In PCB manufacturing, dielectric thickness is not just a design value on a stackup drawing.

From a manufacturer’s point of view, it directly affects impedance control, total board thickness, yield, and cost.

To meet these requirements, PCB Dielectric Stackup uses different prepreg constructions. The glass fabric style, the number of sheets, and the resin content define these constructions. Understanding how single-sheet and multi-sheet prepreg structures work helps designers make realistic production decisions.

1. Overview of PCB Dielectric Stackup

In real production, one target dielectric thickness often has several possible stackup options. The final structure depends on:

- Glass fabric style (for example, 2116, 2313, or 7628)

- Number of prepreg sheets

- Resin content and resin system

Each laminate supplier provides its own prepreg data and construction rules. For this reason, stackup details should always be confirmed with the material supplier or PCB manufacturer.

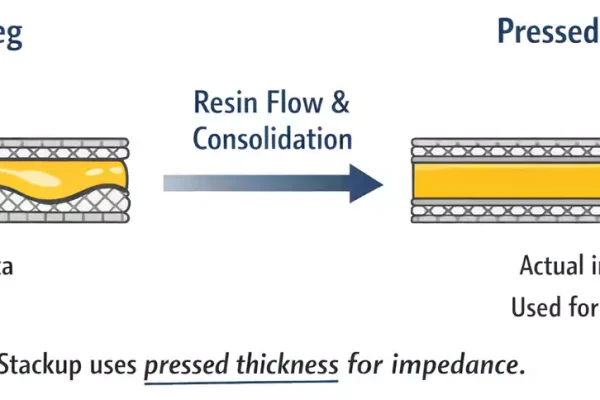

One important point is that most prepreg charts list pressed thickness, not raw material thickness. The final dielectric thickness is measured after lamination, when the resin has flowed, and the glass fabric is fully bonded. This is why the same prepreg style may show slightly different thickness values between suppliers.

For impedance-controlled or high-speed designs, high-performance resin systems are often used. In these materials, the dielectric constant (Dk) is fine-tuned by adjusting resin formulation or resin ratio, sometimes without changing the glass fabric style. This allows better impedance control while maintaining a manufacturable stackup.

2. Single vs. Multiple Prepreg Layers by Thickness Range

Dielectric thickness strongly influences whether a single prepreg sheet or multiple sheets are used.

Thickness ≤ 0.003 inch

At very thin dielectric thicknesses, design options are limited. Most designs must use a single prepreg sheet or an ultra-thin glass fabric. These materials cost more and require tight process control. They are usually reserved for dense or high-speed designs where spacing must be minimized.

Thickness 0.003–0.008 inch

This range offers the most flexibility. Designers can choose either single-sheet or multi-sheet prepreg structures. Thickness can be adjusted by changing the glass style or the sheet count. This range is very common in standard multilayer boards.

Thickness ≥ 0.008 inch

For thicker dielectric layers, multiple prepreg sheets are normally required. A single sheet cannot reach the target thickness. Engineers often estimate thickness by multiplying pressed thickness by sheet count, but final values must always be verified after lamination.

From a manufacturing standpoint, stackup design always combines calculation with process validation.

3. Cost and Thickness Control Considerations

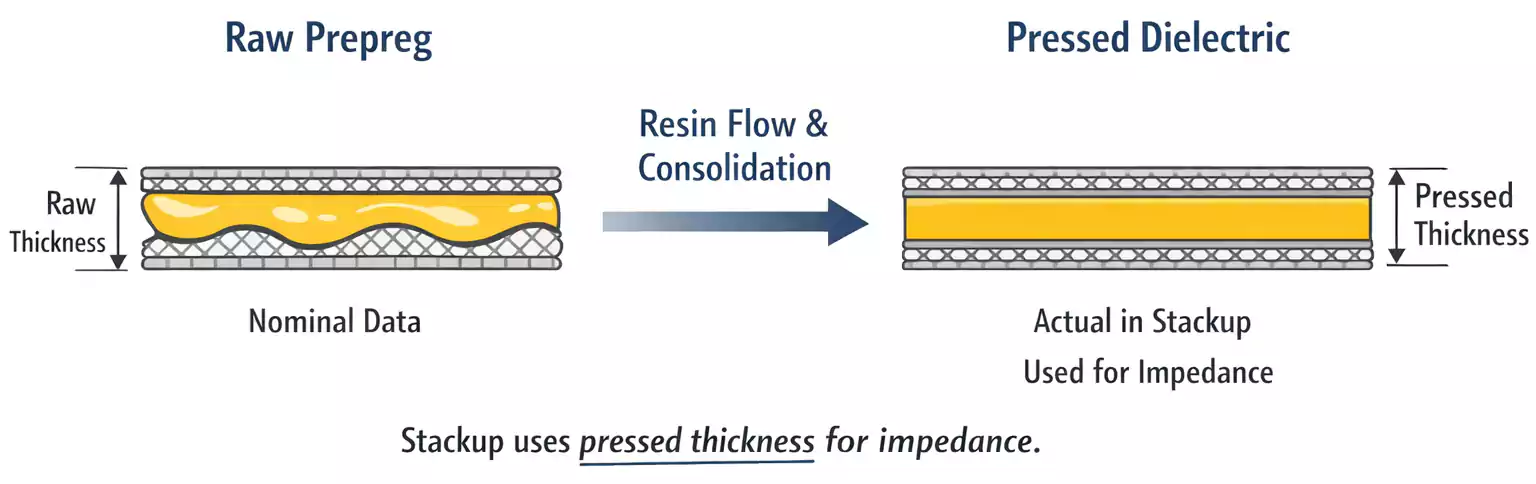

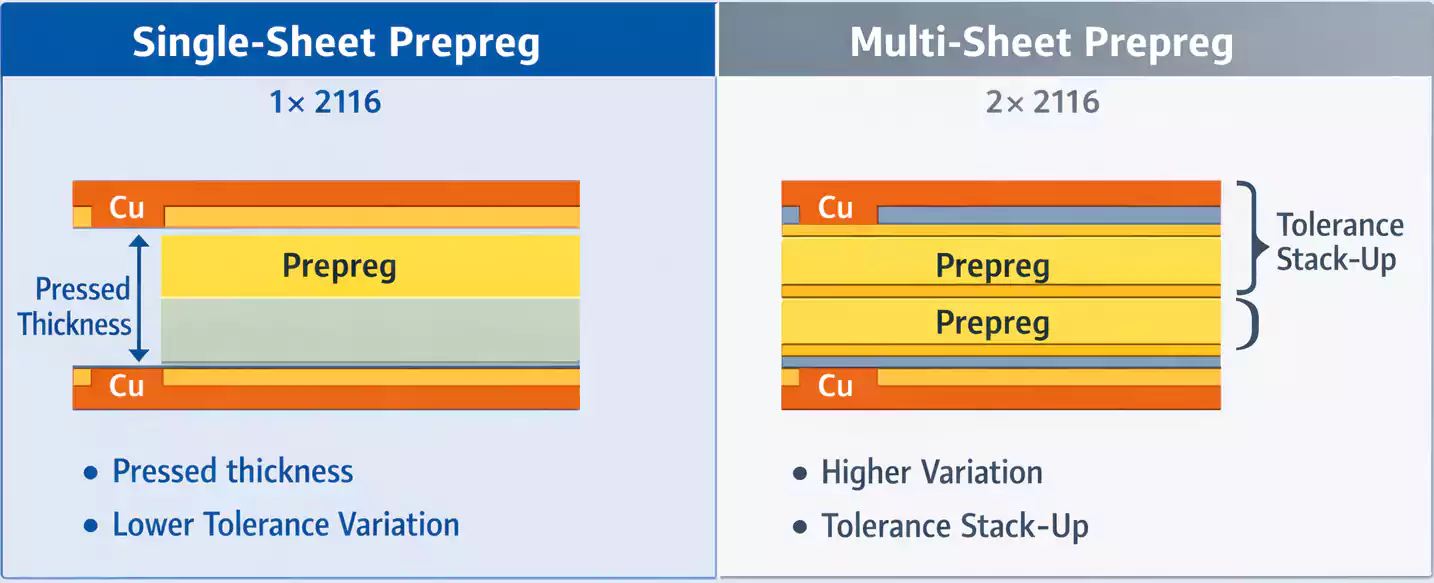

Single-sheet prepreg structures usually cost less. They are easier to control and show better thickness consistency. Resin content is often lower, and statistical variation is smaller because there are fewer variables.

Multi-sheet structures increase cost and thickness variation because tolerances add up with each sheet. However, they are unavoidable for thicker dielectrics and some specialized designs.

Single-sheet structures are not always the best choice. Final decisions must balance cost, electrical performance, mechanical reliability, and material availability.