In modern PCB assembly (PCBA) manufacturing, the Surface Mount Technology (SMT) production line is the backbone of electronic component assembly.

While individual operations are important, it is the stability, precision, and consistency of the entire SMT process flow that ultimately determine product quality and delivery reliability.

This article provides a clear, technical overview of the standard SMT production process, along with practical insights into how different process methods can be implemented for various product requirements.

Why the SMT Process Flow Matters

In SMT manufacturing, every stage is tightly connected to the next.

A small deviation in an early step can magnify into large-scale defects later.

A well-defined, repeatable process flow is therefore essential to ensure:

- High and consistent product quality

- Predictable yields and reduced rework

- Shorter lead times and improved cost efficiency

In short, a robust SMT process is the foundation for any high-quality PCBA production line.

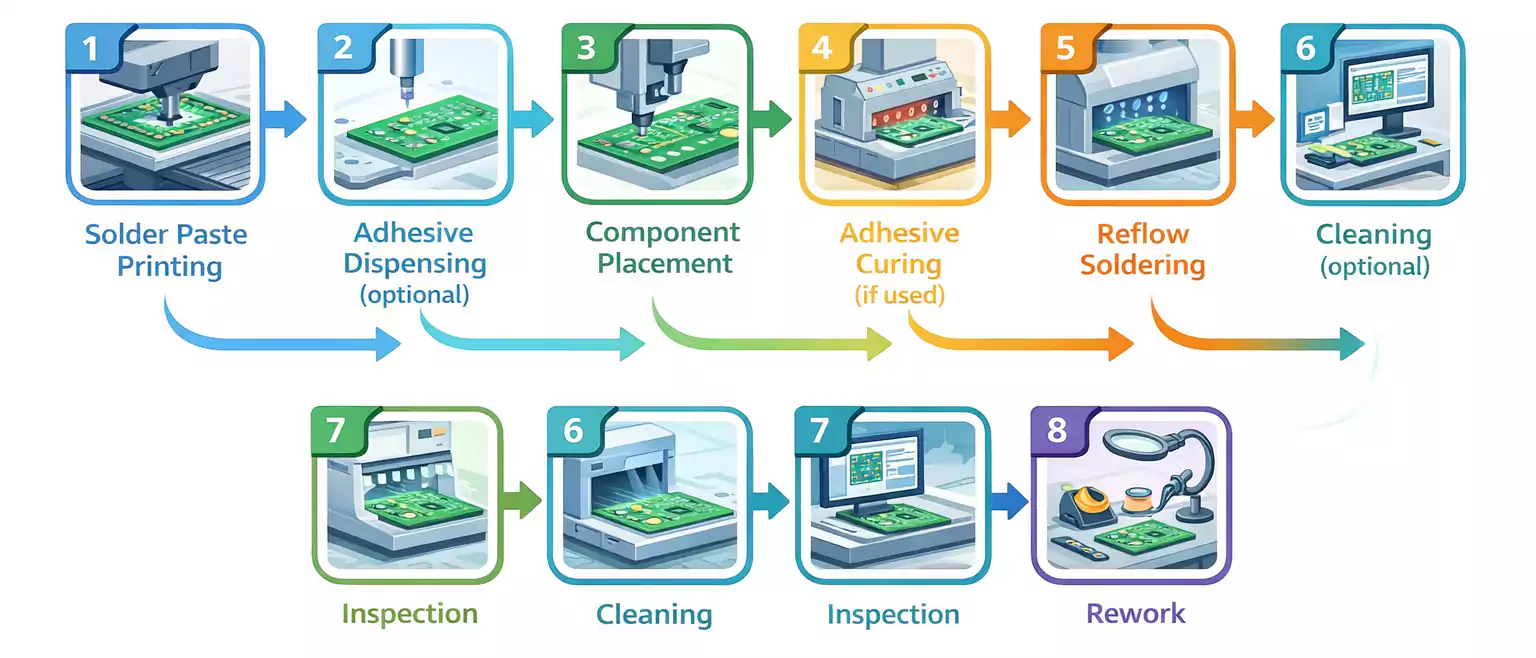

Overview of the SMT Process Flow

Although process details vary by product and factory setup, the standard SMT production line typically follows eight main steps:

- Solder Paste Printing

- Adhesive Dispensing (optional)

- Component Placement

- Adhesive Curing (if adhesive is used)

- Reflow Soldering

- Cleaning (optional)

- Inspection

- Rework

This flow covers the complete surface-mount assembly process — from materials application to solder joint formation, inspection, and repair.

Key SMT Process Steps Explained

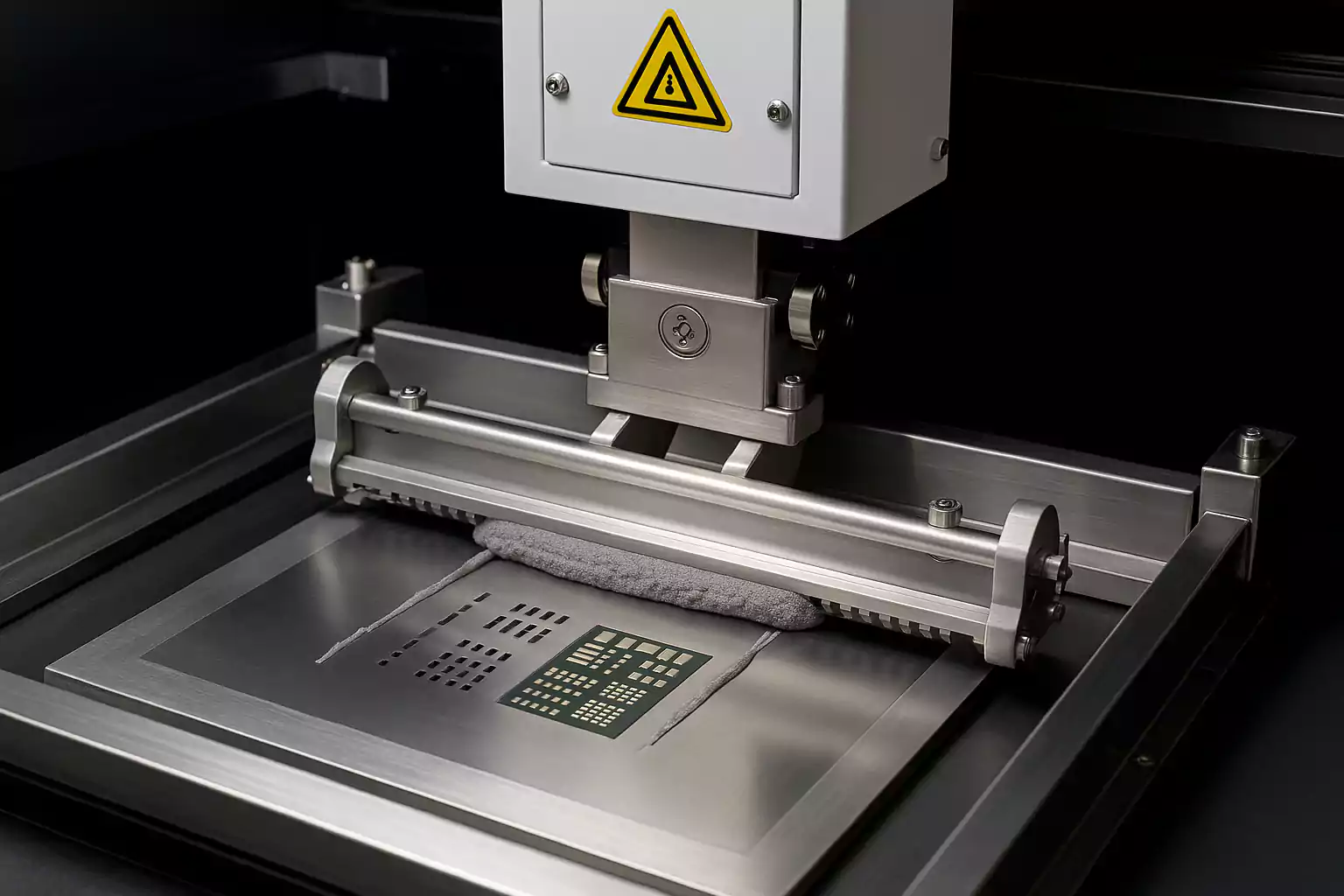

1. Solder Paste Printing

Solder paste printing is the first and one of the most critical steps in SMT production.

A stencil printer applies solder paste precisely to the PCB pads.

Uniform thickness, clean stencil release, and accurate alignment are crucial to achieving reliable solder joints in later stages.

2. Adhesive Dispensing (if required)

In mixed assembly or wave soldering processes, certain components may need to be fixed with adhesive before soldering.

Dispensing ensures these components remain in position during handling or reflow.

This step is optional and only used when product design requires it.

3. Component Placement

The placement process, handled by automated pick-and-place machines, is the core of SMT manufacturing.

Each surface-mount component (SMD) is accurately positioned on the PCB according to the solder paste or adhesive pattern.

Placement precision depends not only on equipment capability but also on the PCB layout and solder paste printing accuracy.

4. Adhesive Curing

If adhesives are applied, a curing process is used to solidify them, typically through controlled heating.

This strengthens the bond between components and the PCB before soldering, ensuring mechanical stability during subsequent steps.

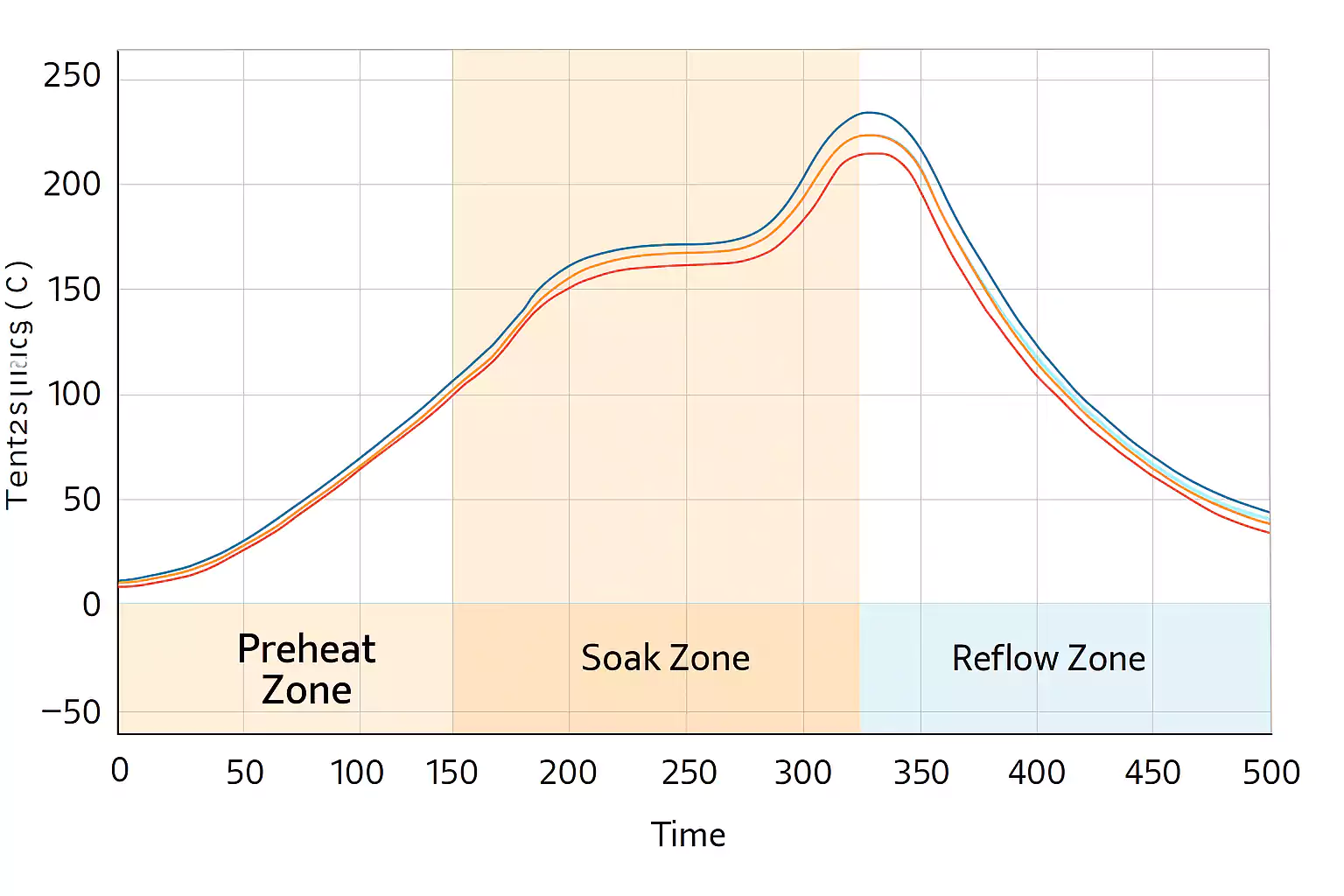

5. Reflow Soldering

Reflow soldering is the central soldering step of the SMT process.

The assembled PCB passes through a reflow oven, where it is heated according to a programmed temperature profile.

Solder paste melts, wets the component leads, and then cools to form strong, reliable solder joints.

Temperature control is critical—too low, and joints are weak; too high, and components may be damaged.

6. Cleaning (optional)

Depending on the solder paste and flux type, cleaning may be required to remove residues that could affect reliability.

Many modern processes use no-clean fluxes, allowing this step to be skipped.

When used, cleaning can be solvent-based or water-based, depending on environmental and customer requirements.

7. Inspection

Inspection is an integral part of SMT quality assurance.

Typical inspection technologies include:

- Automated Optical Inspection (AOI) – Detects solder defects and placement errors.

- X-Ray Inspection – Ideal for hidden joints like BGAs and QFNs.

- In-Circuit Testing (ICT) and Functional Testing (FCT) – Verify electrical performance.

Through multiple inspection layers, manufacturers can detect defects early and maintain process stability.

8. Rework

When inspection reveals defects, a controlled rework process is performed.

Rework typically involves localized heating using hot air, infrared, or focused heat tools to repair solder joints without damaging surrounding components.

Effective rework minimizes scrap and ensures reliable final assemblies.

Different Methods Within the Same SMT Process Step

Even though the SMT process flow is standardized, each stage can be implemented in multiple ways depending on product complexity and manufacturing goals:

- Solder Application – Can be achieved through stencil printing, jet printing, or dispensing.

- Placement Techniques – Include sequential, simultaneous, and inline placement modes.

- Soldering Methods – Primarily reflow soldering, but may also include single- or dual-wave soldering for mixed-technology boards.

The choice of method directly impacts throughput, solder joint quality, and overall cost efficiency.

Manufacturers often tailor process combinations to best match specific product designs.

How Product Type Affects the SMT Process

Different electronic products require different levels of precision and process control:

- High-density and miniaturized products demand tighter placement tolerances and optimized reflow profiles.

- Mixed-assembly boards may incorporate both SMT and through-hole components, requiring hybrid processes.

- High-reliability applications (e.g., automotive and aerospace) require stricter inspection and rework standards.

Thus, the SMT process must be flexible and adaptable to ensure both product quality and manufacturing efficiency.

Conclusion

The SMT production process is the cornerstone of modern PCBA manufacturing.

From solder paste printing to final inspection and rework, each step plays a vital role in ensuring stable, high-quality electronic assemblies.

A well-controlled, repeatable, and optimized SMT process is what separates high-quality manufacturing from average production — enabling faster delivery, higher reliability, and stronger customer trust.