using test coupons and measurement methods when controlled impedance is required. - Microsection / Cross-Section Analysis

Evaluates plated through holes (PTH), vias, and layer registration to verify structural quality. - Solderability / Surface Finish Verification

Confirms finish condition and surface readiness for downstream assembly processes. - Warpage & Dimensional Checks

Validates dimensional stability for high-temperature builds and designs sensitive to flatness and registration. - Ionic Contamination / Cleanliness Testing

Assesses board cleanliness to reduce the risk of corrosion and electrical leakage in humid or high-reliability environments.

Quality & Certifications

Quality at Every Step

- Comprehensive Quality Control Systems

Standardized inspection procedures and process monitoring across critical fabrication steps.

- In-Process Inspection & Process Control

- Electrical Testing (E-Test)

- Traceability & Documentation

- Continuous Improvement Practices

Certifications

- ISO 9001:2015 – Quality Management Systems

- ISO 13485:2016 – Medical Device Manufacturing

- IPC-A-610 & J-STD-001 – Assembly Workmanship Standards

- RoHS / Lead-Free Compliance – Environmental Regulations

- ANSI/ESD S20.20 – ESD Protection

- SMTA Membership – Industry Standards Participation

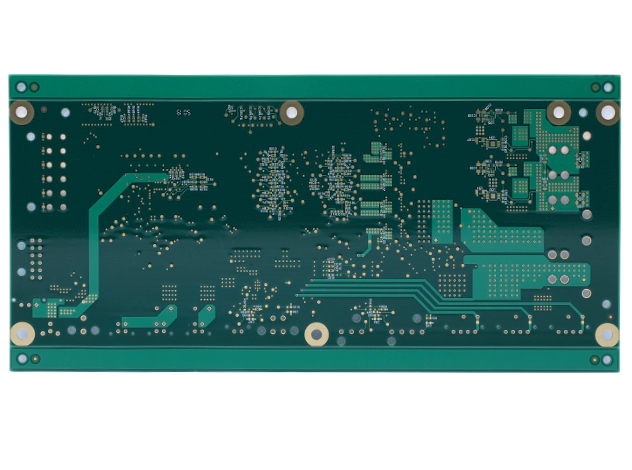

Our portfolio

Our portfolio features High TG PCB builds focused on thermal stability, low warpage, and reliable performance through lead-free reflow. From prototypes to production-ready boards, each build reflects consistent fabrication quality for demanding applications.

Prototyping to Production

FastTurn supports the full product lifecycle from fast-turn High TG PCB prototypes to scalable production, helping teams move smoothly from early validation to stable manufacturing. Our High Tg FR-4 fabrication workflows are built to maintain consistent material control, stackup intent, and quality checks as volumes scale.

High-TG PCB are commonly used in programs that require lead-free reflow, thermal cycling, or higher operating temperatures. By applying early DFM review and heat-reliability-focused process controls, we help reduce iteration cycles and support a cleaner transition to production.

Our Agile Manufacturing Model Supports

- ISO 9001:2015 – Quality Management Systems

- ISO 13485:2016 – Medical Device Manufacturing

- IPC-A-610 & J-STD-001 – Assembly Workmanship Standards

- RoHS / Lead-Free Compliance – Environmental Regulations

- ANSI/ESD S20.20 – ESD Protection

- SMTA Membership – Industry Standards Participation

Industries & Applications We Support

We serve a diverse range of industries with precision-built PCB manufacturing solutions tailored to meet their unique reliability and performance challenges.

Industries & Applications We Support

Industries & Applications

- Automotive Electronics

High Tg PCBs for control modules and electronics exposed to temperature cycling and higher under-hood heat. - Industrial & Automation

Reliable boards for control systems and equipment operating in elevated-temperature or harsh environments. - Energy & Power Systems

High Tg PCBs are used in power management and conversion electronics, where thermal stress is a concern. - Communications & Networking

Thermally stable multilayer builds supporting performance-driven hardware. - Medical Electronics

High Tg PCB fabrication for devices requiring stable performance and consistent quality (as required). - Commercial Electronics

Boards designed to withstand lead-free reflow and repeated assembly cycles. - Emerging Technologies

Prototype-to-production High Tg PCB support for new product development under tighter thermal demands.

Why FastTurn PCB?

Diverse Industry Expertise

We support industrial, medical, energy, communications, and other high-reliability industries, delivering through-hole PCB assembly and mixed-technology PCBA for applications with demanding mechanical and environmental requirements.

End-to-End PCB Assembly Solutions

FastTurn provides end-to-end PCB assembly services under one controlled workflow. Early DFM involvement helps reduce risk and enables a smooth transition from fast-turn prototypes to scalable production.

Turnkey Assembly Services

Our turnkey PCB assembly services include component sourcing, SMT and through-hole assembly, testing, and final integration—simplifying supply chains and improving execution consistency.

Advanced Manufacturing Capabilities

We support complex PCB assemblies through controlled processes, skilled technicians, and flexible assembly lines suited for high-mix and low-to-medium volume production.

Comprehensive Testing & Quality Control

Quality is embedded throughout our PCB assembly process, with inspection and testing methods applied to detect issues early and ensure long-term reliability.

Efficient Lead Times

Streamlined workflows and responsive engineering enable fast prototype turnaround and reliable production schedules without compromising assembly quality.

Inside Our Facilities

FAQ

A high Tg PCB is built with a laminate that has a higher glass transition temperature (Tg) than standard FR-4. It helps improve thermal stability, reduce warpage, and support better via/PTH reliability through lead-free reflow and thermal cycling.

Tg (glass transition temperature) is the temperature at which a resin begins to soften. Above Tg, the board is more prone to dimensional change and Z-axis expansion, which can affect long-term reliability.

High Tg FR-4 is fiberglass-reinforced epoxy (FR-4) formulated with a higher Tg. It’s commonly used for designs that face higher heat, multiple reflow cycles, or stricter reliability requirements.

High Tg FR-4 typically offers better dimensional stability under heat, helping reduce warpage and improve reliability during repeated reflow and thermal cycling compared with standard FR-4.

- Tg:where the material starts to soften (stability changes).

- Td:where the material starts to break down chemically.

Tg impacts reflow/thermal cycling stability; Td indicates high-heat tolerance margin.

Use a high Tg PCB for lead-free reflow, multiple reflow cycles, higher operating temperatures, or designs where warpage and via reliability are critical.

Looking for an expert quick-turn to turnkey PCB solution?

FastTurn PCB specializes in higher layer count PCBs, quick-turn manufacturing, HDI structures, blind and buried vias, as well as controlled impedance and precision fabrication processes.