In modern electronics, the printed circuit board (PCB) is not an isolated component — it’s part of a larger electronic packaging system.

To fully understand how electronic devices are assembled, protected, and interconnected, engineers must recognize the different levels of electronic packaging and how the PCB fits into this hierarchy.

This guide explains the key levels of electronic packaging, their characteristics, and the critical role PCBs play in connecting and supporting electronic packages.

Factors That Influence Electronic Packaging Choices

Choosing the right electronic packaging solution depends on a complex balance of performance, cost, and manufacturability. Engineers typically evaluate:

- Quality and reliability

- Size and weight constraints

- Material and production cost

- Electrical performance and signal speed

- Ease of assembly and repair

- Heat dissipation requirements

- Functional complexity and system integration

There is no “best” universal packaging — only the most appropriate electronic package for a given application.

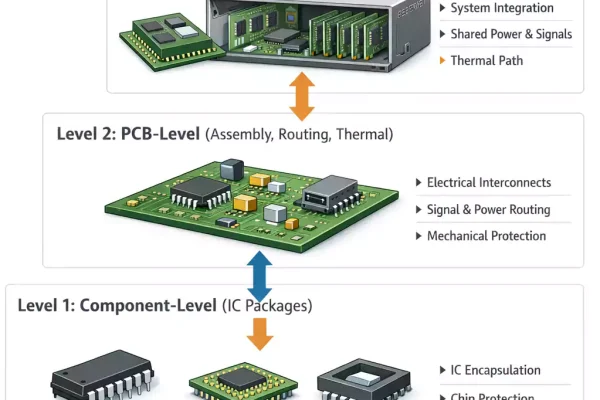

Understanding the Three Levels of Electronic Packaging

Electronic packaging is typically categorized into three hierarchical levels, representing how electronic packages are grouped and integrated within a system.

Level 1: Component-Level Electronic Packaging

Level 1 electronic packaging refers to the encapsulation of a single semiconductor device or electronic component. It provides mechanical protection and an electrical connection between the chip and the outside world.

Common package types:

- Plastic-molded ICs (e.g., DIP, SOIC, QFN)

- Ceramic cavity packages

- Pin Grid Arrays (PGA)

Main functions:

- Protect the bare die from environmental stress.

- Provide standardized lead or pad interfaces.

- Enable electrical, mechanical, and thermal contact between the chip and the board.

In short, Level 1 packaging defines the physical and thermal “home” of the chip.

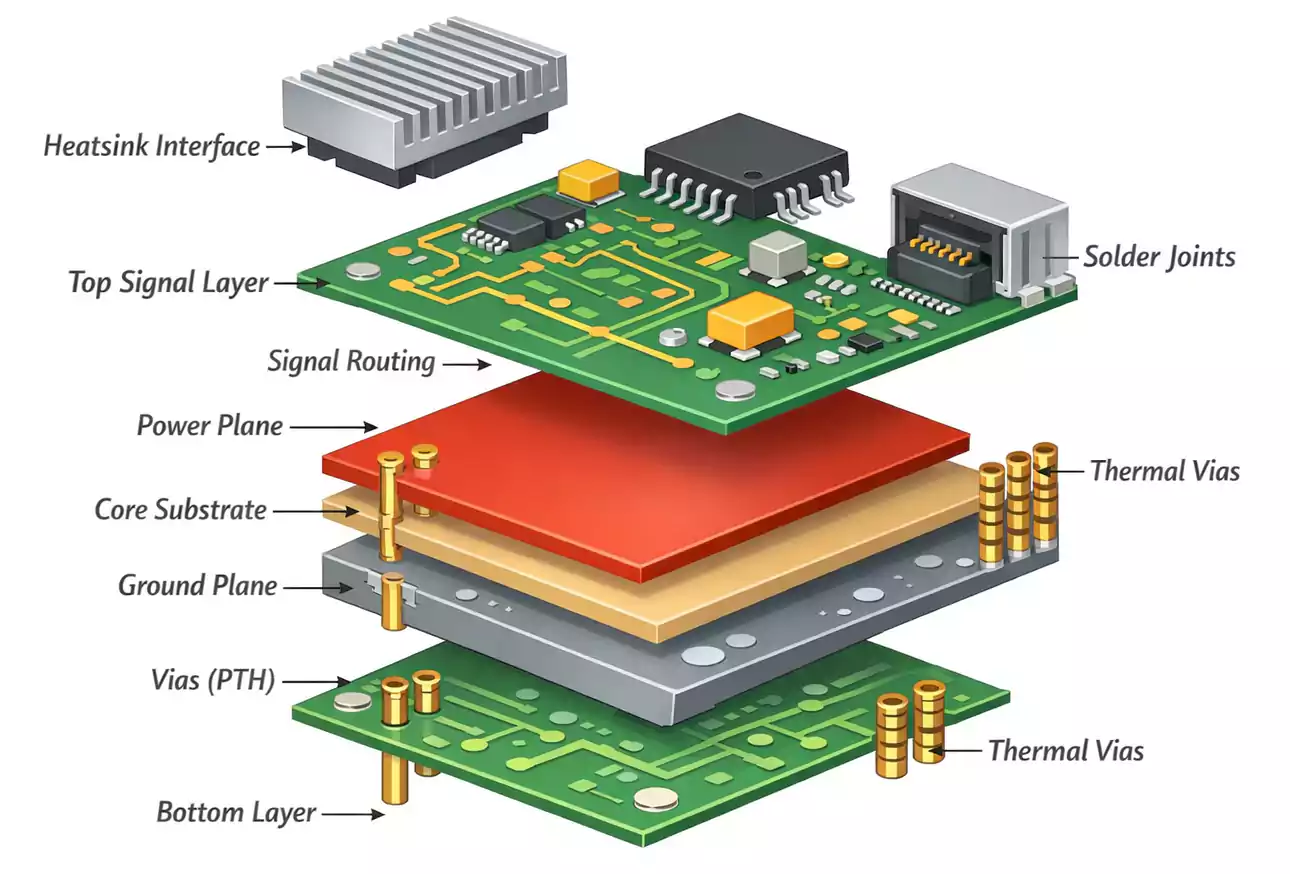

Level 2: PCB-Level Electronic Packaging

Level 2 electronic packaging integrates multiple components or modules onto a printed circuit board (PCB) or substrate to form a complete electrical circuit.

Includes:

- Mounting and soldering of components

- Power and signal routing

- Structural and thermal design considerations

Typical carriers:

- Single-sided or double-sided PCBs

- Multilayer PCBs

- Flexible PCBs

- Rigid-flex PCBs

Industry insight:

At this level, electronic packages (ICs, resistors, capacitors, connectors) are assembled and interconnected to create functional circuits.

This stage largely determines a product’s performance, reliability, and manufacturability.

Level 2 packaging is the core layer of most electronic products — where design, layout, and production precision matter most.

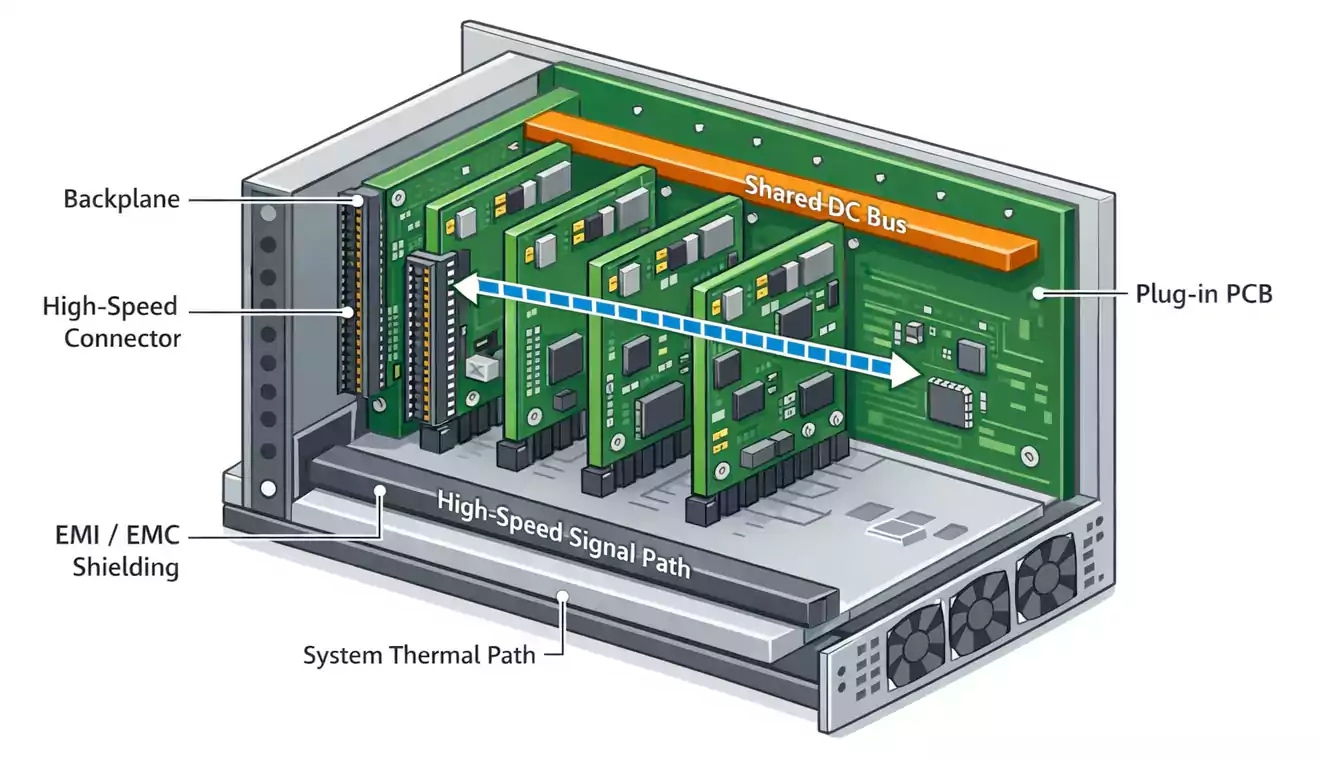

Level 3: System-Level Electronic Packaging

Definition:

Level 3 electronic packaging refers to system-level integration, where multiple PCBs or modules are combined into a complete electronic system.

Typical forms:

- Multi-Chip Modules (MCM)

- System-in-Package (SiP)

- Rack-mounted or backplane-based assemblies

Key features:

- Integration of multiple chips or boards

- Shared power and signal interconnects.

- Designed for high performance, compact size, and superior reliability

At this level, electronic packaging goes beyond individual boards — it becomes a complete electronic ecosystem.

Relationship Between Packaging Levels and PCBs

| Level 1 | Single component | IC packages, PGA |

| Level 2 | Circuit assembly | PCB with mounted components |

| Level 3 | System integration | MCM, backplanes, complete modules |

The PCB serves as the bridge between Level 1 and Level 3 packaging, linking individual electronic packages into a unified, functional system.

Why Electronic Packaging Matters

Electronic packaging is more than physical protection — it’s the foundation for reliability, manufacturability, and thermal management.

Effective packaging design ensures:

- Stable mechanical support

- Efficient thermal paths

- Reliable interconnections

- Long-term durability under stress

Modern electronic systems — from smartphones to aircraft avionics — depend on precise collaboration between component-level packaging and system-level PCB design.

FAQ — Electronic Packaging

What is electronic packaging?

Electronic packaging is the mechanical, electrical, and thermal framework that protects components, routes signals/power, and enables reliable assembly from chip to system.

What are the three levels of electronic packaging?

Level 1: the component/package (single device).

Level 2: the PCB-level assembly of multiple electronic packages.

Level 3: system-level integration (multiple boards/modules).

How do PCBs fit into electronic packaging?

The PCB is the Level-2 carrier that supports electronic packages and interconnects them, bridging chips (Level-1) to systems (Level-3).

How do multilayer PCBs help?

They add power/ground planes and controlled-impedance routing to improve signal integrity, power integrity, and EMI performance.

When should I use rigid-flex?

Use rigid-flex for compact 3D folding, fewer connectors/cables, higher reliability, and weight/space savings.

What is a backplane at Level-3?

A backplane is a slot-based PCB that ties multiple boards into one system and distributes power/high-speed signals.

How does electronic packaging manage heat?

By providing conductive paths, thermal pads/spreaders, and suitable interface materials to keep junction temperatures within spec.

Conclusion

From single-chip electronic packages to multi-board systems, electronic packaging represents the art and science of balancing performance, space, and manufacturability.

Understanding these packaging levels helps engineers choose the right PCB technologies and assembly methods to achieve optimal reliability and performance.

In essence, electronic packaging is where physics, materials, and manufacturing converge — turning electronic concepts into real, functional products.