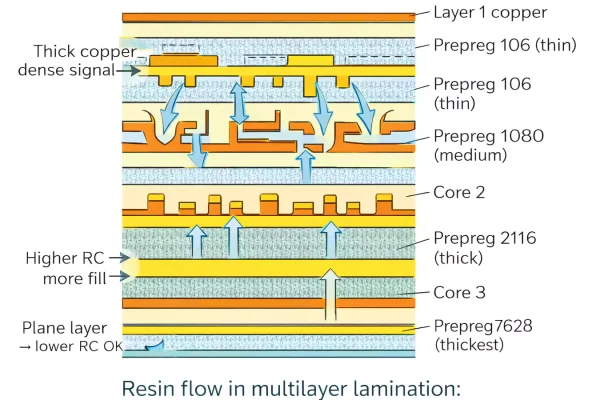

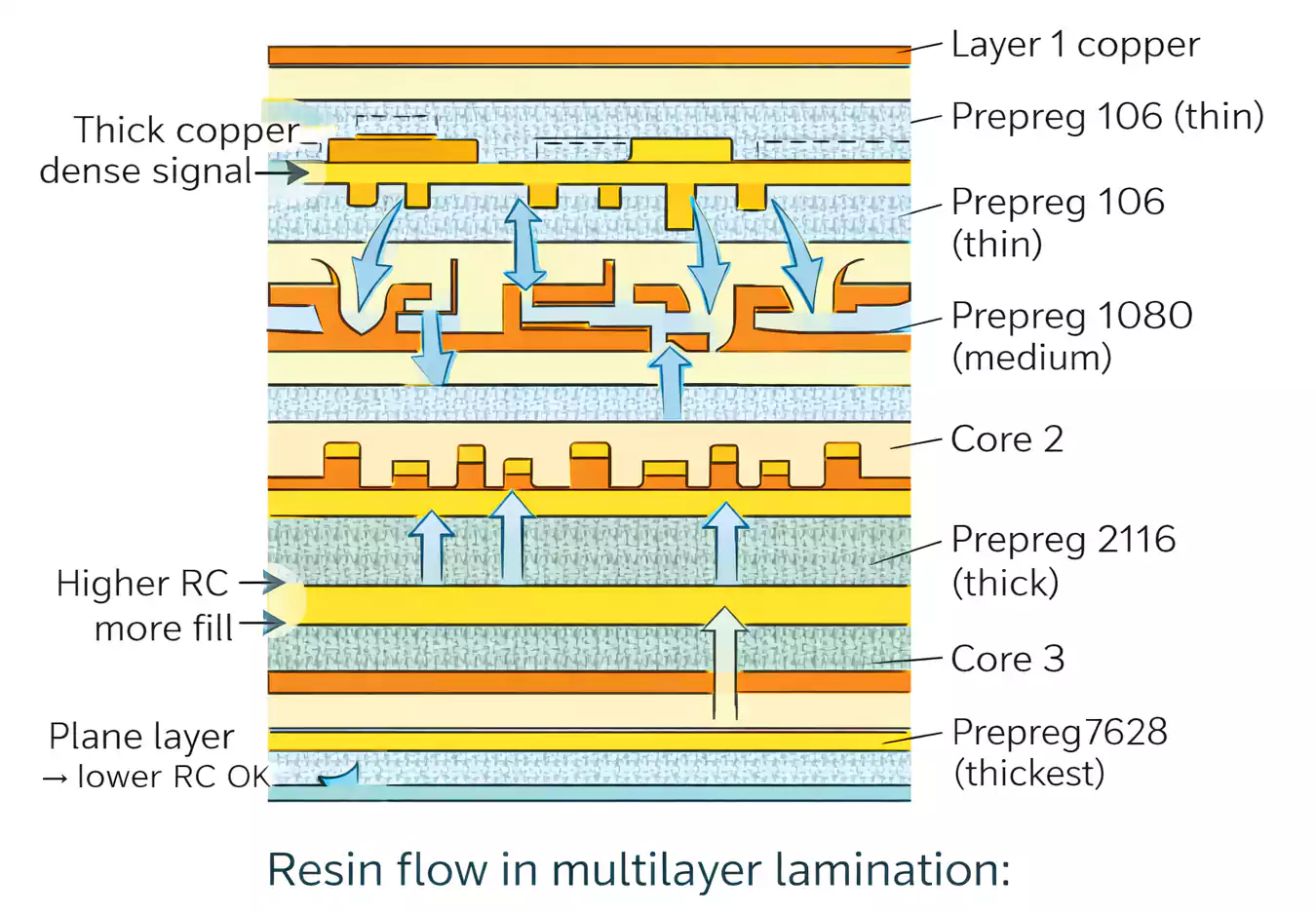

In multilayer Prepreg PCB fabrication, the prepreg — also known as a bonding sheet — is the key adhesive layer that bonds copper-clad laminates and inner layers. Its composition and thickness directly affect dielectric spacing, resin flow, and the ability to fill etched copper traces.

Understanding how to select the proper Prepreg PCB type and manage its final pressed thickness is essential for achieving signal integrity, inter-laminar adhesion, and long-term reliability.

What a Prepreg PCB Is and Why It Matters

Like base laminates, prepreg PCB come in multiple reinforcement configurations. Each glass-cloth style (106, 1080, 2113, 2116, 2165, 7628, etc.) can be coated with different resin contents and exhibit varying flow characteristics.

During lamination, prepreg in PCB stack-ups performs three critical functions:

- Bonding: Creates adhesion between layers.

- Dielectric Control: Defines inter-layer insulation thickness.

- Filling: Resin must flow adequately to fill the inner-layer copper topography.

Because resin behavior depends on resin content (RC %), resin flow, and glass weave density, the choice of Prepreg PCB must balance electrical, mechanical, and processing requirements.

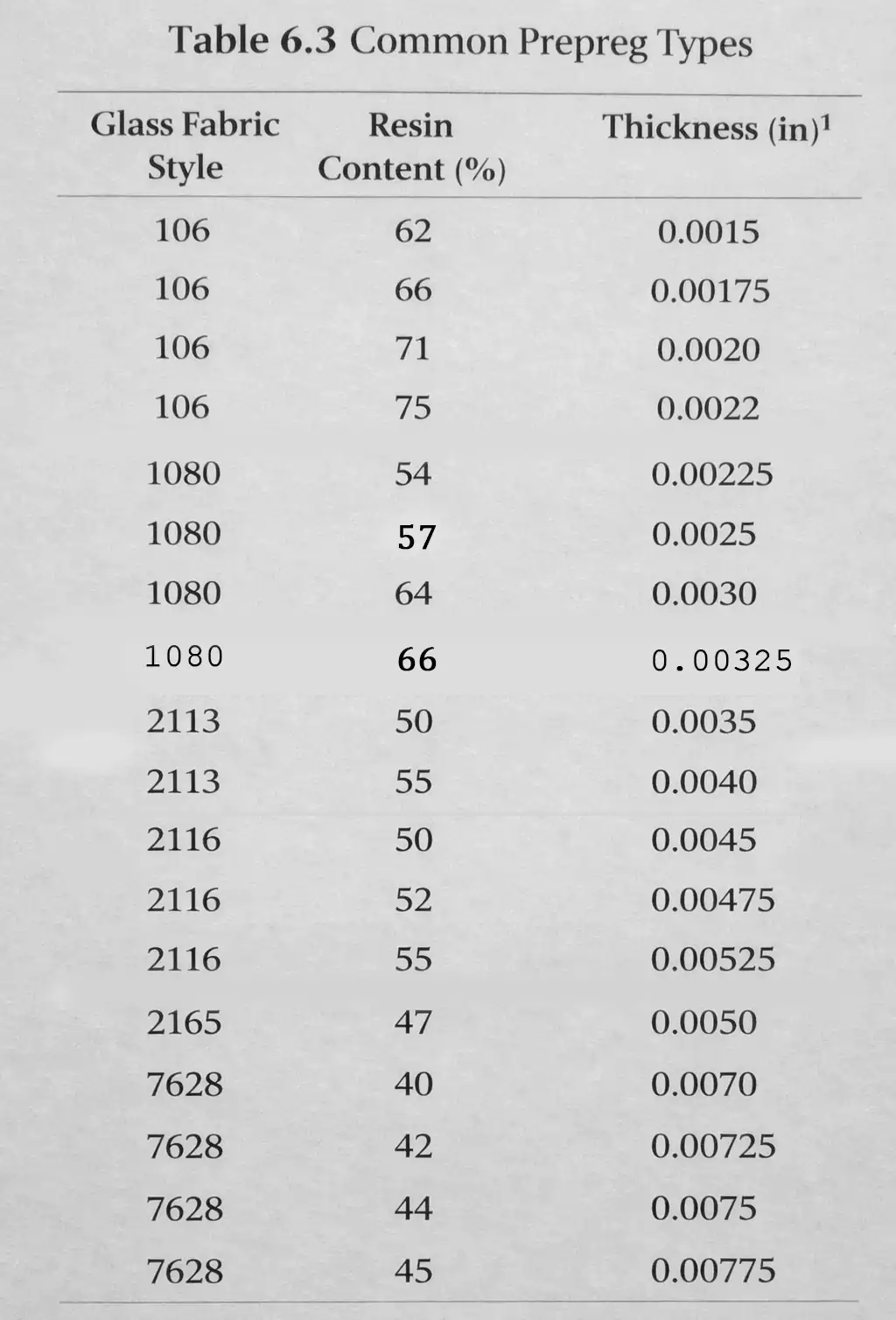

Typical Prepreg PCB Types and Thickness (Table 6.3)

Note ①: All values represent typical pressed thicknesses at a fixed resin-flow rate and without filling copper traces or voids.

In actual Prepreg PCB lamination, when the resin must fill etched patterns or thick copper areas, the final dielectric thickness is reduced from the nominal value.

This clarification helps engineers interpret Table 6.3 correctly — it is a baseline reference, not a guaranteed final board thickness.

How Copper and Line Density Drive Prepreg PCB Selection

Inner-layer copper geometry directly influences how much resin flow is required for void-free bonding:

- Thick copper or high-density signal layers: Require higher RC% and higher resin flow to fill etched gaps.

- Thin copper or plane layers (power/ground): Allow lower RC%, reducing squeeze-out and improving dimensional stability.

For example, 1080HR Prepreg PCB (≈64–66% resin) performs well between heavy-copper signal layers, while 2116SR Prepreg PCB (≈50% resin) is ideal for plane-to-plane bonding applications.

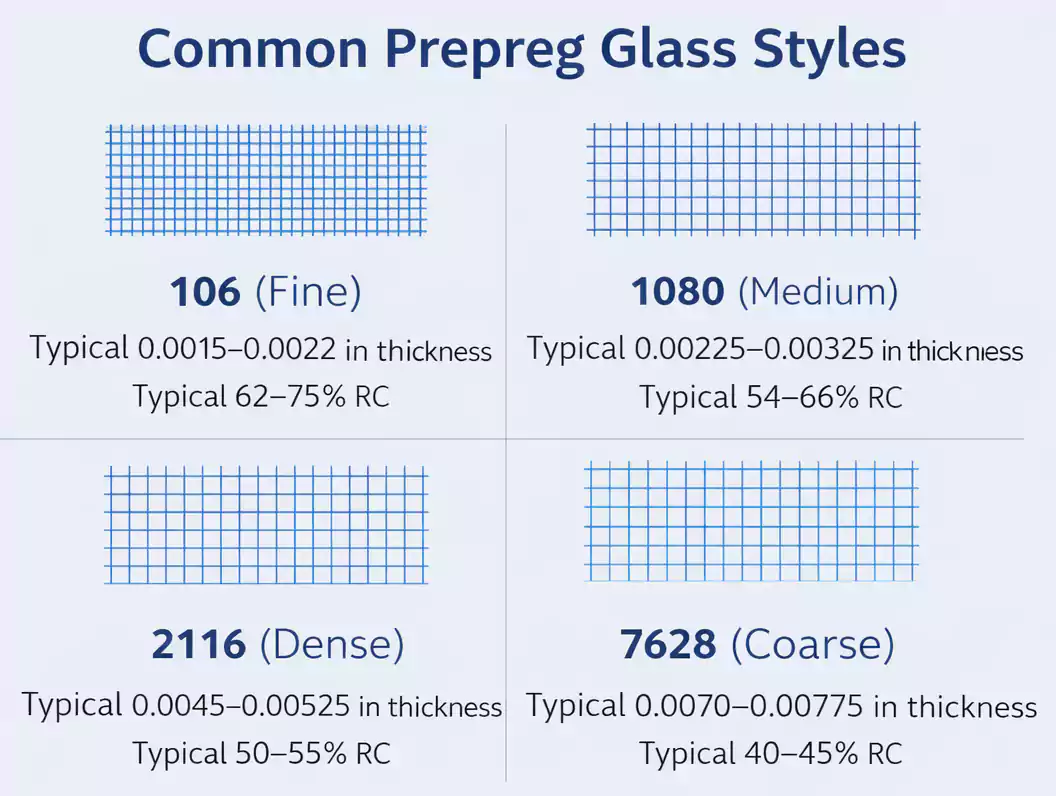

Glass Weave Styles and Pressed Thickness Behavior

Each glass-cloth style in Prepreg PCBs has a unique weave density and fiber count, directly affecting resin uptake and mechanical strength:

| 106 | Very fine weave | Ultra-thin, high flow; ideal for thin dielectrics |

| 1080 | Medium weave | Balanced strength and resin volume; common in multilayers |

| 2113 | Medium-thick | Stable with moderate flow |

| 2116 | Dense weave | Higher glass ratio, suitable for thicker dielectrics |

| 7628 | Coarse weave | Thickest, lowest flow; used for rigid-core bonding |

Trend Insight

Within the same glass style, higher resin content (RC%) produces a thicker pressed dielectric due to increased resin volume and flow potential.

Examples:

- 106 → 62% RC = 0.0015 in; 75% RC = 0.0022 in

- 1080 → 54% RC = 0.00225 in; 66% RC = 0.00325 in

This positive correlation is essential for accurate Prepreg PCB stack-up modeling.

Resin Content and Flow Levels (SR / MR / HR)

Manufacturers supply multiple resin-content levels for each Prepreg PCB style:

- SR (Standard Resin): Low flow; ideal for plane layers.

- MR (Medium Resin): Balanced flow; standard for signal layers.

- HR (High Resin): High flow; designed for thick-copper or etched regions.

Choosing the right RC class ensures full copper filling without excessive squeeze-out, helping maintain dielectric consistency and prevent lamination voids.

Balancing RC and Flow for Reliable Prepreg PCB Lamination

Too little resin leads to voids and delamination, while too much can cause overflow, dielectric shrinkage, and thickness variation.

Data show that increasing RC from 42% to 56% can change Dk by nearly 5%, directly affecting impedance.

Therefore, Prepreg PCB designers must balance electrical needs (impedance) with mechanical requirements (filling and bonding).

Thickness Tolerance and Copper Distribution Effects

Pressed thickness values are guidelines, not fixed. Real Prepreg PCB outcomes depend on:

- Copper pattern density and copper weight

- Lamination pressure and temperature profile

- Resin flow range and curing behavior

Most suppliers specify a ±10% thickness tolerance. To achieve tight impedance control, always use measured dielectric data from your fabricator — not just nominal chart values.

Practical Tips for Prepreg PCB Design

- Start from the target dielectric thickness, not the number of prepreg sheets.

- Match RC and flow to the copper pattern — high RC for etched layers, low RC for plane layers.

- Combine multiple prepreg styles (e.g., 1080 + 2116) to fine-tune overall thickness.

- Specify both RC% and flow level (SR/MR/HR) in your stack-up documentation.

- Verify supplier data — pressed thickness varies between Isola, Panasonic, and Shengyi materials.

Example: Applying Prepreg PCB Selection in Design

For a 6-layer board with 2 oz inner copper, use 1080HR Prepreg PCB (64–66% RC) between cores to ensure full resin fill.

Target dielectric thickness: ≈0.0030–0.0032 in (per Table 6.3).

For plane-to-plane bonding, switch to 2116SR (50–52% RC) to reduce flow and improve dimensional stability.

Conclusion

Selecting and controlling Prepreg PCB materials is a foundation of multilayer PCB quality. Engineers must evaluate glass fabric style, resin content, resin flow, and copper geometry together.

Table 6.3 lists six standard FR-4 prepreg styles — 106, 1080, 2113, 2116, 2165, and 7628 — spanning a range of thicknesses from 0.0015 to 0.0078 inches. Increasing the resin content increases both flow and the final dielectric thickness. These are nominal figures at constant flow with no copper fill; actual boards will press thinner due to resin migration.

In summary, Prepreg is not just glue; it’s a precisely controlled dielectric system.

Mastering the behavior and thickness control of Prepreg PCB resin is key to consistent impedance, tight tolerances, and long-term reliability.