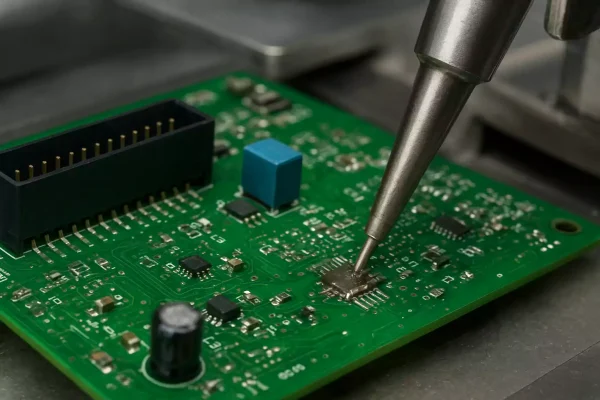

Fundamentals: Wave Soldering vs. Selective Soldering Explained

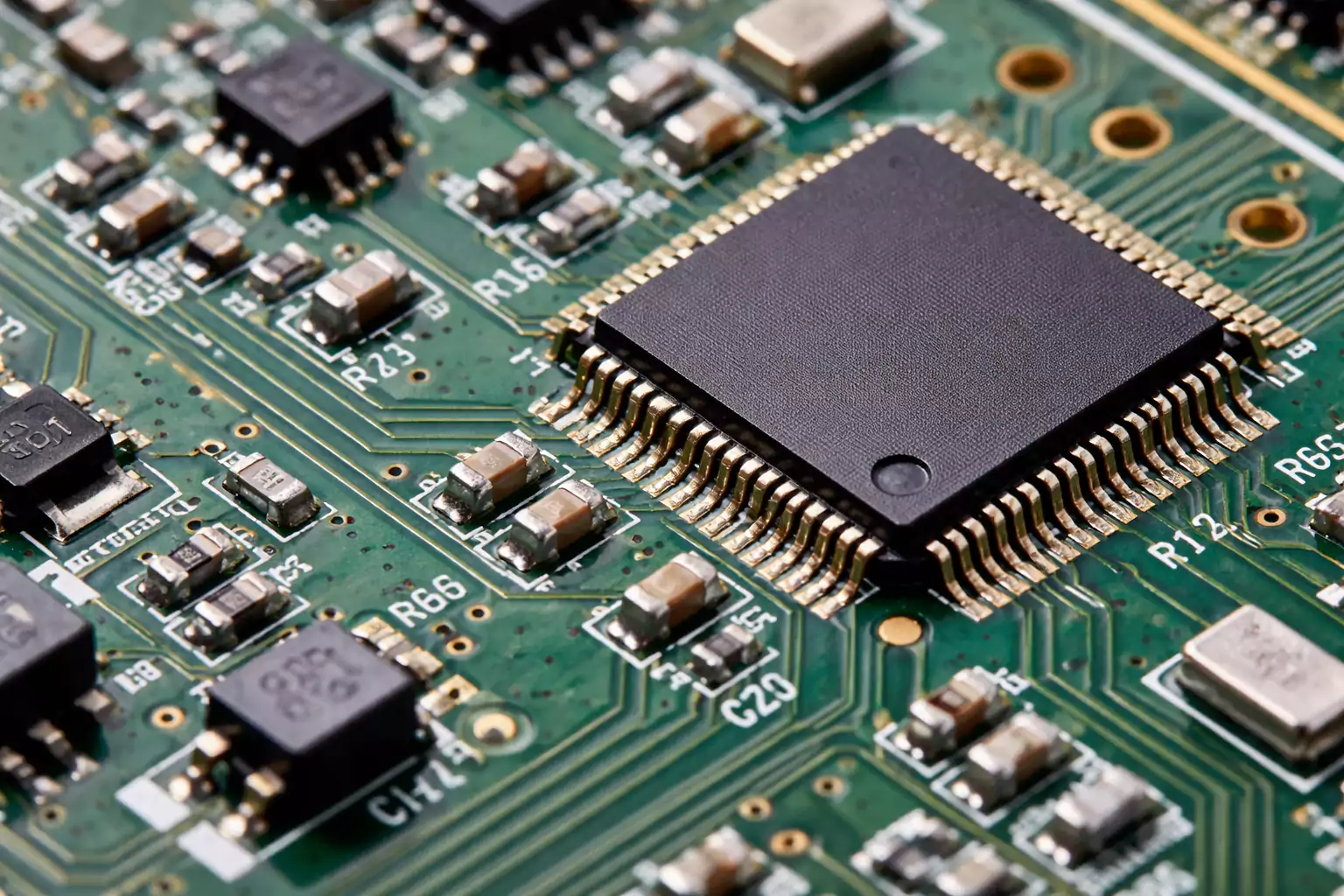

Through-hole technology (THT) assembly still relies heavily on mass soldering methods. Among them, wave soldering and selective soldering are the two dominant techniques. While both achieve reliable through-hole joints, their working principles, process windows, and application boundaries differ significantly.

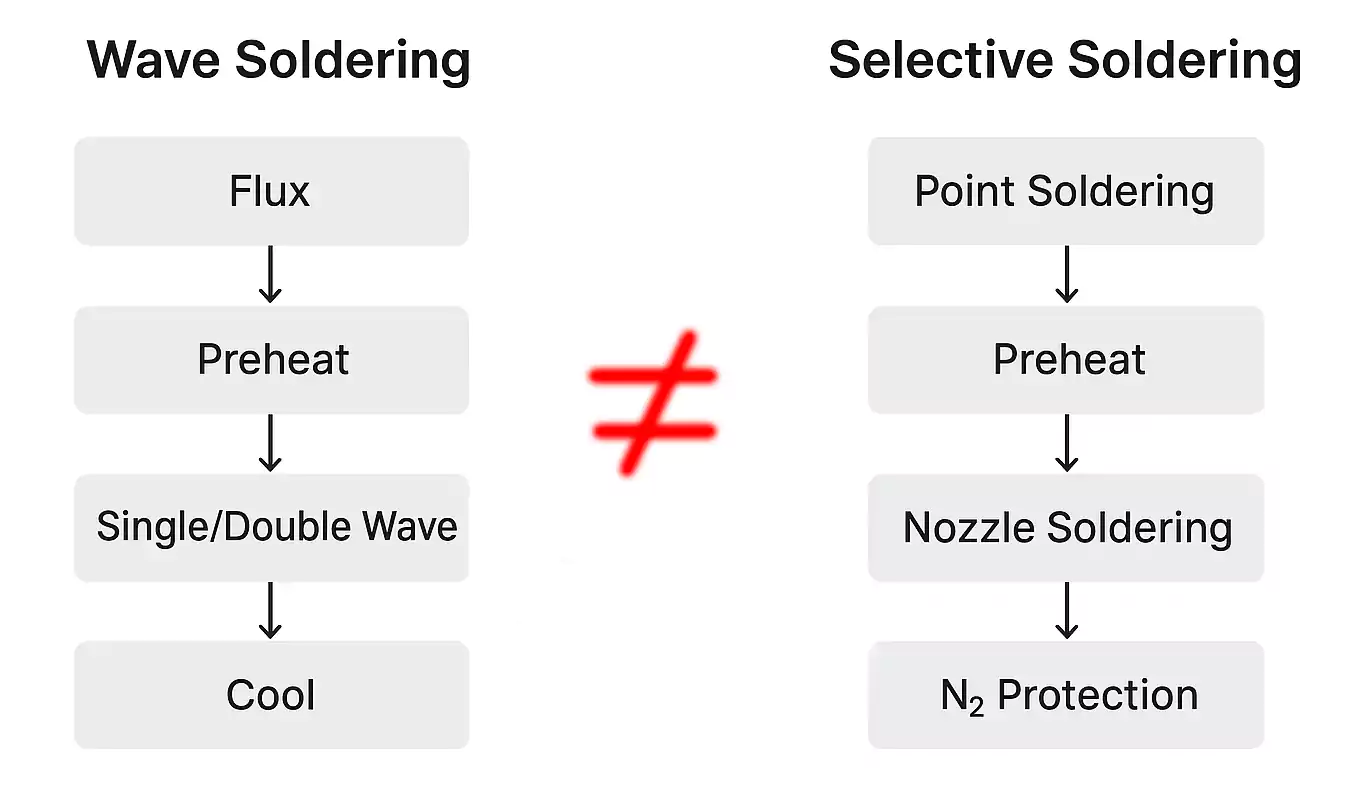

1.Wave Soldering (Whole-Board Process)

Wave soldering immerses the entire PCB’s underside into a molten solder “wave.” It is a high-throughput, whole-board process especially suited for assemblies with a large number of through-hole pins. The process flow is:

- Flux application – a foam or spray flux uniformly coats the underside, removing oxides and promoting solder wetting.

- Preheating – controlled heating drives off flux solvents, activates the chemistry, and reduces thermal shock.

- Solder wave contact – the board passes over a single or dual solder wave:

- Laminar wave ensures uniform wetting across large areas.

- Turbulent wave improves hole filling and mitigates shadowing.

- Cooling and solidification – joints solidify as the board exits the wave.

Key considerations:

- Parameter window: preheat 90–130 °C; solder pot 245–265 °C; conveyor speed 1–2 m/min (typical).

- Design impact: shadowing can cause non-wetting behind tall components; robber pads and thieving features are often added to guide solder flow.

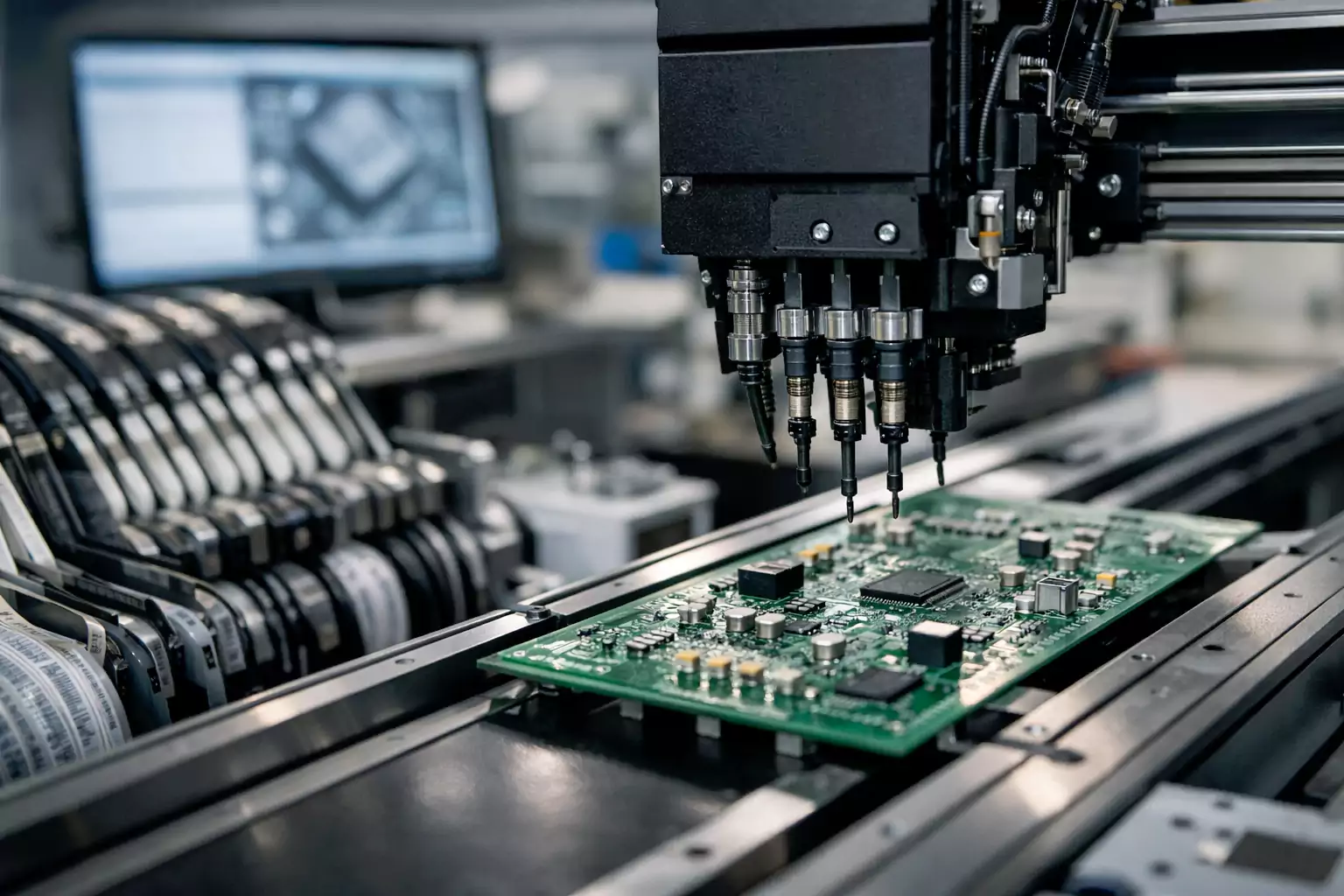

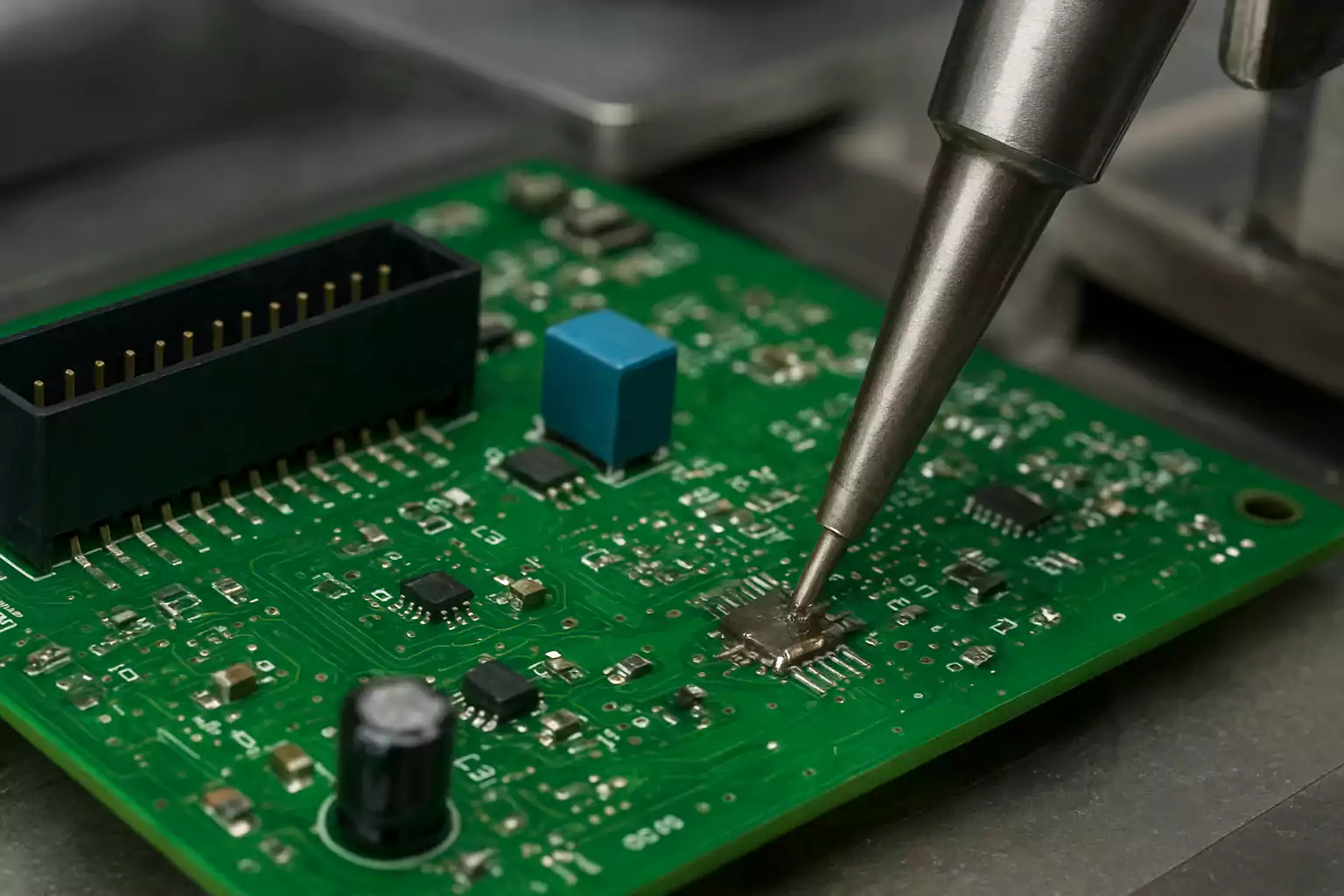

2.Selective Soldering (Localized Process)

Selective soldering addresses the limitations of wave soldering in mixed-technology PCBs. Instead of exposing the entire board, it targets only specific through-hole joints, making it ideal for assemblies that also include SMT components. The process flow is:

- Flux deposition – mini spray or drop-jet applies flux precisely to selected pads.

- Localized preheating – heats only the fluxed region to activate chemistry and improve wetting.

- Mini-wave soldering – a programmable nozzle or fountain forms a localized solder wave that contacts the joint:

- Mini-spray nozzles allow tight spacing.

- Fountain nozzles suit larger connectors.

- Nitrogen atmosphere – shields the solder surface from oxidation, enabling stable wetting and fewer bridges.

Key considerations:

- Programming path: nozzle trajectory, dwell time, and lift-off speed must be optimized per component.

- Process control: narrower thermal profile compared to wave soldering, with less stress on heat-sensitive parts.

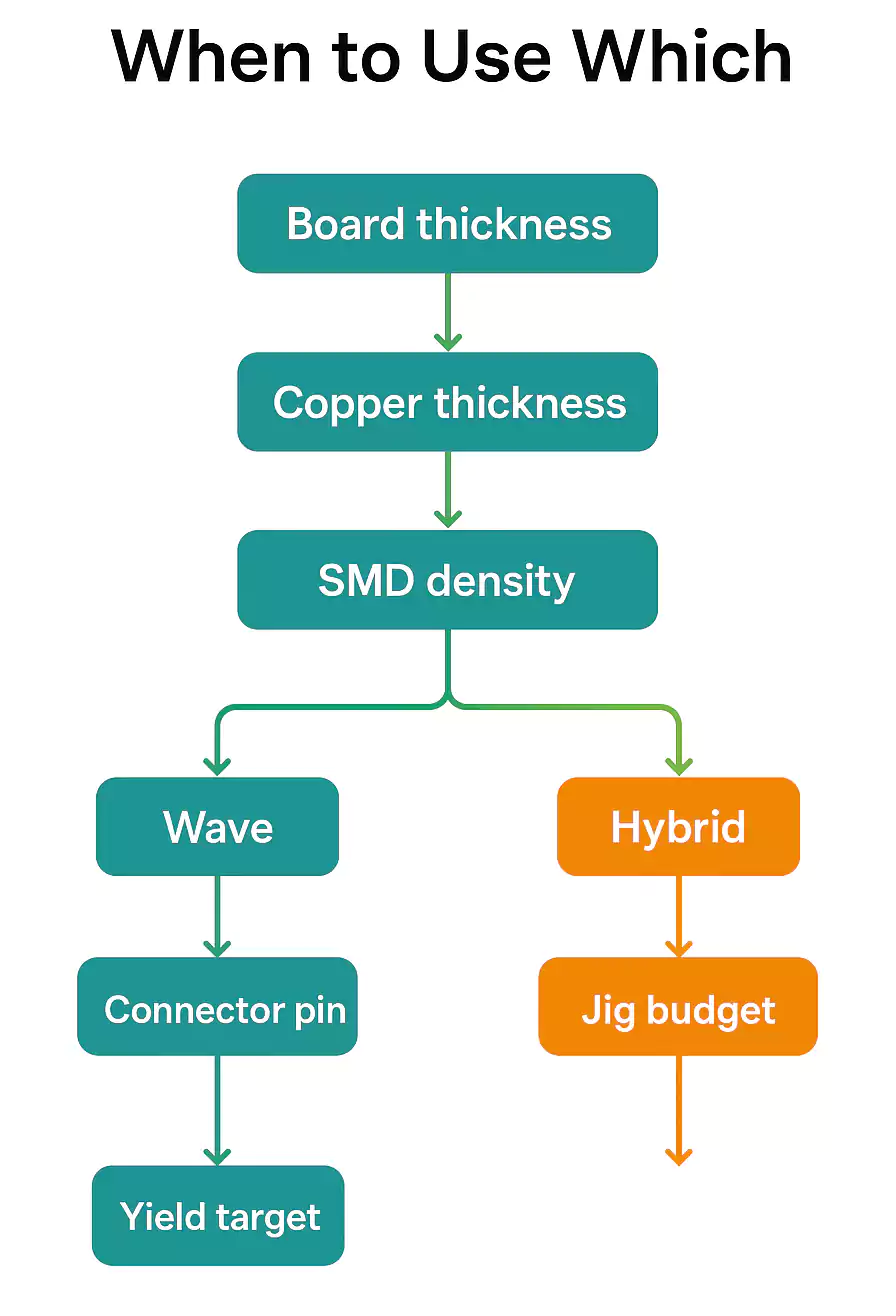

When to Use Which: Applicable Scenarios and Boundaries

1.Based on the BOM

The bill of materials often dictates the soldering path. Wave soldering is efficient when the board has a high percentage of THT parts, large connectors, or repetitive pin counts. Selective soldering is better when THT parts are sparse, mixed with dense SMT areas, or when components have significant height differences or include heat-sensitive devices.

2.Based on PCB Design

Layout plays a critical role. Boards with double-sided assembly, tight component spacing, or non-uniform orientations are difficult for wave soldering due to shadowing and bridging risks. Selective soldering, with programmable nozzles and local heating, handles these constraints more reliably. Proper solder mask openings and the use of thieving pads remain essential for either method.

3.Based on Manufacturing Strategy

Volume and flexibility drive the decision. Wave soldering delivers the lowest cost per unit in high-volume, stable production, provided that fixture lead time and cost are justified. Selective soldering suits low-to-medium volume runs, frequent product changes, or NPI projects where quick program adjustments are more economical than building multiple wave fixtures.

4.Based on Quality Requirements

IPC-A-610 acceptance class is a key filter. For Class 2 (general electronics), wave soldering usually meets requirements if design is optimized. For Class 3 (high reliability, aerospace, medical, automotive safety), selective soldering is often preferred due to its controlled heating, higher consistency in hole fill, and reduced thermal stress on sensitive assemblies.

Pros and Cons: Engineering vs. Cost Perspective

| Dimension | Wave Soldering | Selective Soldering |

|---|---|---|

| Thermal Impact | Higher thermal shock to components and board; less controlled heat distribution. | Localized heating minimizes stress; better suited for heat-sensitive parts. |

| Shadowing & Bridging | More prone to shadowing and solder bridging in dense layouts. | Precise nozzle control reduces shadow effect; lower bridging risk. |

| Hole Fill Consistency | Consistent on simple layouts; challenging on mixed-density or thick boards. | Programmable parameters improve reliability in complex or high-layer PCBs. |

| Cleanability | Larger flux volume can require thorough cleaning. | Less flux usage, easier post-solder cleaning. |

| Parameter Control | Limited tuning options—most parameters affect the entire board. | Independent control for each joint; higher process flexibility. |

| Consumables | Higher solder consumption; more flux required; no nitrogen control. | Lower solder loss; optimized flux use; nitrogen consumption but overall leaner. |

| Fixed Investment | Requires wave solder pallets/fixtures; moderate upfront cost. | Needs machine nozzles and programming time; higher initial capital. |

| Changeover Time | Fast for stable, high-volume runs; less flexible for frequent changeovers. | Slower for initial programming; easier for multi-variant or low-volume runs. |

| Maintenance & Downtime | Larger solder pot cleaning and dross removal required. | Nozzle maintenance and calibration needed, but less solder dross. |

| Rework & Yield | Higher rework rate on mixed-assembly boards. | Lower defect rate in complex assemblies; reduced rework cost. |

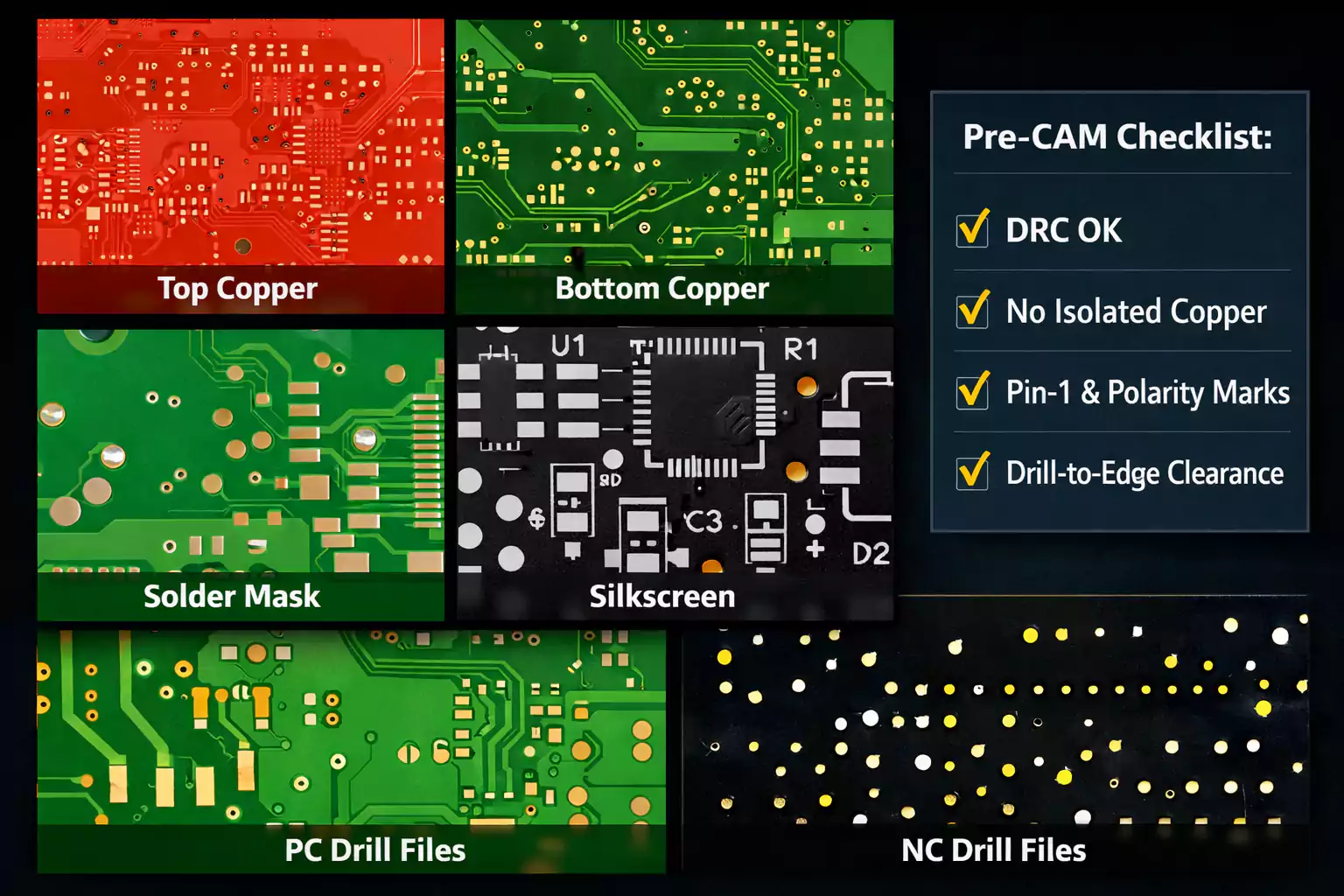

DFM / DFA Design Guidelines

Design for Manufacturability (DFM) and Design for Assembly (DFA) are critical in ensuring high soldering yields, whether you choose wave soldering or selective soldering. By following proven layout and process guidelines, engineers can minimize defects such as bridging, insufficient hole fill, and component shadowing. Below are the key considerations:

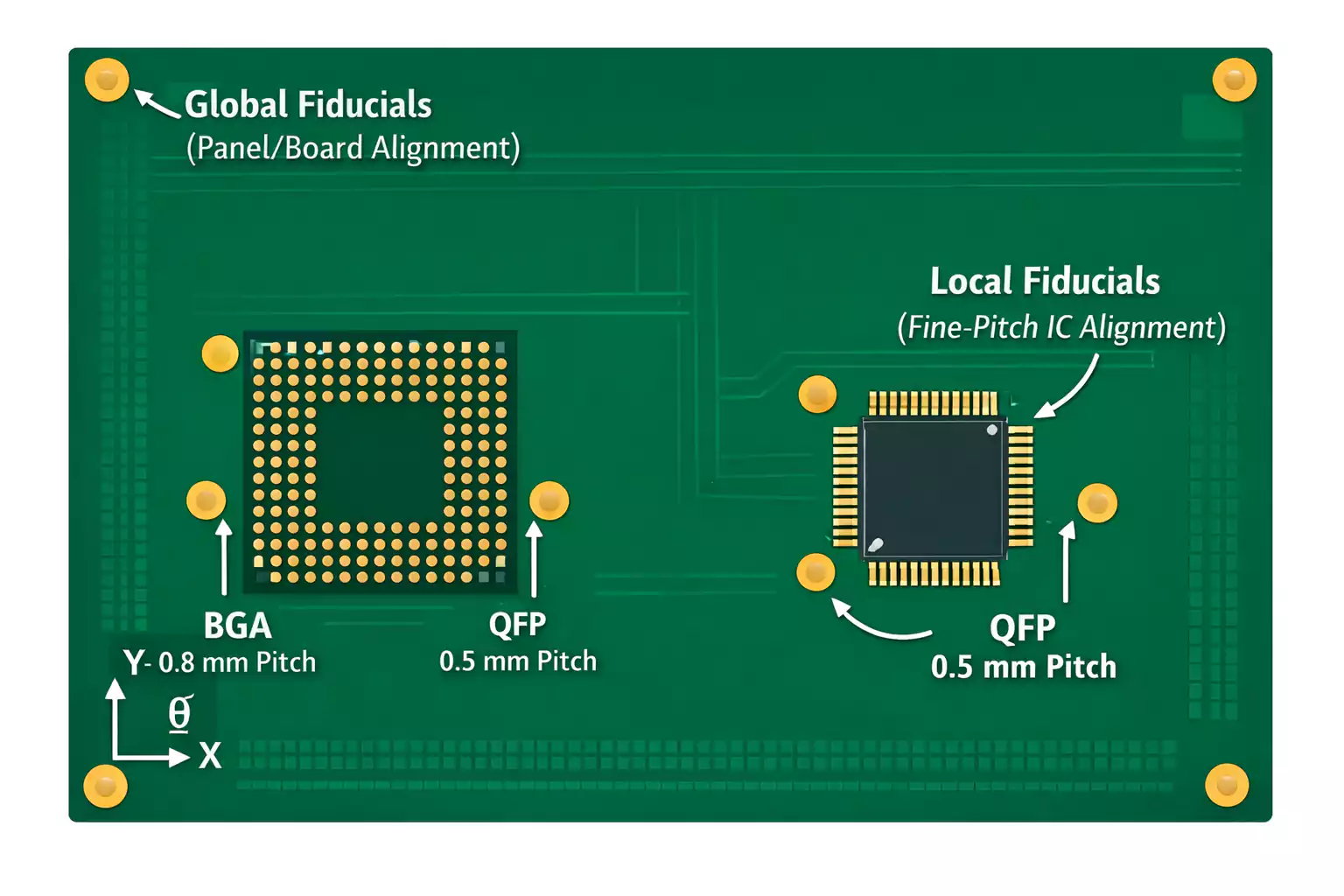

1. Component Orientation and Placement

- Align components with wave flow: In wave soldering, orient axial and radial components so the leads face into the solder wave. Place smaller parts before larger ones to reduce shadowing.

- Maintain spacing: Allow at least 2.5 mm clearance between tall THT parts and nearby SMDs to avoid solder shorts or incomplete wetting.

- Mixed-technology boards: Keep heat-sensitive SMDs away from areas exposed to the solder wave. For selective soldering, ensure nozzle access to every THT joint.

2. Solder Mask and Pad Design

- Defined pad opening: Use solder mask defined (SMD) pads for tighter control, or non-solder mask defined (NSMD) for better wetting, depending on assembly needs.

- Drag pads (robber pads): For wave soldering, add extra pads at the end of connector rows to “pull” excess solder and prevent bridging.

- Mask clearance: Maintain at least 0.25 mm solder mask clearance around THT pads to prevent solder shorts.

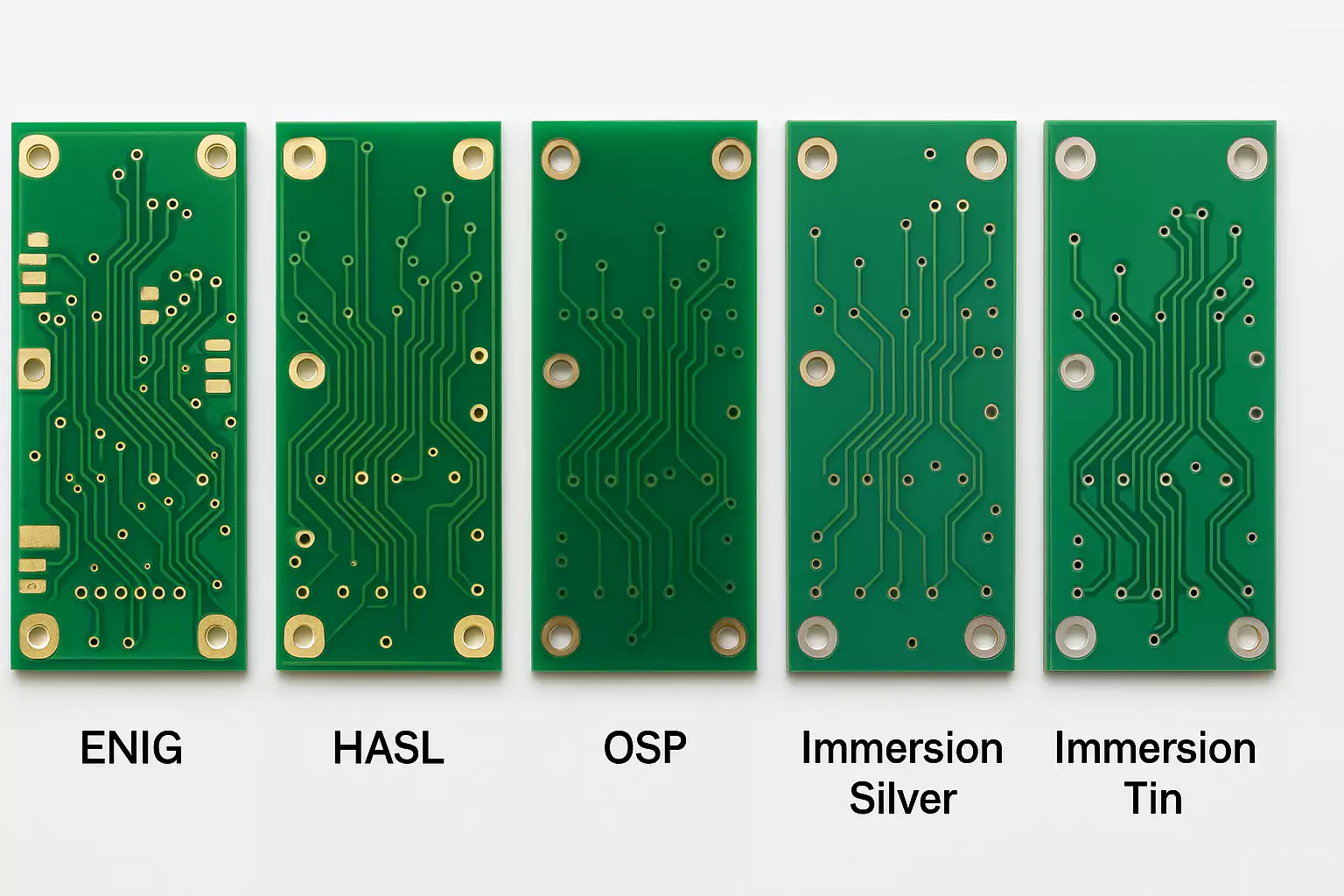

3. Surface Finish Selection

- HASL vs OSP: Hot Air Solder Leveling (HASL) provides a solderable surface but may create uneven topography, which can affect wave soldering on fine-pitch parts.

- OSP (Organic Solderability Preservatives): Better suited for selective soldering, as it provides consistent wetting and flat pads.

4. Mixed Assembly Rules

- SMD–THT interaction: Avoid placing SMT components immediately adjacent to THT pins that will be wave soldered, unless shielded by a solder pallet.

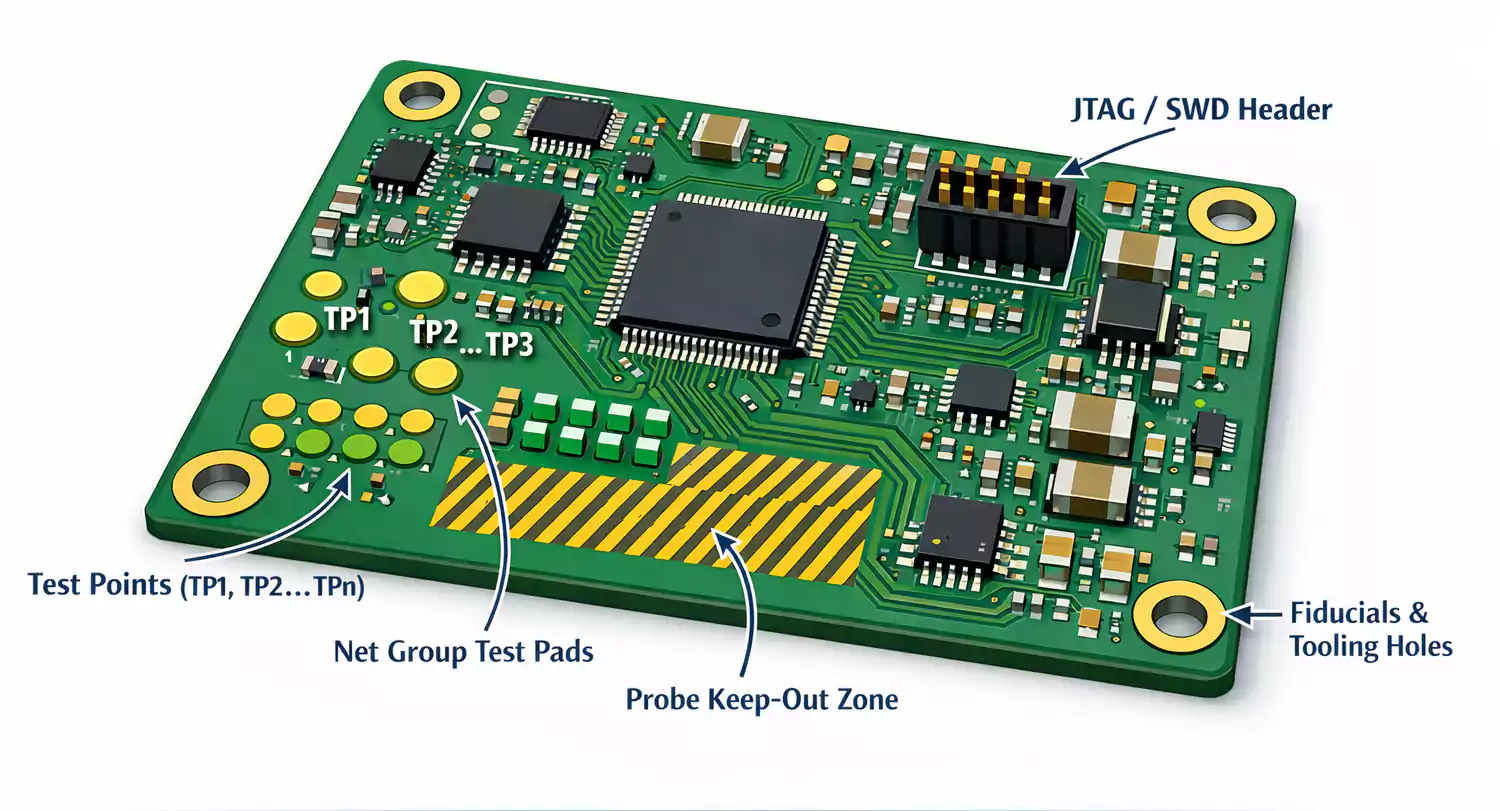

- Via and hole placement: Keep vias and test pads away from wave flow lines to avoid unintended solder wicking.

- Rework accessibility: Ensure there is enough space around high-pin-count connectors for potential rework or selective soldering nozzles.

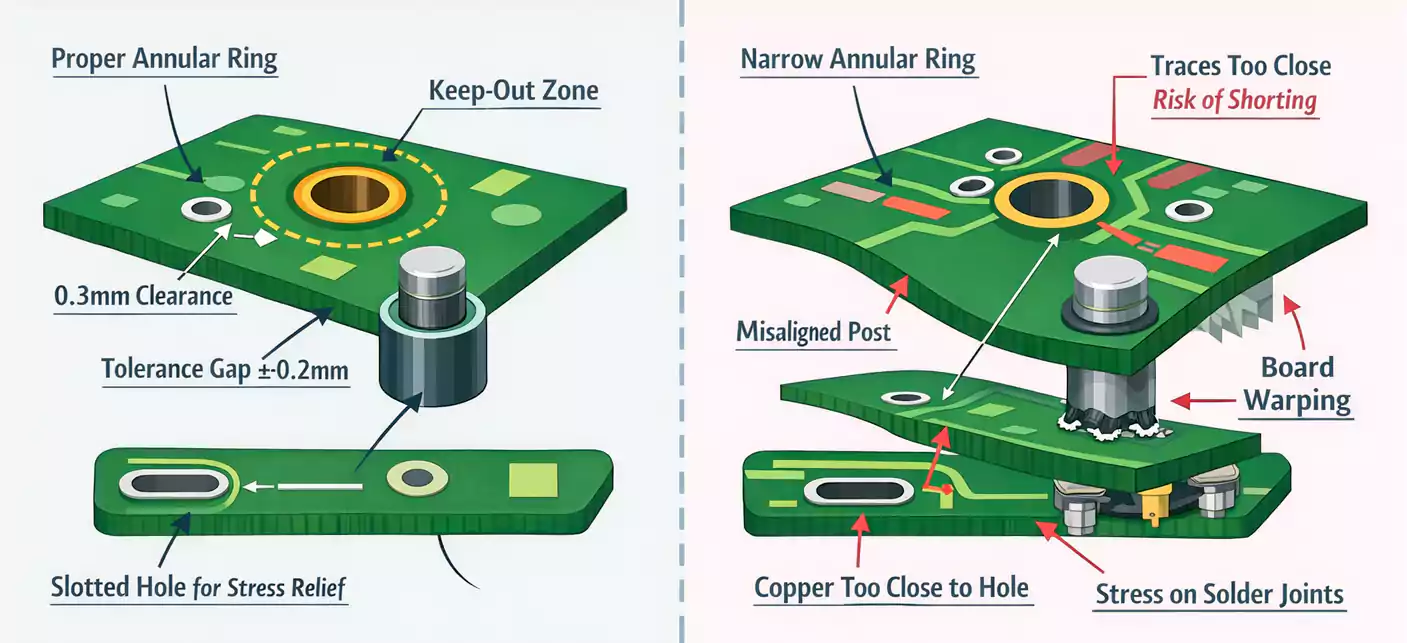

5. Hole and Land Geometry

- Hole diameter: Typically 0.2–0.3 mm larger than the component lead for good solder flow.

- Annular ring: At least 0.3 mm annular ring around the hole to meet IPC Class 2/3 requirements.

- Copper plating thickness: Minimum of 25 µm to ensure reliable hole fill, especially in thicker boards.

6. Flux and Preheat Considerations

- Flux access: Ensure that leads are not too close to tall components, so spray or foam flux can cover the entire joint area.

- Preheat window: Boards should be designed to tolerate 90–120 °C preheat zones without damaging nearby SMDs.

- Residue control: Select low-solids flux for no-clean processes; provide clearance if post-cleaning is required.

Tooling and Programming Cost: How to Quantify the Choice

One of the most overlooked—but financially decisive—factors when choosing between wave soldering and selective soldering is the hidden cost of tooling and programming. Both methods demand upfront investment and ongoing maintenance, but the structure of these costs is very different.

1.Wave Soldering Tooling

- Fixtures and pallets: Wave soldering typically requires custom solder pallets (Durostone, titanium, or composite materials) to mask SMT areas and guide solder flow.

- Lead time and lifetime: Pallet design and fabrication can take several days, and each tool has a finite lifetime before dimensional wear or thermal fatigue sets in.

- Impact on flexibility: For high-mix, low-volume production, the need for frequent new pallets can make wave soldering economically less attractive.

2.Selective Soldering Programming

- Path programming: Selective soldering requires CAD data import, nozzle path planning, and first-article verification.

- Skill and time investment: Engineering time to optimize nozzle diameter, approach angles, and dwell times is substantial, especially for complex boards.

- Reusability: Once validated, programs can be reused with minimal additional cost—making this method advantageous for recurring products with long lifecycles.

3.Nitrogen and Solder Consumption

- Wave soldering: The open solder pot leads to higher oxidation, dross formation, and solder waste. Nitrogen consumption can also be higher when inerting the entire wave.

- Selective soldering: By using localized nitrogen shrouds and smaller solder volumes, consumption of solder and nitrogen is significantly reduced.

Process Parameters and Defect–Countermeasure Matrix

A reliable soldering process depends on controlling flux, preheat, solder contact, and atmosphere. These are the main levers to prevent most THT defects.

Key Process Parameters

- Flux deposition: Adequate coverage without excess.

- Preheat: 90–130 °C before solder contact; too low → poor wetting, too high → flux burn-off.

- Contact time / dwell: 2–4 s typical; balance between fill and copper dissolution.

- Nitrogen (selective soldering): <1000 ppm O₂ improves wetting and reduces icicles.

Defect–Countermeasure Matrix

| Defect | Cause | Countermeasure |

|---|---|---|

| Bridging | Excess solder, tight spacing | Adjust wave height / nozzle path; use solder thieves |

| Insufficient hole fill | Low heat or short dwell | Raise preheat, extend dwell, check hole/pad design |

| Icicles | Long dwell, poor withdrawal | Reduce dwell, use nitrogen shielding |

| Cold joints | Inadequate heat or poor surfaces | Increase preheat, verify surface finish, higher activity flux |

Technology-Specific Tips

- Wave soldering: Align components with conveyor; use solder thieves for fine-pitch connectors.

- Selective soldering: Match nozzle size to lead pitch; keep nozzle 1–2 mm above crest; program dwell per pin.

Inspection Reference

- IPC-A-610: ≥75% hole fill (Class 2), up to 100% for Class 3; smooth fillets, no bridging or icicles >1 mm.

Production Line Layout and Hybrid Strategies

In real-world manufacturing, selective soldering and wave soldering are rarely used in isolation. Modern assembly lines often integrate both methods to balance cost, throughput, and quality. Understanding how to configure the production flow is critical for process engineers and project evaluators.

Three Common Hybrid Flows

- Wave Soldering Before Reflow

- Used when most THT components can tolerate high thermal cycles.

- SMDs are placed on one side only, protected during the wave.

- Advantage: high throughput and minimal programming effort.

- Limitation: not suitable for dense mixed-technology boards.

- Reflow Soldering Before Selective Soldering(mainstream today)

- SMDs are reflowed first, then THT joints are soldered selectively.

- Allows tighter layouts, smaller clearances, and reduced risk of solder bridges.

- Advantage: excellent compatibility with high-density, double-sided boards.

- Limitation: higher equipment and programming costs.

- Wave Soldering Plus Selective Soldering Touch-Up

- The bulk of THT pins are processed by wave soldering.

- Critical or shadowed components are completed by selective soldering.

- Advantage: cost-effective for mid-volume builds with a few complex connectors.

- Limitation: requires both fixtures and selective soldering programs.

When to Stick with Full Wave Soldering

Despite the rise of selective soldering, full wave soldering remains optimal when:

- THT devices dominate the assembly.

- Components are arranged to align with wave direction.

- SMDs are limited to one side or positioned away from the wave.

- Production goals emphasize lowest cost per board and maximum throughput over fine-pitch flexibility.

FAQ: Selective Soldering vs Wave Soldering

Can selective soldering replace wave soldering?

Not always. Selective soldering is ideal for dense mixed-technology boards and heat-sensitive parts. Wave soldering is still the fastest and most cost-effective for high-volume, wave-friendly layouts.

Is selective soldering always more expensive?

Initial equipment and programming costs are higher, but selective soldering reduces solder waste, nitrogen use, and rework. For low- to mid-volume or Class 3 products, it can be more economical over the full lifecycle.

Is wave soldering still relevant for mass production?

Yes. For through-hole–heavy designs with good wave access, wave soldering delivers high throughput at the lowest per-unit cost.

Which process ensures better reliability?

Both can meet IPC Class 2 and Class 3 standards. Selective soldering offers tighter control of flux, heat, and dwell time per joint, which benefits high-reliability applications.

When is a hybrid approach best?

When boards mix high-pin connectors with sensitive or shielded parts. Wave handles bulk joints; selective addresses critical or hard-to-reach pins.

Conclusion

Wave soldering is best for high-volume, connector-heavy assemblies where layouts are optimized for the solder wave and cycle time is critical.

Selective soldering excels with mixed-technology boards, heat-sensitive parts, and Class 3 products, where precision and yield outweigh higher setup costs.

In practice, many manufacturers use a hybrid approach—wave for simple connectors, selective for complex or shielded areas.

For engineers, the key is design rules and yield stability; for evaluators, it’s total cost of ownership. Applying the decision factors outlined ensures the right balance of quality, throughput, and cost efficiency.