In multilayer printed circuit board (PCB) fabrication, dimensional stability is one of the most critical factors that determine registration accuracy and overall manufacturing consistency. As the number of PCB layers increases and the spacing between vias and pads decreases, maintaining precise layer alignment becomes increasingly difficult.

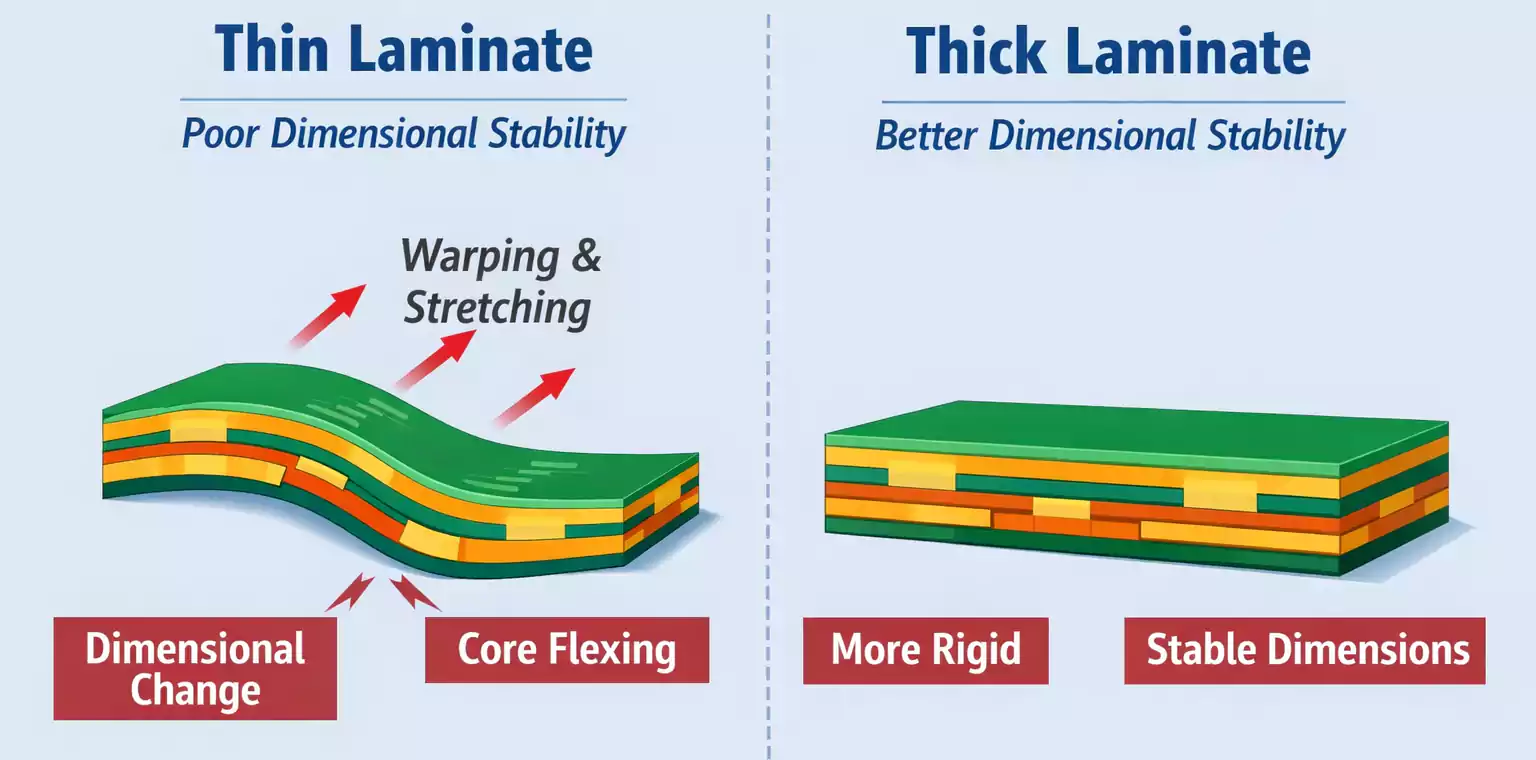

While selecting appropriate materials and optimizing processing parameters can improve interlayer registration, the laminate's dimensional stability remains the most decisive factor — especially in thin laminates, which are inherently less stable than thicker ones.

Why Dimensional Stability Matters

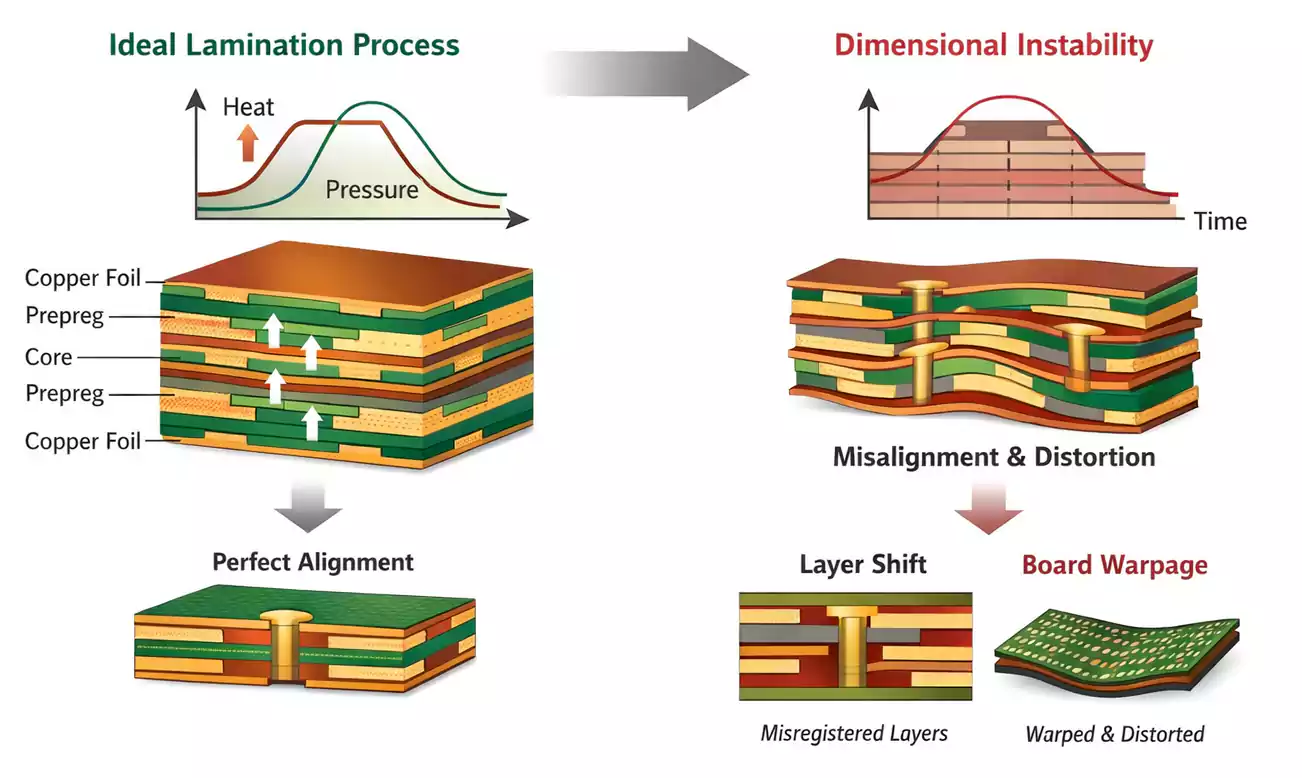

During PCB production, materials undergo multiple cycles of heating, cooling, and mechanical stress. Even slight dimensional changes can cause:

- Misalignment between inner layers and plated through-holes;

- Increased risk of shorts or open circuits;

- Warping or bowing of the finished board;

- Assembly issues and reduced yield.

For high-layer-count, high-density PCBs, achieving dimensional stability is therefore not just a materials challenge but a process-wide discipline.

How to Improve Dimensional Stability

Although many variables in laminate and PCB fabrication can influence dimensional stability, several proven strategies can help manufacturers control and enhance it. These include optimizing lamination parameters, managing resin content, using high-Tg materials, and developing new resin systems and processing technologies.

Let’s examine three major factors in detail.

1. Control During Laminate Manufacturing

In the past, some PCB manufacturers required laminators to bake laminates before shipment or to bake them before use, to relieve residual stresses within the material. While this practice can help slightly, it adds process time and complexity, making it less favorable for modern production.

A more effective approach is to reduce pressure at specific stages during the lamination cycle to minimize stress accumulation in the finished product.

Recent innovations — such as direct current-assisted lamination and continuous lamination processes — have also improved dimensional consistency. These techniques allow for lower lamination pressure and more uniform heat distribution between panels, resulting in better control of thermal expansion and contraction.

Other factors that affect dimensional stability include:

- Glass cloth tension during prepreg manufacturing.

- Heating rate and temperature/pressure profiles during lamination;

- Stack-up prearrangement and core alignment techniques.

Maintaining consistent parameters across batches enhances not only laminate stability but also overall PCB fabrication repeatability.

2. The Role of Reverse-Treated Foil (RTF)

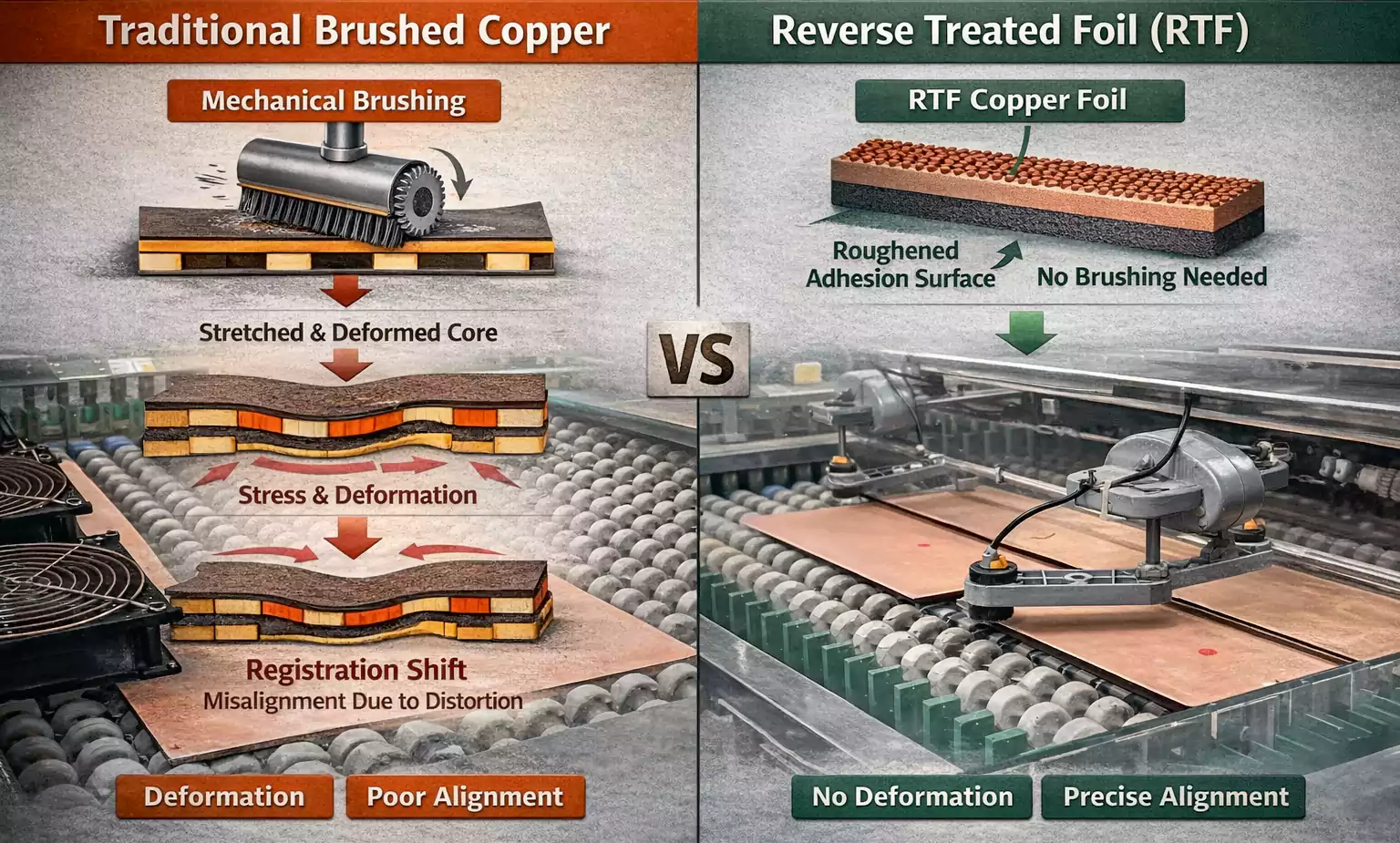

During inner-layer imaging, traditional copper foils often require mechanical brushing or roughening to improve adhesion between the copper surface and photoresist. However, brushing can cause stretching or deformation — especially in thin cores.

Although this deformation is mostly elastic and tends to recover over time, if the core is exposed and imaged before full relaxation, the recovery process continues afterward, causing pattern misregistration. Inconsistent brushing parameters between batches can further worsen alignment issues.

Using reverse-treated foil (RTF) eliminates the need for such mechanical brushing. RTF features a pre-treated rough surface on the outer side, providing strong adhesion to dry-film photoresist while maintaining excellent flatness. By avoiding mechanical stress, RTF significantly improves dimensional stability and registration accuracy.

3. Glass Cloth Type and Resin Content Control

Each glass fabric style (such as 106, 1080, 2116, 7628, etc.) used in laminates and prepregs corresponds to an optimal resin content range. Keeping the resin content within this range ensures proper wet-out of the glass fibers, uniform dielectric thickness, and consistent dimensional behavior.

Different glass weave styles have varying effects on resin absorption, shrinkage, and expansion characteristics. Selecting an appropriate combination of glass cloth types allows manufacturers to cover a wider range of dielectric thicknesses while maintaining uniformity.

Precise resin content control leads to:

- Reduced internal stress between layers;

- Better CTE (Coefficient of Thermal Expansion) matching;

- More consistent finished board thickness.

- Improved registration and overall dimensional stability.

Achieving Dimensional Stability: A System-Level Approach

Improving dimensional stability is not a single-step process — it requires systematic control across materials, process, and equipment. The table below summarizes key improvement strategies:

| Lamination process | Optimize pressure and temperature curves | Reduce residual stress, improve uniformity |

| Copper foil | Use RTF copper | Eliminate brushing, prevent deformation |

| Resin content | Maintain within controlled range | Ensure consistent glass wet-out and dielectric thickness |

| Material selection | Choose high-Tg, low-CTE laminates | Enhance thermal resistance and dimensional control |

| Process consistency | Standardize material handling and prep | Improve repeatability and inter-batch stability |

Conclusion

With the rise of high-density interconnect (HDI) and multilayer PCB designs, dimensional stability has become a defining factor for yield, performance, and reliability.

By carefully managing lamination parameters, selecting suitable copper foils and glass fabrics, and maintaining precise control of resin content, PCB manufacturers can greatly enhance dimensional and registration accuracy.

Looking ahead, the continued development of high-Tg resins, low-moisture materials, and continuous lamination technologies will further improve the dimensional stability of laminates — laying a solid foundation for next-generation high-speed, high-reliability circuit designs.