When every hour counts, you need more than a vendor. You need a partner who handles everything from fabrication to final testing. Fast Turn PCB delivers turnkey PCB assembly with one-on-one engineer support, ISO-certified quality, and fast, reliable delivery. Upload your Gerber and BOM files, and our engineers will review them immediately to shorten your path from prototype to production.

Why Fast Turn PCB Is Different

1. One-on-One Engineering Support

Each project gets a dedicated engineer who works with you from quotation to delivery. Your engineer reviews DFM/DFA, verifies component availability, and ensures manufacturability before production—so you get boards that work the first time.

2. True One-Stop Service

We handle fabrication, sourcing, assembly, inspection, testing, and shipping under one roof. One purchase order, one contact, zero coordination headache.

3. Fast Turnaround

With streamlined internal scheduling and verified supply-chain partners, we specialize in quick-turn assembly for prototypes and small-volume builds. Our team can complete assembly within days once materials are ready, keeping your project on schedule.

4. Certified Quality

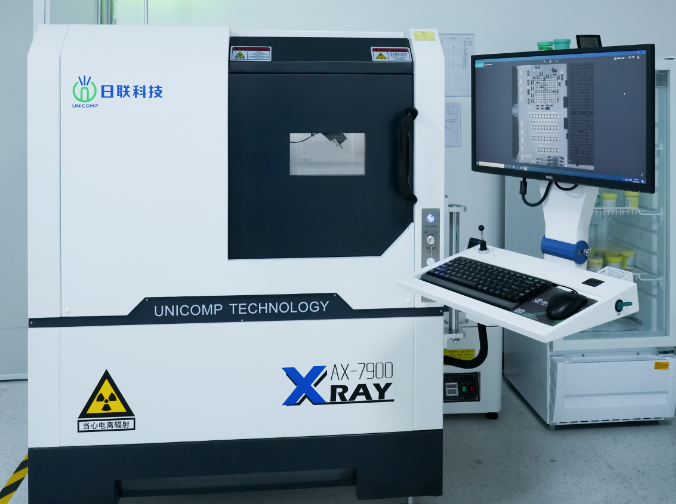

All manufacturing follows ISO 9001 quality management standards and IPC-A-610 Class 2/3 workmanship standards. In-line SPI, AOI, X-ray inspection, and optional functional tests (FCT/ICT) ensure every board meets spec before shipment.

What We Offer

- Full Turnkey Assembly – We handle everything from PCB fabrication and component procurement to final testing.

- Partial Turnkey / Consignment – You can supply selected components or materials while we complete the rest.

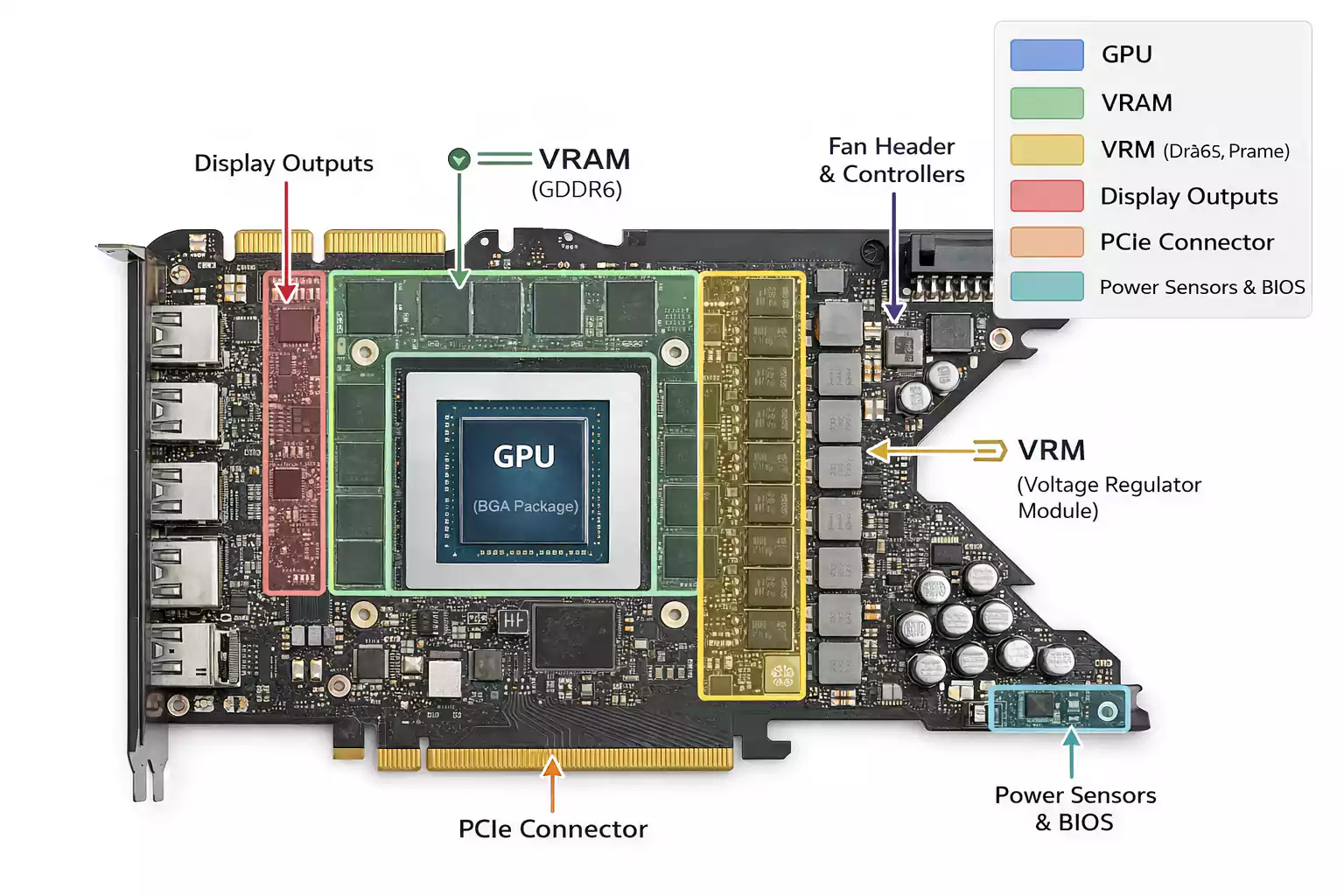

- Assembly Types – SMT, THT, and mixed assemblies covering fine-pitch 01005, BGA, QFN, LGA, and through-hole parts.

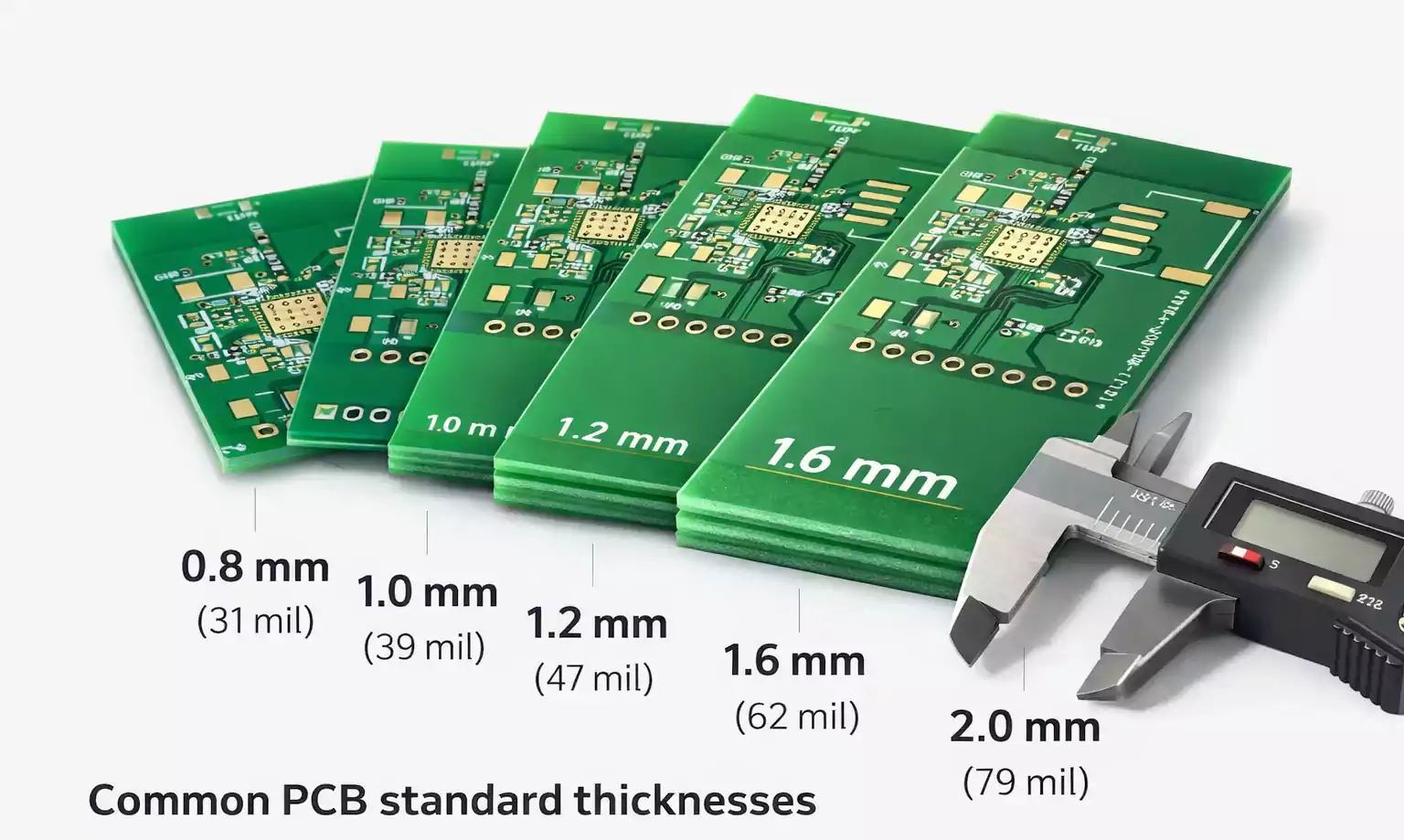

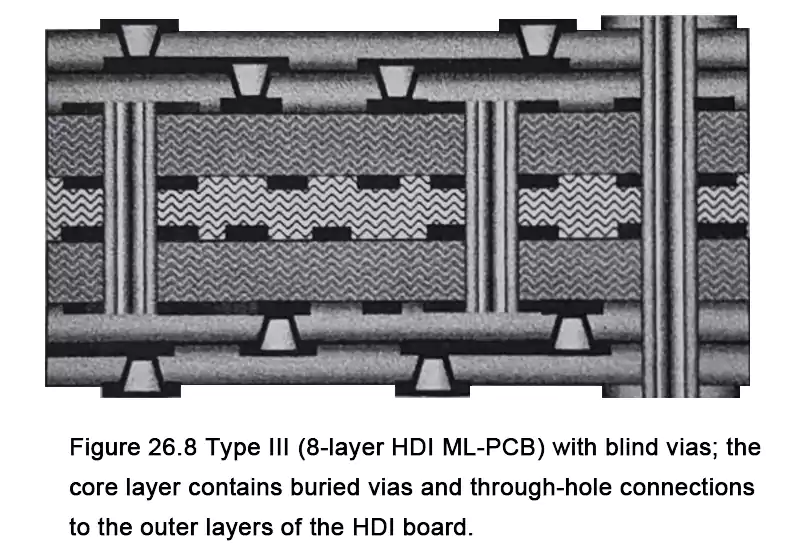

- Board Capabilities – Rigid, flex, and rigid-flex PCBs; impedance-controlled designs; thick-copper options; surface finishes such as ENIG and OSP.

Whether you’re building a first prototype or transitioning to small-volume production, we can adapt the process to fit your schedule and technical requirements.

Our Turnkey Process in Six Steps

1. File Submission

Send us your Gerber or ODB++ data, BOM, and assembly drawing. If available, include a CPL/XY file to expedite placement review.

2. Engineering Review & Quick Quotation

Your dedicated engineer performs a manufacturability and purchasing check, then coordinates with our procurement team to provide a fast, accurate quote.

3. Component Sourcing

We source all parts through verified, traceable channels. If a component is out of stock, our engineer suggests verified equivalents for your approval—avoiding project delays while maintaining electrical performance.

4. PCB Fabrication

Boards are produced in-house or through audited partners, using IPC-compliant processes for lamination, plating, solder mask, and silkscreen.

5. Assembly & Testing

SMT and THT lines feature controlled reflow and wave-solder profiles. In-line SPI monitors paste printing, AOI checks placement, X-ray inspects hidden joints, and optional FCT/ICT validates function when you provide test jigs or firmware.

6. Packaging & Delivery

Each lot passes outgoing inspection, receives bar-code labeling for traceability, and ships securely worldwide.

Typical quick-turn prototypes or small batches can be assembled within just a few days after materials are ready.

Engineering Samples and NPI Support

For engineering samples, development boards, or new product introduction (NPI) runs, Fast Turn PCB offers dedicated priority handling:

- Fast Scheduling: Once files are approved, builds move directly into production slots, minimizing wait time.

- Component Substitution Help: We provide verified alternate part suggestions to keep prototypes moving when lead times or shortages hit.

- Test-Ready Design: Our engineers recommend test-point placement, jig interfaces, and firmware burn-in steps so every sample is ready for FCT.

- Smooth Scale-Up: Version control for Gerber, BOM, and process parameters ensures your prototype can transition to volume production without requalification.

This continuity lets startups and OEMs move from proof of concept to pilot run faster, with predictable results.

Lead Times and Influencing Factors

Fast Turn PCB is built for speed, but we believe transparency is equally important.

- Typical Quick-Turn Window: Assembly can begin within hours after materials are ready.

- Standard Prototypes / Low Volume: Normally completed in 3 to 7 business days.

- Regular Batch Production: Usually 10-15 business days, depending on complexity.

Lead time may vary with component availability, acceptance of equivalents, board layer count, impedance requirements, surface finish, and test coverage. Your engineer will provide realistic delivery estimates during the quotation.

Quality and Traceability

Every assembly passes through a full quality-control chain:

- IQC (Incoming Inspection) – Verifies component part numbers, labels, and certificates.

- In-Process Control: SPI checks solder paste volume and alignment; AOI inspects placement and solder joints.

- X-Ray Inspection: For BGA, QFN, and other hidden solder types.

- Functional Testing (FCT/ICT) – Optional, performed according to your test plan or fixture.

- OQC (Final Audit): Confirms mechanical integrity, polarity, and labeling before shipment.

All results tie back to bar-code and lot numbers, so each board is traceable to its materials and process data. Our ISO 9001 system and IPC-A-610 certified technicians ensure consistent, repeatable quality.

File Requirements and Ordering Guide

To receive an accurate quote and avoid delays, please include:

- Gerber or ODB++ board files with layer definitions and drill data.

- Bill of Materials (BOM) with manufacturer part numbers, packages, reference designators, and quantities.

- Assembly Drawing indicating polarity and special notes.

- Recommended Additions: CPL/XY placement file, test specification, and any special impedance or stack-up requirements.

Files can be submitted through our secure online form or by email. If your project requires an NDA, contact us, and we’ll gladly provide one before file transfer.

Industries We Serve

Fast Turn PCB supports a wide range of applications:

- Wearable and Consumer Electronics – Compact, fine-pitch assemblies for space-constrained designs.

- Industrial Automation and Control – Rugged boards for harsh environments.

- Medical Instrumentation – Clean, reliable assembly under tight quality controls.

- Power & Energy Systems – High-current and thermal-managed designs.

- Communication & IoT – RF and mixed-signal PCBs requiring controlled impedance.

Small teams and NPI projects benefit most from our personal engineering support and fast-turn capacity, reducing iteration time and cost.

Case Highlights & Customer Feedback

- Industrial Sensor Module: From Gerber review to assembled samples in five days, saving the client two weeks of R&D schedule.

- Consumer Power Board: Engineer-recommended equivalent parts cut BOM lead time by 40%.

- IoT Prototype Series: Using the same process parameters from prototype to pilot run eliminated requalification and reduced cost per unit by 12%.

Our customers consistently mention three things: fast responses, consistent quality, and clear communication.

Frequently Asked Questions

What’s the difference between Full and Partial Turnkey?

Full Turnkey means we handle fabrication, procurement, and assembly entirely. Partial Turnkey lets you provide specific parts or boards while we complete the rest. We’ll recommend the best option based on your timeline and inventory.

Can I order without a CPL/XY file?

Yes, but including one improves placement accuracy and shortens setup time. Your engineer can guide you on exporting it from your CAD tool.

Can I specify certain brands or suppliers?

Absolutely. If a part is unavailable, we propose tested alternatives for your approval before building.

What testing options do you offer?

Standard electrical tests and visual inspection are included. Functional and in-circuit testing (FCT/ICT) is available when you supply fixtures or test guides.

Start Your Project Today

Upload your Gerber and BOM files to get a fast quotation. A dedicated engineer will contact you within hours to review your design, verify feasibility, and confirm lead time.

Fast Turn PCB—where one-on-one engineering, ISO-certified quality, and fast, dependable delivery come together to turn your design into a finished product without compromise.