In PCB (Printed Circuit Board) manufacturing, ensuring high-quality standards at every stage of production is paramount. While various quality control measures are applied throughout the PCB production process, FQC (Final Quality Control) is the final checkpoint before products leave the factory. This critical step ensures that only high-quality, defect-free PCBs reach the customer. This guide explains what FQC is, how it fits into the overall manufacturing process, and why FQC packaging is crucial to maintaining PCB integrity during transport.

What Is FQC? (Final Quality Control) in PCB Manufacturing

FQC stands for Final Quality Control, which occurs just before the PCB is shipped out to the customer. This is the last chance to catch any defects that may have slipped through the earlier stages of manufacturing. While initial stages like IQC (Incoming Quality Control) and IPQC (In-Process Quality Control) check for defects in the materials and during production, FQC ensures that the finished PCB meets all required specifications.

The main goal of FQC is to prevent defective PCBs from reaching the customer. It serves as a safeguard against manufacturing errors that may not have been caught in earlier quality control checks, such as electrical faults, physical defects, or issues that arise during packing and shipping. FQC acts as a final “gatekeeper” to guarantee that the product leaving the factory is of the highest possible quality.

The Role of FQC in the PCB Manufacturing Process

PCB production involves multiple stages, each with specific checks to ensure quality. The FQC process happens after the board is fully assembled and tested, but before it is packed for shipping. Here is an overview of where FQC fits in the overall manufacturing process:

- DFM (Design for Manufacturing): Ensures the design is optimized for efficient manufacturing.

- IQC (Incoming Quality Control): Verifies the quality of raw materials before production begins.

- IPQC (In-Process Quality Control): Inspects the PCB during production, focusing on soldering quality and component placement.

- AOI (Automated Optical Inspection): Visually inspects PCBs for any apparent defects.

- FQC (Final Quality Control): A final inspection to ensure the PCB meets all standards before shipping.

- OQA (Outgoing Quality Assurance): Checks the product’s overall packaging and documentation before dispatch.

By the time a PCB reaches the FQC stage, it has already undergone several rounds of testing and inspection. However, FQC remains essential because it ensures that all previous checks were performed correctly and that the board is free of defects that may have occurred after the earlier stages.

What Does FQC Inspect?

FQC is designed to catch a wide range of defects that may compromise the performance, safety, or reliability of the PCB. It involves both visual inspections and functional tests to ensure the boards meet all quality standards.

1. Appearance Check

The first part of FQC is a visual inspection, which checks for common appearance issues, such as:

- Scratches or abrasions on the surface of the board.

- Contamination such as dust, oil, or fingerprint marks.

- Misalignment or displacement of components or solder pads.

- Discoloration or oxidation due to poor handling or storage.

These issues can affect the functionality of the PCB and its ability to be assembled into the final product. For example, visible scratches on copper traces can cause electrical shorts.

2. Dimension and Hole Inspection

Accurate dimensions and correctly positioned holes are crucial for the assembly process. During FQC, the dimensions of the PCB, including:

- Slot holes

- V-cut edges

- Component placement holes

are measured to ensure they match the design specifications. Any discrepancies here could result in misalignment during assembly, making the board unusable.

3. Solder Mask and Silkscreen Checks

The solder mask keeps the PCB’s copper traces from being exposed to air, preventing oxidation. FQC checks for:

- Solder mask coverage: Ensures no copper is exposed.

- Misalignment: If the solder mask is not aligned with the traces, it can cause shorts or affect soldering.

- Legibility of silkscreen markings: Ensures that component labels and other printed information are clear and properly aligned.

4. Gold Fingers and Surface Finish

Gold fingers (the connectors on the edge of the PCB) are a crucial part of many PCBs, especially in high-speed digital applications. FQC checks for any issues with the gold finger’s placement and surface quality, ensuring that no burrs, chips, or oxidation are present. The surface finish, whether it’s ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling), is also inspected for quality.

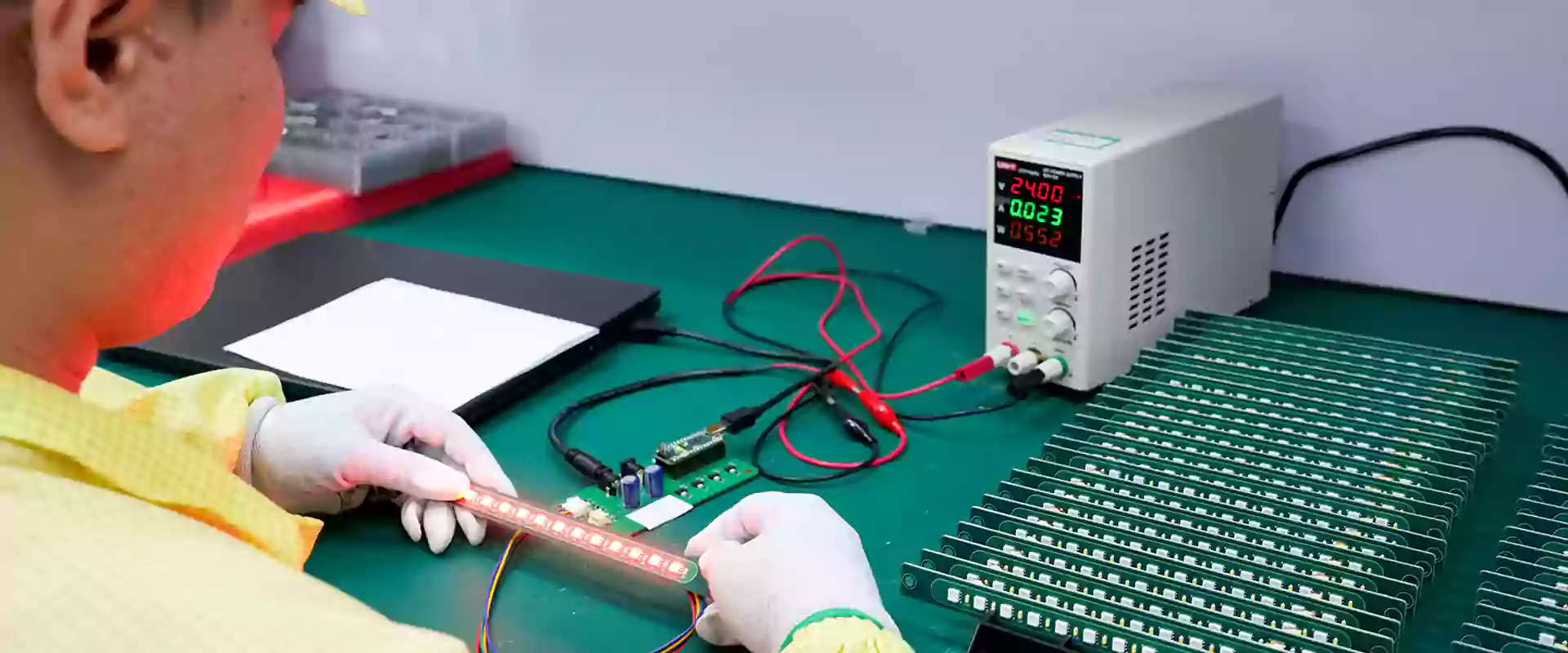

5. Electrical Testing

Electrical testing is a vital part of FQC, as it helps detect faults that are not immediately visible. The most common electrical tests in PCB manufacturing are:

- Flying Probe Test (FPT): Checks for open circuits and shorts by probing specific points on the PCB with needles.

- Fixture Test: This is a more efficient method suitable for mass production, in which the board is tested on a custom-made fixture that contacts the appropriate test points.

These tests ensure that the signal integrity and power delivery to components work as intended.

What Is FQC Packaging?

After FQC inspection, the PCB enters the packaging phase, which is equally vital in ensuring the board arrives safely and in good condition. Packaging helps protect the PCB from damage during transport and storage.

Why FQC Packaging Is Crucial

While FQC checks the quality of the PCB itself, FQC packaging is designed to prevent damage to the PCB during transportation. Even a well-manufactured PCB can be compromised if it’s poorly packaged. Here's how packaging ensures quality during transport:

- Protection from moisture: Humidity can cause oxidation and affect the board’s reliability. To prevent this, PCBs are packed with desiccants (drying agents) and sealed in vacuum bags or moisture-resistant bags.

- Prevention of static damage: PCBs are sensitive to electrostatic discharge (ESD), which can destroy their sensitive components. Therefore, they are packed in anti-static bags or other ESD-safe materials.

- Physical protection: PCBs can be fragile, especially those with thin substrates or fine-pitch components. Bubble wrap or foam inserts are used to cushion the boards during transport, preventing damage from vibration or impact.

- Labeling: Clear labeling is necessary for inventory control and shipping accuracy. This includes marking the board type, quantity, and customer-specific information. Proper labeling ensures that the right boards are shipped to the right destination.

FQC Packaging Steps:

- Cleaning: PCBs are cleaned to remove any residues, dust, or fingerprints that could lead to defects.

- Vacuum Sealing: The board is sealed in a vacuum bag to protect it from moisture and oxidation.

- Anti-Static Packaging: For sensitive components, anti-static bags or shielding are used to protect the board from electrostatic damage.

- Cushioning: The PCB is placed in protective packaging such as bubble wrap or foam to prevent physical damage during transit.

- Labeling: The product is correctly labeled with all necessary identification and shipment details.

- Documentation: A quality control report accompanies the package to confirm that the board has passed all quality checks.

What Does FQC Catch and What Doesn’t It?

FQC is a critical part of the PCB manufacturing process, but it cannot detect everything. Here's a quick breakdown:

FQC Can Catch:

- Electrical defects: Open or short circuits.

- Physical defects: Misalignment, scratches, or improper soldering.

- Surface defects: Poor solder mask coverage or silkscreen issues.

- Moisture and oxidation issues (via packaging).

FQC Cannot Catch:

- Long-term reliability issues: These may require extended testing, such as thermal cycling or stress testing, which FQC does not typically cover.

- Microscopic defects: Certain types of micro-cracks or weak solder joints may not be visible during standard FQC.

Conclusion

FQC is the final checkpoint in PCB manufacturing before the product is shipped to the customer. It ensures that the boards meet the required standards and are free from defects that may have been overlooked in previous stages. Additionally, FQC packaging plays a crucial role in protecting the board during transport and storage, ensuring that it arrives at the customer in perfect condition.

Understanding the FQC process, from inspection to packaging, helps both manufacturers and customers ensure that PCBs are of the highest quality and will perform as expected in their applications. Whether you’re a manufacturer looking to improve your FQC process or a customer ensuring the quality of your PCBs, this final quality control stage is essential for a reliable, functional product.