When designing or manufacturing a printed circuit board (PCB), safety and reliability are always priorities. One important factor is flammability — how easily a material catches fire and how quickly it stops burning. UL 94, developed by Underwriters Laboratories (UL), is the most widely used standard for evaluating the flame resistance of plastic and PCB materials.

This guide explains what UL 94 V-0, V-1, and V-2 mean, how the test is performed, and how to make sure your PCB meets these ratings.

Why Flammability Matters in PCB Design

PCBs are used in products that may generate heat or are close to power components. A flame-retardant material can prevent small ignition sources—such as a short circuit or component failure—from spreading fire. UL 94 defines how materials behave when exposed to flame and sets limits on how long they can burn or drip molten material.

For PCB manufacturers, UL 94 often goes hand in hand with UL 796, which covers PCB construction and safety. Together, these standards ensure that the board and its materials meet recognized fire-safety standards.

UL 94 Flammability Ratings Overview

UL 94 includes several test categories, but for PCB substrates, the most common are V-0, V-1, and V-2, all of which are measured using a vertical burn test.

| V-0 | ≤10 seconds | ≤50 seconds | No flaming drips | ≤30 seconds |

| V-1 | ≤30 seconds | ≤250 seconds | No flaming drips | ≤60 seconds |

| V-2 | ≤30 seconds | ≤250 seconds | Flaming drips allowed | ≤60 seconds |

In short, V-0 is the strictest grade—samples self-extinguish quickly and produce no burning drips. V-1 allows longer flame time but still no flaming drips, and V-2 allows both longer burning and some dripping.

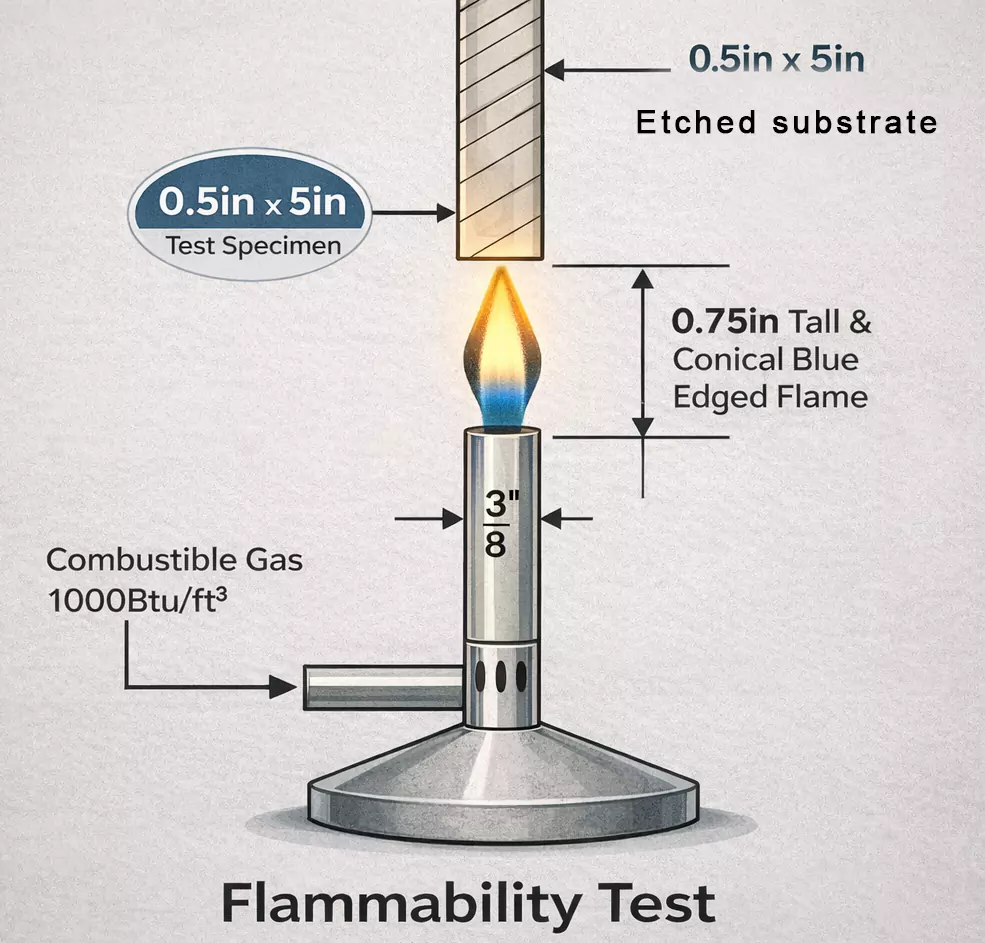

How the Vertical Burn Test Works

In the UL 94 vertical burn test, a small plastic or laminate specimen is clamped vertically. A controlled flame is applied to its lower edge for 10 seconds, then removed. The tester records how long the material continues to burn or glow. The flame is reapplied for another 10 seconds to check for repeat behavior.

Ten test samples are evaluated. To pass a specific class (V-0, V-1, or V-2), the combined burn times and dripping behavior must meet the limits shown above. This test simulates how materials would behave if a small internal flame were to come into contact with a PCB or enclosure.

Other UL 94 categories include HB (Horizontal Burn), 5VB, and 5VA. HB is the least strict (horizontal test), while 5VA is more demanding than V-0. For PCBs, vertical ratings are the main reference.

How to Achieve a V-0 Rating in PCB Manufacturing

1. Choose UL 94 V-0-rated materials

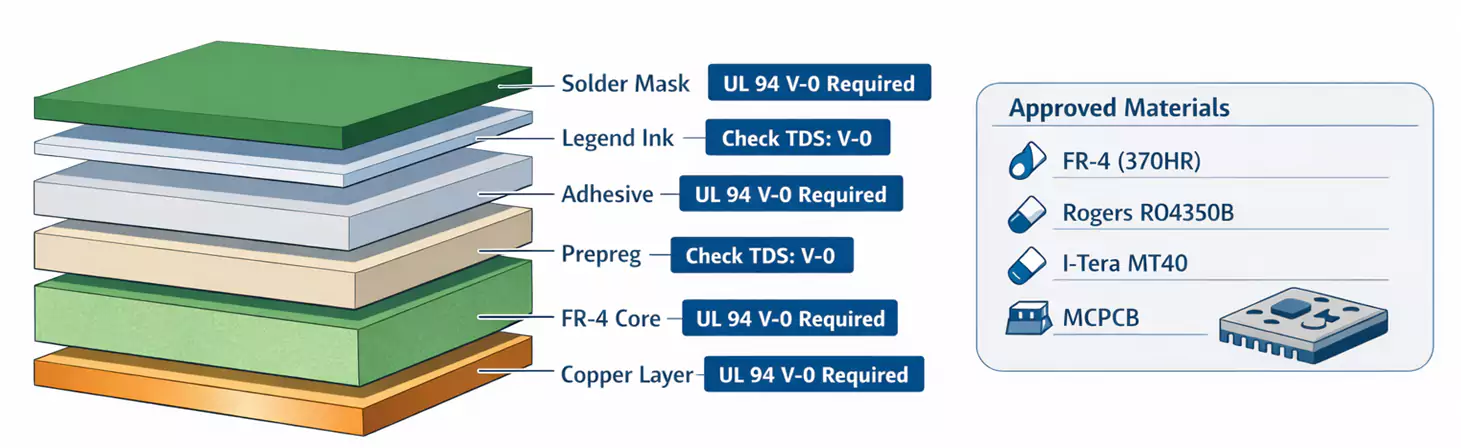

Start with base laminates that already meet UL 94 V-0. Most standard FR-4 materials, such as Isola 370HR, Panasonic MEGTRON, or Shengyi S1000H, are certified V-0. For high-frequency boards, materials like Rogers RO4000 or Isola I-Tera MT40 also achieve this level. Always confirm in the material’s Technical Data Sheet (TDS).

2. Verify all materials in the stack-up

Don’t just check the core laminate. Solder mask, legend ink, adhesives, and encapsulants must also meet the same flame rating. A single non-rated material can compromise the board’s overall performance during testing.

3. Consider design factors

Copper thickness, resin content, and openings in the solder mask affect heat flow. Sharp corners or resin-rich zones can localize heat. Clean flux residues thoroughly; leftover chemicals may promote ignition.

4. Work with a UL-certified fabricator

If your product needs UL marking, use a PCB manufacturer registered under UL 796 with flammability ratings in their file. This ensures consistent production and documentation.

When Is V-0 Required?

For most commercial and industrial electronics, V-0 is the target because it demonstrates the best safety margin. Consumer products, automotive modules, and power supplies usually specify V-0-rated PCBs.

V-1 materials are acceptable for low-power or enclosed applications where dripping or slower self-extinguishing is not a hazard. V-2 is rarely used in critical electronics due to the risk of burning drips that could ignite nearby components.

Flexible polyimide and high-frequency PTFE composites can also meet V-0, but certification depends on the specific grade and thickness.

Common Misunderstandings

- “FR means V-0.”

Not always. “FR” simply means flame retardant, but not every FR-4 or FR-grade resin automatically meets V-0. Always check the UL file or TDS. - “Only the core matters.”

Wrong. All PCB materials—including coatings and adhesives—contribute to the final flammability rating. - “The 10-second rule is enough.”

Each sample is tested multiple times; total burn time and dripping behavior also count. - “Data sheet = compliance.”

Manufacturers must still validate finished board construction if dimensions, resin systems, or copper weights differ from the UL-tested configuration.

Quick FAQ

Q: What’s the main difference between 94V-0 and 94V-2?

A: V-0 materials self-extinguish faster and do not produce flaming drips. V-2 allows burning drips and slower extinguishing.

Q: Is all FR-4 material rated V-0?

A: Most modern FR-4 laminates are, but always confirm the UL listing for your specific material and thickness.

Q: Do I need UL 796 as well?

A: Yes. UL 796 certifies the PCB construction, while UL 94 covers material flammability. Many manufacturers list both together on the UL marking.

Final Thoughts

Flammability ratings are more than numbers — they protect users and products from potential fire hazards. Understanding the UL 94 V-0/V-1/V-2 system helps engineers select the right PCB materials, meet safety standards, and simplify certification.

In short:

- V-0 = Best protection (quick self-extinguishing, no drips)

- V-1 = Moderate protection (longer burn, no drips)

- V-2 = Lowest vertical rating (flaming drips allowed)

Choosing the correct rating at the design stage ensures that your PCB passes compliance testing, meets UL standards, and delivers lasting reliability in the field.