Although many types of reinforcement materials are used in substrates, plain-woven glass fabric (woven from glass fibers) is by far the most common. Other materials include paper, cellophane, nonwoven aramid fibers, nonwoven glass, and various fillers. Woven glass fabric offers several advantages, including excellent mechanical and electrical properties, suitability for manufacturing laminates in a wide range of thicknesses, and relatively low cost.

Woven Glass Fiber

Woven glass fiber is the most common reinforcement used in PCB manufacturing. It is produced by melting inorganic raw materials, drawing them into filaments, spinning yarn, and weaving the yarn into glass fabric. The most widely used type is E-glass for its balanced properties and moderate cost. NE-glass and L-glass are improved variants that offer lower dielectric constants and dissipation factors, but at a higher price. S-glass provides higher strength, though it is more difficult to process.

Glass Fabric

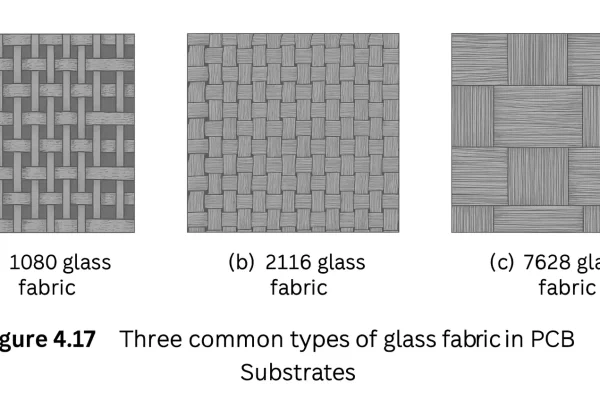

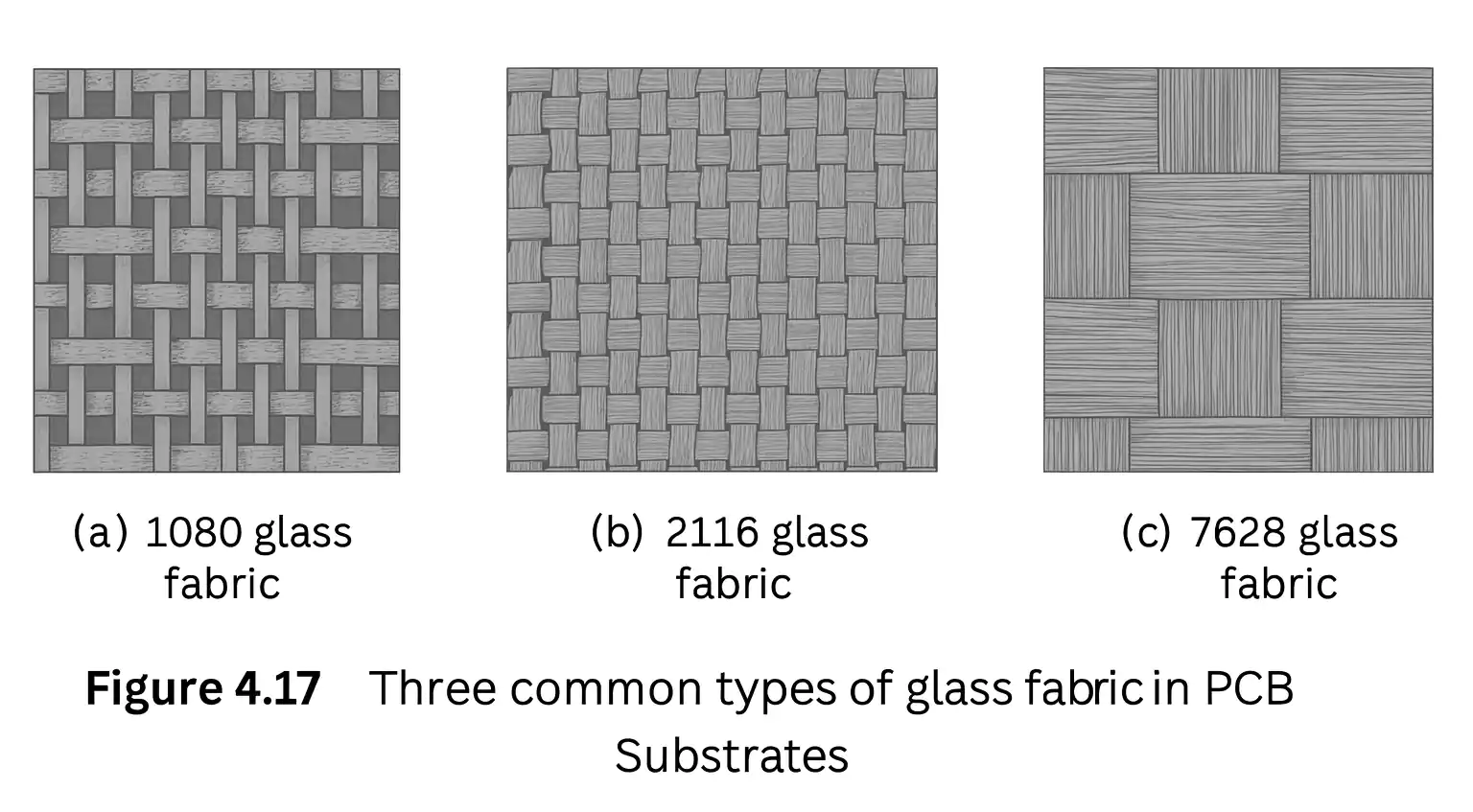

Glass fabric is one of the most common reinforcement materials used in PCB substrates. Its performance is influenced by several factors, including the chemical composition of E-glass, filament diameter, yarn type, and weave style. Different weave structures result in differences in thickness, density, and mechanical behavior, which, in turn, affect a board’s mechanical strength and electrical performance.

In PCB manufacturing, glass fabric is almost always E-glass in a plain-weave construction, in which the warp yarns pass over and under the weft yarns. This structure effectively prevents yarn slippage and improves dimensional stability. Common fabric styles (e.g., 1080, 2116, 7628) have different nominal thicknesses at the same resin content; selecting the right fabric type and thickness is critical for impedance control and overall board thickness design.

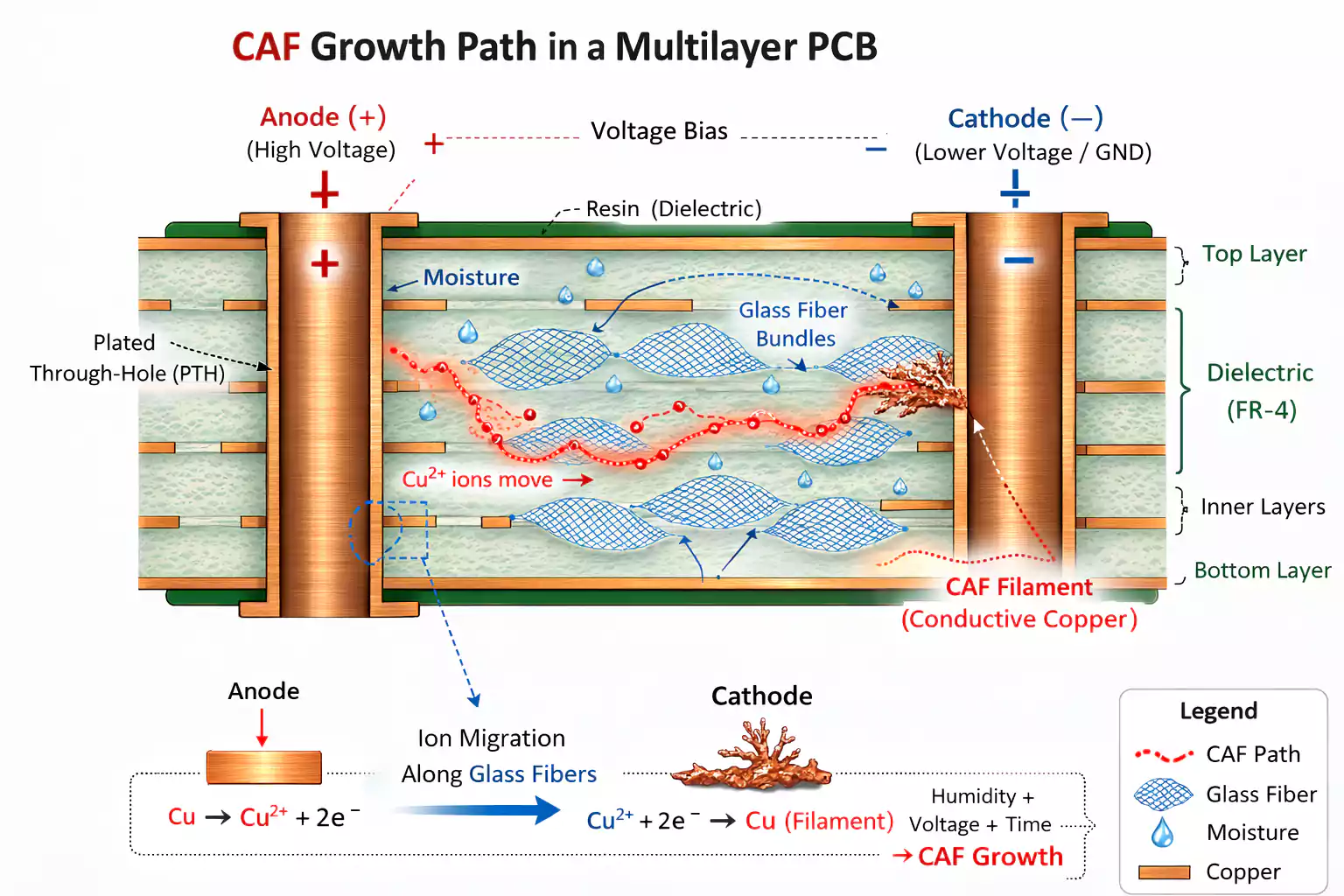

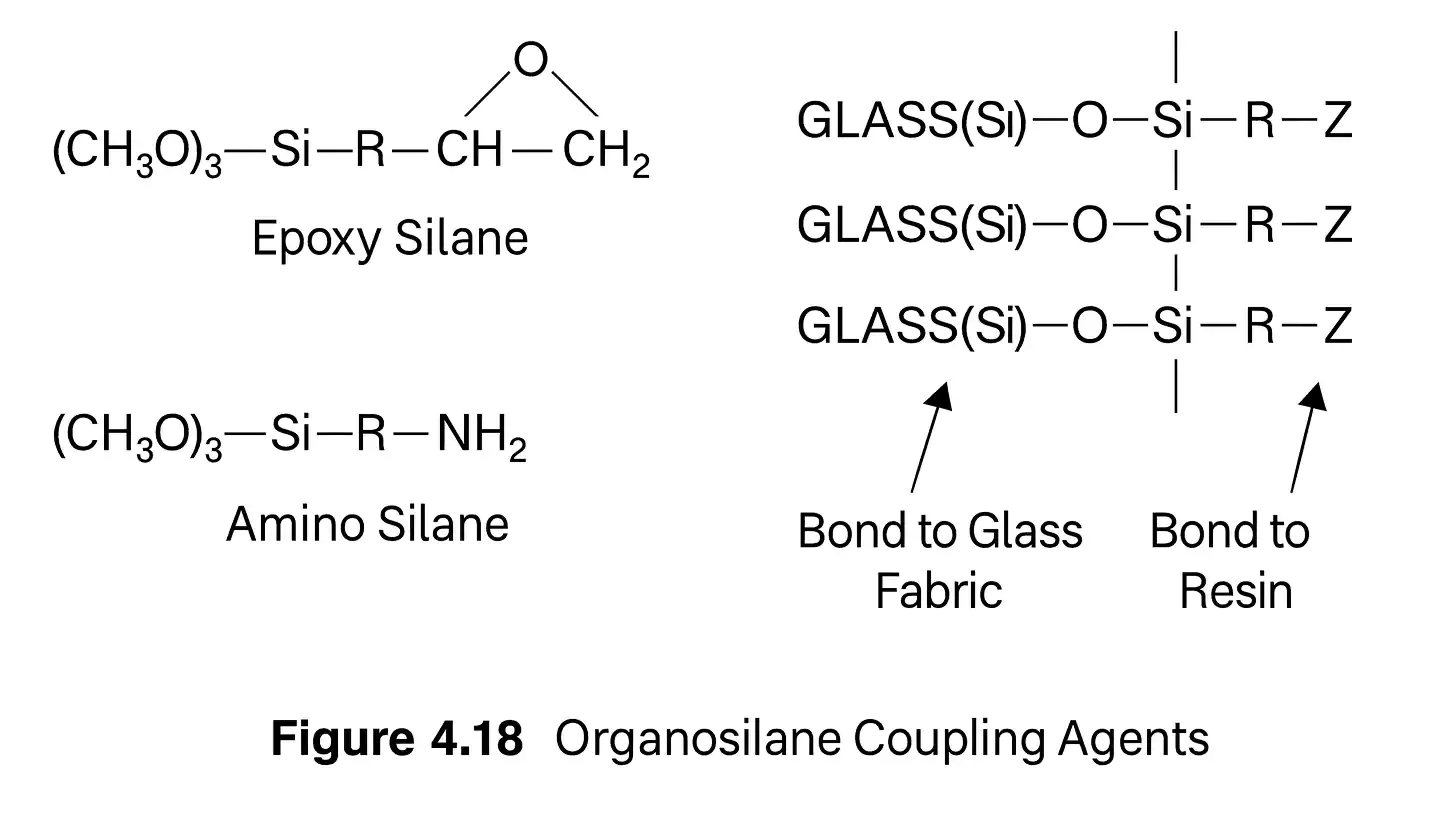

To enhance processing and reliability, glass fabric is typically treated with a silane coupling agent during production. These organosilane compounds improve wetting and interlaminar adhesion, helping the laminate remain stable during drilling and under high humidity. Coupling agents also effectively suppress CAF (Conductive Anodic Filaments), extending the service life of the PCB.

Other Reinforcement Materials

While woven glass fabric is the primary reinforcement material in PCBs, other materials—or hybrid combinations of woven glass fibers—are also commonly used. Below are some of the alternative reinforcement materials:

1. Glass Mat (Nonwoven Glass)

Glass mat is a nonwoven reinforcement material with a more random fiber orientation compared to traditional woven glass fabric. It is made by quenching glass fiber yarn, stretching it into strands approximately 1–2 inches long, and then continuously laying them down in random, spiral-like directions. Glass mat is typically used as the core layer in CEM-3 substrates, making it suitable for general-purpose electronics where performance demands are lower.

2. Nylon Fiber

Unlike inorganic glass fibers, nylon fibers are made from organic compounds such as aramid (aromatic polyamide) and offer distinct performance advantages.

In high-performance PCBs or Multi-Chip Module Laminates (MCM-L), nylon fibers are valued for their:

- Easy plasma or laser ablation, ideal for microvia drilling.

- Lightweight and high strength, improving structural stability.

- Negative axial CTE, helping reduce thermal stress.

These features make nylon fiber a strong alternative to glass fiber in high-frequency and miniaturized PCB designs.

3. Linear Continuous Glass Filaments

Using linear, continuous glass filaments as the reinforcement material for laminate production is a unique, specialized technique. In this method, the resulting laminate consists of three layers of glass filaments, with the outer layers aligned parallel to each other. In contrast, the middle layer is oriented perpendicular to them. With an equal number of continuous glass filaments woven in each direction, the reinforcement structure significantly enhances the laminate's dimensional stability.

4. Paper

Fiber paper can also be used as a reinforcement material in substrates. It may be used on its own or combined with other materials, such as woven glass fabric, to form a composite reinforcement structure. This type of composite can be processed only by punching, not drilling, which makes it economical and practical for high-volume, low-tech consumer electronics such as radios, toys, calculators, and video game consoles.

Paper-based reinforcement is primarily used in FR-2 and FR-3 materials, as well as in the core layer of CEM-1.

5. Fillers

Fillers are fine inorganic particles added to resins to tune material properties. Common types include talc, silica, kaolin, and hollow glass microspheres. With proper loading and dispersion, these fillers can significantly improve multiple performance aspects of PCB substrates.

In high-performance PCB materials, fillers are typically used to:

- Lower dielectric constant (Dk) to improve high-speed and high-frequency signal performance.

- Control the coefficient of thermal expansion (CTE) to reduce interlayer stress and boost reliability.

- Improve drillability, minimizing hole-wall damage during processing.

- Enhance dimensional stability and reduce cost.

Especially for lead-free soldering, fillers help reduce Z-axis expansion, which in turn lowers stress and deformation on plated through holes (PTHs) at elevated temperatures.

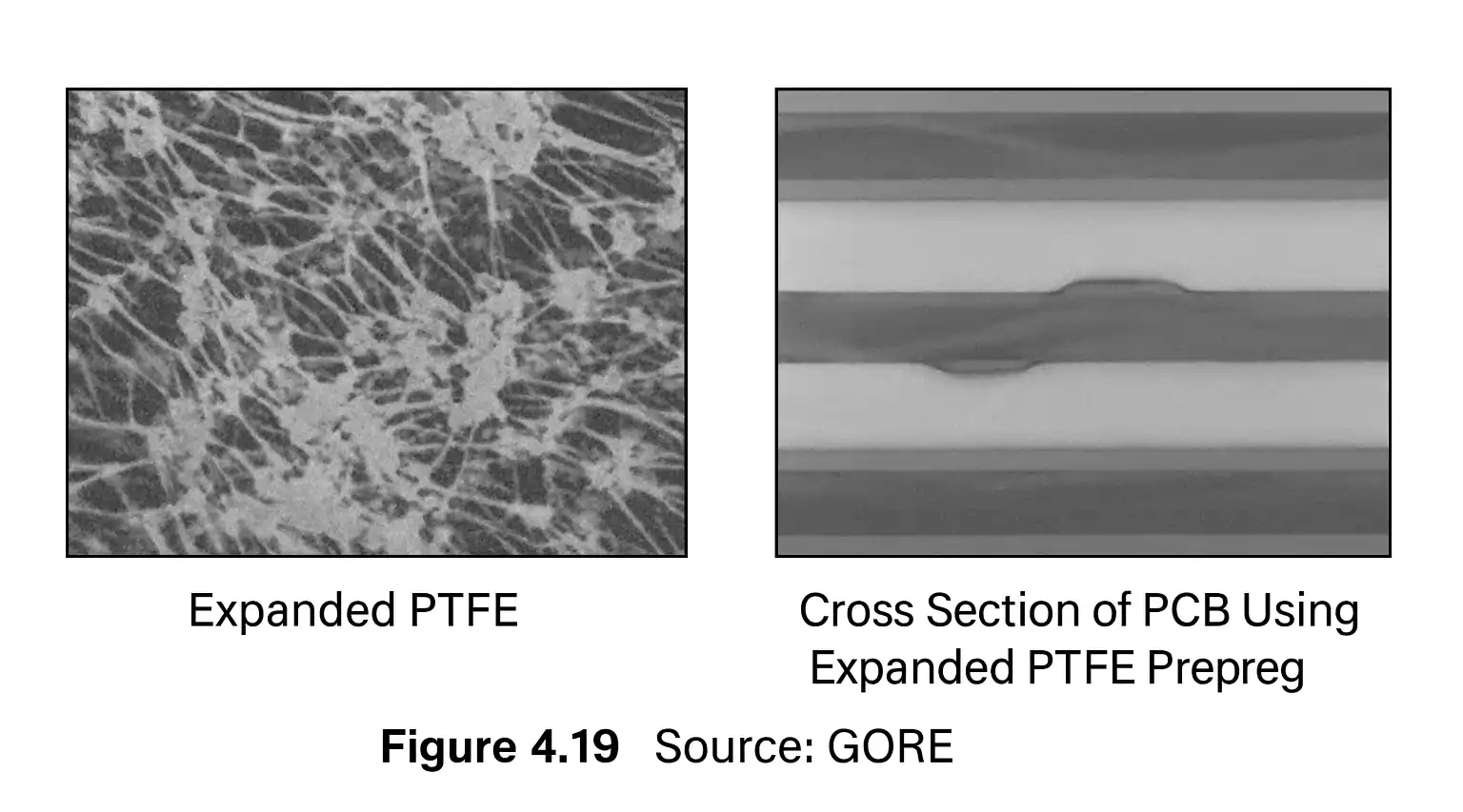

6. Expanded Polytetrafluoroethylene (ePTFE)

Expanded PTFE (ePTFE) is a microporous material that, while not typically classified as a reinforcement material, offers exceptional performance in applications requiring ultra-low dielectric constant or low signal loss, thanks to its sponge-like structure.

ePTFE is often combined with resin to create B-stage prepreg, which is used to bond layers in multilayer PCBs. These prepregs are widely used in high-frequency circuits, including RF and high-speed communication devices.

Conclusion

Reinforcement materials are one of the key determinants of PCB performance. Beyond structural support, they affect electrical properties, thermal stability, and overall reliability. From commonly used E-glass fabric to functional options like fillers and expanded PTFE, selecting and applying the right materials can significantly improve board performance. Understanding their characteristics and use cases helps engineers design higher-quality, more reliable PCBs.