In advanced electronics, simply mounting integrated circuits (ICs) on a printed circuit board (PCB) is no longer enough to meet the extreme demands of size, speed, and reliability.

To overcome these physical and electrical limits, engineers developed the multi-chip module (MCM) — a compact, high-density packaging technology that integrates multiple bare chips onto a single substrate.

Essentially, an MCM is a miniaturized, high-precision PCB, but, from a packaging perspective, it’s a Level-3 system-level package that bridges the gap between conventional IC packages and the carrier PCB.

This article explains what an MCM is, why it’s used, and how different MCM types are designed and manufactured.

What Is a Multi-Chip Module (MCM)?

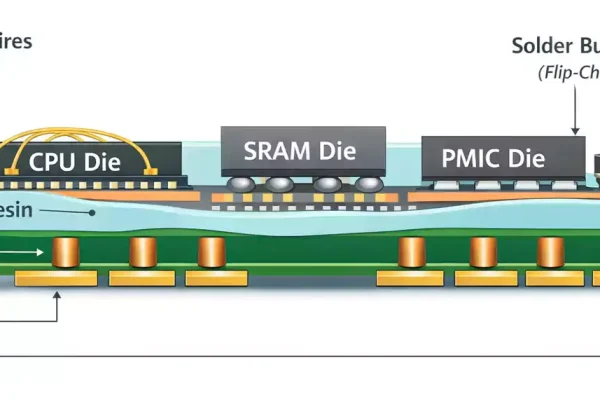

A multi-chip module (MCM) is a packaging technique in which multiple bare dies are mounted directly on a shared substrate, rather than each being enclosed in its own package.

Key Characteristics

- Eliminates individual IC packaging housings

- Allows multiple chips to share one high-density substrate

- Significantly shortens interconnect paths between chips.

- Reduces parasitic inductance and capacitance

Common Interconnection Methods

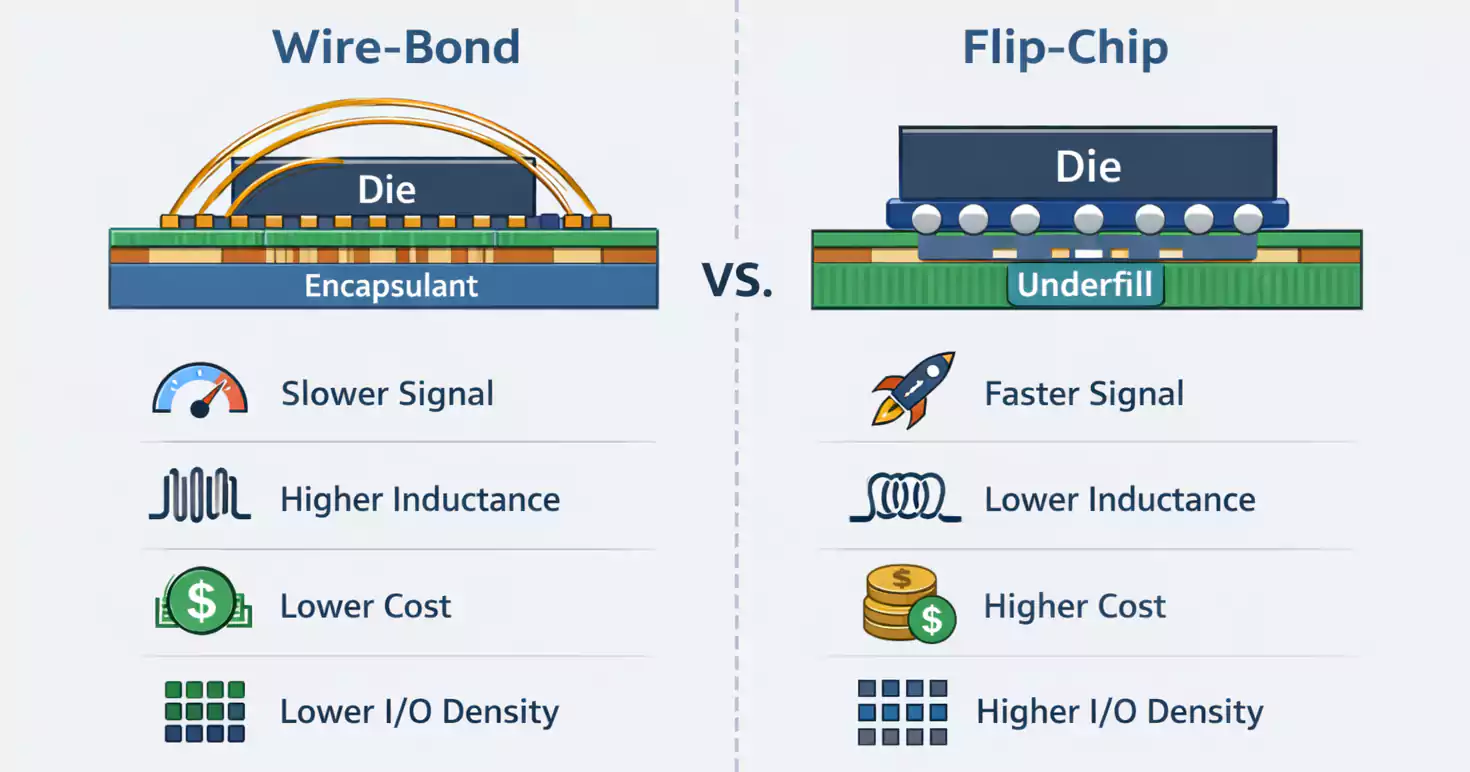

- Wire bonding

- Flip-chip bonding

- Tape Automated Bonding (TAB)

- Flip-TAB bonding

Why Use Multi-Chip Modules?

The motivation for adopting MCM technology centers on miniaturization, performance, and integration.

1. Miniaturization and Weight Reduction

By removing the individual chip packages, MCMs dramatically shrink overall system size and weight — essential for aerospace, defense, and compact consumer electronics.

2. High-Speed Performance

High-speed signals degrade quickly across long PCB traces.

MCMs minimize interconnect distance between chips, enabling much faster signal propagation and cleaner high-speed performance.

3. System-Level Integration

MCMs allow designers to integrate multiple functions or chips into a single, compact module — improving performance while simplifying system assembly.

MCM and Packaging Levels

In the electronic packaging hierarchy:

| Level 1 | Single-chip encapsulation | Plastic IC package, PGA |

| Level 2 | Component-to-PCB assembly | Various PCB types |

| Level 3 | System-level packaging | Multi-chip module (MCM), hybrid systems |

MCMs belong to Level-3 packaging, situated between IC packages and the carrier PCB.

That also means MCMs involve more complex design, tighter manufacturing tolerances, and higher cost than standard PCB-based assemblies.

Types of Multi-Chip Modules

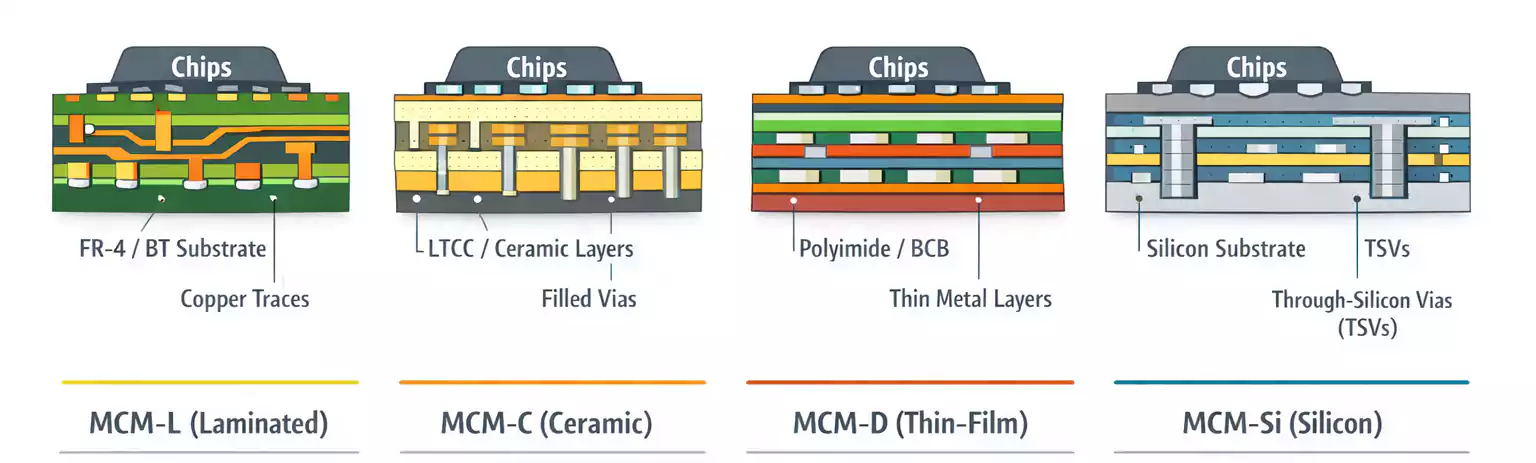

Multi-chip modules are classified by substrate material and manufacturing method.

The five most common types are MCM-L, MCM-C, MCM-D, MCM-D/C, and MCM-Si.

1. MCM-L: Laminated Multi-Chip Module

Technical Overview:

- Uses thin laminated substrates with delicate metal layers

- Built with standard PCB fabrication processes

- Finer holes, pads, and trace widths

- Often fabricated using tools similar to those used in semiconductor production.

Advantages:

- Lowest-cost MCM type

- Mature, easily scalable process.

- Compatible with existing PCB design tools and workflows

MCM-L offers the best balance of cost and manufacturability.

2. MCM-C: Ceramic Multi-Chip Module

Process Description:

- Conductive layers patterned on unfired ceramic tape

- Through-holes punched and filled.

- Layers stacked and co-fired to form a multilayer ceramic substrate.

Key Features:

- Higher cost than MCM-L but cheaper than thin-film MCMs

- Excellent thermal stability and reliability

- Proven technology — used for decades in IBM mainframes

PCB design tools and methodologies can be easily adapted for ceramic MCMs.

3. MCM-D: Thin-Film Multi-Chip Module

Technology Approach:

- Alternating layers of thin dielectric and metal films

- Deposited on substrates such as silicon, ceramic, or metal

- Very similar to IC metallization processes

Advantages:

- Extremely high interconnect density

- Outstanding thermal conductivity

- Ideal for high-frequency, high-performance applications

Limitations:

- Requires advanced design and fabrication equipment

- High cost and limited process availability

4. MCM-D/C: Thin-Film / Co-Fired Hybrid MCM

This hybrid MCM combines:

- A co-fired multilayer ceramic substrate, and

- Thin-film interconnect layers are deposited on top.

Engineering Challenges:

- Complex material compatibility

- Mismatch in thermal expansion coefficients

- High manufacturing difficulty and cost

Typically used in defense or aerospace systems that demand both ceramic durability and thin-film precision.

5. MCM-Si: Silicon Substrate Multi-Chip Module

Concept:

- Uses silicon wafers as the substrate

- Metal patterns (aluminum or copper) formed on silicon dioxide

- Fabrication methods are nearly identical to those used in integrated circuit manufacturing.

Unique Advantages:

- Perfect thermal match with IC dies.

- Excellent thermal conductivity

- Superior reliability even under extreme temperature conditions

High tooling cost and limited scalability, but unmatched in performance for specialized, high-end systems.

Summary: Engineering Tradeoffs in MCM Design

Performance vs. Cost

MCMs provide unmatched electrical and mechanical performance:

- Reduced size and weight

- Lower signal delay and crosstalk

- Better overall reliability

However, these benefits come at the cost of:

- Increased design complexity

- High manufacturing cost

- Lower production yield

Integration vs. Fabrication Feasibility

For most mass-market applications, higher single-chip integration (SoC) is more cost-effective than using multiple discrete dies in an MCM.

However, for low-volume or specialized systems, such as:

- Aerospace and defense electronics

- High-performance computing modules

- Custom graphics or video processors

MCMs remain the optimal solution due to their ability to integrate chips built with different process technologies — such as analog + CMOS or ECL + CMOS — within one module.

Conclusion

The multi-chip module (MCM) represents a key milestone in the evolution of electronic packaging — merging the flexibility of PCBs with the density and precision of semiconductor fabrication.

MCMs enable engineers to achieve system-level integration, faster performance, and superior thermal reliability in compact form factors.

While their cost and complexity limit mass adoption, MCM technology continues to power mission-critical, high-performance systems where traditional PCBs can’t compete.